Professional Documents

Culture Documents

Understanding+the+changes+EN ISO14971 2012

Uploaded by

sqalopezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Understanding+the+changes+EN ISO14971 2012

Uploaded by

sqalopezCopyright:

Available Formats

Understanding the changes to

the risk standard for medical

devices: EN/ISO 14971:2012

Peter Bge

Informa Post Market Surveillance and Vigilance conference

Amsterdam, 24. -26. February 2014

Presentation title Date 1

Peter Bge

>20 years working with development processes within medical devices

>15 years working in ISO and IEC with

ISO14971 Risk Management,

IEC6366 Usability

IEC60601-1 Safety of electrical medical devices

Background

Presentation title Date 2

1. Why the risk standard has been amended

2. Examining the content deviations in Annex

ZA, ZB and ZC and how this will impact

medical device and IVD manufacturers

3. Clarifying how medical device manufacturers

should adapt to meet the requirements of

the standard

4. Some open questions

A gruesome story,

with a happy end, starring the PMS-hero

Presentation title Date 3

In the MDD from 1993 Essential Requirements were

phrased ambiguously regarding risk mgt.

However consensus until the EU Commission in 2011

raised a warning to deharmonise ISO14971.

CEN communicated with the EU Commission, initially

aiming at convincing the Commission,

Having failed in that, CEN wrote Annex Z explaining,

where the Commissions saw it not meeting the Essential

requirements of the MDD, spelled out as 7 Content

deviations.

Resulting in the European EN14971:2012, with Annex

Z being the only difference to ISO14971:2007.

The ISO JWG 1 for ISO14971 has continually been

following the talks with the Commission and given

scientific advice to CEN. But has no formal role.

1. Why the standard has been amended: History

Presentation title Date 4

EN ISO14971:2012 is one of a kind:

An Annex is not normative - but this Annex Z

contains normative requirements,

The content deviations are stated to be from the

original 1993 MDD - but for most readers, they

are new requirements.

Standards usually become mandatory after e.g. 3

years - this became mandatory 19 years ago (!)

Lets hope it will remain a one of a kind.

Some of the deviations are raising the bar/

adding to requirements,

some seem to conflict with the risk mgt principles

of ISO14971, the industry and risk mgt. science.

1. Why the standard has been amended:

The resulting EN14971

Presentation title Date 5

The existing ER do not seem to

express the requirements in Annex Z well.

The proposed new ones have ben fitted to do that

So now its a bit more clear

But are they the right ones?

The question of the

Essential Requirements 1-4

Presentation title Date 6

FDA (U.S.A.) and EU

New requirements are also coming from FDA

Unlike EU they target using internationally recognized

standards more, not less

Unlike EU FDA is actively involved in standardization

E.g. ISO14971 & IEC62366.

Unlike EU FDA seems more committed to discussing

practical issues in industry regarding new

requirements.

Part of the standardization process

FDA seems more interested in raising the bar for data

(related to e.g. risk mgt.) than principles.

Principles are part of the standardization process

1. WhyDifferences between US and EU

Presentation title Date 7

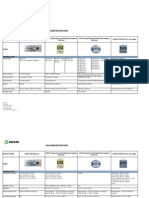

Content deviation Impact. Issues?

1.

Treatment of negligible risks:

manufacturer must take all risks

into account when assessing

Sections 1 and 2 of Annex I of

the directive.

A statement in

the Risk Mgt

Report may be

sufficient

- i.e. also the

acceptable/small ones.

How to demonstrate that

you have identified all risks?

2.

Discretionary power of

manufacturers as to the

acceptability of risks: all risks

have to be reduced as far as

possible and that

all risks combined, regardless

of any "acceptability"

assessment, need to be balanced,

together with all other risks,

against the benefit of the device.

Update of RM

Report may be

sufficient

How to demonstrate

that you have reduced

all, potentially many

small, risks?

What does combined

mean?: Add? - Fault

Tree?

Is this the right focus?

2. The impact of content deviations in Annex Zx

Presentation title Date 8

Do the content deviations also apply to risks that

have been addressed by meeting a standard?

E.g. IEC60601-1 series or ISO10993 series.

If yes, what then is the point in having harmonized standards?

If not, is the concept of risk in MDD different from that in

ISO14971? Suggestion:

14971- Risk can be reduced to an acceptable level, but not to zero..

MDD Risk cannot be reduced to acceptable level, but may be

eliminated by meeting a harmonized standard.

The question of harmonized standards

Presentation title Date 9

Content deviation Impact. Issues?

3.

Risk reduction "as far as

possible" versus "as low as

reasonably practicable":

manufacturers

and Notified Bodies [!] may not

apply the ALARP concept with

regard to economic considerations.

Update of

RM Report

may be

sufficient

1. If disregarding that As Far As

Possible usually is reserved

nuclear plants-safety (i.e. issue

with the science of RM),

2. And disregarding the economic

considerations of society (who is

the ultimate payer), then:

3. You can still apply ALARP on

technical considerations (State of

the Art).

2. The impact of content deviations in Annex Zx

Presentation title Date 10

Content deviation Impact. Issues?

4.

Discretion as to whether a risk-benefit

analysis needs to take place: the

manufacturer must undertake the risk-

benefit analysis for the individual risk

and the overall risk-benefit analysis

(weighing all risks combined against the

benefit) in all cases.

Update of RM

Report may

be sufficient

If the Clinical Evaluation

report is used.

Makes sense for injection

devices.

Makes less sense for devices

used in complex medical

procedures: Then it is truly a

new requirement.

2. The impact of content deviations in Annex Zx

Presentation title Date 11

Content deviation Impact. Issues?

6.

Deviation as to the first risk

control option:

Eliminate or reduce risks as far

as possible (inherently safe

design and construction)"

Update of

RM Report

may be

sufficient

Some think its a new

requirement.

How to demonstrate

that youve done all?

5.

Discretion as to the risk control

options / measures: the

manufacturer must apply all the

"control options" and may not

stop his endeavours if the first

or the second control option has

reduced the risk to an

"acceptable level" (unless the

additional control option(s)

do(es) not improve the safety).

Update of

RM Report

may be

sufficient

Some think its a new

requirement.

How to demonstrate

that youve done all?

2. The impact of content deviations in Annex Zx

ISO 14971, 6.2:

The manufacturer

shall use one or

more of the

following risk

control options in

the priority order

listed:

a) inherent safety

by design;

b) protective

measures in the

medical device

itself or in the

manufacturing

process;

c) information for

safety.

At some point tests will not demonstrate any effect of

additional risk control measures

Shall the manufacturer still do all possible that MAY reduce risk?

Difficult to see happening in the real world

Or only all possible that demonstrably reduces risk?

I.e. if data from e.g. test demonstrates a lower probability or severity of harm or both.

State of the art, e.g. based on market data and literature, is till needed

But if you have to do as much as possible

For all risks, big or small,

Until state of the art makes it impossible to do more,

Then its not ALARP that has been abolished

Its all ALARP!

The question of

as far as possible vs. ALARP?

Presentation title Date

13

Content deviation Impact. Issues?

Information of the users influencing

the residual risk:

b) However, the last indent of

Section 2 of Annex I to Directive

93/42/EEC says that users shall be

informed about the residual

risks. This indicates that, according

to annex I to 93/42/EEC and

contrary to the concept of the

standard, the information given to

the users does not reduce the

(residual) risk any further.

c) Accordingly, manufacturers shall

not attribute any additional risk

reduction to the information

given to the users.

If warnings have

reduced risk

scoring (e.g. RPN),

then analysis has to

be redone.

To justify safety of

existing products,

one way is PMS

data analysis.

Probably the most

effective and easy

way.

1. Difference

between

warning and risk

disclosure?

2. Some warnings

are required by

standards

3. Existence of

Instructions

For Use

(prescriptive

description of

tasks) will still

reduce risk!!!

2. The impact of content deviations in Annex Zx

Go through the Content Deviations

- Identify gaps in your documentation.

Some Content Deviations may be fixed with

adding statements to the Risk Mgt. Report.

Some deviations can only be addressed by

statements, not by data (e.g. #6, reducing risk as far

as possible)

You may need to introduce risk benefit analysis.

#7: Most will have to remove warnings from risk

scoring (RPN):

Potentially biggest issue.

3. How manufacturers should adapt

Presentation title Date 15

Content deviation 7 usually requires more: Usually

update of Risk Analysis and worse - labelling:

1. Remove warnings as a RCM from the risk scoring (RPN

calculations).

2. Do not remove them from the actual IFU/labelling.

1. May be required by standards or even legislation

2. And maybe they actually do have a risk reducing effect!

3. Re-calculate the risk score (e.g. RPN).

1. Identify any seemingly INTOLERABLE risks.

2. Assuming that PMS process has not indicated safety issues,

are they INTOLERABLE? No.

3. You may therefor do a new risk ESTIMATION the rationale

being that the risk estimates have not been linked as close to

PMS data, as they should have been

3. How manufacturers should adapt

Presentation title Date 16

=

All may be used, but

some are more

practical or convincing

than others

If available,

market feed back

data is fastest,

cheapest and most

convincing

Agree your approach

with your Notified Body

before

A review of sources for risk estimates

Presentation title Date 17

ISO 14971, 5. NOTE 6

Information or data for estimating risks can be

obtained, for example, from:

a) published standards;

b) scientific technical data;

c) field data from similar medical devices already in use

including published reported incidents;

d) usability tests employing typical users;

e) clinical evidence;

f) results of appropriate investigations;

g) expert opinion; and

h) external quality assessment schemes.

D 3.2.1. Seven approaches are commonly

employed to estimate probabilities:

use of relevant historical data;

prediction of probabilities using analytical or simulation

techniques;

use of experimental data;

reliability estimates;

production data;

post-production information; or

use of expert judgment.

1. A ISO14971 compliant system will have established

links between

Risk, incl. Failure Mode: How a failure is observed

(should be searchable in e.g. a FMECA, but may not be).

- and codes for Complaints

leading again to found Technical Errors

2. Risk Analysis: Do ERRORS happen?

PMS: Complaints indicate presence of ERRORS

3. Risk Analysis: Do ERRORS lead to harm?

With what SEVERITY?

PMS: Adverse-events indicate medical consequences of

ERRORS

PMS: Complaints without Adverse Events may indicate

low severity scenarios

4. In less-than-perfect complaint handling this may

require expert judgment

(i.e. meetings between Risk and PMS people)

Review risk analysis on marketed products

Presentation title Date 18

You may end up with 2 -10 risks,

with both complaints and adverse

events.

Users will face the ERROR from

time to time.

And some will experience HARM

You have monitored these risks,

and determined that they are

acceptable.

The remaining risks:

Should as per this analysis, be

lower.

Update your risk analysis

accordingly

You may have done this to

perfection (as you should acc. to

ISO14971), or you may not

Handling the critical risks

Presentation title

Date 19

P5

P4

P3

P2

P1

S1 S2 S3 S4 S5

X

X

X X

For residual risks that are judged acceptable, the

manufacturer shall decide which residual risks to

disclose

and what information is necessary to include in the

accompanying documents (ISO14971, 6.4)

I.e. the critical risks

But may not describe all needed elements:

1. Error: What not to do (warning),

2. Resulting probability

3. Consequence (harm) and

4. Severity.

E.g. Do not press button, as this may lead to burns,

requiring healthcare intervention.

Impact

This old requirement is NOT part of Annex Z

But weaknesses if any, become clear

And may if applicable be the most costly part!

But thats another story

Critical risks in Information For Safety

Presentation title Date 20

+ +

Thanks for listening!

Presentation title Date 21

You might also like

- IEC 60601-1 Medical Design Standards - 3rd EditionDocument7 pagesIEC 60601-1 Medical Design Standards - 3rd Editionacm573100% (1)

- As ISO 10993.7-2003 Biological Evaluation of Medical Devices Ethylene Oxide Sterilization ResidualsDocument10 pagesAs ISO 10993.7-2003 Biological Evaluation of Medical Devices Ethylene Oxide Sterilization ResidualsSAI Global - APACNo ratings yet

- ASTM Standards and Analytical Methods for PlasticsDocument41 pagesASTM Standards and Analytical Methods for PlasticsEduardo SalgadoNo ratings yet

- Form B (Per Rule 8 (A) For Submission of Research Protocol (S) Application For Permission For Animal ExperimentsDocument12 pagesForm B (Per Rule 8 (A) For Submission of Research Protocol (S) Application For Permission For Animal Experimentssachin jadhavNo ratings yet

- Guide Mqa 030 001Document30 pagesGuide Mqa 030 001SeanNo ratings yet

- Guideline MD Listing and Authorization MDS-G5 PDFDocument153 pagesGuideline MD Listing and Authorization MDS-G5 PDFSyed SalmanNo ratings yet

- A2 LaDocument10 pagesA2 LaAri DhamayantiNo ratings yet

- Type of deviation conformity assessmentDocument14 pagesType of deviation conformity assessmentNurul Fatia JannahNo ratings yet

- New Guidance On Product Family Adoption For Radiation Sterilization: AAMI TIR 35:2016Document39 pagesNew Guidance On Product Family Adoption For Radiation Sterilization: AAMI TIR 35:2016RakeshNo ratings yet

- Biocompatibility MatrixDocument1 pageBiocompatibility MatrixMico StanojevicNo ratings yet

- Sterilization - Validation, Qualification RequirementsDocument2 pagesSterilization - Validation, Qualification Requirementsgloryclaudia_100% (1)

- SCA Cool Logistics - An Introduction To Control Temperature PackagingDocument49 pagesSCA Cool Logistics - An Introduction To Control Temperature PackagingIhsan Mhd IlhamNo ratings yet

- Technical Tip: Product Adoption For Ethylene Oxide SterilizationDocument2 pagesTechnical Tip: Product Adoption For Ethylene Oxide SterilizationSyed Hassan Waqar Gilani100% (1)

- Guidance for Industry Premarketing Risk AssessmentDocument28 pagesGuidance for Industry Premarketing Risk AssessmentMorcosNo ratings yet

- EMEA EtO GuidelineDocument3 pagesEMEA EtO GuidelineSpectre SpectreNo ratings yet

- Protocol Synopsis Sample Sheet (HW)Document6 pagesProtocol Synopsis Sample Sheet (HW)rockmanx182No ratings yet

- SS ISO 10993-1-2018 - PreviewDocument14 pagesSS ISO 10993-1-2018 - PreviewmarkNo ratings yet

- CEMarking PDFDocument9 pagesCEMarking PDFniteen123No ratings yet

- Risk Benefit Analysis EmergoDocument9 pagesRisk Benefit Analysis Emergomuzammil21_adNo ratings yet

- IVD SYMBOLSDocument23 pagesIVD SYMBOLSHuỳnh ChâuNo ratings yet

- GWP White Paper - The Standard - enDocument16 pagesGWP White Paper - The Standard - enAhmad Atsari SujudNo ratings yet

- Medical Device Administrative Control System (MDACS) : List of Recognised Standards For Medical DevicesDocument85 pagesMedical Device Administrative Control System (MDACS) : List of Recognised Standards For Medical DevicesCompliance Department100% (1)

- D 5623 RefDocument4 pagesD 5623 RefseterisparigusNo ratings yet

- AG TCF 1 06. Biological Evaluation Report Non Absorbable Suture) 12 ClauseDocument5 pagesAG TCF 1 06. Biological Evaluation Report Non Absorbable Suture) 12 ClauseKarina GorisNo ratings yet

- Autonics RoHS Compliance CertificateDocument2 pagesAutonics RoHS Compliance CertificateDarwinPowChonLongNo ratings yet

- Presentation Manufacturing Process Biologics Kowid Ho Afssaps enDocument30 pagesPresentation Manufacturing Process Biologics Kowid Ho Afssaps enJ Diaz100% (1)

- Phosphate Buffered Saline SolutionDocument2 pagesPhosphate Buffered Saline Solutionyuvanraj21100% (1)

- ICH Guidance For PSURDocument24 pagesICH Guidance For PSURAwais KhanNo ratings yet

- Inive-IBPSA-BS05 0603 608Document6 pagesInive-IBPSA-BS05 0603 608Palwasha MalikNo ratings yet

- Cyclohexanone MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesCyclohexanone MSDS: Section 1: Chemical Product and Company IdentificationNada NovindaNo ratings yet

- Impurezas AgilentDocument32 pagesImpurezas AgilentArmando SaldañaNo ratings yet

- GL1018001EN00Document13 pagesGL1018001EN00Rahmat SukmonoNo ratings yet

- 520 NotesDocument200 pages520 Notesandika adikaraNo ratings yet

- EngDocument76 pagesEngMaimunah Novita SariNo ratings yet

- IEC 60601-1 Changes From 2nd To 3rd Edition (Intertek)Document18 pagesIEC 60601-1 Changes From 2nd To 3rd Edition (Intertek)AshitG100% (1)

- Reprocessing Biotech ProductsDocument14 pagesReprocessing Biotech ProductsawadsonNo ratings yet

- Alternatives To Animal ExpirementsDocument86 pagesAlternatives To Animal ExpirementsVinay Cam100% (1)

- Central Drugs Standard Control Organisation: in - Vitro Diagnostic (IVD) DevicesDocument16 pagesCentral Drugs Standard Control Organisation: in - Vitro Diagnostic (IVD) DevicesSusmita Ghosh0% (1)

- Data Logger Selection Chart Vacker Dubai UAEDocument10 pagesData Logger Selection Chart Vacker Dubai UAEVacker Group UAENo ratings yet

- Gamma IrradiationDocument27 pagesGamma Irradiationmuzammil21_adNo ratings yet

- Raman spectrometry method for pharmaceutical analysisDocument2 pagesRaman spectrometry method for pharmaceutical analysismihazav100% (1)

- Clinical Evaluation ReportDocument14 pagesClinical Evaluation ReportGavrila VeronicaNo ratings yet

- Design & Analysis of Gauge R&R StudiesDocument220 pagesDesign & Analysis of Gauge R&R StudiesmanchorusNo ratings yet

- Regulatory System in AmericaDocument134 pagesRegulatory System in AmericaMicaela CajamarcaNo ratings yet

- Biocompatibility PrinciplesDocument19 pagesBiocompatibility PrinciplesJorge OspinoNo ratings yet

- Iso - 22118 - 2011 - PCRDocument16 pagesIso - 22118 - 2011 - PCRCuong Nguyen100% (1)

- NGVF 2016 D1.T2.4.1 Gordon Farquharson WFI - New PH Eur Production Specification PDFDocument39 pagesNGVF 2016 D1.T2.4.1 Gordon Farquharson WFI - New PH Eur Production Specification PDFParth PatelNo ratings yet

- ISO 109931 Devices Guidance - 0Document68 pagesISO 109931 Devices Guidance - 0Dipo2No ratings yet

- Awareness of Application of Risk Managment Based On ISO 14971-2019 Standard - HandoutDocument84 pagesAwareness of Application of Risk Managment Based On ISO 14971-2019 Standard - HandoutVidyashree PujariNo ratings yet

- WHO TRS 1003 Full-VersionDocument252 pagesWHO TRS 1003 Full-VersionMechaheb MassinissaNo ratings yet

- Accelerated Stability TestingDocument5 pagesAccelerated Stability TestingKevin GaralaNo ratings yet

- Guidance Technical Documentation and Design Dossiers Fornon Active Medical DevicesDocument25 pagesGuidance Technical Documentation and Design Dossiers Fornon Active Medical DevicesCamila CamposNo ratings yet

- Agilent-Introduction ISO 17025 & AccreditationDocument27 pagesAgilent-Introduction ISO 17025 & AccreditationediwskiNo ratings yet

- As 4369.1-1996 Surgical Dressings Single-Use X-Ray Detectable Abdominal SpongesDocument6 pagesAs 4369.1-1996 Surgical Dressings Single-Use X-Ray Detectable Abdominal SpongesSAI Global - APACNo ratings yet

- P34 e Beam PowerpointDocument25 pagesP34 e Beam Powerpointomerbb100% (1)

- RoHS Guidance UKDocument32 pagesRoHS Guidance UKZoli0984No ratings yet

- The New EU GMP Annex 1 Draft - Impact On Environmental Monitoring ProgramsDocument8 pagesThe New EU GMP Annex 1 Draft - Impact On Environmental Monitoring Programsdiohoong1No ratings yet

- Presentation MED 2011Document44 pagesPresentation MED 2011altugNo ratings yet

- Risks and Opportunities: in ISO/IEC 17025:2017 and ISO 15189:2012Document48 pagesRisks and Opportunities: in ISO/IEC 17025:2017 and ISO 15189:2012Elena Iulia Cucolea100% (1)

- CBB2093 (1) IntroductionDocument20 pagesCBB2093 (1) IntroductionNazrul Amin MuhammadNo ratings yet

- Permatran-W Model 101K ManuscriptDocument122 pagesPermatran-W Model 101K ManuscriptsqalopezNo ratings yet

- Optiplex 990 Spec SheetDocument49 pagesOptiplex 990 Spec SheetsqalopezNo ratings yet

- Optiplex 990 Spec Sheet PDFDocument2 pagesOptiplex 990 Spec Sheet PDFyoucheff mochammadNo ratings yet

- First Article Inspection FAI AS9102 PresentationDocument28 pagesFirst Article Inspection FAI AS9102 Presentationsqalopez100% (3)

- Conductivity and Resistivity Values For Misc. MaterialsDocument8 pagesConductivity and Resistivity Values For Misc. MaterialsAla'a HusseinNo ratings yet

- QPCDocument14 pagesQPCsqalopezNo ratings yet

- Discover CanadaDocument68 pagesDiscover CanadaqatharyNo ratings yet

- Get Rid of Clutter and Organize Your ShopDocument6 pagesGet Rid of Clutter and Organize Your ShopsqalopezNo ratings yet

- 910-220-EN Rev E - EPOCH 4 (EN)Document208 pages910-220-EN Rev E - EPOCH 4 (EN)sqalopezNo ratings yet

- Epoch4 EnglischDocument164 pagesEpoch4 EnglischsqalopezNo ratings yet

- Increase SpeedDocument4 pagesIncrease SpeedsqalopezNo ratings yet

- Merrimack Supplier First Article Inspection Instructions and FormsDocument6 pagesMerrimack Supplier First Article Inspection Instructions and FormssqalopezNo ratings yet

- How To Appraise SuppliersDocument23 pagesHow To Appraise SupplierssqalopezNo ratings yet

- First Article Inspection InstructionDocument21 pagesFirst Article Inspection Instructiongranburyjohnstevens100% (1)

- First Article Inspection SummaryDocument5 pagesFirst Article Inspection Summarypawoe3064No ratings yet

- 13F Internal Audit ChecklistDocument5 pages13F Internal Audit ChecklistXiang Liu0% (1)

- First Article Inspection - Aerospace FormsDocument6 pagesFirst Article Inspection - Aerospace Formssqalopez100% (1)

- Vendor Selection ProcedureDocument14 pagesVendor Selection ProceduresqalopezNo ratings yet

- THE BASICS OF FAILURE MODE AND EFFECT ANALYSIS (FMEADocument32 pagesTHE BASICS OF FAILURE MODE AND EFFECT ANALYSIS (FMEApsrajjNo ratings yet

- Get Rid of Clutter and Organize Your ShopDocument6 pagesGet Rid of Clutter and Organize Your ShopsqalopezNo ratings yet

- GD&T FundamentalsDocument2 pagesGD&T FundamentalssqalopezNo ratings yet

- SPC ManualDocument178 pagesSPC ManualsqalopezNo ratings yet

- MSA Reference Manual 4th EditionDocument241 pagesMSA Reference Manual 4th EditionMukhammadali Shukuraliev100% (2)

- 13F Internal Audit ChecklistDocument5 pages13F Internal Audit ChecklistXiang Liu0% (1)

- 13F Internal Audit ChecklistDocument5 pages13F Internal Audit ChecklistXiang Liu0% (1)

- FMEA For Manufacturing and Assembly ProcessDocument9 pagesFMEA For Manufacturing and Assembly ProcessAsep SuryanaNo ratings yet

- PTP Ultrasonic Testing Level 1Document79 pagesPTP Ultrasonic Testing Level 1sqalopez100% (2)

- Vendor Quality System Requirements ProcedureDocument8 pagesVendor Quality System Requirements ProceduresqalopezNo ratings yet

- 8 DDocument4 pages8 DsqalopezNo ratings yet

- Angel FishDocument1 pageAngel FishWilla CrowellNo ratings yet

- Dof Omm Ss Skirting Sk-02Document8 pagesDof Omm Ss Skirting Sk-02Ideal DesignerNo ratings yet

- Mr. Frank Remedios Certified Career Counselor Authorised Franchise-Brain CheckerDocument24 pagesMr. Frank Remedios Certified Career Counselor Authorised Franchise-Brain Checkerrwf0606No ratings yet

- Ilogic LinkDocument13 pagesIlogic Linkbekirrrr100% (1)

- Adoption ApplicationDocument3 pagesAdoption ApplicationwriterhildNo ratings yet

- Examen 03 Aula - F PostgradoDocument5 pagesExamen 03 Aula - F PostgradodiegoNo ratings yet

- Servo LubesDocument2 pagesServo LubesVignesh VickyNo ratings yet

- 9Document2 pages9هلال العمديNo ratings yet

- Adult Education and Lifelong Learning Peter JarvisDocument63 pagesAdult Education and Lifelong Learning Peter JarvisKatherine Uran RamirezNo ratings yet

- R-101 and D-101 energy balancesDocument4 pagesR-101 and D-101 energy balancesPuteri MimieNo ratings yet

- An Overview of Radar Cross Section Measurement Techniques: Airplanes AIRDocument3 pagesAn Overview of Radar Cross Section Measurement Techniques: Airplanes AIRiamnbroneNo ratings yet

- Ashok LeylandDocument4 pagesAshok Leylandsodhiseema100% (1)

- STTH2002C: High Efficiency Ultrafast DiodeDocument16 pagesSTTH2002C: High Efficiency Ultrafast DiodeAseng saputraNo ratings yet

- Watson Studio - IBM CloudDocument2 pagesWatson Studio - IBM CloudPurvaNo ratings yet

- Gabi InfoDocument21 pagesGabi Infoangel antoinette dagoyNo ratings yet

- Cambridge O Level: Agriculture 5038/12 October/November 2020Document30 pagesCambridge O Level: Agriculture 5038/12 October/November 2020Sraboni ChowdhuryNo ratings yet

- Module 3 - Subsequent To AcquisitionDocument8 pagesModule 3 - Subsequent To AcquisitionRENZ ALFRED ASTRERONo ratings yet

- Chapter 2 ResearchDocument14 pagesChapter 2 ResearchabibualNo ratings yet

- Myo Cny 2023 MenuDocument12 pagesMyo Cny 2023 Menulihanyong17No ratings yet

- TBEM CII Exim Bank Award ComparisonDocument38 pagesTBEM CII Exim Bank Award ComparisonSamNo ratings yet

- Human PhysiologyDocument4 pagesHuman Physiologyshahzain92No ratings yet

- Family Nursing Care PlanDocument2 pagesFamily Nursing Care PlanSophia Ella OnanNo ratings yet

- Effective Postoperative Pain Management StrategiesDocument10 pagesEffective Postoperative Pain Management StrategiesvenkayammaNo ratings yet

- Tax - CIR Vs Cebu Toyo DigestDocument3 pagesTax - CIR Vs Cebu Toyo DigestDyannah Alexa Marie RamachoNo ratings yet

- Hydraulic Cylinders Series CD210 CG210Document72 pagesHydraulic Cylinders Series CD210 CG210Le Van TamNo ratings yet

- Logistic RegressionDocument17 pagesLogistic RegressionLovedeep Chaudhary100% (1)

- MIT6 003S10 FrontDocument11 pagesMIT6 003S10 Frontclique_devNo ratings yet

- Hepatobiliary Surgery BlumgartDocument301 pagesHepatobiliary Surgery Blumgartaejazahsan100% (7)

- How COVID-19 Affects Corporate Financial Performance and Corporate Valuation in Bangladesh: An Empirical StudyDocument8 pagesHow COVID-19 Affects Corporate Financial Performance and Corporate Valuation in Bangladesh: An Empirical StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Vandergrift - Listening, Modern Theory & PracticeDocument6 pagesVandergrift - Listening, Modern Theory & PracticeKarolina CiNo ratings yet