Professional Documents

Culture Documents

Arc Welding Guide for Beginners

Uploaded by

Suhayl AzminOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arc Welding Guide for Beginners

Uploaded by

Suhayl AzminCopyright:

Available Formats

1.

0 OBJECTIVES

To perform on of the welding techniques and understand important of arc welding.

Define the problem that occurs on the arc welding.

Recognize the type of metal, electrode, and tools that are used in arc welding.

Recognize types of arc welding and steps to create the arc welding.

To know safety measure when use the welding machine along the welding process.

2.0 INTRODUCTION

Shielded metal arc-welding (SMAW) is one of the oldest, simplest and most versatile

joining process.

Nearly half of all industrial and maintenance welding currently is performed by this

process.

The electric arc is generated by touching the tip of a coated electrode against

workpiece and withdrawing it quickly to a distance sufficient to maintain the arc.

The heat generated melts a portion of the electrode tip, its coating and the base metal

in the immediate arc area.

The Stick welding power source provides constant current (CC) and may be either

alternating current (AC) or direct current (DC), depending on the electrode being

used. The best welding characteristics are usually obtained using DC power sources.

The electrode coating deoxidizes the weld area provides a shielding gas to protect it

from oxygen in the environment.

This welding process can be accomplished by a number of different methods. One

primary difference in this method is the energy sources used for welding-an electric

arc, gas flame, laser, even ultrasound.

As a rule, welding is pretty much the same across industries, so welders have the

flexibility of shifting from one industry to another, depending on demand.

Today, welders is needed almost everywhere, welding careers are in demand right

now. If you are good welding with some experience, you have got a real good chance

of finding a job just about anywhere in country.

3.0 SAFETY

3.1 Safety in shop floor

Arc welding can be hazardous

Read and follow all labels and the owners manual carefully

Only qualified person are to install, operate or service the

machine.

Keep children away

Pacemaker weares keep away

Welding wire and drive parts may be at welding voltage

Electric shock can kill

Always wear dry insulating gloves

Insulate yourself from work and ground

Do not touch live electrical parts

Disconnect input power before servicing

Keep all panels and covers securely inplace

Fumes and gases can be hazardous

Keep your head out of the fumes

Ventilate area, or use breathing device

Welding can cause fire or explosion

Do not weld near flammable material

Watch for fire

Do not locate unit over combustion surface

Do not weld on closed containers.

Arc rays can burn eyes and skin

Wear welding helmet with correct filter

3.2 Objectives Of Shop Floor Safety

To ensure student are able to do a work in a safe environment.

To make sure student know the hazards in the workshop and safety action

should be taken by them.

To train student to operate the machine safely and avoid the hazard.

Warned student the right way to use the machine that is not broken.

Warned student to report any emergencies or accidents to the supervisor.

3.3 Safety Measure in Shop Floor

Welding is a process involving with electricity and high temperature (heat), so we

must take precaution in doing this process to as precaution. The safety are:

1) Wear safety equipment such as head shield, glove and apron (safety

jacket) before start welding.

2) Do not watch the ultraviolet rays spatter when welding using eye without a

head Shield.

3) Carry Out at a comfortable area and where the is good welding will be done away

from the flammable materials.

4) Do not disturb other student that are still work.

5) Do not use tools that we do not recognize.

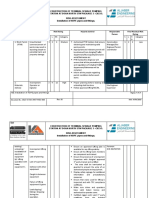

4.0 METHODOLOGY

1. First, cut the iron rod into 10 cm pieces and each student get two pieces of it

2. Clean the surface of the metal plate with wire brush before welding.

3. Mark the point where you wish to begin your weld on the metal plate.

4. Select the appropriate electrode with the type of your work.

5. Adjust the electrical current between the electrodes as suitable for the particular size

80-90

6. Welding on a flat surface and the angle between the electrode and the object of work

is between 15-30 degree .

7. The metal plate has two surface, so one of surface do a welding line in three line.

While another surface do a welding woven in three line also.

8. Then, strike an arc with long scratching motion of the electrode across the workpiece.

9. Finally of the weld, quickly lift the electrode away from the workpiece.

10. The electrode was dropped from the holder and put down the electrode holder.

11. Wearing clear shield on the welding helmet, chip away the slag on the weld bead.

12. After completed all the above process, make sure to tidy up your worktable.

5.0 OBSERVATION

1. The north is not uniform or uneven

Using the appropriate degrees of inclination.

Adjust the voltage

2. The plates are not in a straight position

Making a nail at the end of the weld plates

Use the support plate to establish the position of the plate to get a straight

plate

3. The difference should affect the melting of metals

80-85 = slow molten metal

6.0 RESULT

As a result, what I can conclude on my work is that:

By using high current, the electrode melt faster and molten puddle will be excessively

large and irregular. It will also leave a groove in the base metal along both sides of

the weld and therefore undercut will occur.

Effects of high current:

Spatter occurs in large drops alongside the weld.

Bead is too wide, too thin and undercut at edges.

Flux melts too rapidly, runs off the top of the weld.

If the current is too low, there is not enough heat to melt the base metal and the

molten pool will be too small.

Effects of low current during weld:

Inadequate penetration (weak weld).

Difficulty in striking arc.

Arc goes out often and difficulty in maintaining the arc.

From my welding techniques is that the speed that I used is too fast. As a result, the

molten pool will be thin and irregular. This will also lead to lack of penetration where

shallow fusions happen between weld metal and base metal.

7.0 CONCLUSION

As conclusion, the objective can achievable to do the practical welding. The student must

have skill to do the welding, used the knowledge and understanding of the theories, and also

welding techniques are applied in the practical welding. The practical task have been

complete and the report will accomplished to prove the student can be do the practical task of

Shielded metal arc-welding (SMAW).

You might also like

- JJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Document9 pagesJJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Ah Tiang100% (1)

- Arc Weld ReportDocument14 pagesArc Weld ReportAsyraf Razali67% (6)

- Safety Tips for Arc Welding WorkshopDocument10 pagesSafety Tips for Arc Welding WorkshopHabibah ArbainNo ratings yet

- Welding Lab Report. Part 1Document6 pagesWelding Lab Report. Part 1Ayuub Abdi Mahamed100% (1)

- Learn Welding Skills and Safety ProceduresDocument11 pagesLearn Welding Skills and Safety ProceduresJia Yee Ten100% (1)

- Mechanical Workshop Arc Welding Lab ReportDocument12 pagesMechanical Workshop Arc Welding Lab ReportDuventhiren83% (6)

- SMAW Welding GuideDocument13 pagesSMAW Welding GuideCheng Yee71% (7)

- Arc Welding ReportDocument6 pagesArc Welding ReportYe Chonn100% (6)

- Report Workshop Gas WeldingDocument6 pagesReport Workshop Gas WeldingDzulkhairie DK0% (1)

- Gas Welding Workshop ReportDocument12 pagesGas Welding Workshop ReportDuventhirenNo ratings yet

- Gas Welding ReportDocument6 pagesGas Welding ReportYe Chonn77% (13)

- DJJ 20042 Welding Report 1 - Welding ProcedureDocument15 pagesDJJ 20042 Welding Report 1 - Welding ProcedureMohamad Salleh AbdullahNo ratings yet

- Welding Discontinuities and Their CausesDocument2 pagesWelding Discontinuities and Their Causeszarif73% (15)

- FittingDocument14 pagesFittingMuhd Ashraf67% (3)

- GAS WELDING REPORT (Mohamad Syazwan Bin Abd Aziz F2029)Document21 pagesGAS WELDING REPORT (Mohamad Syazwan Bin Abd Aziz F2029)Mohd Naqiuddeen Khalil93% (45)

- Arc Welding Report PUODocument15 pagesArc Welding Report PUOadam zuhairi67% (3)

- Gas Welding ReportDocument17 pagesGas Welding ReportNorasilah Chan67% (3)

- Report Machine Sem3Document8 pagesReport Machine Sem3Fazerin Shah100% (3)

- Report MesinDocument8 pagesReport MesinWan Muhamad FaizNo ratings yet

- DJJ3032 - Workshop Practice 3 (Lathe Machining)Document8 pagesDJJ3032 - Workshop Practice 3 (Lathe Machining)Afiq Fahmi100% (2)

- JJ 103 Fitting ReportDocument12 pagesJJ 103 Fitting ReportNasrul Haziq Murad55% (20)

- Mesin Report SEM 2Document17 pagesMesin Report SEM 2Fiqri Ash RuleNo ratings yet

- Lathe Report Sem 1 DegDocument9 pagesLathe Report Sem 1 DegTarmizi Bahari74% (27)

- Fitting ReportDocument18 pagesFitting ReportAriff Azizi67% (3)

- Report Lathe MachineDocument13 pagesReport Lathe Machinehairul akmal0% (1)

- REPORT JF303 TUNSTERN INERT GAS (TIGDocument12 pagesREPORT JF303 TUNSTERN INERT GAS (TIGaizatulasmira60% (5)

- Thermal Equilibrium ExperimentDocument3 pagesThermal Equilibrium ExperimentFish Bone25% (8)

- Case Study JUN20Document9 pagesCase Study JUN20senyapsialNo ratings yet

- Improve Aluminum Casting with Smoother MoldsDocument1 pageImprove Aluminum Casting with Smoother MoldsNurulSyafiqah0% (1)

- OAW SMAW Flat WeldingDocument12 pagesOAW SMAW Flat WeldingHaikal SubriNo ratings yet

- Report FittingDocument1 pageReport FittingNordianaaida Eda67% (3)

- JJ303 Report TigDocument10 pagesJJ303 Report TigAh Tiang67% (9)

- Welding GAS ReportDocument11 pagesWelding GAS Report15 thn50% (2)

- Report MIG WeldingDocument12 pagesReport MIG WeldingKee Zhenyuan25% (12)

- Djj10022 Fitting ReportDocument7 pagesDjj10022 Fitting ReportTamil passang songNo ratings yet

- Discussion FoundryDocument1 pageDiscussion Foundryzuhud24No ratings yet

- Report FittingDocument33 pagesReport FittingNaqiuddin MuhamadNo ratings yet

- Lab Report TIGDocument4 pagesLab Report TIGAlimah Azeli50% (2)

- A Lab Report On Fitting Workshop PracticeDocument6 pagesA Lab Report On Fitting Workshop PracticeBilal Mobeen88% (17)

- Safety Precautions of EDMDocument2 pagesSafety Precautions of EDMApek Suasana0% (3)

- Lab Report Edm Wirecut PDFDocument23 pagesLab Report Edm Wirecut PDFeizy andy88% (8)

- Report WeldingDocument11 pagesReport WeldingSomasundaram SomanoNo ratings yet

- DJJ1032 Fitting (Hexagon Gauge) : Muhammad Ariff Bin Shukri TeyDocument14 pagesDJJ1032 Fitting (Hexagon Gauge) : Muhammad Ariff Bin Shukri TeyTak ProNo ratings yet

- Report MIG WeldingDocument12 pagesReport MIG Weldingyuwaraja0% (2)

- Arc Welding Techniques ExplainedDocument4 pagesArc Welding Techniques ExplainedFaris Kadesh50% (2)

- Practical Task 3 PumpDocument8 pagesPractical Task 3 Pumpshirleyna sara100% (2)

- Foundry ReportDocument2 pagesFoundry ReportPreavin Kutty Thamotharan50% (2)

- DJJ10022 REPORT (Fitting)Document6 pagesDJJ10022 REPORT (Fitting)Muhd Imran Kasyidi OmarNo ratings yet

- Hands-on arc welding experienceDocument3 pagesHands-on arc welding experienceromjhrytemjh100% (4)

- Inventor ReportDocument7 pagesInventor Report2cekal50% (2)

- DJJ 10033-Chapter 5.GEARDocument34 pagesDJJ 10033-Chapter 5.GEARStepianus JtNo ratings yet

- Understand Oxy Acetylene and Arc WeldingDocument14 pagesUnderstand Oxy Acetylene and Arc WeldingEzuddin Yazid100% (1)

- Lathe Machine ReportDocument28 pagesLathe Machine ReportFaizal64% (11)

- Welding ProjectDocument10 pagesWelding ProjectSean LimNo ratings yet

- SMAW Introduction GuideDocument8 pagesSMAW Introduction GuideAndrew TanNo ratings yet

- PORT DICKSON POLYTECHNIC MECHANICAL ENGINEERING CNC MACHINE WORKSHOP REPORTDocument19 pagesPORT DICKSON POLYTECHNIC MECHANICAL ENGINEERING CNC MACHINE WORKSHOP REPORTsujeetsaurabhNo ratings yet

- Mig ReportDocument14 pagesMig ReportDhana KumaranNo ratings yet

- SMAW Guide Shielded Metal Arc WeldingDocument44 pagesSMAW Guide Shielded Metal Arc WeldingAndrew TanNo ratings yet

- Introduction To Arc Welding: Information Sheet - "Document14 pagesIntroduction To Arc Welding: Information Sheet - "Eahbm KaduNo ratings yet

- Exp 2Document5 pagesExp 2alexchong93No ratings yet

- ReportDocument2 pagesReportSuhayl AzminNo ratings yet

- Lab Fluid (14november) PDFDocument110 pagesLab Fluid (14november) PDFSuhayl AzminNo ratings yet

- StatikDocument2 pagesStatikSuhayl AzminNo ratings yet

- How UTHM Students Spend ScholarshipsDocument4 pagesHow UTHM Students Spend ScholarshipsSuhayl Azmin100% (1)

- Resume (Contoh)Document1 pageResume (Contoh)Suhayl AzminNo ratings yet

- Karnival Bahasa Jerman Seksyen 2 Sesi 2013/2014Document7 pagesKarnival Bahasa Jerman Seksyen 2 Sesi 2013/2014Suhayl AzminNo ratings yet

- Gantt ChartDocument2 pagesGantt ChartSuhayl AzminNo ratings yet

- LAB SHEET and ReportsDocument1 pageLAB SHEET and ReportsSuhayl AzminNo ratings yet

- ProposalDocument9 pagesProposalSuhayl AzminNo ratings yet

- Chapter 2 - Technical DefinitionsDocument20 pagesChapter 2 - Technical DefinitionsSuhayl AzminNo ratings yet

- Marking and Measurement ToolsDocument9 pagesMarking and Measurement ToolsSuhayl AzminNo ratings yet

- Sample Progress ReportDocument2 pagesSample Progress ReportSuhayl AzminNo ratings yet

- 1 Objectives 1 2 2 3 Discussion and Result 3-4 4 Types 5 5 Types of Feeding Systems and Accessories 6Document8 pages1 Objectives 1 2 2 3 Discussion and Result 3-4 4 Types 5 5 Types of Feeding Systems and Accessories 6Suhayl AzminNo ratings yet

- Guidelines and Procedures For The Design and Fabrication of Mechanical Components in Senior DesignDocument10 pagesGuidelines and Procedures For The Design and Fabrication of Mechanical Components in Senior DesignVignesh MechzNo ratings yet

- Taekwondo SparringDocument3 pagesTaekwondo SparringSuhayl AzminNo ratings yet

- Assignment StaticDocument24 pagesAssignment StaticSuhayl AzminNo ratings yet

- Universiti Tun Hussein Onn Malaysia: Mechanical Engineering Dynamics DDE2063 BY En. Khairulnizam Bin OthmanDocument24 pagesUniversiti Tun Hussein Onn Malaysia: Mechanical Engineering Dynamics DDE2063 BY En. Khairulnizam Bin OthmanSuhayl AzminNo ratings yet

- Chapter 2 - Technical DefinitionsDocument20 pagesChapter 2 - Technical DefinitionsSuhayl AzminNo ratings yet

- Introduction To Technical Communication: Cydwee@uthm - Edu.myDocument12 pagesIntroduction To Technical Communication: Cydwee@uthm - Edu.mySuhayl AzminNo ratings yet

- Gulpandgasp 110202222416 Phpapp01Document35 pagesGulpandgasp 110202222416 Phpapp01Suhayl AzminNo ratings yet

- Gulp and GaspDocument6 pagesGulp and GaspSuhayl AzminNo ratings yet

- Gulp and GaspDocument6 pagesGulp and GaspSuhayl AzminNo ratings yet

- Design of Welded JointsDocument21 pagesDesign of Welded JointsBib GmzNo ratings yet

- Quick Guide To API 510Document27 pagesQuick Guide To API 510ABDULLAH SHAHABNo ratings yet

- Tank in Service Inspection ChecklistDocument8 pagesTank in Service Inspection ChecklistAhmadiBinAhmad100% (3)

- Workshop Welding ShopDocument80 pagesWorkshop Welding ShopBhaskar KandpalNo ratings yet

- OSHA Construction Safety Regulations Table of ContentsDocument6 pagesOSHA Construction Safety Regulations Table of ContentsarifbudimanNo ratings yet

- HL780 9SDocument583 pagesHL780 9SAnonymous yjK3peI7100% (3)

- Mechanical Cementation ProductsDocument20 pagesMechanical Cementation Productstafhim rashidNo ratings yet

- Welding Handbook - Welding Processes-Arc and Gas Welding and Cutting, Brazing, and SolderingDocument600 pagesWelding Handbook - Welding Processes-Arc and Gas Welding and Cutting, Brazing, and SolderingAnonymous QHMuqEMBmNo ratings yet

- RISK ASSESSMENT For Installation of HDPE Pipes and Fittings...Document21 pagesRISK ASSESSMENT For Installation of HDPE Pipes and Fittings...721917114 4757% (7)

- NCDMB Cet - Flowline Construction Repairs and Replacement in Oml 17 20022023 - R2Document3 pagesNCDMB Cet - Flowline Construction Repairs and Replacement in Oml 17 20022023 - R2Peter ObueroNo ratings yet

- Engineering Design - A Systematic Approach - Robert Matousek - Springer (1963) PDFDocument270 pagesEngineering Design - A Systematic Approach - Robert Matousek - Springer (1963) PDFNithin C.P.No ratings yet

- Hygienic Welding of Staineless EHEDGDocument21 pagesHygienic Welding of Staineless EHEDGscandalthegood100% (2)

- Welding Specification for Plant Piping SystemsDocument78 pagesWelding Specification for Plant Piping Systemsmasoud132No ratings yet

- Whats New Simufact - Welding 6.0 enDocument56 pagesWhats New Simufact - Welding 6.0 enSureshbabu NarayanasamyNo ratings yet

- The Welding Handbook 10th Edition 4th RevisionDocument552 pagesThe Welding Handbook 10th Edition 4th RevisionGREEN STARSNo ratings yet

- Welding inspection reportDocument3 pagesWelding inspection reportBOUZAIDANo ratings yet

- Hazard Matrix of Work Activities (HIRAC)Document15 pagesHazard Matrix of Work Activities (HIRAC)ROLAN RULLODA100% (1)

- 25 - Kelvin Shih - Improve Energy Efficiency and Weld QualityDocument27 pages25 - Kelvin Shih - Improve Energy Efficiency and Weld QualityAlexandre Lima LopesNo ratings yet

- Proofex PGP: Loose Laid PVC Waterproofing MembraneDocument2 pagesProofex PGP: Loose Laid PVC Waterproofing Membranekalidindivenkataraju100% (1)

- CSA W47.1 W59 13 Guides WeldCanadaDocument5 pagesCSA W47.1 W59 13 Guides WeldCanadamehdi810100% (2)

- Product Reference Manual - Section 8 - Arc Equipment & ProcessesDocument33 pagesProduct Reference Manual - Section 8 - Arc Equipment & Processesnishant361No ratings yet

- Jindal Saw Process FlowDocument2 pagesJindal Saw Process Flowvikalp shriNo ratings yet

- Acknowledgement: Name FacultyDocument23 pagesAcknowledgement: Name FacultySurendra JoshiNo ratings yet

- Report of Underwater WeldingDocument7 pagesReport of Underwater WeldingMunirAzeemNo ratings yet

- As 4722-2009 Passenger Ropeways and Passenger ConveyorsDocument8 pagesAs 4722-2009 Passenger Ropeways and Passenger ConveyorsSAI Global - APACNo ratings yet

- Automated Drain Cleaner Design and Progress ReportDocument12 pagesAutomated Drain Cleaner Design and Progress ReportMohd Anwar83% (6)

- CV (Sr. QA QC Engineer)Document5 pagesCV (Sr. QA QC Engineer)mansih457100% (1)

- Schuyler Maritime Catalog PDFDocument36 pagesSchuyler Maritime Catalog PDFAbu ShabeelNo ratings yet

- API 1104 Sample QuestionsDocument12 pagesAPI 1104 Sample QuestionsPatrick Dominguez80% (5)

- Soldadura Manual KukaDocument78 pagesSoldadura Manual KukaEduardoNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessFrom EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo ratings yet

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)