Professional Documents

Culture Documents

Perkins 400-2300 Series

Uploaded by

ravikant87Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Perkins 400-2300 Series

Uploaded by

ravikant87Copyright:

Available Formats

P

u

b

l

i

c

a

t

i

o

n

N

o

.

1

7

1

5

/

0

6

/

0

3

P

r

i

n

t

e

d

i

n

E

n

g

l

a

n

d

P

e

r

k

i

n

s

E

n

g

i

n

e

s

C

o

m

p

a

n

y

L

i

m

i

t

e

d

2

0

0

3

@Perkins

2300 Series

The Start of A New Generation

Asia

Perkins Engines (Asia Pacific) Pte Ltd

14 Tractor Road

Singapore 627973

Telephone +65 6867 8450

Fax +65 6867 8451

Europe, Middle East and Africa

Perkins Engines Company Limited

Peterborough PE1 5NA

United Kingdom

Telephone +44 (0)1733 583000

Fax +44 (0)1733 582240

Latin America

Perkins Engines Latin America Inc

701 Waterford Way

Suite 200

Miami, FL 33126-4668, USA

Telephone +1 305 476 6900

Fax +1 305 476 6910

North America

Perkins Engines Inc

N4 AC 6160

PO Box 610

Mossville, IL 61552-0610, USA

1-888-PERK-ENG

Telephone +1 309 578 7364

Fax +1 309 578 7329

www.perkins.com

@Perkins

All information in this document is substantially correct at time of printing but may be altered

subsequently by the company

Ease of installation

In 160 countries, in thousands of applications, Perkins has become a world leader, having

established itself as a byword for todays off-highway diesel engines with its unique

combination of performance, reliability and value.

The requirements of the marketplace, legislators, customers and users have been

carefully researched to create a new engine family specifically for the Gen Set market -

the 2300 Series.

Offering a value solution with proven core components and a full ElectropaK specification,

the 14 litre 2300 Series combines cleanliness

with class-leading power density and a

low cost of ownership.

The use of full authority

electronic engine control and

a sophisticated

Mechanically actuated,

Electronically controlled

Unit Injector system

(MEUI) permits

extremely precise

control of fuel

injection timing and

duration. The

ensuing combustion

process is

complete, efficient

and clean, enabling

the 2300 Series to

comply with the

requirements of

1

/2 TA

Luft (1986), EPA Tier 2

and EU Stage 2

legislation, whilst still

producing exceptional power

output from a compact

package.

The engines environmental credentials are

further endorsed through the use of Perkins

new Ecoplus oil and fuel filtration system, which employs low

cost incinerable filter elements encased in re-useable canisters to cut operator disposal

costs and reduce the waste buried in our planet.

Clean, Ef

Clean, Ef

ficient,

ficient,

Powerful, V

Powerful, V

alue

alue

The introduction of 2300 Series

opens the way for new levels

of quality to be achieved.

Beginning with predictive

design techniques and

finite element

analysis, progressing

through extensive

development and

field trials in

customer

applications, the

2300 Series has

been created and

tested with

quality in mind.

This attention to

detail in the design

and manufacturing

stages pays dividends

when it comes to

operating the engine. High

performance, combined with

excellent fuel consumption, 500

hour oil change intervals, extended

maintenance periods, up to two years

warranty and a full suite of electronic service

and diagnostic tools sees the 2300 Series usher in a

truly New Generation of gen set power.

Intr

Intr

oducing the

oducing the

2300 Series

2300 Series

Perkins has been a major

contributor in the design

and manufacture of diesel

engines for off-highway

machinery for nearly 70

years.

Cost Of Ownership

Parts support

Ease of service

Improved economy

Durability

Overhaul

Reliability

Number of cylinders 6

Cylinder arrangement Vertical in-line

Bore/Stroke 137 x 165 mm

Displacement 14.6 litres

Cycle 4 stroke

Induction system Turbocharged and air-to-air charge cooled

Combustion system Direct injection

Compression ratio 15.9:1

Firing order 1-5-3-6-2-4

Rotation Anti-clockwise viewed on flywheel

Fuel system type Mechanically actuated electronically controlled

unit injectors

Cooling system Water cooled

ElectropaK dry weight 1690 kg

ElectropaK Length 2422 mm

Width 1107 mm

Height 1614 mm

" Electro unit and fan to flywheel

specifications are also available

" Guards for Electro unit

" Second electric starter

" Standard single electric starter deleted

" Immersion heater for engine block,

thermostatically controlled

(110V or 240V)

" Fuel cooler and connecting pipework

" Air cleaner rain hood

" Standard breather hose deleted

" Additional speed sensor

" Coolant temperature switch/sender

" Oil pressure switch/sender

" Hours counter

Engine Options

Fuel System Mechanically actuated electronically controlled unit fuel

injectors with full authority electronic control

Fuel cooler

Electrical Equipment 24 volt starter motor and 24 volt 70 amp alternator with

DC output

ECM mounted on engine with wiring looms and sensors giving 3 level

engine protection system

Governing Speed deviation and recovery times governed to ISO8528-5

class G3

Isochronous capability

Flywheel and Housing High inertia flywheel to SAE J620 size 14

SAE

1

/2 flywheel housing

Cooling System Gear-driven circulating pump

Mounted belt-driven fan

Radiator supplied loose incorporating air-to-air charge cooler

System designed for ambients up to 50C

Lubrication System Wet sump with filter and dipstick

Full-flow replacement Ecoplus filter element

Oil cooler integral with filter header

Air Inlet Mounted air filter

Mountings Front engine mounting bracket

Literature Users Handbook and Parts Manual

" Finish coat gloss paint

" Essential maintenance tool kit

" Additional parts book

" Additional users handbook

" Mechanical and Electronic installation

manual

" Diagnostic manual

" Workshop manual

" Mating interface connector to customer

interface harness

" Crimping tool for wiring the mating

interface connector

" Hand held fault code reader (J1939)

" Engine Service Tool communications

adaptor

Net Gross

kVA kWe kW bhp kW bhp

2306C-E14TAG1 1500 rpm Baseload 250 200 226 303 217 292

Prime 300 240 270 362 261 350

Standby 350 280 313 420 304 408

1800 rpm Baseload 281 225 262 351 245 328

Prime 344 275 316 424 299 401

Standby 379 303 346 464 329 442

2306C-E14TAG2 1500 rpm Baseload 275 220 248 333 239 321

Prime 350 280 313 420 304 408

Standby 400 320 353 473 344 461

1800 rpm Baseload 313 250 289 388 272 364

Prime 400 320 365 489 348 466

Standby 438 350 393 527 376 505

2306C-E14TAG3 1500 rpm Baseload 300 240 270 362 261 350

Prime 400 320 353 473 344 461

Standby 450 360 396 531 387 519

1800 rpm Baseload 344 275 316 424 299 401

Prime 438 350 393 527 376 504

Standby 500 400 447 599 430 577

Engine Data

Engine Data

Standar

Standar

d Electr

d Electr

opaK

opaK

Specifications

Specifications

Engine Engine Speed Duty Cycle

Engine Power Typical Gen set

Output

1

2

2

3

4

5

6

7

8

9

10

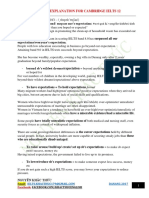

Design Featur

Design Featur

es

es

Exhaust Manifold (10)

The exhaust manifold utilises stainless steel thermal sleeves in the

exhaust ports. The sleeves are surrounded by an air gap which helps

to contain the heat in the exhaust gases until they reach the

turbocharger, reducing the amount of heat that is transferred to the

cooling system, adding to the thermal efficiency of the

turbocharger and reducing the cost of

the charge cooler.

Cylinder Head (1)

The single-piece cast iron head incorporates a

four valve per cylinder layout with a centrally

positioned unit injector; this provides

greater volumetric efficiency giving

improved power and reduced

emissions. The cylinder head

also incorporates a long

overlap camshaft, which

enables the engine to get

higher air throughput for

increased durability at

higher powers.

Composites (2)

Composite material has

been selected for the engine

top cover, sump and timing

gear cover. Contributing to

the reduction of noise

transmission through their

isolated mountings, these

components are also

responsible for reducing the

cost and weight of the

engine. The composite sump

also offers an increased

capacity to give longer oil life

and extend the time between

services to 500 hours.

Roller Rockers

(8)

Reduce wear on the

cam lobes and followers

giving increased

intervals between

adjustment and

reducing the overall

maintenance required

of the engine.

Mounted Air

System (7)

The mounted air cleaner has a

built in restriction indicator and

offers a fully matched cost effective

air filtration system that will protect the

engine across a wide variety of medium

and heavy duty applications.

Engine

Control

Module (6)

Controlling the unit injectors, the

full authority electronic control

system permits precise control

of the injection timing and

duration, to give complete,

clean and efficient combustion.

Piston(5)

Articulated pistons feature steel

crowns and aluminium skirts for

durability at high power outputs,

plus reduced friction and noise.

Sculpted Engine

Block (3)

The sculpted engine block with ladder

frame construction and internal galleries

adds to the structural integrity of the overall

engine assembly, reducing vibration and noise

transmission and reducing the potential for leaks from

oil, coolant or fuel systems.

Ecoplus

Filtration (4)

The Ecoplus fuel and oil filters feature re-useable

canisters with disposable high efficiency filter elements,

improving engine protection, contributing to extended oil

change intervals, reducing cost of ownership and

reduced environmental impact.

2

MEUI

(Mechanically actuated

Electronically controlled

Unit Injectors) (9)

Variable injection timing and duration giving

lower emission levels and fuel

consumption. High injection pressure for

better fuel atomisation, more complete

combustion and greater efficiency.

The elimination of high pressure

fuel lines, removes the potential

for leaks and reduces the

overall maintenance cost

of the engine.

New Spiral

roving

This unique

feature eliminates

pleat dancing or

flexing, resulting in

a dramatic

increase in

filtration efficiency,

helping to

maximise engine

life.

New moulded

end cap

Filter pleats are

actually moulded

into the caps

during

manufacture.

When hardened an

impenetrable bond

is formed, putting

an end to leaks!

Fuel Filtration

" Ease of maintenance

" Low cost of ownership

" 500 hour standard

service intervals

Ecoplus filters provide

" Engine protection -

further improved

filtration

" Ease of maintenance -

for ease of filtration and

removal

" Non-metallic materials -

making the elements

easier to process and

dispose of

Ecoplus is a high performance

solution that promotes better

engine protection and lower

running costs.

Secondary Fuel

Filter 2 microns

filtration

Coolant

temperature

sensor

Boost pressure

sensor

Inlet manifold air

temperature sensor

Electronic unit injector

harness connector

Engine Control

Module (ECM)

OEM interface

connector

Engine harness

connector

Oil pressure

sensor

Atmospheric pressure

sensor

Crankshaft

speed/timing

Fuel temperature

sensor

Camshaft

speed/timing

Inlet Air Manifold Temperature

Engine Hardware

Fuel Temperature

Coolant Temperature

OEM Interface Connectors

36-1 TOOTH

CRANK

GEAR

36+1 TOOTH

CAM GEAR

12PIN Connector

Internal Injector Harness

Main Engine Harness

Lub Oil Pressure

Sensor

Boost

Pressure Sensor

Crank Speed/Timing

Cam Speed/Timing

Atmospheric Pressure Sensor

Service

Tool

Connector

Machine

Interface

Connector

Calibration

Probe

Engine Control

Module

Ecoplus

Ecoplus

Engine Electr

Engine Electr

onics

onics

High Performance

Better Value

Ecoplus Features

Clean Change System Technology

Ecoplus exclusive design and construction provides an easy and cleaner solution for replacing filters. This unique

filtration gives a higher performance solution which promotes better engine protection and lower running costs.

Oil Filtration

Ecoplus oil flow is the reverse of conventional spin-on or element filters.

Dirt and abrasive particles are captured on the inside of the

element ensuring:

" Canister remains clean

" Replacement and disposal of used filters is

simple and hassle free

" Oil filtration to 35 microns

Ecoplus oil filtration system has a unique

canister and filter head design

incorporating:

" Drain plug - no spillage or mess

" Heavy duty construction - impact

resistant

" Square drive cast in - simple

canister removal

" Quick lock thread design -

ensures the canister cannot be

damaged or fitted incorrectly

during element change

" Option of oil sampling valve

Primary Fuel Filter 10

micron filtration. 98%

efficient in removing

emulsified water

New acrylic

beads

Eliminates pleat

bunching to

capture

contaminates. This

makes a significant

contribution to the

removal of more

debris, the

Ecoplus filters can

be up to 66%*

more effective at

removing debris.

New non-metallic

centre tube

30% stronger than

metal tubing used in

conventional filters.

The risk of metal

contaminates being

introduced during

the manufacturing

process is removed.

This subsequently

stops damage to

critical engine

components.

ECM

Perkins electronic control system is designed specifically for the off-highway diesel engine market

from a proven technology base. This allows the use of an engine-mounted ECM with high temperature

and vibration tolerances, coupled to wiring harnesses and sensors designed for use in the harshest off-

highway environments.

The full authority electronic control system gives the

operator the benefits of:

" Improved fuel consumption through

more precise control of injection

timing and duration

" Machine protection under

extreme operating

conditions

" Easy servicing and

fault diagnostics

" Improved functionality

and flexibility

" Improved reliability

through better

engine

monitoring and

planned

maintenance

The electronic engine

control system used on

2300 Series has been

designed for easy service

and diagnosis through

Perkins TIPSS suite of

electronics tools.

* The information in this publication came from

testing randomly sampled Ecoplus and

conventional filters. Test results are on file and

certified to represent only the parts actually tested.

Perkins implies nothing further, and no one should

infer that these parts typify the makers overall

production

At Perkins we are constantly researching, developing and

investing in products and services. Our systems offer

registered users the chance to stay ahead when it

comes to knowledge, training and support. Individual

modules provide them with the latest information

on engines and new service practices the minute

we introduce them.

The new Perkins 2300 Series family of

engines is supported worldwide by Perkins'

international distribution network of over

4,000 dealers.

More than just a name, Perkins provides a

total product service providing technical

information, efficient service support and

rapid access to over 50,000 parts and

exchange units.

The hub of this worldwide distribution network is

the purpose-built Distribution Centre in

Manchester, UK, believed to be the best-equipped

and most efficient of its

type in the world. In

addition, a Regional

Distribution Centre in

Singapore serves our customers in South-East Asia.

From these centres a fast, efficient parts distribution

service is provided 24 hours a day, 365 days a

year.

Perkins customers know that wherever a Perkins

engine operates, the user will always have

peace of mind provided by the Perkins

distribution network.

TIPSS - A Step Change

TIPSS - A Step Change

in Parts and Service

in Parts and Service

W

W

orldwide After

orldwide After

Sales Support

Sales Support

We understand that cutting-edge engines demand an integrated and

professional approach to maintenance and service support.

To meet these needs, and to coincide with the launch of our electronic engine

ranges, Perkins has developed TIPSS (The Integrated Parts and Service

System) which represents a step change in diesel engine

parts and service support. TIPSS is a suite of

interactive support solutions that give registered

users instant access to a consistently updated

bank of information, wherever and whenever

it is needed.

Our ultimate aim is to distribute our vast

resource of knowledge and essential

technical information throughout our

global network - to provide Perkins

best practice to all our customers. By

exploiting web technology TIPSS

offers all our distribution channels a

multilingual internet and DVD real time

service.

The exclusive system delivers rapid

response solutions to diagnose and rectify

problems, access Perkins parts and

workshop information and provide updates on

our latest developments and training support.

Over 4,000 dealers

Worldwide distribution network

Two years warranty

Offering full flexibility, it can be operated via a desktop

connection or out in the field where engineers can

access the latest user-friendly technical

information on the spot, saving time and

money for our customers.

Ideally suited for use with Distributor

helpdesks or call centres, TIPSS integrates

parts book and service data, a diagnostic

guide, electronic service tool, electronic

global ordering and Perkins interactive

training.

For our customers, TIPSS means one call,

repair completed first time, in the shortest

time and at the most efficient cost. This

allows Perkins powered machines to continue

to operate productively.

You might also like

- Bending MachinesDocument1 pageBending Machinesravikant87No ratings yet

- Robin EY20 Parts CatalogDocument36 pagesRobin EY20 Parts CatalogVictor Isaac Pasten Araya50% (6)

- Brand Strategy For Travel RetailingDocument13 pagesBrand Strategy For Travel Retailingravikant87No ratings yet

- Star BucksDocument15 pagesStar Bucksravikant87No ratings yet

- Brand Strategy For Travel RetailingDocument13 pagesBrand Strategy For Travel Retailingravikant87No ratings yet

- Star BucksDocument15 pagesStar Bucksravikant87No ratings yet

- Proposal WritingDocument3 pagesProposal Writingravikant87No ratings yet

- Star BucksDocument15 pagesStar Bucksravikant87No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Individual Assignment ScribdDocument4 pagesIndividual Assignment ScribdDharna KachrooNo ratings yet

- National Advisory Committee For AeronauticsDocument36 pagesNational Advisory Committee For AeronauticsSamuel ChristioNo ratings yet

- Tender34 MSSDSDocument76 pagesTender34 MSSDSAjay SinghNo ratings yet

- 5505 SW 138th CT, Miami, FL 33175 ZillowDocument1 page5505 SW 138th CT, Miami, FL 33175 Zillowlisalinda29398378No ratings yet

- Boiler Check ListDocument4 pagesBoiler Check ListFrancis VinoNo ratings yet

- USA V BRACKLEY Jan6th Criminal ComplaintDocument11 pagesUSA V BRACKLEY Jan6th Criminal ComplaintFile 411No ratings yet

- Daftar PustakaDocument4 pagesDaftar PustakaRamli UsmanNo ratings yet

- Covey - Moral CompassingDocument5 pagesCovey - Moral CompassingAsimNo ratings yet

- Condy LatorDocument11 pagesCondy LatorrekabiNo ratings yet

- Guide to Fair Value Measurement under IFRS 13Document3 pagesGuide to Fair Value Measurement under IFRS 13Annie JuliaNo ratings yet

- Guidelines Tax Related DeclarationsDocument16 pagesGuidelines Tax Related DeclarationsRaghul MuthuNo ratings yet

- Binomial ExpansionDocument13 pagesBinomial Expansion3616609404eNo ratings yet

- WWW - Istructe.pdf FIP UKDocument4 pagesWWW - Istructe.pdf FIP UKBunkun15No ratings yet

- VEGA MX CMP12HP Data SheetDocument2 pagesVEGA MX CMP12HP Data SheetLuis Diaz ArroyoNo ratings yet

- HistoryDocument144 pagesHistoryranju.lakkidiNo ratings yet

- Computer Portfolio (Aashi Singh)Document18 pagesComputer Portfolio (Aashi Singh)aashisingh9315No ratings yet

- Development of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993Document14 pagesDevelopment of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993pghasaeiNo ratings yet

- IELTS Vocabulary ExpectationDocument3 pagesIELTS Vocabulary ExpectationPham Ba DatNo ratings yet

- FALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFDocument3 pagesFALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFJISHNU TKNo ratings yet

- Janome DC6030 Sewing Machine Instruction ManualDocument56 pagesJanome DC6030 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- NPV Irr ArrDocument16 pagesNPV Irr ArrAnjaliNo ratings yet

- Environmental Assessment of Sewer ConstructionDocument32 pagesEnvironmental Assessment of Sewer ConstructionKaleab TadesseNo ratings yet

- Employee Engagement A Case Study at IVRCL-1Document7 pagesEmployee Engagement A Case Study at IVRCL-1Anonymous dozzql7znKNo ratings yet

- Recycle Used Motor Oil With Tongrui PurifiersDocument12 pagesRecycle Used Motor Oil With Tongrui PurifiersRégis Ongollo100% (1)

- Equipment, Preparation and TerminologyDocument4 pagesEquipment, Preparation and TerminologyHeidi SeversonNo ratings yet

- Modul-Document Control Training - Agus F - 12 Juli 2023 Rev1Document34 pagesModul-Document Control Training - Agus F - 12 Juli 2023 Rev1vanesaNo ratings yet

- Political Reporting:: Political Reporting in Journalism Is A Branch of Journalism, Which SpecificallyDocument6 pagesPolitical Reporting:: Political Reporting in Journalism Is A Branch of Journalism, Which SpecificallyParth MehtaNo ratings yet

- Assessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyDocument4 pagesAssessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyVijay KumarNo ratings yet

- Mythi From AndromedaDocument383 pagesMythi From AndromedaRico MinnerNo ratings yet

- Drafting TechnologyDocument80 pagesDrafting Technologyong0625No ratings yet