Professional Documents

Culture Documents

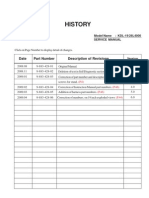

AEP Model Service Manual

Uploaded by

Josip Hrdan0 ratings0% found this document useful (0 votes)

128 views27 pagesSLV-D930D

Original Title

SLV-D930D

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSLV-D930D

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

128 views27 pagesAEP Model Service Manual

Uploaded by

Josip HrdanSLV-D930D

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 27

AEP Model

SLV-D920 B/D920 E/D920 N/D925 E/

D930 D/D960P B/D960P E

UK Model

SLV-D930 GI

Russian Model

SLV-D920 R

SERVICE MANUAL

DVD PLAYER/

VIDEO CASSETTE RECORDER

SPECIFICATIONS

RMT-V503C/V503D

TS-10 MECHANISM

Refer to the SERVICE MANUAL of VHS MECHANI-

CAL ADJUSTMENT MANUAL VII for MECHANICAL

ADJUSTMENTS. (9-921-790-11)

PAL

System

Laser

Semiconductor laser

Signal format system

PAL/(NTSC)

SLV-D920 B/D960P B:

SECAM

SLV-D920 B/D920 N/D920 R/D960P B:

MESECAM

Channel coverage

SLV-D920 B/D920 E/D925 E/D930 D/D960P B/

D960P E:

PAL (B/G):

VHF E2 to E12

VHF Italian channel A to H

UHF E21 to E69

CATV S01 to S05, S1 to S20

HYPER S21 to S41

SLV-D930 GI:

PAL (I):

VHF IA to IJ, SA10 to SA13

UHF B21 to B69

CATV S01 to S05, S1 to S20

HYPER S21 to S41

SLV-D920 B/D960P B:

SECAM (L):

VHF F2 to F10

UHF F21 to F69

CATV B to Q

HYPER S21 to S41

SLV-D920 N/D920 R:

PAL (B/G, D/K):

VHF E2 to E12, R1R12

UHF E21 to E69, R21R69

CATV S01 to S05, S1 to S41

RF output signal

SLV-D920 E/D920 N/D920 R/D930 D/D930 GI/

D960P E:

UHF channels 21 to 69

Aerial out

75-ohm asymmetrical aerial socket

Tape speed

SP: PAL 23.39 mm/s

(recording/playback)

NTSC 33.35 mm/s

(playback only)

SLV-D920 B/D960P B:

SECAM 23.39 mm/s

(recording/playback)

MESECAM 23.39 mm/s

(playback only)

SLV-D920 N/D920 R:

MESECAM 23.39 mm/s

(recording/playback)

Continued on next page

SLV-D920 B/D920 E/D920 N/D920 R/D925 E/

D930 D/D930 GI/D960P B/D960P E

RMT-V503D SLV-D960P E

3. Block Diagram

3-2 3-1

DECK ASS'Y (DP-15)

DRIC1

(FAN8004)

Motor Dri ver

Di sk Motor

Pi ck- up & I/ V Amp

Feed Motor

DIC3 (24C02)

EPROM

C

o

a

x

i

a

l

S

u

p

e

r

DIC1

MN20S0005

A/ V Decoder

AIC2

(PCM1752KE)

2CH Audi o DAC

IC701

(PT6961)

LED Dri ve

(DT701)

VIC1

(LA73054)

Vi deo Amp 6CH S/ W

AUDIO L/ R

AUDIO L/ R

DIC2

AM26LV160B

IMB Fl ash Memory

DIC4

(TC74VHCT125)

Level Shi fter

IC802

(Bu4053)

output si gnal swi tch

IC501

(LA72646)

Hi - FI Audi o Processor

IC301

(LA71750EM)

Vi deo Si gnal Processor

IC601

(uPD7B4928GF)

VCR Mai n Mi com

P

b

C

O

M

P

O

N

E

N

T

A/ V Common

YP

r

A

U

D

I

O

L

V

I

D

E

O

A

U

D

I

O

R

Front A/ V Jack

O

p

t

i

c

a

l

DIC5 64MB SD RAM

IC605 EEPROM

STEREO

SCART JACK

RF/ LD Control

SLV-D920 B/D920 E/D920 N/D920 R/D925 E/

D930 D/D930 GI/D960P B/D960P E

5-4 5-3

5-1 S.M.P.S.

5-6 5-5

5-2 Power Drive

5-8 5-7

5-3 OSD/VPS/PDS

5-10 5-9

5-4 A2/NICAM

5-12 5-11

5-5 A/V

5-14 5-13

5-6 Hi-Fi

5-7 Input-Output (2 Scart Jack)

5-16 5-15

5-18 5-17

5-8 TM

5-20 5-19

5-9 I/O (RCA)

5-22 5-21

5-10 SYSCON

5-24 5-23

5-11 Logic/Function

5-26 5-25

5-12 SECAM (SLV-D920 B/D960P B)

5-13 DVD A/V

5-28 5-27

5-30 5-29

5-14 DVD Decoder Servo

6-1

6. ALIGNMENT AND ADJUSTMENTS

6-1 VCR ADJUSTMENT

6-1-1 Reference

1) X- Poi nt (Tracki ng center) adj ustment, Head swi tchi ng adj ustment and NVRAM opti on setti ng can be adj usted wi th remote control .

2) When repl aci ng the Mai n PCB Mi com (IC601) and NVRAM (IC605: EEPROM) be sure to adj ust the Head swi tchi ng adj ustment and

NVRAM opti on setti ng .

3) When repl aci ng the cyl i nder assy, be sure to adj ust the X- Poi nt and Head swi tchi ng adj ustment .

4) How to adj ustment.

- Intermi ttentl y short- ci rcui t the Test Poi nt on Mai n PCB wi th pi ncers to the adj ustment mode.

- If the correspondi ng adj ustment button i s pressed, the adj ustment i s performed automati cal l y.

- When the adj ustment i s compl eted, be sure to turn the power off.

6-1-1(a) Location of adjustment button of remote control

X-Point (Tracking Center) Adjustment ;

Head Switching Adjustment ;

NVRAM Option Setting ;

Fig. 6-1

SLV-D920 B/D920 E/D920 N/D920 R/D925 E/

D930 D/D930 GI/D960P B/D960P E

6-2

TEST

TEST BUTTON

6-1-1(b) TEST location for adjustment mode setting

Fig. 6-2 VCR Main PCB (Top View)

6-3

6-1-2 Head Switching Point Adjustment

1) Playback the alignment tape.

2) Press the TEST botton on VCR MAIN PCB to set the adjustment mode. (See Fig. 6-2)

3) Press the 1, 0 buttons ; remote control adjustment operates automatically. (See Fig. 6-1)

6-1-3 NVRAM Option Setting

1) NVRAM Opti on i s adj usted i n the factory.

2) In case Mai n PCB Mi com (IC601) and NVRAM (IC605 ; EEPROM) are repl aced, be sure to set the correspondi ng opti on number of the

requi red model . (If the opti on i s not set, the uni t wi l l operate.)

1) Press the TEST botton on VCR MAIN PCB to set the adjustment mode.

2) Press the 1, 4 buttons on the remote control. The option setting is appears. (See Fig. 6-3)

3) Select the option number (See table 6-1) of corresponding model with , , , buttons on the remote control.

4) After selecting the option number is completed, press the ENTER button of remote control.

(If ENTER button is pressed, the selected number is changescolor. ; See Fig. 6-4)

5) Press the RETURN button of remote control again to store the option number.

6) Turn the Power off.

Fig. 6-3 Fig. 6-4

CHG : OK SAVE : RETURN

01 02 03 04 05 06 07 08

09 10 11 12 13 14 15 16

17 18 19 20 21 22 23 24

25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48

49 50 51 52 53 54 55 56

57 58 59 60 61 62 63 64

65 66 67 68 69 70 71 72

CHG : OK SAVE : RETURN

01 02 03 04 05 06 07 08

09 10 11 12 13 14 15 16

17 18 19 20 21 22 23 24

25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48

49 50 51 52 53 54 55 56

57 58 59 60 61 62 63 64

65 66 67 68 69 70 71 72

6-4

< Table 6-1 NVRAM Option Table >

MODELS OPTION NUMBER

SLV- D920 E1 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 16, 32, 34, 35, 38, 40, 42, 45, 47, 50, 60, 61, 63, 68, 69, 70, 71, 72

SLV- D920 E2 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 16, 32, 34, 35, 38, 40, 42, 45, 47, 50, 60, 61, 63, 68, 69, 70, 71, 72

SLV- D920 B 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 16, 20, 21, 26, 32, 33, 34, 35, 36, 38, 40, 45, 47, 50, 60, 61, 63, 68, 69, 70, 71, 72

SLV- D925 E 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 16, 32, 34, 35, 38, 40, 42, 45, 47, 50, 60, 61, 63, 68, 69, 70, 71, 72

SLV- D930 GI 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 15, 25, 26, 32, 33, 34, 35, 38, 40, 41, 45, 47, 50, 60, 61, 63, 68, 69, 70, 71

SLV- D930 D 2, 4, 5, 6, 7, 9, 10, 11, 12, 13, 15, 16, 32, 34, 35, 38, 40, 42, 45, 47, 50, 60, 61, 63, 68, 69, 70, 71, 72

SLV- D920 N 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 16, 20, 32, 36, 38, 42, 45, 47, 50, 60, 61, 63, 68, 69, 70, 71, 72

SLV- D920 R 6, 7, 8, 9, 10, 11, 12, 13, 15, 20, 32, 36, 37, 39, 42, 43, 45, 47, 50, 54, 60, 61, 63, 68, 69, 70, 71

SLV- D960P E1 2, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 16, 32, 34, 35, 38, 40, 42, 45, 47, 48, 49, 60, 61, 63, 64, 67, 68, 69, 70, 71, 72

SLV- D960P E2 2, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 16, 32, 34, 35, 38, 40, 42, 45, 47, 48, 49, 60, 61, 63, 64, 67, 68, 69, 70, 71, 72

SLV- D960P B 2, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 16, 20, 21, 26, 32, 33, 34, 35, 36, 38, 40, 45, 47, 48, 49, 60, 61, 63, 64, 67, 68, 69, 70, 71, 72

6-5

6-2 VCR MECHANICAL ADJUSTMENT

6-2-1 Tape Transport System and Adjustment Locations

The tape transport system has been adjusted precisely in the factory. Alignment is not necessary except for the

following :

1) Noise observed on the screen.

2) Tape damage.

3) Parts replacement in the tape transport system.

Lower flange height of tape guide is used as the reference for the transport adjustment.

To maintain the height of the tape guide and prevent damage, do not apply excessive force onto the main base.

Fig. 6-6 Tape Travel Diagram

CYLINDER ASS' Y

TAKE UP REEL DISK

#8 GUIDE POST

#9 GUIDE POST

SUPPLY REEL DISK

CAPSTAN

PINCH ROLLER

GUIDE ROLLER "T"

GUIDE ROLLER "S"

FULL ERASE HEAD

#3 GUIDE POST

TENSION POST

HEIGHT SCREW

TILT SCREW

X - POSITION

ADJUST SILT

AZIMUTH SCREW

POST TENSION

MAIN BASE

FE HEAD CYLINDER ASS' Y PINCH ROLLER

GUIDE ROLLER "S" GUIDE ROLLER "T"

#8 GUIDE POST #9 GUIDE POST

CAPSTAN SHAFT

ACE HEAD

#3 GUIDE POST

Fig. 6-5 Location of Tape Transport Adjustment

6-6

6-2-2 Tape Transport System Adjustment

When parts are replaced, perform the required adjustments by referring to procedures for the tape transport

system. If there are any changes to the tape path, first run a T-120 tape and make sure excessive tape wrinkle does not occur at the tape guides.

If tape wrinkle is observed at the guide roller S, T, turn the guide roller S, T until wrinkle disappears.

If the tape wrinkle is still observed at the tape guide, perform the tilt adjustment of the ACE head.

(1) ACE Head Assembly Adjustment

a. ACE HEAD HEIGHT ADJUSTMENT

1) Run the alignment tape (Color bar) in the playback mode.

2) Observe surface of the audio head using a dental mirror.

3) Turn screw (C) clockwise or counterclockwise until the gap of lower tape edge and the lower edge of the control head is about 0.25mm. (Refer

to Fig. 6-7 and 6-8)

Fig. 6-7 Location of ACE Head Adjustment Screw

SCREW (A)

TLIT ADJUST

X- POSITION

ADJUSTING SLIT

SCREW (C)

HEIGHT ADJUST

SCREW (D)

X- POSITION LOCKING

SCREW (B)

AZIMUTH ADJUST

0 ~ 0 .25 mm

AUDIO HEAD

VIDEO HEAD

CONTROL HEAD

Fig. 6-8 ACE Head Height Adjustment

6-7

b. ACE HEAD TILT ADJUSTMENT

1) Playback a blank tape and observe the position of the tape at the lower flange of tape guide.

2) Confirm that there is no curl or wrinkle at the lower flange of tape guide as shown in Fig. 6-9 (B).

3) If a curl or wrinkle of the tape occurs, slightly turn the screw (A) tilt adjust on the ACE head assy.

4) Reconfirm the ACE head height.

(A) (B)

(BAD)

WRINKLE

(GOOD)

Fig. 6-9 Tape Guide Check

c. AUDIO AZIMUTH ADJUSTMENT

1) Load alignment tape (Mono scope) and playback the 6KHz signal.

2) Connect channel-1 scope probe to audio output.

3) Adjust screw (B) to achieve maximum audio level. (See Fig. 6-7)

6-8

d. ACE HEAD POSITION (X-POINT) ADJUSTMENT

1) Playback the alignment tape (Color bar)

2) Press the TEST botton on VCR MAIN PCB to set the adjustment mode. (See Fig. 6-2)

3) Press the 0, 5 remote control buttons, then adjustment is operates automatically. (See Fig. 6-1)

4) Connect the CH-1 probe to Envelope the CH-2 probe to HD switching pulse and then trigger to CH-1.

5) Insert the (-) driver into the X-Point adjustment hole and adjust it so that envelope waveform is maximum.

Test point: W568 (Audio Output)

W569 (Envelope)

W570 (HD S/W -Trigger)

W571 (Control Pulse)

Fig. 6-10 Location of Test point (VCR Main PCB-Top View)

AUDIO OUTPUT

CONTROL PULSE

HEAD SWITCHING

ENVELOPE

6-9

(2) Linearity adjustment (Guide roller S, T adjustment)

1) Playback the Mono Scope alignment tape (SP mode).

2) Observe the video envelope signal on an oscilloscope (triggered by the video switching pulse).

3) Make sure the video envelope waveform (at its minimum) meets the specification shown in Fig. 6-11.

If it does not, adjust as follows :

Note:

a=Maximum output of the video RF envelope.

b=Minimum output of the video RF envelope at the entrance side.

c=Minimum output of the video RF envelope at the center point.

d=Maximum output of the video RF envelope at the exit side.

4) If the section A in Fig. 6-12 does not meet the specification, adjust the guide roller S up or down.

5) If the section B in Fig. 6-12 does not meet the specification, adjust the guide roller T up or down.

a

a b c d

c,b,d/a 63%

b

c

d

Fig. 6-11 Envelope Waveform Adjustment

A B

A B

H' D SWITCHING PULSE

ENVELOPE

Fig. 6-12 Adjustment Points

6-10

6) Play back the Mono Scope alignment tape (SP mode).

7) Connect an oscilloscope CH-1 to the Envelope and CH-2 to the HD SW Pulse for triggering.

8) Turn the guide roller heads with a flat head ( ) driver to obtain a flat video RF envelope as shown in Fig. 6-13.

Fig. 6-13 Guide Roller S, T Height Adjustment

IDEAL ENVELOPE

S HEIGHT TOO HIGH S HEIGHTTOOLOW THEIGHTTOOHIGH T HEIGHT TOO LOW

GUIDE ROLLER S GUIDE ROLLER T

Fig. 6-14 Video Envelope Rising when Operation mode Changes from RPS to Play Mode

ENTRANCE SIDE ENVELOPE

(3) Check Transitional Operation from RPS to Play

Check transition from RPS mode to play mode : Using a pre-recorded SP tape, make sure the entry side of envelope comes to an appropriate

steady state within 3 seconds (as shown in Fig. 6-14).

If the envelope waveform does not reach specified peak-to peak amplitude within 3 seconds, adjust as follows :

1) Make sure there is no gap between the supply roller lower flange and the tape.

If there is a gap, adjust the supply guide roller again.

2) Change operation mode from the RPS to the play mode (again) and make sure the entry side of envelope rises within 3 second.

6-11

(4) Envelope Check

1) Make recordings on T-120 (E-120) and T-160 (E-180) tape.

Make sure the playback output envelope meets the specification as shown in Fig. 6-15.

2) Play back a self recorded tape (recording made on the unit using with T-120 (E-120).

The video envelope should meet the specification as shown in Fig. 6-15.

In SP mode, (A) should equal (B).

If the head gap is wide, upper cylinder should be checked.

Fig. 6-15 Envelope Input and Output Level

(5) Tape Wrinkle Check

1) Run the T-160 (E-180) tape in the playback, FPS, RPS and Pause modes and observe tape wrinkle at each guide.

2) If excessive tape wrinkle is observed, perform the following adjustments in Playback mode :

Tape wrinkle at the guide roller S, T section : Linearity adjustment.

Tape wrinkle at tape guide flange : ACE head assembly coarse adjustment.

6-2-3 Reel Torque

1) The rotation of the capstan motor causes the holder clutch assy to rotate through the belt pulley.

2) The spring wrap PLAY/REV of holder clutch assy drives the disk reel S, T through gear idler by rotation of gear center assy.

3) Brake is operated by slider cam at FF/REW mode.

4) Transportation of accurate driving force is done by gears. (Gear Center Assy)

Note: If the spec. does not meet the followings specifications, replace the holder clutch assy and then recheck.

< Table 6-2 >

MODE TORQUE g/cm GAUGE

PB 42 11 Cassette Torquemeter

RPS 145 30 Cassette Torquemeter

A

B

You might also like

- Daewoo Chassis CP 520v DTX 21g2, 21b4, 21u7Document59 pagesDaewoo Chassis CP 520v DTX 21g2, 21b4, 21u7Monete FlorinNo ratings yet

- Sp20so - La20s51b - Samsung - TFT-LCD TVDocument28 pagesSp20so - La20s51b - Samsung - TFT-LCD TVmiguel197234100% (1)

- 9537 Chassis Anubis SDD Manual de ServicioDocument55 pages9537 Chassis Anubis SDD Manual de ServicioTecniksNo ratings yet

- JBL E250p Service Manual 3282Document15 pagesJBL E250p Service Manual 3282AndrewWerdnaNo ratings yet

- HD66766 10Document100 pagesHD66766 10fenikseemNo ratings yet

- Sitronix ST7565RDocument72 pagesSitronix ST7565RStuart CouttsNo ratings yet

- Daewoo Cp185 Chassis Dta14c4tff TV SMDocument53 pagesDaewoo Cp185 Chassis Dta14c4tff TV SMMoyses MoyNo ratings yet

- Daewoo DP42SMLV Service ManualDocument62 pagesDaewoo DP42SMLV Service ManualReginald SosaNo ratings yet

- PPM50H3QX - Edc D62BDocument28 pagesPPM50H3QX - Edc D62BTomCat1928No ratings yet

- Hitachi LCD Driver HD44780U WithnotesDocument60 pagesHitachi LCD Driver HD44780U Withnotesepc_kiranNo ratings yet

- Sony VHS SLV 610 710Document86 pagesSony VHS SLV 610 710StefanoViganó100% (1)

- Toyota Standaard RadioDocument46 pagesToyota Standaard RadioEddy Glaser100% (9)

- Noe TVDocument29 pagesNoe TVZoi LleshiNo ratings yet

- Daewoo Chassis CP 102s DTB 21s6, 21s7Document57 pagesDaewoo Chassis CP 102s DTB 21s6, 21s7Catalin AlexandruNo ratings yet

- Panasonic Th-42pz70 42py70Document177 pagesPanasonic Th-42pz70 42py70danhusanuNo ratings yet

- Brandt 51011 Chassis A01 LCD TVDocument25 pagesBrandt 51011 Chassis A01 LCD TVAmadou FallNo ratings yet

- TV-770B (KX-503B) repair manualDocument18 pagesTV-770B (KX-503B) repair manualvaldir_azevedo_11No ratings yet

- Daewoo Dtd14h9 Dtd21h9 CH Cp093fDocument58 pagesDaewoo Dtd14h9 Dtd21h9 CH Cp093fminagabiroNo ratings yet

- HD44780U (LCD-II) : (Dot Matrix Liquid Crystal Display Controller/Driver)Document59 pagesHD44780U (LCD-II) : (Dot Matrix Liquid Crystal Display Controller/Driver)Alexander Du PlessisNo ratings yet

- Schneider Hcs-515 SCHDocument12 pagesSchneider Hcs-515 SCHbvm690% (1)

- CP830F Service Manual OverviewDocument98 pagesCP830F Service Manual OverviewEd JaNo ratings yet

- CEM2000 Car Entertainment System CEM2000XDocument22 pagesCEM2000 Car Entertainment System CEM2000XJúnior ZambonNo ratings yet

- Memorex Mi1111 s5l8310w S1a0903 pt2314 s3p825 44c1000bj-7Document26 pagesMemorex Mi1111 s5l8310w S1a0903 pt2314 s3p825 44c1000bj-7nelus008No ratings yet

- Panasonic TH-42PV60E GP9DE Chassie Service ManualDocument217 pagesPanasonic TH-42PV60E GP9DE Chassie Service ManualWims280100% (3)

- Pioneer Deh 3100r Deh 3130rDocument69 pagesPioneer Deh 3100r Deh 3130revagualdaNo ratings yet

- Service Manual for Pioneer DEH-1450/1450B CD PlayerDocument57 pagesService Manual for Pioneer DEH-1450/1450B CD PlayerLUIS LOPEZ QUISPENo ratings yet

- Daewoo Dub2850gb - CP780Document79 pagesDaewoo Dub2850gb - CP780Richard DruryNo ratings yet

- Service Manual: DEH-P4350Document67 pagesService Manual: DEH-P4350Lolo SortoNo ratings yet

- ST7735Document167 pagesST7735jatonfireNo ratings yet

- LC-32SB23U Parts GuideDocument8 pagesLC-32SB23U Parts GuideSeekerof1No ratings yet

- Az1137 CD Sound Machine: It Is Only For Serial Number: NSXXXXXXXXXDocument38 pagesAz1137 CD Sound Machine: It Is Only For Serial Number: NSXXXXXXXXXAmin SantanaNo ratings yet

- ¡ Semiconductor: General DescriptionDocument19 pages¡ Semiconductor: General DescriptionВалерий ГрицкевичNo ratings yet

- Pioneer PDP LX5090H Service Manual (EN)Document25 pagesPioneer PDP LX5090H Service Manual (EN)Mandu CerianoNo ratings yet

- Nikken Slim ChuckDocument16 pagesNikken Slim ChuckJohn SavioNo ratings yet

- KDL 19 L 4000Document48 pagesKDL 19 L 4000Silvestre Dominguez Guinaldo100% (1)

- Deh P3000RDocument68 pagesDeh P3000Rpite3No ratings yet

- WEG SSW 06 Soft Starter Usassw06 Brochure EnglishDocument6 pagesWEG SSW 06 Soft Starter Usassw06 Brochure EnglishBujar IbrahimiNo ratings yet

- Sony HCD Wz5Document46 pagesSony HCD Wz5dhanysiregarNo ratings yet

- SERVICE REF. NO. LCD-42XF8T-00Document48 pagesSERVICE REF. NO. LCD-42XF8T-00Cristian HerreraNo ratings yet

- CU EU Cylinders Pistones NeumaticosDocument80 pagesCU EU Cylinders Pistones NeumaticosbloggusbloggusNo ratings yet

- A Aiwa Service Manual CD MechanismDocument22 pagesA Aiwa Service Manual CD MechanismcobrabrNo ratings yet

- Philips Bj3.0e-La Chassis SM 1Document263 pagesPhilips Bj3.0e-La Chassis SM 1arbreacame0% (1)

- Ferraz Shawmut High Voltage Fuses CatalogueDocument93 pagesFerraz Shawmut High Voltage Fuses CataloguerocketvtNo ratings yet

- 14 Juntas CardanDocument30 pages14 Juntas CardanMarlon Arista VasquezNo ratings yet

- Pioneer Deh-3750mpDocument61 pagesPioneer Deh-3750mpElena Palacios GalecioNo ratings yet

- 42” PLASMA PDP MONITOR CHASSIS SERVICE MANUALDocument62 pages42” PLASMA PDP MONITOR CHASSIS SERVICE MANUALVic DiNo ratings yet

- TYPE 1,2: Paramount Parts List Weed Eater Parts List Poulan Parts List Parts List RDocument3 pagesTYPE 1,2: Paramount Parts List Weed Eater Parts List Poulan Parts List Parts List RMark MihalkoNo ratings yet

- TYPE 1,2: Paramount Parts List Weed Eater Parts List Poulan Parts List Parts List RDocument3 pagesTYPE 1,2: Paramount Parts List Weed Eater Parts List Poulan Parts List Parts List RMark MihalkoNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 4 out of 5 stars4/5 (1)

- Advanced AutoCAD® 2017: Exercise WorkbookFrom EverandAdvanced AutoCAD® 2017: Exercise WorkbookRating: 1 out of 5 stars1/5 (1)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- HEXYLON Release Notes 1.33Document9 pagesHEXYLON Release Notes 1.33Josip HrdanNo ratings yet

- HEXYLON Release Notes 1.33Document9 pagesHEXYLON Release Notes 1.33Josip HrdanNo ratings yet

- VAX150W - Test ProtocolDocument9 pagesVAX150W - Test ProtocolJosip HrdanNo ratings yet

- 14-DSC-14 Main PBA Recovery Repair Guide 140522Document1 page14-DSC-14 Main PBA Recovery Repair Guide 140522Josip HrdanNo ratings yet

- Samsung HT-C453 Schematic DiagramDocument12 pagesSamsung HT-C453 Schematic DiagramJosip HrdanNo ratings yet

- Technical Manual Storage Electric Water Heaters - VLSDocument18 pagesTechnical Manual Storage Electric Water Heaters - VLSdim-elNo ratings yet

- VLS Evo 100 EuDocument4 pagesVLS Evo 100 EuJosip HrdanNo ratings yet

- HTS-022 Tray Does Not Come Out Door LockDocument2 pagesHTS-022 Tray Does Not Come Out Door LockJosip HrdanNo ratings yet

- Manual For Planing and InstalationDocument78 pagesManual For Planing and InstalationJosip HrdanNo ratings yet

- Gerard Installation ManualDocument0 pagesGerard Installation ManualMilan CetrovicNo ratings yet

- Lc32sh130e-K-32sh340e SM GBDocument108 pagesLc32sh130e-K-32sh340e SM GBJosip HrdanNo ratings yet

- H8 Chassis Technical Training ManualDocument41 pagesH8 Chassis Technical Training ManualJosip HrdanNo ratings yet

- Level 2 Samsung Repair GuideDocument24 pagesLevel 2 Samsung Repair GuideJosip HrdanNo ratings yet

- Fino 20S-25S-30SDocument30 pagesFino 20S-25S-30SJosip Hrdan0% (1)

- How to prepare firmwareDocument5 pagesHow to prepare firmwareiancourtNo ratings yet

- Samsung HT-C453 Disassembly & ReassemblyDocument4 pagesSamsung HT-C453 Disassembly & ReassemblyJosip HrdanNo ratings yet

- FINO 20SE/30SE Parts List and Service ManualDocument17 pagesFINO 20SE/30SE Parts List and Service ManualJosip HrdanNo ratings yet

- Fino 15se 20se 30seDocument29 pagesFino 15se 20se 30seJosip HrdanNo ratings yet

- DMC LZ5Document54 pagesDMC LZ5Popescu IonutNo ratings yet

- ST71T EngDocument74 pagesST71T EngJosip HrdanNo ratings yet

- Blu-Ray Disc Home Cinema System: Service ManualDocument121 pagesBlu-Ray Disc Home Cinema System: Service ManualJosip HrdanNo ratings yet

- Repair guide for Samsung ES25 camera "P modeDocument1 pageRepair guide for Samsung ES25 camera "P modeJosip HrdanNo ratings yet

- 220TW9FB 00Document117 pages220TW9FB 00Joan Sanchez RojasNo ratings yet

- Samsung HT-C453 TroubleshootingDocument23 pagesSamsung HT-C453 TroubleshootingJosip HrdanNo ratings yet

- JVC TV Power Supply Training GuideDocument110 pagesJVC TV Power Supply Training GuidePanagiotis Argyropoulos60% (5)

- Samsung HT-C453 Schematic DiagramDocument12 pagesSamsung HT-C453 Schematic DiagramJosip HrdanNo ratings yet

- JVC Auto+radio KD-G409Document10 pagesJVC Auto+radio KD-G409Josip HrdanNo ratings yet

- HT F4550Document65 pagesHT F4550Josip Hrdan100% (1)

- XL HF201Document54 pagesXL HF201Josip HrdanNo ratings yet

- Direct Broadcast Satellites Specifications and CapacitiesDocument12 pagesDirect Broadcast Satellites Specifications and CapacitiesMuhamed El MosalmyNo ratings yet

- The Kasablanka Price ListDocument12 pagesThe Kasablanka Price ListzanwuNo ratings yet

- Chapter 5Document4 pagesChapter 5api-247337167No ratings yet

- ISDB Presentation 2Document41 pagesISDB Presentation 2Jose EspinoNo ratings yet

- TCL M66 ChassisDocument10 pagesTCL M66 Chassiskachappilly20120% (1)

- Vhs To DVD 3.0 Se: HonestechDocument33 pagesVhs To DVD 3.0 Se: HonestechGiulia SpatrisanoNo ratings yet

- China+TP SIS231 P85,+TP SIS231 PT85+LCD PDFDocument48 pagesChina+TP SIS231 P85,+TP SIS231 PT85+LCD PDFPOLAKU2002100% (1)

- BeinDocument4 pagesBeinTecMundoNo ratings yet

- LMD 2030WDocument2 pagesLMD 2030WPhong DoNo ratings yet

- A - EntertainmentDocument58 pagesA - EntertainmentRadio Parts100% (1)

- Product Service Manual - Level 2: Applicable Country & RegionsDocument107 pagesProduct Service Manual - Level 2: Applicable Country & RegionsJoao Jose Santos NetoNo ratings yet

- How TV WorksDocument17 pagesHow TV WorksSarita Madwal KargetiNo ratings yet

- Sharp Le810-820 Training Course EnglishDocument134 pagesSharp Le810-820 Training Course EnglishJulio DanielNo ratings yet

- XenonDocument104 pagesXenonMundo IPTVNo ratings yet

- Colour TelevisionDocument77 pagesColour Televisionfaroltek100% (2)

- High-quality signal generator for broadcast testingDocument7 pagesHigh-quality signal generator for broadcast testingjsrt234956No ratings yet

- Electric Mirror®: GenesisDocument4 pagesElectric Mirror®: GenesisNicksy MolmsNo ratings yet

- Denon AVR-770SD Use ManualDocument83 pagesDenon AVR-770SD Use ManualMuhammad Naveed ShahNo ratings yet

- Service Manual Service Manual: DV-SP800Document95 pagesService Manual Service Manual: DV-SP800Pablo PereiraNo ratings yet

- CCTV Price ListDocument34 pagesCCTV Price ListdevNo ratings yet

- Daewoo DLX32D1SMSB Manual de Servicio LCDDocument40 pagesDaewoo DLX32D1SMSB Manual de Servicio LCDAlexis ColmenaresNo ratings yet

- Metro Cash Carry India Televisions CatalogDocument40 pagesMetro Cash Carry India Televisions Catalogu4rishiNo ratings yet

- Dolby Vision Whitepaper - An Introduction To Dolby Vision - 0916Document5 pagesDolby Vision Whitepaper - An Introduction To Dolby Vision - 0916Moaz ElgabryNo ratings yet

- Manual - Telecomanda Terris 10 in 1Document24 pagesManual - Telecomanda Terris 10 in 1Dan Mihai RusuNo ratings yet

- Manual Panasonic Ny MDDocument3 pagesManual Panasonic Ny MDPopescu IonutNo ratings yet

- Ghost Adventures S13e03 Palace Saloon HDTV x264-w4fDocument2 pagesGhost Adventures S13e03 Palace Saloon HDTV x264-w4fAnonymous wISY6CIf8No ratings yet

- LG+LCD TV 22-32LF15RDocument170 pagesLG+LCD TV 22-32LF15RJoko PramonoNo ratings yet

- Home Cinema 3900 Full HD 1080pDocument5 pagesHome Cinema 3900 Full HD 1080pShareefThabetAlmqtriNo ratings yet

- Training Manual DVD-E360.EnDocument74 pagesTraining Manual DVD-E360.EnjbetoviNo ratings yet