Professional Documents

Culture Documents

FG - Construction Documents - 07-003 PDF

Uploaded by

Walter R. SchulzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FG - Construction Documents - 07-003 PDF

Uploaded by

Walter R. SchulzCopyright:

Available Formats

SCALE

PROJECT NUMBER:

DATE:

DRAWN BY:

CHECKED BY:

PROJECT NAME:

REVISION SCHEDULE:

THE CLIMATIC AND GEOGRAPHIC DESIGN CRITERIA WILL

VARY BY REGION FOR ANY PROJECT. FOR THIS REASON,

FREEGREEN INC. CANNOT COMPLETE THIS TABLE UNTIL WE

KNOWWHERE THE PROJECT SITE IS LOCATED. ONCE YOU

HAVE A SITE LOCATION, PLEASE INQUIRE INTO OUR DESIGN

SERVICES AT Design@FreeGreen.com

1

NOTES:

348 MEDFORD ST. SUITE 1

CHARLESTOWN, MA 02129

COPYRIGHT BY FREEGREEN INC. ALL RIGHTS RESERVED.

www.FreeGreen.com

FREE GREEN

FEATURED PRODUCTS

348 MEDFORD ST. SUITE 1

CHARLESTOWN, MA 02129

www.FreeGreen.com

COPYRIGHT BY FREEGREEN INC. ALL RIGHTS RESERVED.

CLIMATIC AND GEOGRAPHIC DESIGN CRITERIA

GROUND

SNOW

LOAD

(LB)

WIND

SPEED

(MPH)

SEISMIC

DESIGN

CATEGORY

SUBJECT TO DAMAGE FROM

WEATHERING

FROST LINE

DEPTH

TERMITE DECAY

WINTER

DESIGN

TEMP

ICE SHIELD

UNDERLAY

REQUIRED

FLOOD

HAZARD

BUILDING CODE COMPLIANCE

1

RESIDENCE FOR:

SITE ADDRESS:

PHONE:

E-MAIL:

- Attention CA, OR, WA, and NV residents: Our house plans do not meet Earthquake Seismic/Wind

code requirements.

- Attention GA, SC, and NC Coastal residents: Plans may have to be engineered to meet local

Hurricane/Wind codes.

- Attention AL, AZ, CO, CT, DE, FL, ID, LA, MD, MA, MN, NV, NH, NJ, NY, OH, PN, UT, and VA

residents: Plans may have to be engineered to meet local building codes. Please call your local

building department before placing order.

Some cities and states now require that a licensed architect or engineer review and "seal" a blueprint,

or officially approve it, prior to construction. Prior to application for a building permit or the start of

actual construction, we strongly advise that you consult your local building official who can tell you if

such a review is required.

HOUSE AREAS

BUILDER:

ADDRESS:

PHONE:

E-MAIL:

ENGINEER:

ADDRESS:

PHONE:

E-MAIL:

ARCHITECT:

ADDRESS:

PHONE:

E-MAIL:

THE ABOVE AREA CALCULATIONS ARE BASED ON THE METHOD LAID OUT IN

ANSI STANDARD Z765

4

/8

/2

0

1

0

1

0

:4

7

:4

1

A

M

CVR

COVER PAGE

07-003

SEASIDE BARN

07 APRIL, 2010

MI

BU, SH

ARCHITECTURAL

A-00-1 GENERAL NOTES

A-00-2 LEED-H RATING SYSTEM CHECKLIST

A-00-3 NAHB GREEN BUILDING STANDARD

A-01-1 ELEVATIONS

A-01-2 ELEVATIONS

A-02-1 ENTRY LEVEL FLOOR PLAN

A-02-2 UPPER LEVEL FLOOR PLAN

A-03-1 BUILDING SECTION

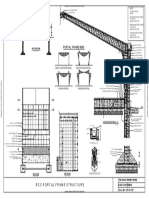

A-04-1 DETAILS 1

A-04-2 DETAILS 2

A-04-3 DETAILS 3

A-04-4 DETAILS 4

A-05-1 FOUNDATION PLAN

A-05-2 ENTRY LEVEL FLOOR FRAMING PLAN

A-05-3 UPPER LEVEL FLOOR FRAMING PLAN

A-05-4 ROOF FRAMING PLAN

A-06-1 WINDOW SHADING DETAILS

ELECTRICAL

E-01-1 ELECTRICAL PLANS

CONDITIONED

CRAWL SPACE:

SUB LEVEL:

ENTRY LEVEL:

UPPER LEVEL:

TOTAL:

UN-CONDITIONED

GARAGE:

BASEMENT:

ATTIC:

DECK/PATIO:

TOTAL:

-

-

1344 SF

1344 SF

2688 SF

-

-

-

504 SF

504 SF

No. Description Date

SCALE

PROJECT NUMBER:

DATE:

DRAWN BY:

CHECKED BY:

PROJECT NAME:

NOTES:

REVISION SCHEDULE:

348 MEDFORD ST. SUITE 1

CHARLESTOWN, MA 02129

COPYRIGHT BY FREEGREEN INC. ALL RIGHTS RESERVED.

www.FreeGreen.com

FREE GREEN

GENERAL REQUIREMENTS:

1. Owner / Client Responsibilities: Reference is made throughout these General Notes to

responsibilities and standards of care to be fulfilled by those providing services in the development and

construction of this project. Owner / Client shall be responsible for adherence to those requirements by the

Owner, Builder, Developer, General Contractor, Subcontractors and other professional Consultants not

retained by the Designer.

2. Builder's Set: The scope of this set of plans is to provide a builder's set of construction

documents and general notes hereinafter referred to as plans. After formal review and approval

by a licensed engineer and or architect, this set of plans is sufficient to obtain a building permit;

however, all materials and methods of construction necessary to complete the project are not

necessarily described. The plans delineate and describe only locations, dimensions, types of

materials and general methods of assembling or fastening. The FreeGreen Specification book

received with this plan set specifies the particular products or materials recommended for this

home design. The implementation of these plans requires an Owner/ Client/ Contractor thoroughly

knowledgeable with the applicable building codes and methods of construction specific to this

product type and type of construction.

3. Building Maintenance: The exposed materials used in the construction of this project will

deteriorate as the completed project ages unless properly and routinely maintained. Owner /

Client shall provide or cause the development of a plan to keep these exposed materials

protected and maintained.

4. Codes: All construction shall comply with the most stringent requirements of all current applicable

city, county, state and federal laws, rules, codes, ordinances and regulations. If the General

Contractor or any Subcontractor performs any work in conflict with the above mentioned laws,

rules, codes, ordinances and regulations, then the contractor in violation shall bear all costs of

repair arising out of the non - conforming work.

5. Permits: The general building permit and plan check shall be secured and paid for by Owner

/Client. All others permits shall be secured and paid for by the Subcontractor directly responsible.

6. Insurance: The General Contractor and every Subcontractor performing work or providing

services and/ or materials for the work are required to purchase and maintain in force All Risk

Builders Insurance prior to commencement of the work and/ or furnishing labor, services and

materials. Each All Risk policy shall be in an amount sufficient to cover the replacement value

of the work being performed and/ or the labor, services and materials being supplied by the

General Contractor, Subcontractors, Designer, and all professional Consultants.

7. Insurance: Owner/ Client shall cause the General Contractor and every Subcontractor performing

work or providing services and / or materials for the work to purchase and maintain General

Liability Insurance.

8. Named Products: The Designer makes no guarantee for products identified by trade name or

manufacturer.

9. Scope: The General Contractor and Subcontractors shall furnish all labor, equipment, and material

indicated on the plans and reasonably inferred or required by the applicable codes.

10. Substitution: Substitutions of specific materials or products listed on the FreeGreen Specification

Sheet shall not be made without written authorization by Owner/ Client. The General Contractor

and any Subcontractor shall not make the structural substitutions or changes without prior written

authorization fromthe structural engineer.

11. Changes: Any addition, deletion, or change in the scope of the work described by the plans

shall be by written change order only. Any approval fromthe building official for a change in the

work shall be the responsibility of the General Contractor.

12. Intention: The General Contractor shall ensure that all labor, materials, equipment and

transportation shall be included in the work for complete execution of the project. The Designer

shall not be responsible for the means and methods of construction.

13. Review of Drawings: The General Contractor and all Subcontractors shall review the full content

of the plans for discrepancies and omissions prior to commencement of work. The General

Contractor and all Subcontractors shall be responsible for any work not in conformance with the

plans or in conflict with any code.

14. Use of the Drawings: Dimensions take precedence over scaled measurements. Details and

sections on the drawings are shown at specific locations and are intended to show general

requirements throughout. Details noted typical imply all like conditions treated similarly, unless

noted otherwise. The architectural details shown are intended to further illustrate the visual design

concept and the minimumrecommended weather protection for this project. Building code

requirements, structural considerations, trade association manuals and publications and product

manufacturer's written instructions shall also be considered in order to complete the construction

of the details, and in some cases may supercede the details.

15. Approved Drawings: The General Contractor shall be responsible for coordinating the work

between the different Subcontractors and requiring all Subcontractors to use the most current

building department approved set of plans.

16. Cutting and Patching: All Subcontractors shall do their own cutting, fitting, patching, etc. to make

the several parts come together properly and fit it to receive the work of other trades.

17. Clean up: All trades shall, at all times, keep the premises free fromaccumulation of waste

materials or rubbish caused by their work. Subcontractors shall remove all rubbish, tools,

scaffolding and surplus materials and leave the job in a broom- clean condition. All fixtures,

equipment, glazing, floors, etc., shall be left clean and ready for occupancy upon completion of

the project.

18. Storage of Materials: The General Contractor and Subcontractors shall be responsible for storing

the materials on the site according to material suppliers' or manufacturers' instructions. The

materials shall be kept secure and protected frommoisture, pests, and vandals. Any loss arising

out of materials stored at the site shall be the responsibility of the General Contractor or

Subcontractor who stored the damaged or lost materials.

ROUGH CARPENTRY:

1. Framing:

A. Blocking and Bridging:

(1) Stud Walls: Per applicable building code. Full height walls shall have continuous

studs frombottomto top plate.

(2) Ceiling Joists: Per applicable building code. Use solid bridging.

(3) Backing: Provide solid backing at all pendant or surface - mounted electrical

fixtures, rails, grab bars, bath accessories, etc.

B. Fire stopping: Per applicable building code.

C. Stud Walls: Per applicable building code. All studs to have full bearing on plate. All studs

to be at 16 O.C. unless noted otherwise. Studs to be sized per requirements of code.

D. Use continuous, full height studs in accordance with the highest standard of construction

and framing practices.

E. All angled walls to be at 45 degrees unless noted otherwise

F. Built up roofs, waterproof balcony decks and exterior horizontal areas are to be framed

with slope to ensure water drainage without ponding.

G. Provide crickets as indicated and as necessary for proper water drainage and to redirect

channeled or run off water away fromvertical surfaces.

H. Provide blocking where required to provide uniformsurface where flush joists and beams

are different depths.

I. Use mitered joints at fascia splices.

J. Unless otherwise noted, all dimensions to exterior walls are given frominside or outside

face of rough framing. All dimensions to interior partitions are given fromcenterline of

rough framing.

K. Align bottomof all adjacent window and door headers, unless noted otherwise on framing

plan.

2. Trusses:

A. The General Contractor shall have City/ County approved truss plans on the job site prior

to foundation inspection. The Truss Manufacturer shall submit calculations, shop

drawings, details, bridging and erection bracing signed by a registered Engineer to the

Building Department and Structural Engineer, for their review prior to fabrication.

B. Truss manufactures shall provide members of adequate bearing area in such a width to

insure against over - stressing of supporting timber, multiple joists, girders and plates or

provide bearing plates and details to do same.

C. The General Contractor shall coordinate with the Truss Manufacturer, Framing, Electrical,

Plumbing and Mechanical Contractors at fire protected areas to maintain required fire

protection without penetrations unless allowed by code and local jurisdiction.

FINISH CARPENTRY:

1. Scope:

A. Furnish and install all finish carpentry complete, including trim, door frames, paneling and

shelving.

B. Installation of finish hardware, bath accessories, cabinet pulls, etc.

2. Workmanship:

A. All joints shall be tight and true and securely fastened. Corners shall be neatly mitered,

butted, or coped, with nails set and surfaces free of tool marks.

B. Wood work shall be accurately scribed to fit adjoining surfaces.

C. All work shall be machined or hand sanded, sharp edges and splinters removed, and

completely prepared for finish.

D. Full length continuous boards shall be used wherever applicable or specifically noted.

3. Fitting and Hanging Doors:

A. Each door shall be accurately cut, trimmed, and fitted to its respective frame and

hardware with due allowance for painter's finishes.

B. Clearance at the lock and hanging stiles and at the top shall not exceed 1/8. Clearance

at the bottomshall be adjusted for finish floor covering.

C. Lock stile edges shall be beveled.

D. Door shall operate freely, but not loosely, without sticking or binding, without hinge bound

conditions, and with all hardware properly adjusted and functioning.

4. Materials:

A. Door frames: Frames shall be set plumb and true, rigidly secured, and protected during

the course of construction.

B. Door Stops and Casing: Size and profile as selected by Owner/ Client.

C. Exterior Trim: Refer to drawings for exterior trimmaterial & sizes. For wood, medium

dencity overlay (MDO) or fiber cement, all cut sides/faces/edges must be primed and

painted. If specific product brand is specified on drawings, see manufacturers

specifications and installation instructions.

D. Interior Trim:

(1) Interior Rails: Clear material, finished to match casework.

(2) Window Trim: 1x clear wood to match casework or as noted in drawings (verify

with Owner/Client).

(3) Base Boards: As noted in drawings or approved by Owner/Client.

INSULATION:

1. Installation:

A. Thermal Insulation: Install insulation between joists, below all roof surfaces, and areas

including any vertical wall areas separating living spaces fromunconditioned space and

between studs at all exterior walls. Insulation shall be securely installed and tightly fitted

without compressing the normal Loft thickness. Provide insulation stops/ baffles as

required to prevent obstruction of vents.

B. Sound insulation: Install insulation between studs, securely and tightly fitted at walls as

indicated on drawings.

C. Plumbing insulation: All domestic hot water piping shall have R-4 insulation. Insulation

shall be properly installed on all piping elbows to adequately insulate the 90 degree bend.

D. The General Contractor and Subcontractors shall be responsible for storing the materials

on the site according to material supplier's or manufacturers' instructions. The materials

shall be kept secure and protected frommoisture.

2. Materials:

A. At a minimum, all insulation specified for this house meets or exceeds the R-value

requirements listed in Chapter 4 of the 2004 International Energy Conservation Code and

also the Grade II specifications set by the National Home Energy Rating Standards.

B. A pre-drywall thermal bypass inspection must be performed by a qualified rater.

THERMAL & MOISTURE PROTECTION:

1. Foundations:

A. Provide adequate drainage away fromwalls & foundations.

B. Seal all plumbing, electrical and other penetrations of walls and floors and seal joints.

C. Slope final grade away fromfoundation.

D. Provide capillary break at all concrete slabs (poly not req. if <20 rainfall; gravel not req.

for free draining soils = IRC Group 1.

E. Exterior surface of below grade walls damp proofed or water proofed.

F. Slope garage floor towards main vehicle entry.

G. Foundation cont. footing drain with stone covered with filter fabric, drained to daylight.

H. Basement foundation walls use porous backfill material.

I. Provide cont. crushed stone under footings.

J. Provide rigid insulation as specified directly under slab.

2. Walls:

A. Install windows, doors, exterior cladding, flashings & sealants as detailed in this

drawing set.

B. All deck ledgers must be pressure treated material.

C. All penetrations that pass through exterior cladding into structure must be fully sealed.

D. Install materials with proper detailing to control degradation frommoisture.

3. Roofs:

A. Ice flashing over sheathing at eaves (except climates CZ1-4).

B. Metal drip edge at all exposed roof decking.

C. Bituminous membrane at all eaves, valleys & penetrations (not req. if <20 rainfall).

D. Step flashing at all roof/wall intersections & terminated with kickout flashing.

E. Installed systemfor diverting roof water fromhouse. (e.g. gutters).

F. No. 30 roof felt underlayment minimum.

G. Reduce ice dams: No non-airtight recessed light fixtures in insulated ceilings.

H. Roof insulation as specified in this drawing set.

4. Wet Rooms:

A. Install drains or drain pans to capture leaks under water heaters or use tankless

water heaters.

B. Properly install washer and water heater drain pans.

C. Use highly durable materials in wet areas.

D. Install no carpet in kitchens, bathrooms, spa areas, or within 3 of exterior door.

E. Use nonpaper-faced backer board on walls in tub, shower and spa areas.

5. Air Infiltration:

A. Install IC airtight rated recessed lights in insulated ceilings.

B. Complete air barrier between attic and conditioned space & all penetrations sealed.

C. Air filter housings must be airtight to prevent bypass or leakage.

D. Air seal ventilation ductwork.

6. Interstitial Condensation:

A. Clothes dryers vented outdoors.

B. Insulate all cold water pipes and avoid plumbing in exterior walls.

C. >1 Permfinish on inside of exterior walls.

(only req. in hot/humid & mixed/humid climates)

7. Heat Loss:

A. Insulate all ventilation exhaust ductwork (min R-8) outside of the insulated envelope.

B. R-5 slab edge insulation break at foundation wall intersection & R-10 slab edge

insulation outward of any walk-out slab edge.

C. Install insulation wind baffles at attic eave bays.

8. Ultraviolet Radiation:

A. Install materials with proper detailing to control degradation fromsun.

9. Other:

A. Minimum25-year expected lifetime roof warranty.

B. Define proper refrigerant charge to be within 10%of manufacturer recommendations.

C. Mechanical equipment must be accessible for service, including AC condensate drain

pan & trap.

D. Use rigid duct or other methods to keep fan back-pressure below 0.2 for EOV systems.

HEATING, VENTILATION & AIR CONDITIONING:

1.Scope:

A. Supply all labor, transportation, material, etc., for installation of a complete heating and air

conditioning systemto operate according to all applicable standards and best practices of

the trade including, but not limited to: mechanical units, ducts, registers, catwalks, grilles,

boots, vent pipes, dampers, combustion air, fans, ventilators, refrigerant, etc. All

materials, work, etc., to comply with all requirements of all legally constituted public

authorities having jurisdiction including all county and state ordinances. Furnish and install

all equipment complete and operable. Verify all material and installation requirements

and limitations at fire and sound assemblies.

B. Provide rubberized asphaltic membrane materials at all penetrations of the water -

resistive membrane at exterior walls.

2. Installation:

A. Provide required clearances for duct work and to combustibles.

B. Provide a permanent electric outlet and switched light fixture wherever equipment is

installed.

C. No alterations to the structural frame, diaphragms, connections or shear panels shall be

made without prior written approval fromthe Structural Engineer.

D. No equipment located in garages.

E. All combustion equipment shall be directly vented with an outdoor combustion air supply.

F. All penetrations of fire assemblies shall meet the requirements of the building code and

Section 7D.

G. All HVAC equipment shall be approved prior to installation per nationally recognized

standards and evidenced by listing and label of an approved agency.

H. Combustion air fromoutside shall be supplied to all fuel burning appliances.

I. Install air filters with a minimumefficiency reporting value (MERV) 10 and ensure that

air handlers can maintain adequate pressure and air flow. Air filter housings must be air

tight to prevent bypass or leakage.

J. All fixed appliances are required to be securely fastened in place. Provide seismic bracing

or anchor unit to platformwhere appropriate.

K. Install centralized HVAC systemequipped with additional controls to operate in

dehumidification mode.

L. Condenser pad or compressor fromground must not be less than 3 above grade.

M. The General Contractor and Subcontractors shall be responsible for storing the materials

on the site according to material supplier's or manufacturers' instructions. The materials

shall be kept secure and protected frommoisture.

ELECTRICAL:

1. Scope:

A. Supply all labor, transportation, materials, etc, for installation of complete electrical

systemto operate according to the best practices of the trade and including but not

limited to: Fixtures, appliances, wiring, switches, outlets, television jacks, services,

grounds, temporary power, junction boxes, conduit, sub - panels, etc. All work, materials,

etc, to comply with all requirements of all legally constituted authorities having jurisdiction

including all County and State ordinances. Furnish and install electrical work complete

and operable. Verify all material and installation requirements and limitations at fire and

sound assemblies.

B. Provide rubberized asphaltic membrane materials at all penetrations of the water-

resistive membrane at exterior walls.

2. Installation:

A. Electrical systeminstalled according to latest version of N.E.C or local code, whichever

is more stringent.

B. Provide separate circuits each for dishwasher, garbage disposal, refrigerator, washer,

dryer, F.A.U. and microwave oven.

C. Switched outlets shall be hot.

D. Bathroomand Kitchen fans: Install local exhaust systems in all

bathrooms and in the kitchen to meet the requirements of section 5 of

ASHRAE Standard 62.2-2007. Design and install fan ducts to meet the

requirements of section 7 of ASHRAE Standard 62.2-2007.Exhaust air to

outdoors and also use ENERGY STAR labeled bathroomexhaust fans.

E. For every bathroomexhaust fan, install an occupancy sensor or an

automatic humidistat controller or an automatic timer to operate the fan

for a timed interval after occupant leaves the roomor a continuously

operating exhaust fan.

F. All fixtures, outlets, receptacles etc., penetrating fire assemblies shall be rated and

installed to meet the requirements of the building code. Outlet boxes on opposite sides of

fire assembly walls shall be separated by a horizontal distance of at least 24.

G. All equipment installed outdoors and exposed to weather shall be weatherproof.

H. Provide ground fault circuit interrupters, G.F.C.I., at all baths, garages, out-door and wet

area outlets. All branch circuits that supply 125 - volt single - phase, 15 and 20 ampere

receptacle outlets installed in dwelling unit bedrooms shall be protected by an arc - fault

circuit interrupter(s).

I. Each conductor of every systemshall be permanently tagged in compliance with O.S.H.A

J. The complete electrical systemshall be grounded in accordance with the presently

adopted edition of the N.E.C., Art. #250. Proper ground requires #4 copper wire, 20' - 0

long, embedded into concrete and provide bond to gas or water line.

K. Use only competent and skilled personnel and performall work, including aesthetic as

well as electrical and mechanical aspects to standards consistent with the best practices

of the trade.

L. No alterations to the structural frame, diaphragms, connections or shear panels shall be

made without approval fromthe Structural Engineer.

PLUMBING:

1.Scope:

A. Supply all labor, transportation, materials, etc. for installation of complete plumbing

systemto operate according to the best practices of the trade and including but not limited

to: fixtures, hot and cold water piping, exhaust flues, combustion air, gas piping, log

lighters, drains, soil and vent piping, hot water heaters, pipe insulation, meters, valves,

vaults, etc. All materials, work, etc. to comply with all requirements of all legally

constituted public authorities having jurisdiction including all county and state

ordinances. Furnish and install plumbing work complete and operable,

including trenching and backfilling. Verify all

material and installation requirements and limitations at fire and sound assemblies.

B. Provide rubberized asphaltic membrane materials at all penetrations of the water -

resistive membrane at exterior walls.

C. Protect pipes fromfreezing. Place all water lines and waste lines within conditioned

space and where approved thermal insulation is between line and unheated area.

2.Installation:

A. Roughing-in shall be completed, tested and inspected as required by code before closing

-in with other work.

B. Openings in pipes, drains, and fittings shall be kept covered during construction.

C. Provide solid backing for securing fixtures. All fixtures to be set level.

D. Provide cleanouts at ends of all lines and where required by codes.

E. Copper tubing shall be fully sweated to fittings.

F. Black iron and galvanized steel pipe joints shall be made with approved pipe thread

compound.

G. Provide shut- off valves at each fixture.

H. Provide condensate line at each F.A.U location. Provide primary & secondary condensate

line to an approved drainage receptacle at attic F.A.U locations. Install condensate line for

each piece of condensating HVAC equipment per manufactureres specifications.

I. Provide cold water line to refrigerator space in recessed box or in cabinet immediately

adjacent to refrigerator space.

J. Isolate all piping fromstructure with fiber padding and at all penetrations with elastic

caulking or sound isolators.

K. All vents to lead to outside air, where possible, locate all roof vents to rear side or ridges.

Vents to terminate a minimumof 3'-0 fromwindows.

L. All horizontal A.B.S. piping shall be hung with approved hangers at 4' -0 on center

minimumand spaced to permit expansion and contraction without hitting adjoining pipe.

Vertical piping shall be supported at 8'-0 on center with wrought steel U straps securely

fastened to building frame.

M. Provide air chambers at lavatory, dishwasher and clothes washer water connections. Set

vertically as close to fixture as possible.

N. Provide tee for irrigation at main shut-off.

O. Provide water heater with pressure/ temperature relief valve and pan and drain line piped

to the exterior of the buildings.

P. All combustion equipment shall be directly vented.

Q. No alterations to the structural frame, diaphragms, connections or shear panels shall be

made without prior written approval fromthe structural Engineer.

R. Provide non- removable backflow device on all exterior hose bibs.

S. A 12 minimumaccess panel to bathtub trap connection is required.

T. Provide pressure regulator for water service where pressure exceeds 80 psi

U. Provide drain pan under washer with drain in laundry roomand shut off valve if washer is

located above living space.

V. Provide solid metal pipe for dryer vent to exterior. Do not install screen on dryer vent.

Provide energy efficient dryer vent (with floating shuttle).

4

/8

/2

0

1

0

1

0

:4

7

:1

2

A

M

A-00-1

GENERAL NOTES

07-003

SEASIDE BARN

07 APRIL, 2010

MI

BU, SH

No. Description Date

SCALE

PROJECT NUMBER:

DATE:

DRAWN BY:

CHECKED BY:

PROJECT NAME:

348 MEDFORD ST. SUITE 1

CHARLESTOWN, MA 02129

COPYRIGHT BY FREEGREEN INC. ALL RIGHTS RESERVED.

www.FreeGreen.com

FREE GREEN

I. MAX POINTS AVAILABLE: (P = PREREQUISITE)

II. ESTIMATED POINTS ELIGIBLE BY THIS DESIGN:

III. CREDIT ATTEMPTED: (YES/NO)

IV. TOTAL:

I. II. III. IV.

LEED certification is based on 18 prerequisites and 67 credits. The prerequisites are basic performance standards: they

are mandatory for every project, and no points are awarded for meeting them. To achieve certification, builders earn credit

points by exceeding the minimumstandards of the prerequisites. In total, 136 credit points are available.

Prerequisites and points are classified in eight credit categories:

1. Innovation & Design (ID) Process.

Special design methods, unique regional credits, measures not currently addressed in the Rating System, and exemplary

performance levels.

2. Location & Linkages (LL).

The placement of homes in socially and environmentally responsible ways in relation to the larger community.

3. Sustainable Sites (SS).

The use of the entire property so as to minimize the project's impact on the site.

4. Water Efficiency (WE).

Water conservation practices, both indoor and outdoor.

5. Energy & Atmosphere (EA).

Energy efficiency, particularly in the building envelope and heating and cooling design.

6. Materials & Resources (MR).

Efficient utilization of materials, selection of environmentally preferable materials, and minimization of waste during

construction.

7. Indoor Environmental Quality (EQ).

Improvement of indoor air quality by reducing the creation of and exposure to pollutants.

8. Awareness & Education (AE).

The education of homeowner, tenant, or multifamily building manager about the operations and maintenance of the

green features of a LEED Home.

Required Points

Certified

Table 1

LEED for Homes Certification Levels

How to use the LEED for Homes Green Building Rating SystemChecklist:

If you plan to have your project LEED certified, this page will provide you with a

brief but clear outline of the program's mandatory and credit requirements.

Please visit www.usgbc.org/LEED/homes for complete participation

requirements, credit descriptions and to purchase the most current edition of

the LEED for Homes Reference Guide as show on the upper left hand corner

of this page.

If you choose not to have your project certified but would like to incorporate

green practices, products and materials, use this sheet as a guide to select

the green features you would like to include.

FreeGreen Inc. has made an effort to include many green building practices,

products and materials right into this free home plan set. If followed as

presented, this home design is already eligible for a variety of points under

LEED for Homes Green Building Rating System. This page also identifies

these achievable points for your convenience. SEE COLUMN "II."

What is the LEED for Homes Green Building Rating System?

LEED for Homes is a national, voluntary certification system, developed by

national experts and experienced builders, that promotes the design and

construction of high-performance green homes and encourages the adoption

of sustainable practices by the homebuilding industry.

The LEED for Homes Rating Systemis part of the suite of nationally

recognized LEED Green Building Rating Systems administered by USGBC.

Like all LEED Rating Systems, it is the market's leadership system, targeting

the top 25% of home building practices in terms of environmental responsibility.

LEED provides industry resources and tools on how to "green" any new home.

With LEED, homebuilders can differentiate their structures as meeting the

highest performance measures, and homebuyers can readily identify high-

quality green homes. LEED provides national consistency in defining the

features of a green home, enables builders anywhere in the country to obtain

a green rating on their homes, and assures homebuyers of the quality of their

purchases, all based on a recognized national brand.

INNOVATION AND DESIGN PROCESS (ID)

CREDIT CATEGORIES & CERTIFICATION LEVELS

ID 1: INTEGRATED PROJECT PLANNING

Intent. Maximize opportunities for integrated, cost-effective adoption of green design

and construction strategies.

1.1 Preliminary Rating

1.2 Integrated Project Team 1

ID 2: DURABILITY MANAGEMENT PROCESS

Intent. Promote durability and high performance of the building enclosure and its

components and systems through appropriate design, materials selection, and

construction practices.

2.1 Durability Planning

2.2 Durability Management

2.3 Third-Party Durability Management Verification 3

(P) (pg. 37)

(pg. 37)

(pg. 37)

(pg. 31)

(pg. 31)

I. II. III. IV.

I. II. III. IV. I. II. III. IV. I. II. III. IV.

ID 3: INNOVATIVE OR REGIONAL DESIGN

Intent. Minimize the environmental impact of the home by incorporating additional

green design and construction measures that have tangible and demonstrable

benefits beyond those in the LEED for Homes Rating System.

TOTAL ESTIMATED POINTS ELIGIBLE BY THIS DESIGN:

CERTIFICATION LEVELS

The LEED for Homes Rating Systemworks by requiring a minimumlevel of performance through prerequisites and

rewarding improved performance in each of the above categories. The level of performance is indicated by four performance

tiers. See (Table 1).

45-59

Silver 60-74

Gold 75-89

Platinum 90-136

Total available points 136

HOME SIZE ADJUSTMENT

The adjustments in (Table 2) below compensate for the overarching effects of home size on consumption by adjusting the

award level point thresholds based on home size. For further explanation see pages 8-11 in the LEED H Reference Guide.

Required Points

Certified

Table 2

Threshold Adjustment Certification Levels

Silver

Gold

Platinum

Total available points 136

HOWTO PARTICIPATE IN LEED FOR HOMES

There are five basic steps for a builder to follow in participating in LEED for Homes:

1. Contact a LEED for Homes Provider and register the project with USGBC.

2. Identify a project team

3. Build the home to the stated goals. Build onsite HERS and green rating tasks.

4. Achieve certification as a LEED home.

5. Post-certification and marketing support.

For full participation requirements or to purchase the LEED H Reference Guide, please visit www.usgbc.org/LEED/homes

(P)

1.3 Professional Credentialed with Respect to LEED for Homes 1 (pg. 31)

1.4 Design Charrette 1 (pg. 31)

1.5 Building Orientation for Solar Design 1 (pg. 31)

(P)

3.1 Innovation #1 (pg. 45) 1

3.2 Innovation #2 (pg. 45)

3.3 Innovation #3 (pg. 45)

3.4 Innovation #4 (pg. 45)

1

1

1

LOCATION AND LINKAGES (LL)

LL 1: LEED FOR NEIGHBORHOOD DEVELOPMENT

Intent. Minimize the environmental impact of land development practices by building

homes in LEED for Neighborhood Development certified developments.

1 LEED for Neighborhood Development (pg. 51) 10 (OR LL 2-6)

LL 2: SITE SELECTION

Intent. Avoid development on environmentally sensitive sites.

2 Site Selection (pg. 55) 2

LL 3: PREFERRED LOCATIONS

Intent. Encourage the building of LEED homes near or within existing communities.

3.1 Edge Development (pg. 59) 1

3.2 Infill (pg. 59) 2

3.3 Previously Developed (pg. 59) 1

(OR LL 3.1)

LL 4: INFRASTRUCTURE

Intent. Encourage the building of LEED homes in developments that are served

by or are near existing infrastructure (i.e., sewers and water supply).

4 Existing Infrastructure (pg. 65) 1

LL 5: COMMUNITY RESOURCES / TRANSIT

Intent. Encourage the building of LEED homes in development patterns that allow

for walking, biking, or public transit (thereby minimizing dependency on personal

automobiles and their associated environmental impacts.

5.1 Basic Community Resources / Transit (pg. 69) 1

5.2 Extensive Community Resources / Transit (pg. 69) 2

5.3 Outstanding Community Resources / Transit (pg. 69) 3

(OR LL 5.1, 5.3)

(OR LL 5.1, 5.2)

LL 6: ACCESS TO OPEN SPACE

Intent. Provide open space to encourage walking, physical activity, and time spent

outdoors.

6 Access to Open Space (pg. 75) 1

SUSTAINABLE SITES (SS)

SS 1: SITE STEWARDSHIP

Intent. Minimize the environmental damage to the building lot during the construction

process.

1.1 Erosion Controls During Construction (pg. 81) (P)

1.2 Minimize Disturbed Area of Site (pg. 81) 1

SS 2: LANDSCAPING

Intent. Design landscape features to avoid invasive species and minimize demand for

water and synthetic chemicals.

2.1 No Invasive Plants (pg. 89) (P)

2.2 Basic Landscape Design (pg. 89) 2

2.3 Limit Conventional Turf (pg. 89) 3

2.4 Drought-Tolerant Plants (pg. 89) 2

2.5 Reduce Overall Irrigation Demand by at Least 20% (pg. 90) 6

(OR SS 2.5)

(OR SS 2.5)

(OR SS 2.5)

SS 3: LOCAL HEAT ISLAND EFFECTS

Intent. Design landscape features to reduce local heat island effects.

3 Reduce Local Heat Island Effects (pg. 111) 1

SS 4: SURFACE WATER MANAGEMENT

Intent. Design site features to minimize erosion and runoff fromthe home site.

4.1 Permeable Lot (pg. 115) 4

4.2 Permanent Erosion Controls (pg. 115) 1

4.3 Management of Runoff fromRoof (pg. 115) 2

SS 5: NONTOXIC PEST CONTROL

Intent. Design home features to minimize the need for poisons for control of

insects, rodents, and other pests.

5 Pest Control Alternatives (pg. 125) 2

SS 6: COMPACT DEVELOPMENT

Intent. Make use of compact development patterns to conserve land and promote

community livability, transportation efficiency, and walkability.

6.1 Moderate Density (pg. 129) 2

6.2 High Density (pg. 129) 3

6.3 Very High Density (pg. 129) 4

(OR SS 6.1, 6.3)

(OR SS 6.1, 6.2)

WATER EFFICIENCY (WE)

WE 1: WATER REUSE

Intent. Use municipal recycled water or offset central water supply through the

capture and controlled reuse of rainwater and/or graywater.

1.1 Rainwater Harvesting System (pg. 135) 4

1.2 Graywater Reuse System (pg. 135) 1

1.3 Use of Municipal Recycled Water System (pg. 135) 3

(OR WE 1.3)

(OR WE 1.3)

WE 2: IRRIGATION SYSTEM

Intent. Minimize outdoor demand for water through water-efficient irrigation.

2.1 High-Efficiency Irrigation System (pg. 145) 3

2.2 Third-Party Inspection (pg. 146) 1

2.3 Reduce Overall Irrigation Demand by at Least 45% (pg. 146) 4

(OR WE 2.3)

(OR WE 2.3)

WE 3: INDOOR WATER USE

Intent. Minimize outdoor demand for water through water-efficient irrigation.

3.1 High-Efficiency Fixtures and Fittings (pg. 159) 3

(pg. 159) 6 3.2 Very High-Efficiency Fixtures and Fittings

ENERGY & ATMOSPHERE (EA)

EA 1: OPTIMIZE ENERGY PERFORMANCE

Intent. Improve the overall energy performance of a home by meeting or exceeding

the performance of an ENERGY STAR labeled home.

1.1 Performance of ENERGY STAR for Homes (pg. 169) (P)

1.2 Exceptional Energy Performance (pg. 169) 34

EA 2: INSULATION

Intent. Design and install insulation to minimize heat transfer and thermal bridging.

2.1 Basic Insulation (pg. 179) (P)

2.2 Enhanced Insulation (pg. 179) 2

(OR EA 2-11)

(OR EA 2-11)

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2)

EA 3: AIR INFILTRATION

Intent. Minimize energy consumption caused by uncontrolled air leakage into and

out of conditioned spaces.

3.1 Reduced Envelope Leakage (pg. 185) (P)

3.2 Greatly Reduced Envelope Leakage (pg. 185) 2

3.3 Minimal Envelope Leakage (pg. 185) 3

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2)

EA 4: WINDOWS

Intent. Maximize the energy performance of windows.

4.1 Good Windows (pg. 189) (P)

4.2 Enhanced Windows (pg. 189) 2

4.3 Exceptional Windows (pg. 189) 3

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2) (OR EA 4.2)

(OR EA 3.2)

EA 5: HEATING AND COOLING DISTRIBUTION SYSTEM

Intent. Minimize energy consumption due to thermal bridges and/or leaks in the

heating and cooling distribution system.

5.1 Reduced Distribution Losses (pg. 195) (P)

(pg. 195) 2

(pg. 195) 3

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2) (OR EA 5.2)

5.2 Greatly Reduced Distribution Losses

5.3 Minimal Distribution Losses

EA 6: SPACE HEATING AND COOLING EQUIPMENT

Intent. Reduce energy consumption associated with the heating and cooling system.

6.1 Good HVAC Design and Installation (pg. 201) (P)

2

4

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2) (OR EA 6.2)

6.2 High-Efficiency HVAC

6.3 Very High-Efficiency HVAC

(pg. 201)

(pg. 201)

EA 7: WATER HEATING

Intent. Reduce energy consumption associated with the domestic hot water system,

including improving the efficiency of both the hot water systemdesign and the layout

of the fixtures in the home.

7.1 Efficient Hot Water Distribution (pg. 207)

1

3

2

7.2 Pipe Insulation (pg. 208)

7.3 Efficient Domestic Hot Water (DHW) Equipment (pg. 208) (OR EA 1, 7.1, 7.2)

EA 8: LIGHTING

Intent. Reduce energy consumption associated with interior and exterior lighting.

8.1 ENERGY STAR Lights (pg. 213) (P)

1.5

3

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2) (OR EA 8.2)

(pg. 213)

(pg. 213)

8.2 Improved Lighting

8.3 Advanced Lighting Package

EA 9: APPLIANCES

Intent. Reduce appliance energy consumption.

9.1 High-Efficiency Appliances (pg. 217)

1

(OR EA 1, 7.1, 7.2)

(OR EA 1, 7.1, 7.2) (pg. 217) 9.2 Water-Efficient Cloths Washer

2

EA 10: RENEWABLE ENERGY

Intent. Reduce consumption of nonrenewable energy sources by encouraging the

installation and operation of renewable electric generation systems.

10 (OR EA 1, 7.1, 7.2) (pg. 221) 10 Renewable Energy System

EA 11: RESIDENTIAL REFRIGERANT MANAGEMENT

Intent. Select and test air-conditioning refrigerant to ensure performance and

minimumcontributions to ozone depletion and global warming.

(pg. 227) 11.1 Refrigerant Charge Test (P)

(pg. 227) 11.2 Appropriate HVAC Refrigerants 1

MATERIAL & RESOURCES (MR)

MR 1: MATERIAL-EFFICIENT FRAMING

Intent. Optimize the use of framing materials.

1.1 Framing Order Waste Factor Limit (pg. 235) (P)

1.2 Detailed Framing Documents (pg. 235) 1

1.3 Detailed Cut List and Lumber Order (pg. 235) 1

1.4 Framing Efficiencies (pg. 235) 3

1.5 Off-Site Fabrication (pg. 235) 4

(OR MR 1.5)

(OR MR 1.5)

(OR MR 1.5)

MR 2: ENVIRONMENTALLY PREFERABLE PRODUCTS

Intent. Increased demand for environmentally preferable products and products or

building components that are extracted, processed, and manufactured within the

region.

2.1 FSC-Certified Tropical Wood

2.2 Environmentally Preferable Products 8

(P) (pg. 247)

(pg. 247)

MR 3: WASTE MANAGEMENT

Intent. Reduce waste generated to a level below the industry norm.

3.1 Construction Waste Management Planning

3.2 Construction Waste Reduction 3

(P) (pg. 261)

(pg. 261)

INDOOR ENVIRONMENTAL QUALITY (EQ)

IQ 1: ENERGY STAR WITH INDOOR AIR PACKAGE

Intent. Improve the overall quality of a home's indoor environment by installing an

approved bundle of air quality measures.

1.1 ENERGY STAR with Indoor Air Package 13 (pg. 273) (OR IQ 2-10)

IQ 2: COMBUSTION VENTING

Intent. Minimize the leakage of combustion gases into the occupied space of the

home.

2.1 Basic Combustion Venting Measures (pg. 277) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2) (P)

2.2 Enhanced Combustion Venting Measures (pg. 277) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2) 2

IQ 3: MOISTURE CONTROL

Intent. Control indoor moisture levels to provide comfort, reduce the risk of mold, and

increase the durability of the home.

3.1 Moisture Load Control (pg. 285) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2) 1

IQ 4: OUTDOOR AIR VENTILATION

Intent. Reduce occupant exposure to indoor pollutants by ventilating with outdoor air.

4.1 Basic Outdoor Air Ventilation (pg. 289) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2) (P)

(pg. 289) 2 4.2 Enhanced Outdoor Air Ventilation

(pg. 289) 1 4.3 Third-Party Performance Testing (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2)

IQ 5: LOCAL EXHAUST

Intent. Reduce moisture and exposure to indoor pollutants in kitchen and bathrooms.

5.1 Basic Local Exhaust (pg. 299) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2) (P)

(pg. 299) 1 5.2 Enhanced Local Exhaust

(pg. 299) 1 5.3 Third-Party Performance Testing

IQ 6: DISTRIBUTION OF SPACE HEATING AND COOLING

Intent. Provide appropriate distribution of space heating and cooling in the home to

improve thermal comfort and energy performance.

6.1 Roomby RoomLoad Calculations (pg. 305) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2)

(pg. 305) 1 6.2 Return Air Flow or Roomby RoomControls

(pg. 305) 2 6.3 Third-Party Performance Testing

(P)

(OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2)

(OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2)

IQ 7: AIR FILTERING

Intent. Reduce particulate matter fromthe air supply system.

7.1 Good Filters (pg. 311) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2)

(pg. 311) 1 7.2 Better Filters

(pg. 311) 2 7.3 Best Filters

(P)

(OR IQ 7.2)

IQ 8: CONTAMINANT CONTROL

Intent. Reduce occupants' and construction workers' exposure to indoor airborne

contaminant through source control and removal.

8.1 Indoor Contaminant Control during Const. (pg. 315) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2)

(pg. 315) 2 8.2 Indoor Contaminant Control

(pg. 315) 1 8.3 Preoccupancy Flush (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2)

1

IQ 9: RADON PROTECTION

Intent. Reduce occupant exposure to radon gas and other soil gas contaminants.

9.1 Radon-Resistant Const. in High Risk Areas (pg. 323) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2)

(pg. 323)

(P)

9.2 Radon-Resistant Const. in Mod. Risk Areas (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2) 1

IQ 10: GARAGE POLLUTANT PROTECTION

Intent. Reduce occupant exposure to indoor pollutants originating froman adjacent

garage.

10.1 No HVAC in Garage (pg. 327) (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2)

(pg. 327)

(P)

10.2 Minimize Pollutants fromGarage (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2) 2

(pg. 327) 10.3 Exhaust Fan in Garage (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2) 1

(pg. 327) 10.4 Detached or No Garage (OR IQ 1, 4.2, 5.2, 5.3, 7.2/7.3, 8.2) 3 (OR IQ 10.2, 10.3)

AWARENESS & EDUCATION (AE)

AE 1: EDUCATION OF HOMEOWNER OR TENANT

Intent. Maintain the performance of the home by educating the occupants (i.e., the

homeowner or tenant) about the operations and maintenance of the home's LEED

features and equipment.

1.1 Basic Operations Training (pg. 335) (P)

1.1 Enhanced Training (pg. 336) 1

AE 2: EDUCATION OF BUILDING MANAGER

Intent. Maintain the performance of the home by educating the building manager

about the operations and maintenance of the home's LEED features and equipment.

2 Education of Building Manager (pg. 339) 1

4

/8

/2

0

1

0

1

0

:4

7

:1

4

A

M

A-00-2

LEED-H RATING

SYSTEM CHECKLIST

07-003

SEASIDE BARN

07 APRIL, 2010

MI

BU, SH

45-59

60-74

75-89

90-136

(P)

1

1

1

3

(P)

(P)

2

2

2

1

3

(P)

1

(P)

2

(P)

1

(P)

1

(P)

(P)

3

25.5

(P)

1.5

SCALE

PROJECT NUMBER:

DATE:

DRAWN BY:

CHECKED BY:

PROJECT NAME:

348 MEDFORD ST. SUITE 1

CHARLESTOWN, MA 02129

COPYRIGHT BY FREEGREEN INC. ALL RIGHTS RESERVED.

www.FreeGreen.com

FREE GREEN

I. MAX POINTS AVAILABLE: (M = MANDATORY REQUIREMENT PRESENT)

II. ESTIMATED POINTS ELIGIBLE BY THIS DESIGN:

III. CREDIT ATTEMPTED: (YES/NO)

IV. TOTAL:

I. II. III. IV.

301 - GENERAL

301.1 Environmental performance levels. The building, project, site, and or development's environmental performance

level shall consist of all mandatory requirements, plus points assessed using the point systemspecified within this Chapter.

The level of performance shall be in accordance with Table 302, 303 or 305.5 as acceptable.

301.2 Awarding of points. Points shall be awarded as follows:

(1) The maximumnumber of points that can be awarded for each practice is noted with that practice.

(2) Points allocation for multi-unit buildings shall be as prescribed in section 304.

(3) The Adopting Entity shall allow new products and practices to be added where deemed to meet the intent of this

Standard. Points assigned for any new product or practice shall be determined by the Adopting Entity.

302 - GREEN SUBDIVISIONS

302.1 Site design and development. The threshold points required for the environmental performance levels to qualify a new

or existing subdivision as green under this Standard shall be in accordance with Table 302 and based on points in Chapter 4.

Green Subdivision Category

Performance Level Points

One

Star

Two

Stars

Three

Stars

Four

Stars

400 Site Design and Development

Table 302

Threshold Point Ratings for Site Design and Development

79 104 134 175

Green Building Category

Performance Level Points (1) (2)

Bronze Silver Gold Emerald

Lot Design, Preparation, and

Development

Table 303

Threshold Point Ratings for Green Buildings

39 66 93 119 500

Resource Efficiency 45 79 113 146 600

Energy Efficiency 30 60 100 120 700

Water Efficiency 14 26 41 60 800

Indoor Environmental Quality 36 65 100 140 900

Operation, Maintenance and

Building Owner Education

8 10 11 12 1000

Additional Points fromany

category

50 100 100 100

Total Points: 222 406 558 697

303 - GREEN BUILDINGS

303.1 Green buildings. The threshold points required for the environmental performance levels for a green building shall be

in accordance with Table 303. To qualify for one of these performance levels, all of the following shall be satisfied:

(1) The threshold number of points, in accordance with Table 303, shall be achieved as prescribed in Categories 1 through 6.

The lowest level achieved in any category shall determine the overall performance level achieved for the building.

(2) In addition to the threshold number of points in each category, all mandatory provisions of each category shall be

implemented.

(3) In addition to Section 701, either Section 702 (Performance Path) or Section 703 (Prescriptive Path) shall be used to

establish the threshold performance level under Category 3 (Energy Efficiency).

(4) In addition to the threshold number of points prescribed in Categories 1 through 6, the additional points prescribed in

Category 7 shall be achieved fromany of the categories. Where deemed appropriate by the Adopting Entity, additional

points from Category 7 may be assigned to another category (or categories) to increase the threshold points required for that

category (or categories). Points shall not be reduced by the Adopting Entity in any of six other categories.

1

2

3

4

5

6

How to use the NAHB National Green Building Standard Checklist:

If you plan to have your project certified by the NAHB National Green Building

Standard, this page will provide you with a brief but clear outline of the

program's mandatory and credit requirements. Additional clarifying text can

be found in the full National Green Building Standard. This checklist is a

worksheet only and is not a substitute for online scoring at

NAHBGreen.org which. Scoring through NAHBGreen.org is required for

home certification in the NAHBGreen program.

To purchase the National Green Building Standard or for more information

visit www.BuilderBooks.com.

If you choose not to have your project certified but would like to incorporate

green practices, products and materials, use this sheet as a guide to select

the green features you would like to include.

FreeGreen Inc. has made an effort to include many green building practices,

products and materials right into this free home plan set. If followed as

presented, this home design is already eligible for a variety of points under

NAHB National Green Building Standard Rating System. This page also

identifies these achievable points for your convenience.

SEE COLUMN "II."

What is the NAHB National Green Building Standard?

In 2007 the National Association of Home Builders (NAHB) and the

International Code Council (ICC) partnered to formto establish a much-

needed and nationally-recognizable standard definition of what is meant by

"Green Building."

A consensus committee was formed to develop this standard in compliance

with the requirements of the American National Standards Institute (ANSI).

The resulting ANSI approved ICC-700-2008 National Green Building

Standard defines green building for single and multifamily homes, residential

remodeling projects and site development projects while still allowing for the

flexibility required for regionally-appropriate best green practices.

Similar to the NAHB Model Green Homebuilding Guidelines, a builder,

remodeler or developer must incorporate a minimumnumber of features

in the following areas: energy, water, and resource efficiency, lot and site

development, indoor environmental quality, and home owner education.

The more points accrued, the higher the score.

The Standard, however, includes more mandatory items and suggests

that higher thresholds be met in several categories. A new threshold -

"Emerald" - was added to denote the highest achievement in residential

green construction.

902.0 Intent. Pollutants generated in the building are controlled

902.1 Spot ventilation. (pg. 75) 31 (M)

902.2 Building ventilation systems. (pg. 76) 28

902.3 Radon control. (pg. 77) 15 (M)

902.4 HVAC systemprotection. (pg. 77) 3

902.5 Central vacuumsystem. (pg. 77) 5

902.6 Living space contaminants. (pg. 78) 8

903 MOISTURE MANAGEMENT: VAPOR, RAINWATER, PLUMBING, HVAC

903.0 Intent. Moisture and moisture effects are controlled

903.1 Tile backing materials. (pg. 78) (M)

903.2 Capillary breaks. (pg. 78) (M) 3

903.3 Crawlspaces. (pg. 79) (M) 16

903.4 Moisture control measures. (pg. 79) (M) 10

903.5 Plumbing. (pg. 80) 9

903.6 Duct insulation. (pg. 81) 2 (M)

903.7 Relative humidity. (pg. 81) 8

904 INNOVATIVE PRACTICES

904.1 Humidity monitoring system. (pg. 81) 2

904.2 Kitchen exhaust. (pg. 81) 2

1000 OPERATION, MAINTENANCE, & BLDG OWNER EDUCATION

1001 BUILDING OWNERS' MANUAL FOR ONE AND TWO-FAMILY DWELLINGS

1001.0 Intent. Information on the building's use, maintenance, and green

components is provided.

1001.1 Building owner's manual. (pg. 83) (M) 10

1002 TRAINING OF BUILDING OWNERS ON OPERATION & MAINTENANCE FOR

ONE & TWO-FAMILY DWELLINGS AND MULIT-UNIT BUILDINGS

1002.1 Training of building owners. (pg. 84) 6

1003 CONSTRUCTION, OPERATION, & MAINTENANCE MANUALS & TRAINING

FOR MULTI-UNIT BUILDINGS

1003.0 Intent. Manuals are provided to the responsible parties (owner, management,

tenant, and/or maintenance team) regarding the construction, operation, and

maintenance of the building...

1003.1 Building construction manual. (pg. 85) (M) 4

1003.2 Operations manual. (pg. 85) (M) 5

1003.3 Maintenance manual. (pg. 86) (M) 4.5

400 SITE DESIGN AND DEVELOPMENT

400.0 Intent. This section applies to land development for the eventual construction of

buildings or additions thereto that contain dwelling units. The rating earned under

Section 303 based on practices herein, applies only to the site as defined in Chapter 2.

The buildings on the site earn their own performance level by complying with the

provisions of Section 303, 304, or 305.5, as applicable.

300 COMPLIANCE METHOD

401 SITE SELECTION

401.0 Intent. The site is selected to minimize environmental impact by one or

more of the following:

401.1 Infill Site.

401.2 Greyfield/brownfield site.

4

5

402 PROJECT TEAM, MISSION STATEMENT, AND GOALS

402.0 Intent. The site is designed and constructed by a teamof qualified

professionals trained in green development issues.

402.1 Team.

402.2 Training.

4

3

402.3 Project checklist. 3 (M)

(pg. 15)

(pg. 15)

(pg. 15)

(pg. 15)

(pg. 15)

I. II. III. IV.

I. II. III. IV. I. II. III. IV. I. II. III. IV.

403 SITE DESIGN

403.0 Intent. The project is designed to avoid detrimental environmental impacts,

minimize any unavoidable impacts, and mitigate for those impacts that do occure.

The project is designed to minimize environmental impacts and to protect, restore,

and enhance the natural features and environmental quality of the site.

403.1 Natural resources.

403.2 Building orientation.

403.3 Slope disturbance.

403.4 Soil disturbance and erosion.

403.5 Stormwater management.

403.6 Landscape plan.

403.7 Wildlife habitat.

403.8 Operations and maintenance plan.

403.9 Existing buildings.

403.10 Existing and recycled materials.

403.11 Environmentally sensitive areas.

403.12 Density.

403.13 Mixed-use development.

(pg. 16)

(pg. 16)

(pg. 16)

(pg. 16)

(pg. 16)

(pg. 17)

(pg. 17)

(pg. 18)

(pg. 18)

(pg. 18)

(pg. 18)

(pg. 18)

(pg. 18)

(Points awarded only if there are developable steep slopes in the project area)

404 SITE DEVELOPMENT AND CONSTRUCTION

404.0 Intent. Environmental impact during construction is avoided to the extent

possible; impacts that do occure are minimized, and any significant impacts are

mitigated.

404.1 On-site supervision and coordination. (pg. 18)

404.2 Trees and vegetation. (pg. 18)

404.3 Soil disturbance and erosion. (pg. 19)

404.4 Wildlife habitat. (pg. 19)

405 INNOVATIVE PRACTICES

405.0 Intent. Innovative site design, preparation, and development practices are

used to enhance environmental performance. Waivers or variances fromlocal

development regulations are obtained, and innovative zoning practices are used to

implement such practices, as applicable.

405.1 Driveways and parking areas. (pg. 19)

405.2 Street widths. (pg. 20)

405.3 Cluster development. (pg. 20)

405.4 Zoning. (pg. 20)

405.5 Wetlands. (pg. 20)

405.6 Mass transit. (pg. 20)

500 LOT DESIGN, PREPARATION, AND DEVELOPMENT

500.0 Intent. This section applies to lot development for the eventual construction of

residential buildings, multi-unit buildings, or additions thereto that contain dwelling units.

The buildings on the lot earn their own performance level by complying with the

provisions of Section 303, 304, or 305.5, as applicable.

501.1 Lot. (pg. 21)

501.2 Mass Transportation. (pg. 21)

501 LOT SELECTION

18

6

28

12

21

54

5

5

6

1

6

10

6

4

12

31

19

5

6

10

18

7

6

9

9

502 PROJECT TEAM, MISSION STATEMENT, AND GOALS

502.1 Project team, mission statement, and goals. (pg. 21) 4

503 LOT DESIGN

503.0 Intent. The lot is designed to avoid detrimental environmental impacts first,

minimize any unavoidable impacts, and mitigate for those impacts that do occure.

The project is designed to minimize environmental impacts and to protect, restore,

and enhance the natural features and environmental quality of the lot.

503.1 Natural resources. (pg. 22) 24

503.2 Slope disturbance. (pg. 22) 24

503.3 Soil disturbance and erosion. (pg. 23)

503.4 Stormwater management. (pg. 23) 20

503.5 Landscape plan. (pg. 23) 34

503.6 Wildlife habitat. (pg. 24) 4

503.7 Mixed-use development. (pg. 24) 6

503.8 Environmentally sensitive areas. (pg. 24) 6

503.9 Density. (pg. 24) 10

(Points awarded only if there are developable steep slopes in the project area)

15

504 LOT CONSTRUCTION

504.0 Intent. Environmental impact during construction is avoided to the extent

possible; impacts that do occure are minimized, and any significant impacts are

mitigated.

504.1 On-site supervision and coordination. (pg. 25) 4

504.2 Trees and vegetation. (pg. 25) 11

504.3 Soil disturbance and erosion. (pg. 25) 34

505 INNOVATIVE PRACTICES

505.0 Intent. Innovative lot design, preparation and development practices are

used to enhance environmental performance. Waivers of variances fromlocal

development regulations are obtained, and innovative zoning practices are used to

implement such practices.

505.1 Driveways and parking areas. (pg. 26) 4

505.2 Heat island mitigation. (pg. 26) 4

600 RESOURCE EFFICIENCY

601 QUALITY OF CONSTRUCTION MATERIALS AND WASTE

601.0 Intent. Design and construction practices that minimize the environmental

impact of the building materials are incorporated, environmentally efficient building

systems and materials are incorporated, and waste generated during construction is

reduced.

601.1 Conditioned floor area. (pg. 27) 15

601.2 Material usage. (pg. 28) 9

601.3 Building dimensions and layouts. (pg. 28) 13

601.4 Framing and structural plans. (pg. 28) 4

601.5 Prefabricated components. (pg. 28) 38

601.6 Stacked stories. (pg. 28) 8

601.7 Site-applied finishing materials. (pg. 28) 12

601.8 Foundations. (pg. 29) 3

601.9 Above grade wall systems. (pg. 29) 4

602 ENHANCED DURABILITY AND REDUCED MAINTENANCE

602.0 Intent. Design and construction practices are implemented that enhance the

durability of materials and reduce in-service maintenance.

602.1 Exterior doors. (pg. 29) 5

602.2 Roof overhangs. (pg. 29) 4

602.3 Foundation drainage. (pg. 30) 4 (M)

602.4 Drip edge. (pg. 30) 3

602.5 Roof water discharge. (pg. 30) 4

602.6 Finished grade. (pg. 30)

602.7 Termite barrier. (pg. 30) 4

(M)

602.8 Termite-resistant materials. (pg. 31) 6

602.9 Water-resistive barrier. (pg. 31) (M)

602.10 Ice barrier. (pg. 31) (M)

602.11 Foundation waterproofing. (pg. 31) 4

602.12 Flashing. (pg. 31) 6

602.13 Roof surfaces. (pg. 32) 3

602.14 Recycling. (pg. 32) 6

603 REUSED OR SALVAGED MATERIALS

603.0 Intent. Practices that reuse or modify existing structures, salvages materials

for other uses, or use salvaged materials in the building's construction are

implemented.

603.1 Reused of existing building. (pg. 32) 12

603.2 Salvaged materials. (pg. 32) 3

603.3 Scrap materials. (pg. 32) 4

604 RECYCLED-CONTENT BUILDING MATERIALS

604.1 Recycled content. (pg. 32) 9

605 RECYCLED CONSTRUCTION WASTE

605.0 Intent. Waste generated during construction is recycled. All waste classified

as hazardous shall be properly handled and disposed.

605.1 Construction waste management plan. (pg. 33) 6

605.2 On-site recycling. (pg. 33) 7

605.1 Recycled construction materials. (pg. 33) 6

606 RENEWABLE MATERIALS

606.0 Intent. Building materials derived fromrenewable resources are used.

606.1 Biobased products. (pg. 33) 8

606.2 Wood-based products. (pg. 34) 7

606.3 Manufacturing energy. (pg. 34) 6

607 RESOURCE-EFFICIENT MATERIALS

607.1 Resource-efficient materials. (pg. 34) 9

608 INDIGENOUS MATERIALS

608.1 Indigenous materials. (pg. 34) 10

609 LIFE CYCLE ANALYSIS

609.1 Life cycle analysis. (pg. 35) 15

610 INNOVATIVE PRACTICES

610.1 Manufacturer's environmental management systemconcepts. (pg. 35) 10

700 ENERGY EFFICIENCY

701 MINIMUM ENERGY EFFICIENCY REQUIREMENTS

701.1 Mandatory requirements. (pg. 39)

701.1.1 Minimum Performance Path requirements. (pg. 39)

701.1.2 MinimumPrescriptive Path requirements. (pg. 39)

701.1.3 Alternative bronze level compliance. (pg. 39)

701.2 Emerald level points. (pg. 39)

701.1.3 Adopting Entity review. (pg. 39)

701.4 Mandatory practices. (pg. 40)

701.4.1 HVAC systems. (pg. 40) (M)

701.4.2 Duct systems. (pg. 40) (M)

701.4.3 Insulation and air sealing. (pg. 41) (M)

701.4.4 Fenestration. (pg. 43) (M)

702 PERFORMANCE PATH

702.1 Point allocation. (pg. 43) (M)

702.2 Energy cost performance level. (pg. 43) 120

703 PRESCRIPTIVE PATH

703.1 Building envelope. (pg. 44)

703.2 Insulation and air sealing. (pg. 46) 15

703.3 Fenestration. (pg. 48) 12

703.4 HVAC equipment efficiency. (pg. 49)

703.5 Water heating design, equipment, and installation. (pg. 52)

704 ADDITIONAL PRACTICES

704.1 Application of additional practice points. Points fromSection 704 can be

added to points earned in Section 702 (Performance Path), Section 703 (Prescriptive

Path), or Section 701.1.3 (alternative bronze level compliance).

(Max points vary)

(Max points vary)

704.2 Lighting and appliances. (pg. 54)

704.3 Renewable energy and solar heating and cooling. (pg. 56)

704.4 Ducts. (pg. 59)

704.5 HVAC design and installation. (pg. 60)

704.6 Installation and performance verification. (pg. 60)

705 INNOVATIVE PRACTICES

705.1 Energy consumption control. (pg. 62)

705.2 Renewable energy service plan. (pg. 62)

800 WATER EFFICIENCY

801 INDOOR AND OUTDOOR WATER USE

801.0 Intent. Measures that reduce indoor and outdoor water usage are

implemented.

801.1 Indoor hot water usage. (pg. 63)

801.2 Water-conserving appliance. (pg. 64)

801.3 Food waste disposers. (pg. 64)

801.4 Showerheads. (pg. 65)

801.5 Faucets. (pg. 65)

801.6 Water closets and urinals. (pg. 66)

801.7 Irrigation systems. (pg. 66)

801.8 Rainwater collection and distribution. (pg. 67)

801.9 Water filters. (pg. 67)

802 INNOVATIVE PRACTICES

802.1 Gray water. (pg. 68)

802.2 Composting or waterless toilets and/or urinals. (pg. 68)

802.3 Automatic shutoff water devices. (pg. 68)

900 INDOOR ENVIRONMENTAL QUALITY

901 POLLUTANT SOURCE CONTROL

901.0 Intent. Pollutant sources are controlled.

901.1 Space and water heating options. (pg. 69)

901.2 Fireplaces and fuel-buring appliances. (pg. 70)

901.3 Garages. (pg. 71)

901.4 Wood materials. (pg. 71)

901.5 Carpets. (pg. 72)

901.6 Hard-surface flooring. (pg. 72)

901.7 Wall coverings. (pg. 72)

901.8 Architectural coatings. (pg. 73)

901.9 Adhesives and sealants. (pg. 73)

901.10 Cabinets. (pg. 74)

901.11 Insulation. (pg. 74)

901.12 Carbon monoxide (CO) alarms. (pg. 74)

901.13 Building entrance pollutants control. (pg. 75)

901.14 Non-smoking areas. (pg. 75)

902 POLLUTANT CONTROL

29

(Max points vary)

52

9

43

7

7

14

1

5

8

28

19

8

1

(M)

(Max points vary)

24 (M)

2

25

(M)

(M)

7

10

10 (M)

10 (M)

6

4

13

10

5

5

3

1

1

TOTAL ESTIMATED POINTS ELIGIBLE BY THIS DESIGN:

NOTE: Points available for renovations and

additions as specified in the NAHB Green Building

Standard are not listed on this sheet. For a

description of points available for renovations and

additions as specified in the NAHB Green Building

Standard please purchace the full standard at

www.BuilderBooks.com.

(Max points vary)

(1) In addition to the threshold number

of points in each category, all mandatory

provisions of each category shall be

implemented.

(2) For dwelling units greater than 4,000

square feet (372 square meter), the

number of points in Category 7

(Additional Points fromany category)

shall be increased in accordance with

Section 601.1. The "Total Points" shall

be increased by the same number of

points.

304 - GREEN BUILDINGS

304.1 Green Multi-Unit Buildings. For multi-unit buildings, points for the green building practices that apply to multiple units

shall be credited once for the entire building. Where points are credited, practices shall be implemented in all units, as

applicable. Where apllication of a prescribed practice allows for a different nuber of points for different units in a multi-unit

building, the fewer number of points shall be awarded.

(Max points vary)

4

/8

/2

0

1

0

1

0

:4

7

:1

5

A

M

A-00-3

NAHB GREEN

BUILDING STANDARD

07-003

SEASIDE BARN

07 APRIL, 2010

MI

BU, SH

6

2

7

M

3

4

M

M

4

6

3

M

M

M

M

3

6

1

10

7

10

3

12

15

M

3

2

107

GROUND SLOPES AWAY FROM

WALL @5%OR 6" PER 10'

1

ROOF CONSTRUCTION: (TOP DOWN)

- STANDING SEAMMETAL ROOFING PANELS

- ROSIN PAPER SLIP SURFACE

- FULLY-ADHERED MEMBRANE WATERPROOFING

- 5/8" SHEATHING

- 2x10 RAFTERS W/ SPRAY FOAM INSULATION (UNVENTED)

- 1/2" GYPSUM BOARD (REQ FOR THERMAL BARRIER)

STANDING SEAM METAL ROOFING

EXT WALL CONSTRUCTION: (OUTSIDE to IN)

- CLEAR CEDAR SHINGLES

- CORRUGATED SPACER MESH

- BUILDING PAPER OR HOUSE WRAP DRAINAGE PLANE

W/ MIN 6" OVERLAP AT HORZ JOINTS

- 1/2" SHEATHING

- 2x6 STUD WALL W/ SPRAY FOAMINSULATION

- 1/2" GYPSUM BOARD W/ VAPOR

SEMI-PERMIABLE LATEX PAINT

CEDAR SHINGLE SIDING

1

3

12

3

12

T.O. FOOTING EL: (-) 5'-0" (OR AS REQ)

T.O. FOUNDATION WALL EL: (-) 1'-3"

T.O. ENTRY LEVEL SUB FLR EL: 0'-0"

B.O. FLOOR FRAMING EL: 9'-1"

T.O. UPPER LEVEL SUB FLR EL: 10'-1"

T.O. GABLE WALL PANEL EL: 17'-2"

B.O. CEILING JOISTS / RAFTER TIES EL: 18'-2"

T.O. RIDGE RAFTER EL: +/- 24'-5 1/8"

+

/-

2

4

' -

5

1

/8

"

V

.I.F

.

8

' -

1

"

1

0

' -

1

"

(

-

)

5

' -

0

"

1

' -

3

"

9

' -

1

"

1

' -

0

"

1

' -

0

"

7

' -

1

"

+

/-

6

' -

3

1

/8

"

V

.I.F

.

GROUND SLOPES AWAY FROM

WALL @5%OR 6" PER 10'

3

12

3

12

3

12

3

12

1 1 1

4 4

1

EGRESS EGRESS

MASONRY CHIMNEY

DECK RAILS @36" MIN

ABOVE DECK SURFACE

2

B

.O

. W

IN

D

O

W

H

E

A

D

E

R

6

' -

0

"

1

A-04-1

2

A-04-3

3

A-04-1

4

A-04-2

3

A-04-2

2

A-04-4

1

A-04-4

4

A-04-4

1

T.O. FOOTING EL: (-) 5'-0" (OR AS REQ)

T.O. FOUNDATION WALL EL: (-) 1'-3"

T.O. ENTRY LEVEL SUB FLR EL: 0'-0"

B.O. FLOOR FRAMING EL: 9'-1"

T.O. UPPER LEVEL SUB FLR EL: 10'-1"

T.O. GABLE WALL PANEL EL: 17'-2"

B.O. CEILING JOISTS / RAFTER TIES EL: 18'-2"

T.O. RIDGE RAFTER EL: +/- 24'-5 1/8"

+

/-

2

4

' -

5

1

/8

"

V

.I.F

.

8

' -

1

"

1

0

' -

1

"

(

-

)

5

' -

0

"

1

' -

3

"

9

' -

1

"

1

' -

0

"

1

' -

0

"

7

' -

1

"

+

/-

6

' -

3

1

/8

"

V

.I.F

.

GROUND SLOPES AWAY FROM

WALL @5%OR 6" PER 10'

T.O. BEAM EL: 8'-4 1/8" ABOVE

T.O. ENTRY LEVEL SUB FLR

PT BEAM AS REQ W/ 1/2" CEDAR COVER BOARDS

6x6 POST ON GALV STEEL POST

ANCHOR TYPICAL TO EXTERIOR

12" DIA CONC SUPPORT

W/ FOOTING BELOW

FROST DEPTH TYP (OR AS REQ) 3

6

12

6

12

20

12

20

12

3

12

3

12

DECK CONSTRUCTION: (TOP DOWN)

TROPICAL HARDWOOD, PT WOOD OR COMPOSITE DECKING -

2x8 PT DECK JOISTS @16" O/C -

1

1 1

6 6

5

EGRESS

MASONRY CHIMNEY

DECK RAILS @36" MIN ABOVE DECK SURFACE

B

.O

. W

I N

D

O

W

H

E

A

D

E

R

7

' -

0

"

B

. O

. W

IN

D

O

W

H

E

A

D

E

R

7

' -

0

"

2

A-04-3

3

A-04-3

2

A-04-2

3

A-04-2

2

A-04-1

SCALE

PROJECT NUMBER:

DATE:

DRAWN BY:

CHECKED BY:

PROJECT NAME:

NOTES:

REVISION SCHEDULE:

348 MEDFORD ST. SUITE 1

CHARLESTOWN, MA 02129

COPYRIGHT BY FREEGREEN INC. ALL RIGHTS RESERVED.