Professional Documents

Culture Documents

Theory of Flowmeter Demonstration

Uploaded by

FarisRazzakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Theory of Flowmeter Demonstration

Uploaded by

FarisRazzakCopyright:

Available Formats

THEORY

Rotameter

The rotameter is a flow meter in which a rotating free float is the indicating element. Basically, a

rotameter consists of a transparent tapered vertical tube through which fluid flow upward. Within

the tube is placed a freely suspended float of pump-bob shape. The rotameter's operation is

based on the variable area principle: fluid flow raises a float in a tapered tube, increasing the

area for passage of the fluid. The greater the flow, the higher the float is raised. The height of

the float is directly proportional to the flowrate. The float rises only a short distance if the rate of

flow is small, and vice versa. The points of equilibrium can be noted as a function of flow rate.

With a well-calibrated marked glass tube, the level of the float becomes a direct measure

of flow rate.

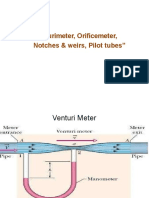

Venturi Meter

The venturi meter consists of a venturi tube and a suitable differential pressure gauge. The

venturi tube has a converging portion, a throat and a diverging portion as shown in the figure

below. The function of the converging portion is to increase the velocity of the fluid and lower its

static pressure. A pressure difference between inlet and throat is thus developed, which

pressure difference is correlated with the rate of discharge. The diverging cone serves to

change the area of the stream back to the entrance area and convert velocity head into

pressure head.

Venturi flow rate

[ (

[ (

)]

.Equation 1

[ (

[ (

)]

.Equation 2

Where

()

Orifice Meter

The orifice for use as a metering device in a pipeline consists of a concentric square-edged

circular hole in a thin plate, which is clamped between the flanges of the pipe as shown in the

figure below.

Pressure connections for attaching separate pressure gauges are made at holes in the pipe

walls on both side of the orifice plate. The downstream pressure tap is placed at the minimum

pressure position, which is assumed to be at the vena contracta. The centre of the inlet

pressure tap is located between one-half and two pipe diameters from the upstream side of the

orifice plate, usually a distance of one pipe diameter is employed. Flowrate of the orifice can be

calclulate using equation below.

[ (

[ (

)]

[ (

[ (

)]

()

)

90

0

elbow

Energy losses are proportional to the velocity head of the fluid as it flows around an elbow,

through an enlargement or contraction of the flow section, or through a valve. Figure below

shows flow round a 90

o

elbow which has a constant circular cross section.

Experimental values for energy losses are usually expressed in terms of a dimensionless loss

coefficient K. The value of loss coefficient K is dependent on the ratio of the bend radius, R to

the pipe inside diameter D. As this ratio increase, the value of K will fall and vice versa.

Where,

K = Coefficient of losses

V = Velocity of flow

g = 9.81 m/s2

You might also like

- 2263 34 350 Module4Document78 pages2263 34 350 Module4RameshNo ratings yet

- Lab ReportDocument23 pagesLab ReportAmy Farhana100% (1)

- THEORY Fluid MechanicsDocument1 pageTHEORY Fluid MechanicsAinaaaaNo ratings yet

- Orifcie Sizing CalulationDocument25 pagesOrifcie Sizing CalulationmgkvprNo ratings yet

- VenturimeterDocument45 pagesVenturimetersulakshna kiranNo ratings yet

- Measurement of Fluid Flow Using Pitot Tube, Orifice Plate & Other DevicesDocument5 pagesMeasurement of Fluid Flow Using Pitot Tube, Orifice Plate & Other DeviceslishadNo ratings yet

- FLOW METER DEMONSTATION ReportDocument15 pagesFLOW METER DEMONSTATION ReportAbenezer TasewNo ratings yet

- Venturimeter Flow Measurement DeviceDocument8 pagesVenturimeter Flow Measurement DeviceLance HernandezNo ratings yet

- Notch and WeirsDocument33 pagesNotch and WeirsAbdur RashidNo ratings yet

- Figure1.1: U-Tube ManometerDocument5 pagesFigure1.1: U-Tube Manometeraydn_89No ratings yet

- Im316 Flow MeasurementDocument67 pagesIm316 Flow MeasurementSelvarajNo ratings yet

- Measurement and Industrial Instrumentation: Volumetric Flow RateDocument36 pagesMeasurement and Industrial Instrumentation: Volumetric Flow RateAnshuman BeheraNo ratings yet

- OrificeDocument10 pagesOrificeRicha GhoshNo ratings yet

- CH 5Document22 pagesCH 5Ina Marie LampitocNo ratings yet

- Answer No 3Document15 pagesAnswer No 3Politik Itu KejamNo ratings yet

- Title: Transportation of FluidsDocument72 pagesTitle: Transportation of FluidsRishi Gethu MassNo ratings yet

- B21ME030 Lab4 PDFDocument8 pagesB21ME030 Lab4 PDFJaydeep Prajapati (B21ME030)No ratings yet

- FALLSEM2018-19 - MEE1004 - ETH - MB309 - VL2018191003741 - Reference Material I - Fluid Mechanics-2 PDFDocument48 pagesFALLSEM2018-19 - MEE1004 - ETH - MB309 - VL2018191003741 - Reference Material I - Fluid Mechanics-2 PDFSivaram PeramNo ratings yet

- MODULE 5.1-5.5 Coefficients To TubesDocument18 pagesMODULE 5.1-5.5 Coefficients To TubesFrancis HernandezNo ratings yet

- Impellers Fadol NaamaniDocument22 pagesImpellers Fadol NaamaniMohammad AmmarNo ratings yet

- OrificeDocument9 pagesOrificeMithu312100% (1)

- Ce6412 04Document114 pagesCe6412 04karthickaryanNo ratings yet

- Experiment: Flow Tthrough Venturi MeterDocument4 pagesExperiment: Flow Tthrough Venturi MeterMuhammadZAmjadNo ratings yet

- FALLSEM2019-20 CHE1005 ETH VL2019201001209 Reference Material I 01-Aug-2019 Lecture 11Document15 pagesFALLSEM2019-20 CHE1005 ETH VL2019201001209 Reference Material I 01-Aug-2019 Lecture 11ermiasNo ratings yet

- Venturimeter, OrificemeterDocument13 pagesVenturimeter, OrificemetersantaNo ratings yet

- 3.4 Discharge and Velocity MeasurementDocument35 pages3.4 Discharge and Velocity MeasurementLayike AlemayehuNo ratings yet

- Lab 4 (Flowmeter Demonstration)Document23 pagesLab 4 (Flowmeter Demonstration)Muhamad Baihakhi ShamsudinNo ratings yet

- Orifice DischargeDocument12 pagesOrifice Dischargehammada1001100% (3)

- Faculty of Chemical EngineeringDocument32 pagesFaculty of Chemical EngineeringArif HanafiNo ratings yet

- Air CalibrationDocument7 pagesAir Calibrationendang dian lestariNo ratings yet

- 3 Reciprocating Pump Air Vessel and Indicator Diag - 231127 - 162720Document41 pages3 Reciprocating Pump Air Vessel and Indicator Diag - 231127 - 162720Muhammad MubashirNo ratings yet

- Flow Measurement TechniquesDocument32 pagesFlow Measurement Techniquesmuh amarNo ratings yet

- ReviewDocument31 pagesReviewkarlobrondialNo ratings yet

- Fluid Flow Lab: Experiment 4Document13 pagesFluid Flow Lab: Experiment 4shubhamNo ratings yet

- Flow Meter Type DetectorsDocument9 pagesFlow Meter Type DetectorsAli AimranNo ratings yet

- Unit 4.1 FMDocument39 pagesUnit 4.1 FMRishi Gethu MassNo ratings yet

- Fluid LABDocument9 pagesFluid LABKayfe sayfadeenNo ratings yet

- قياسات نموذجيDocument11 pagesقياسات نموذجيMohammed KasimNo ratings yet

- VENTURIMETERDocument4 pagesVENTURIMETERKailash RajuNo ratings yet

- Tutorial Flow Measurement (GROUP D)Document8 pagesTutorial Flow Measurement (GROUP D)Nur Fatiha Aziera Ain Binti Mohd KhimeNo ratings yet

- Vacuum Booster Application of Bernoulli's PrincipleDocument9 pagesVacuum Booster Application of Bernoulli's PrincipleDouglas OngomNo ratings yet

- Energy Equation & Its ApplicationsDocument47 pagesEnergy Equation & Its ApplicationsRopah ChihuriNo ratings yet

- Venturimeter, Orificemeter, Notches & Weirs, Pilot TubesDocument10 pagesVenturimeter, Orificemeter, Notches & Weirs, Pilot TubesDanish LatifNo ratings yet

- Variable Area Meters 1Document3 pagesVariable Area Meters 1zakir551No ratings yet

- 211 Department of Civil EngineeringDocument6 pages211 Department of Civil EngineeringMARSDEN RONNYNo ratings yet

- Fluid Mechanics Lab Experiment 2Document8 pagesFluid Mechanics Lab Experiment 2SSShakeelNo ratings yet

- Orifice Discharge UnitDocument8 pagesOrifice Discharge UnitMontazer WorkNo ratings yet

- Measure flow rates with an orifice plateDocument14 pagesMeasure flow rates with an orifice plateAyoun Ul HaqueNo ratings yet

- Flow Measurement Comparison of Venturi, Orifice and RotameterDocument4 pagesFlow Measurement Comparison of Venturi, Orifice and RotameterohdausNo ratings yet

- Experiment 2 - Flow Measurement: Page 1 of 6Document6 pagesExperiment 2 - Flow Measurement: Page 1 of 6fadyaNo ratings yet

- Flow Measuring DevicesDocument39 pagesFlow Measuring DevicesAbdul Moeed Kalson100% (1)

- Calibration of An Orifice Plate Flow Meter (Fluid Exp 8)Document7 pagesCalibration of An Orifice Plate Flow Meter (Fluid Exp 8)hayder alaliNo ratings yet

- Venturi MeterDocument27 pagesVenturi MeterChristopher GarciaNo ratings yet

- Venturi Orifice Meter: Flow Measuring DevicesDocument22 pagesVenturi Orifice Meter: Flow Measuring DevicesAryan ChaurasiaNo ratings yet

- Mostafa Qasim Fluid ReportDocument7 pagesMostafa Qasim Fluid ReportMostafa HamawandyNo ratings yet

- ORIFICEMETER + ROTAMETERDocument19 pagesORIFICEMETER + ROTAMETERZaidNo ratings yet

- Pitot Tube (Minor Project) by Kamal JoshiDocument13 pagesPitot Tube (Minor Project) by Kamal JoshiKamal JoshiNo ratings yet

- Flow MeasurementDocument11 pagesFlow MeasurementRaj Ven100% (1)

- ChronologyDocument2 pagesChronologyFarisRazzakNo ratings yet

- Lab ReportDocument9 pagesLab ReportFarisRazzakNo ratings yet

- ADVANCED CHEMICAL REACTION FLUIDIZED BED BIOREACTORDocument16 pagesADVANCED CHEMICAL REACTION FLUIDIZED BED BIOREACTORFarisRazzakNo ratings yet

- PastyearDocument1 pagePastyearFarisRazzakNo ratings yet

- Procedure Weak AcidDocument1 pageProcedure Weak AcidFarisRazzakNo ratings yet

- Apparatus: 1. Continuous Stirred Tank ReactorDocument3 pagesApparatus: 1. Continuous Stirred Tank ReactorFarisRazzakNo ratings yet

- Apparatus: 1. Continuous Stirred Tank ReactorDocument3 pagesApparatus: 1. Continuous Stirred Tank ReactorFarisRazzakNo ratings yet

- Chapter 2 FypDocument8 pagesChapter 2 FypFarisRazzakNo ratings yet

- Heat ExchangerDocument25 pagesHeat ExchangerFarisRazzak67% (3)

- Water QualityDocument2 pagesWater QualityFarisRazzakNo ratings yet

- Introduction BiodieselDocument5 pagesIntroduction BiodieselFarisRazzakNo ratings yet

- Osbourne ReynoldDocument19 pagesOsbourne ReynoldFarisRazzakNo ratings yet

- A Four-Node Plate Bending Element Based On Mindlin Reissner Plate Theory and A Mixed InterpolationDocument17 pagesA Four-Node Plate Bending Element Based On Mindlin Reissner Plate Theory and A Mixed InterpolationAdnan AhmedNo ratings yet

- H&MT - Lesson 2Document8 pagesH&MT - Lesson 2prashantpkvNo ratings yet

- Phase Changes in MatterDocument29 pagesPhase Changes in MatterLindsay CrystalNo ratings yet

- Sumipex® PMMA Resin - General Purpose: Product InformationDocument1 pageSumipex® PMMA Resin - General Purpose: Product InformationVu TranNo ratings yet

- L04 Analysis of Statically Determinate BeamsDocument42 pagesL04 Analysis of Statically Determinate BeamsN GraceNo ratings yet

- All Sheets ConcreteDocument72 pagesAll Sheets ConcreteSulaiman Mohsin AbdulAziz100% (1)

- Pump Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDocument20 pagesPump Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignAlexanderNo ratings yet

- Marian Ivan - Theoretical GeomechanicsDocument81 pagesMarian Ivan - Theoretical GeomechanicsdrakicNo ratings yet

- Assignment 1Document9 pagesAssignment 1Rie UsunNo ratings yet

- FRP Piping Modeling TutorialDocument5 pagesFRP Piping Modeling TutorialFRANCISCONo ratings yet

- Mass Transfer Operations Model QuestionsDocument8 pagesMass Transfer Operations Model QuestionsIastraNo ratings yet

- Examples For Equation of StateDocument5 pagesExamples For Equation of StateAntarim Dutta100% (1)

- Sun JWB Asec98Document8 pagesSun JWB Asec98Angela CollinsNo ratings yet

- Engine Room Bilge Pump Troubleshooting GuideDocument98 pagesEngine Room Bilge Pump Troubleshooting Guideanil kumarNo ratings yet

- Me2301 Thermal EngineeringDocument1 pageMe2301 Thermal Engineeringskings1264No ratings yet

- Issues Using Welded Built-Up Box Columns Steel Moment FramesDocument13 pagesIssues Using Welded Built-Up Box Columns Steel Moment Framesclam2014No ratings yet

- Work Done in Isothermal ProcessDocument1 pageWork Done in Isothermal ProcessKrishna PATELNo ratings yet

- Cantilever Retaining Wall ExampleDocument10 pagesCantilever Retaining Wall ExampleReab SimanthNo ratings yet

- Basic Practices in Compressors Selection-Purdue UniversityDocument11 pagesBasic Practices in Compressors Selection-Purdue UniversityLuis Joel Ramos RamosNo ratings yet

- AASHTO M 320-10 Performance Graded Asphalt BinderDocument7 pagesAASHTO M 320-10 Performance Graded Asphalt BinderplavingalneemaNo ratings yet

- Ce223 Lab1. M Yuka 17300275Document7 pagesCe223 Lab1. M Yuka 17300275Mathew YukaNo ratings yet

- Lewis Number Effects on Turbulent Burning VelocityDocument8 pagesLewis Number Effects on Turbulent Burning VelocitycoccoNo ratings yet

- Water Hammer Analysis ReportDocument22 pagesWater Hammer Analysis ReportAh Leng LauNo ratings yet

- Chapter 2 Literature ReviewDocument27 pagesChapter 2 Literature Reviewteklemariam negashNo ratings yet

- Pre ASTM D2137-11 (2018)Document3 pagesPre ASTM D2137-11 (2018)RangaNo ratings yet

- FM 4 Fluid Kinematics CompleteDocument48 pagesFM 4 Fluid Kinematics Completeالياس يونس مرغلانيNo ratings yet

- Partial Differential Equations of Fluid DynamicsDocument48 pagesPartial Differential Equations of Fluid DynamicsinsanNo ratings yet

- Science Grad9: Quarter 4 - Module 7 Heat, Work and EnergyDocument14 pagesScience Grad9: Quarter 4 - Module 7 Heat, Work and EnergyAinah DimasangcaNo ratings yet

- Direct driven axial flow fansDocument4 pagesDirect driven axial flow fansVictor AfandiNo ratings yet

- Pinch and Approach Point On HRSGDocument12 pagesPinch and Approach Point On HRSGluaguNo ratings yet