Professional Documents

Culture Documents

Watlow Fluid Delivery Heaters

Uploaded by

EliasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Watlow Fluid Delivery Heaters

Uploaded by

EliasCopyright:

Available Formats

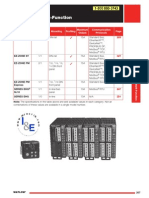

Max. Operating Typical Max.

Temperatures Watt Densities

Fluid Delivery Heaters Sheath Materials F C W/in

2

W/cm

2

Page

FREEFLEX

Polymeric 212 100 10 1.5 385

Syringe Polycarbonate

laminate

185 85 2 0.3 388

383 WATLOW

Fluid Delivery Heaters

F

l

u

i

d

D

e

l

i

v

e

r

y

H

e

a

t

e

r

s

Fluid Delivery Heaters

Extended Capabilities For

FREEFLEX

Heaters

385 WATLOW

Watlows miniature heated polymeric tubing assemblies

provide a flexible heat-up and transport system for

moving fluids within diameters as small as

1

/32 in.

(0.8 mm). The FREEFLEX

heater heats fluids up to

212F (100C) and maintains temperature during transfer

from a reservoir to a point of use. In some applications,

the tubing can actually serve as the reservoir for limited

volumes of fluid, helping to reduce start-up times.

For higher temperatures, contact your Watlow

representative.

Watlows innovative design places the heating element

and sensor directly in contact with the perimeter of the

tubing to produce efficient, responsive heating and

temperature control of the tube contents. The element is

evenly wound to ensure reliable, close contact for uniform

heating along a portion or the entire length of the line.

A flexible, durable jacket covers the wound element to let

the tubing flex and move in a dynamic system. This allows

for fluid delivery to multiple locations from a single supply

source. In stationary applications, the FREEFLEX heated

tubing is conveniently routed through available space or

around other system components. This saves space and

provides an uncomplicated retrofit in existing systems.

The FREEFLEX heaters efficient heating element design

can incorporate an optional thermocouple, thermistor or

resistance temperature detector (RTD) temperature

sensor into the thermal package. Users can select leads

to exit from one or both ends of the assembly. Typical

standard PTFE tubing is available in

1

/32,

1

/16,

1

/8 or

3

/16 in. (0.8, 1.6, 3.2, 4.8 mm) inside diameters. Contact

your Watlow representative for other sizes and materials.

Typical Applications

Medical: automated clinical analyzers, tissue

processing equipment

Analytical: sample preheating for LC and HPLC

systems, breathalyzers

Semiconductor processing: wafer drying

equipment, DI water heating

Printing: ink jet printers, rapid prototyping systems,

photo lithography

General process: wax/paraffin processing and

non-combustible gas heating

Water purification systems

Precision cleaning equipment

Aerospace

Military

Features and Benefits

Flexible heat-up and transport system

Eliminates the need for heated reservoir systems in

many applications

Direct contact between the heating element and

tubing

Provides fast, efficient, highly responsive heating

Available in three configurations

FREEFLEX design allows tubing to flex, coil or bend

around system components, enabling convenient

retrofits

Pre-formed design allows a longer tube length in a

smaller volume

Molded design provides a compact heating

assembly for easy installation

Integral sensors

Maintain close control of heater and fluid

temperatures

Low voltage design

Ensures safety

Miniature sizes as small as

1

/32 in. (0.8 mm) inside

diameter

Heats and transports fluids within tiny spaces

Convenient retrofit

Allows for routing flexible tubing around system

components and using existing control system

UL

recognition

Available on qualified designs by request

E

X

T

E

N

D

E

D

C

A

P

A

B

I

L

I

T

Y

386 WATLOW

Fluid Delivery Heaters

Extended Capabilities For

FREEFLEX Heaters

Technical Data

W/ft W/m O.D. Temperature

C (F) (Ambient)

0 0 70 (21)

5 1.5 140 (60)

10 3.0 210 (99)

15 4.6 265 (129)

20 6.1 310 (154)

25 7.6 340 (171)

O.D. Temperature vs. Watts/Meter

O

.

D

.

T

e

m

p

e

r

a

t

u

r

e

(

F

)

350

300

250

200

150

100

50

0

0 5 10 15 20 25 30

O.D. Temperature vs. Watts/Foot

177

149

121

93

66

38

10

1.5 3.0 4.6 6.1 7.6

O

.

D

.

T

e

m

p

e

r

a

t

u

r

e

(

C

)

O.D. Temperature vs. Watts/Unit Length

Dry Tube - No Flow

Water Temperature Rise/Foot vs. Flow Rate vs. Watt Density ( in. (1.6 mm) I.D. Tube)

Flow Rate of Water (mL/Minute)

W

a

t

e

r

T

e

m

p

e

r

a

t

u

r

e

R

i

s

e

(

F

/

F

o

o

t

)

90

80

70

60

50

40

30

20

10

0

10 20 30 40 50 60 70 80 90 100

164

146

128

109

91

73

55

36

18

0

W

a

t

e

r

T

e

m

p

e

r

a

t

u

r

e

R

i

s

e

(

C

/

M

e

t

e

r

)

50.0

37.5

25.0

12.5

W/ft

164

123

82

41

W/m

Water Temperature Rise F/Foot

Flow Rate (mL/minute)

W/ft 10 30 50 100

50.0 82 29 19 10

37.5 64 22 14 7

25.0 41 16 10 5

12.5 22 8 5 3

Water Temperature Rise C/Meter

Flow Rate (mL/minute)

W/m 10 30 50 100

164 149 52 35 18

123 116 40 26 13

82 75 29 18 9

41 40 15 9 5

Water Temperature Rise/Length Versus Flow Rate Versus Watt Density

FREEFLEX Outside Diameter Temperature Versus Watts/Length

E

X

T

E

N

D

E

D

C

A

P

A

B

I

L

I

T

Y

387 WATLOW

Fluid Delivery Heaters

Extended Capabilities For

FREEFLEX Heaters

Typical Application Requirements

When requesting a quote please specify:

Fluid Type

Inlet Temperature

Outlet Temperature

Flow Rate

Voltage - Typically less than 36V

Watts/ft - See chart on previous page for typical values

Maximum Allowable Outside Surface

Temperature

Tube Size

1

/32 in. (0.8 mm) I.D. x

1

/16 in. (1.6 mm) O.D.

1

/16 in. (1.6 mm) I.D. x

1

/8 in. (3.2 mm) O.D.

1

/8 in. (3.2 mm) I.D. x

3

/16 in. (4.8 mm) O.D.

3

/16 in. (4.8 mm) I.D. x

1

/4 in. (6 mm) O.D.

Other (specify size)

Tube Material

PTFE standard

Silicone rubber

Others upon request

Tube Length - 12 to 120 in. (305 to 3048 mm) typical

Total

Heated

Unheated (specify)

Tube Fittings

No fittings (1 in. [25 mm] bare tubing each end)

Other (specify)

Tube Flexing

Static (to route around components in system)

Dynamic (subject to more continuous flexing)

Occasional, frequent or continuous

Note: Min. recommended flexing radius

1

/32 in. (0.8 mm) I.D. x

1

/16 in. (1.6 mm) O.D. PTFE

1 in. (25 mm)

1

/16 in. (1.6 mm) I.D. x

1

/8 in. (3.2 mm) O.D. PTFE

1

1

/2 in. (38 mm)

1

/8 in. (3.2 mm) I.D. x

3

/16 in. (4.8 mm) O.D. PTFE

2 in. (51 mm)

3

/16 in. (4.8 mm) I.D. x

1

/4 in. (6 mm) O.D. PTFE

3 in. (76 mm)

Heater Leads

One at each end

Both at one end

Standard lead insulation (UL

Style 1180 CSA

white PTFE)

Other insulation (specify)

Heater Lead Length

Standard 12 in. (305 mm) w/customer end

stripped/tinned

1

/2 in. (13 mm)

Other (specify)

Heater Lead Exit Direction

Inboard/outboard

Temperature Sensor

Thermocouple (#30 AWG PFA - Type J)

Thermistor (specify) 10K at 72F (25C) standard

Other temperature sensors size/types (specify)

Sense heater element or tube temperature

Sensor Lead Exit Direction

Inboard/outboard

Temperature Sensor Lead Length

12 in. (305 mm)

Other (specify)

FREEFLEX Heater

FREEFLEX Heater

SENSOR LOCATION/MOUNTING

{ {

Heated Center

Outboard Outboard

Inboard Inboard

Each End

Lead

Direction

1 in. (25 mm)

Bare Tube Typ.

in. (15.9 mm)

No Heat Typ.

Power Leads

Fluid Flow Direction

Inlet

Power Leads at

End of Heater

Typ. Sensor

Placement

Outlet

Power Leads Exit

From Body of Heater

Inset Outset (Standard)

D in.

Inlet Outlet

Sense Tube

(Tube Contact in

Non-Heated Area)

Sense Jacket

(External to Jacket;

Separate Boot)

Sense Heater

(Under Jacket, Between

Elements in Heated Area)

S in.

Lead Orientation

Typical FREEFLEX Layout

FREEFLEX Heater

FREEFLEX Heater

SENSOR LOCATION/MOUNTING

{ {

Heated Center

Outboard Outboard

Inboard Inboard

Each End

Lead

Direction

1 in. (25 mm)

Bare Tube Typ.

in. (15.9 mm)

No Heat Typ.

Power Leads

Fluid Flow Direction

Inlet

Power Leads at

End of Heater

Typ. Sensor

Placement

Outlet

Power Leads Exit

From Body of Heater

Inset Outset (Standard)

D in.

Inlet Outlet

Sense Tube

(Tube Contact in

Non-Heated Area)

Sense Jacket

(External to Jacket;

Separate Boot)

Sense Heater

(Under Jacket, Between

Elements in Heated Area)

S in.

Lead Location

FREEFLEX Heater

FREEFLEX Heater

SENSOR LOCATION/MOUNTING

{ {

Heated Center

Outboard Outboard

Inboard Inboard

Each End

Lead

Direction

1 in. (25 mm)

Bare Tube Typ.

in. (15.9 mm)

No Heat Typ.

Power Leads

Fluid Flow Direction

Inlet

Power Leads at

End of Heater

Typ. Sensor

Placement

Outlet

Power Leads Exit

From Body of Heater

Inset Outset (Standard)

D in.

Inlet Outlet

Sense Tube

(Tube Contact in

Non-Heated Area)

Sense Jacket

(External to Jacket;

Separate Boot)

Sense Heater

(Under Jacket, Between

Elements in Heated Area)

S in.

Sensor Location/Mounting Description

FREEFLEX Heater

FREEFLEX Heater

SENSOR LOCATION/MOUNTING

{ {

Heated Center

Outboard Outboard

Inboard Inboard

Each End

Lead

Direction

1 in. (25 mm)

Bare Tube Typ.

in. (15.9 mm)

No Heat Typ.

Power Leads

Fluid Flow Direction

Inlet

Power Leads at

End of Heater

Typ. Sensor

Placement

Outlet

Power Leads Exit

From Body of Heater

Inset Outset (Standard)

D in.

Inlet Outlet

Sense Tube

(Tube Contact in

Non-Heated Area)

Sense Jacket

(External to Jacket;

Separate Boot)

Sense Heater

(Under Jacket, Between

Elements in Heated Area)

S in.

E

X

T

E

N

D

E

D

C

A

P

A

B

I

L

I

T

Y

388 WATLOW

Fluid Delivery Heaters

Extended Capabilities for

Syringe Heaters

The Watlow syringe heater was developed to match

the unique needs of medical injection applications.

It produces consistent results by reducing temperature

and viscosity variations. Fluid and drug delivery that

maintain precise liquid temperatures and reduce fluid

viscosity maximize patient comfort and reduce risk.

Body temperature injections are more easily introduced,

particularly for patients in a frail or distressed condition.

The Watlow syringe heater is available in two

configuration types with an optional, repeatable

temperature sensing controller. The silicone/wire

configuration accommodates varying syringe size

needs. The translucent, high-tech laminate construction

of the polycarbonate/foil design enables fluid levels and

air bubbles to be easily viewed and monitored. Both

heater forms are designed to snap on to the syringe

with one hand and hold firmly during a procedure.

An overmold design houses the optional electronic

controller and/or temperature sensor to allow

trouble-free servicing and extend heater life. The

overmold can be modified and color matched for

seamless, integrated appearance.

Specifications

Silicone/Wire and Polycarbonate/Foil

Length: 5 in. (127 mm) max.

Formed heater diameter: formed to fit syringe.

Typical diameter is 2 in. (50 mm) to 6 in. (150 mm)*

Voltage: dependent on application, over 48V may

impact agency approvals

Control accuracy: 5.4F (3C)

Max. operating surface temperature: 185F (85C)

Approximate control pod dimensions: 1 x 1 x 2.75 in.

(25 x 25 x 70 mm)*

Cord pull strength: Up to 89 N (20 lb

F

)*

* Dependent on design requirements.

Features and Benefits

Long operational life

Improves system reliability

Reduces equipment down time and minimizes the

need to reschedule procedures

Two heater configurations provide flexibility and

adaptability

Silicon wire enables maximum flexibility to

accommodate various syringe sizes

Polycarbonate/foil provides high tech appearance and

functionality

Customizable to most OEM requirements

Allows over-mold to be modified and color matched for

a seamless, integrated appearance

Optional precise, repeatable temperature sensing

control

Maximizes patient comfort

Minimizes patient risk

Increases the consistency of test results by eliminating

temperature and viscosity variations

Carries a longer product life than bimetal thermostats

E

X

T

E

N

D

E

D

C

A

P

A

B

I

L

I

T

Y

You might also like

- Watlow Resistance Temperature SensorsDocument21 pagesWatlow Resistance Temperature SensorsEliasNo ratings yet

- Watlow SERV-RITE WireDocument40 pagesWatlow SERV-RITE WireEliasNo ratings yet

- Watlow AccessoriesDocument30 pagesWatlow AccessoriesEliasNo ratings yet

- Watlow Cartridge HeatersDocument49 pagesWatlow Cartridge HeatersEliasNo ratings yet

- Waltlow Specialty HeatersDocument17 pagesWaltlow Specialty HeatersEliasNo ratings yet

- Watlow Mineral InsulatedDocument13 pagesWatlow Mineral InsulatedEliasNo ratings yet

- Watlow Thermocouple SDocument62 pagesWatlow Thermocouple SEliasNo ratings yet

- Watlow Heater Selection MatrixDocument4 pagesWatlow Heater Selection MatrixEliasNo ratings yet

- Watlow Circulation HeatersDocument54 pagesWatlow Circulation HeatersEliasNo ratings yet

- Watlow Strip Clamp On HeatersDocument15 pagesWatlow Strip Clamp On HeatersEliasNo ratings yet

- Watlow Immersion HeatersDocument163 pagesWatlow Immersion HeatersEliasNo ratings yet

- Watlow Reference DataDocument19 pagesWatlow Reference DataEliasNo ratings yet

- Watlow Flexible HeatersDocument46 pagesWatlow Flexible HeatersEliasNo ratings yet

- Watlow Thermostats and AccessoriesDocument10 pagesWatlow Thermostats and AccessoriesEliasNo ratings yet

- Watlow Tubular HeatersDocument55 pagesWatlow Tubular HeatersEliasNo ratings yet

- Watlow Data LoggersDocument10 pagesWatlow Data LoggersEliasNo ratings yet

- Watlow Radiant HeatersDocument16 pagesWatlow Radiant HeatersEliasNo ratings yet

- Watlow High Temperature HeatersDocument33 pagesWatlow High Temperature HeatersEliasNo ratings yet

- Watlow Power Switching DevicesDocument38 pagesWatlow Power Switching DevicesEliasNo ratings yet

- Watlow Air HeatersDocument32 pagesWatlow Air HeatersEliasNo ratings yet

- Watlow Agency Heaters CertificationsDocument6 pagesWatlow Agency Heaters CertificationsEliasNo ratings yet

- Watlow Band Barrel HeatersDocument13 pagesWatlow Band Barrel HeatersEliasNo ratings yet

- Watlow Nozzle HeatersDocument5 pagesWatlow Nozzle HeatersEliasNo ratings yet

- Watlow Operator InterfacesDocument11 pagesWatlow Operator InterfacesEliasNo ratings yet

- Watlow Temperature and ProcessDocument24 pagesWatlow Temperature and ProcessEliasNo ratings yet

- Watlow Controller AccessoriesDocument12 pagesWatlow Controller AccessoriesEliasNo ratings yet

- Watlow Integrated Multi-FunctionDocument45 pagesWatlow Integrated Multi-FunctionEliasNo ratings yet

- Watlow SoftwareDocument10 pagesWatlow SoftwareEliasNo ratings yet

- Watlow Limits ScannersDocument24 pagesWatlow Limits ScannersEliasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 3rd Year Survival Guide TipsDocument15 pages3rd Year Survival Guide TipsTravelle Franklin-Ford EllisNo ratings yet

- Multiple Choice RadioactivityDocument4 pagesMultiple Choice RadioactivityGodhrawala AliasgerNo ratings yet

- Mindray UMEC 12 Specifications FDADocument11 pagesMindray UMEC 12 Specifications FDAAlejandra Baas GuzmánNo ratings yet

- DLL - Science 6 - Q2 - W1Document6 pagesDLL - Science 6 - Q2 - W1AnatasukiNo ratings yet

- Manufacturing ProcessDocument6 pagesManufacturing Processbro nawalibmatNo ratings yet

- 02-Plant Morphology (Exercise)Document5 pages02-Plant Morphology (Exercise)varshavishuNo ratings yet

- Tunnels: Rock TunnellingDocument4 pagesTunnels: Rock TunnellingAndrés García CaseroNo ratings yet

- ICH Topic Q 3 B (R2) Impurities in New Drug Products: European Medicines AgencyDocument14 pagesICH Topic Q 3 B (R2) Impurities in New Drug Products: European Medicines AgencyJesus Barcenas HernandezNo ratings yet

- Higuey, Dom Rep Mdpc/Puj: .Eff.23.MayDocument5 pagesHiguey, Dom Rep Mdpc/Puj: .Eff.23.MayVanessa Yumayusa0% (1)

- Amma Mobile InsuranceDocument1 pageAmma Mobile InsuranceANANTH JNo ratings yet

- Coca-Cola's CSR efforts to refresh world sustainablyDocument4 pagesCoca-Cola's CSR efforts to refresh world sustainablyAfolarin AdioNo ratings yet

- Commercial Inverter AC Service ManualDocument116 pagesCommercial Inverter AC Service ManualEdwin JaramilloNo ratings yet

- PPEsDocument11 pagesPPEsPrithivirajan CuddaloreNo ratings yet

- Masagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningDocument6 pagesMasagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningjhonaNo ratings yet

- ITC's diverse businesses: cigarettes, packaging, hotels, paperboards, stationery, matches, incense sticks, retail, food, exportsDocument1 pageITC's diverse businesses: cigarettes, packaging, hotels, paperboards, stationery, matches, incense sticks, retail, food, exportsShashank JainNo ratings yet

- Vocational training at BHELDocument36 pagesVocational training at BHELafNo ratings yet

- Flow Crete OverviewDocument1 pageFlow Crete OverviewsathiyanNo ratings yet

- Boiler BlowdownDocument2 pagesBoiler BlowdownbaratheonNo ratings yet

- The Problem of Drop Outs and School Building ConstructionDocument26 pagesThe Problem of Drop Outs and School Building ConstructionSweetaddy castilloNo ratings yet

- Environmental Monitoring Plans For Decommissioning of Nuclear FacilitiesDocument9 pagesEnvironmental Monitoring Plans For Decommissioning of Nuclear FacilitiesEric GozzerNo ratings yet

- Recent Developments in Carbapenems: ReviewDocument16 pagesRecent Developments in Carbapenems: ReviewFrancielleNo ratings yet

- Gpat 2014 SolvedDocument12 pagesGpat 2014 Solvedjhansi100% (1)

- Clean Room Laboratory ReportDocument6 pagesClean Room Laboratory ReportHaider IftikarNo ratings yet

- Chapter 4 MoldingDocument46 pagesChapter 4 MoldingTamirat NemomsaNo ratings yet

- Hedging The Risk of Portfolio by Using Index Option ContractDocument3 pagesHedging The Risk of Portfolio by Using Index Option ContractAlina MalikNo ratings yet

- Jobaid Investigating Causes PDFDocument16 pagesJobaid Investigating Causes PDFNina MarianaNo ratings yet

- Original Instruction Manual: Hypro Series 9303Document24 pagesOriginal Instruction Manual: Hypro Series 9303vandoNo ratings yet

- Transactional Analysis (TA)Document21 pagesTransactional Analysis (TA)Rohan TandonNo ratings yet

- Ten Laws of BoundariesDocument17 pagesTen Laws of Boundariesstjohn30067% (3)

- Understanding Steam Turbine VibrationDocument30 pagesUnderstanding Steam Turbine VibrationkatibraNo ratings yet