Professional Documents

Culture Documents

V105n11p809ore Pass Practice in Canadian Mines

Uploaded by

Ricardo MartinezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V105n11p809ore Pass Practice in Canadian Mines

Uploaded by

Ricardo MartinezCopyright:

Available Formats

Ore pass practice in Canadian mines

by J. Hadjigeorgiou*, J.F. Lessard*, and F. Mercier-Langevin*

Synopsis

This paper reviews ore pass practice in some Canadian mines in

Quebec and Ontario. In particular it reviews ore pass configuration,

flow control mechanisms and monitoring practice. A review of the

type of problems encountered and the tools to restore flow is also

presented.

Ore pass practice in some Canadian

mines

Ore pass systems are an integral part of the

materials handling system in the majority of

Canadian underground mines. This paper

presents some observations from a series of

in-depth studies in Canadian Mines. The main

source of information is a comprehensive

study by Hadjigeorgiou and Lessard (2004) in

Quebec mines, with further data derived by

ongoing investigations in Ontario operations

in the Sudbury basin. Extracted ore and

tonnage of Quebec operations are summarized

in Table I.

Ontario mines included in this investigation are massive deposits of nickel and

copper. Daily extraction tonnage ranged from 3

500 to 10 000 tons.

At every participating site, underground

assessments were complemented by data

collection, and site interviews with key mine

personnel from engineering, production, safety

and training departments. Collected mine data

included design, engineering, problems

encountered, and the successes and failures of

interventions. During site visits, the best

practices for safely removing hang-ups were

also recorded.

drop raising). In Quebec mines, Alimak raising

was used in 63% of driven ore passes while

only 3% were raise bored. Conventional and

drop raises represent 29% and 5% of the

sections, respectively. The dominance of

Alimak driven passes over raise bored passes

in Quebec mines is attributable to several

causes. It ensures a reasonable degree of

safety for the miners, while still allowing the

installation of support. Furthermore, the ability

to drive the Alimak pass from a single access

(as opposed to raise boring, which requires

that both the bottom and top accesses be

developed) and a strong expertise of local

mining contractors are also contributing

factors.

In the surveyed Ontario mines, raise

boring was used for 30% of excavated ore pass

sections, while Alimak was used in 39%. The

rationale for the use of raise boring was to

limit ground disturbance during excavation. A

chronological review of ore passes, however,

indicated that Ontario mines are moving away

from raise boring and using Alimak more

widely. In fact close to 70% of recently

excavated ore pass sections were driven by

Alimak, while only 15% were driven by raise

borer. The recent predominance of Alimak

raises is attributed to their facility to integrate

the installation of ground support during the

excavation cycle.

Ore pass section length

There is an inherent relationship between the

type of excavation method and section length.

Typically, sections excavated by drop raising

or conventional raising are shorter than

sections driven by Alimak or raise bored,

Table II. Atlas Copco (1997) reported the same

general trend in other raise applications.

Ore pass configuration

Ore passes are developed using either

mechanical (raise borer) or drill and blast

techniques (Alimak, conventional raising and

The Journal of The South African Institute of Mining and Metallurgy

VOLUME 105

* Laval University, Quebec City, Canada.

The South African Institute of Mining and

Metallurgy, 2005. SA ISSN 0038223X/3.00 +

0.00. This paper was first published at the SAIMM

Colloquium, Design, Development and Operation of

Rockpasses, 1617 November 2004..

REFEREED PAPER

DECEMBER 2005

809

Excavation method

T

r

a

n

s

a

c

t

i

o

n

P

a

p

e

r

Ore pass practice in Canadian mines

Table I

Quebec mines participating in the survey

Mine

Laronde

Louvicourt

Bousquet II

Bouchard-Hbert

Gonzague-Langlois

Doyon

Mouska

Kiena

Bell-Allard

Niobec

Type of orebody

Extracted ore

tpd*

Massive

Massive

Massive

Massive

Massive

Narrow-vein

Narrow-vein

Massive

Massive

Massive

Au, Zn, Cu

Cu, Zn, Au, Ag

Au, Cu

Zn, Cu, Au, Ag

Zn, Cu, Au, Ag

Au

Au, Ag

Au, Ag

Zn, Cu

Nb

5000

4300

1700

3000

3000

3500

450

2000

2200

3300

*tons per day

Table II

Excavation methods and recorded sections length

for Quebec mines

Excavation

method

Alimak raising

Conventional raising

Drop raising

Raise boring

Avgerage

length

(m)

Standard

deviation

(m)

106

48

47

132

51

20

22

62

Maximum Minimum

length

length

(m)

(m)

273

99

90

215

30

10

27

64

The length of ore pass sections in Quebec mines varies

widely (from 10 m to 273 m). Most excavated sections were

of a length between 30 to 100 m with a mean value of 87 m,

Figure 1. Ontario mines report longer sections averaging 108

m with a standard deviation of 60 m. In general it would

appear that the average section length in Canadian mines is

higher than the 46 m reported by Beus et al. (2001) for the

United States.

There are several practical and financial considerations

that influence the selection of an ore pass length. If, for

example, an operation aims to minimize its capitalized

development, it will end up driving short ore pass sections,

going from one level or sub-level to the next, concurrently as

the various levels are entering into production. Quite often a

mine that experienced problems when driving and operating

long sections will subsequently opt for shorter sections when

constructing new ore and waste passes. An excavation of

greater length is more likely to intersect zones of poor

ground. It also has a higher potential for problems and is

harder to bypass. Longer sections may also result in higher

material flow velocity in passes operated as flow-through.

and compaction. It should be noted that all vertical sections

are shorter than 100 m.

Ontario mines favor steep ore passes (80 8.3) in an

effort to ensure continuous material flow and limit hang-up

occurrences. A statistical analysis, however, can obscure site

specific practice. In one particular mine, operating in depth

and using multiple ore passes, the average inclination was

greater than 87.

Ore pass section shape

The majority of excavated ore passes are square or

rectangular. Circular sections are usually associated with

raise boring methods but in some instances, circular sections

were excavated using Alimak. In most cases, the main factor

dictating the choice between a rectangular and a square

section is local mine experience. Circular shape was used

based on anticipated higher stress regimes. It is of interest to

note that a review of ore pass surveys reveals that under

high stress, and with material flowing in an ore pass, a

design circular shape is not maintained for long (in unlined

ore passes).

Ore pass cross-sectional dimensions

Design dimensions for Quebec operations are given in

Figure 3. In the case where the cross-section varies along the

length of an ore pass section the smaller dimension, being

the most critical, is recorded. In the case of rectangular crosssections, again the smallest dimension is used. This results

in an average dimension of 2.1 m for Quebec mines. Ontario

mines have a relatively larger cross-sectional dimension of

2.5 0.6 m. Ore pass size is an important factor influencing

material flow. This is reflected in empirical guidelines linking

the potential for hang-ups with ore pass size and material

size.

Figure 1Length of excavated sections for Quebec mines (153)

Ore pass section inclination

Ore pass inclination in Quebec operations varies between 45

and 90, with an average inclination of 70, Figure 2.

Interviewed mine personnel provided contradictory justification for the choice of inclination and its desired effect on

material flow. The choice for a particular inclination is

dictated by the need to facilitate material flow, while at the

same time slow it down. Shallow sections may restrict flow,

especially if a high proportion of fine material is present,

while steeper excavations result in higher material velocities

810

DECEMBER 2005

VOLUME 105

REFEREED PAPER

Figure 2Inclination of excavated sections for Quebec mines (153)

The Journal of The South African Institute of Mining and Metallurgy

Ore pass practice in Canadian mines

Flow control infrastructure

Material flow control infrastructures used in Canadian mines

can be classified into 5 categories:

Finger raises

Finger raises are used to funnel material into a pass

intersecting two or more production levels. Typically, a finger

raise is a square opening with a smaller cross-sectional area

than the rockpass it feeds. The most common dimensions for

a finger raise are 1.5 and 1.8 m. The majority of ore passes

do not employ fingers or rely on a single finger. It is quite

unusual to have more than 3 fingers leading into a section.

A review of available cavity monitoring surveys, complemented by on site interviews, suggests that fingers often

result in localized impact zones to the detriment of the wall

integrity of ore passes. This is usually aggravated if fingers

are excavated using longhole blasting that often damages the

surrounding rock mass.

Screening of oversize material

Oversize material dumped into the passes may lead to

blockages or interlocking hang-ups. This can be avoided by

either instructing the mucking crew or by installing the

necessary infrastructure to restrict the entrance of the

oversize material. Canadian mines use some control of

infrastructure for approximately 55% of reported ore pass

systems. Typical types of infrastructure are illustrated in

Figure 4.

High maintenance costs are often associated with

scalpers, since big blocks tend to wedge between the bars.

Mucking crews can be persuasive in trying to push the

block through the bars with the bucket. This practice

damages both the bars and the scoop. Broken and missing

bars are often the result of this practice. The ability of a

scalper to retain big blocks is therefore greatly diminished. In

addition, the intrusion of a bar in the ore pass can lead to

severe obstruction further down the system. Another problem

associated with the use of scalpers is that big slabs of rock

can pass through. Of the three types of boulder retaining

infrastructure, grizzlies are the best to keep big blocks out of

the passes. Grizzlies require less maintenance than scalpers.

The grid dimensions with respect to muck size or bucket size

are critical. If the opening is too small, a lot of plugging at the

grizzlies will arise, hindering the mucking. Mantles are

relatively easier to construct and, given that they allow for

larger rock fragments (in excess of 90 cm), they have no

additional requirements for rock breakers. This is an

advantage for infrastructure costs, but the flow of large rocks

in an ore pass can contribute to wall degradation.

The Journal of The South African Institute of Mining and Metallurgy

Chutes with control chains are the most popular flow

control infrastructure in Quebec mines, Figure 5.

a) Scalper

b) Grizzly

c) Mantle

Figure 4Typical screening infrastructure

VOLUME 105

REFEREED PAPER

DECEMBER 2005

811

Figure 3Minimum diameter of excavated sections for Quebec

mines (153)

Control chains are heavy weighed chains suspended

from a headblock. They rely on their weight to slow

down or regulate the flow of ore from an ore pass. In

some instances where an additional level of control

over the flow of ore is needed, a hydraulic cylinder can

be added.

Chutes with crash gates are formed by a steel-lined

slide to which is attached a steel door (hinged at the

top) that physically stops the movement of ore when it

is pushed by hydraulic cylinders .The design is simple

and efficient, but there are known issues, such as the

steel door being kept from closing completely by a big

rock

Chutes with control chains operate on the same

principle as crash gates, with the difference that the

steel door is replaced by the set of chains. This

arrangement solves most of the problems associated

with large blocks wedged in the steel door

Chutes with control chains and gate are a variation on

the principle of the chute with control chains in that the

material flow is slowed by control chains but it is also

further hindered by the gradual lifting of the chute lip

or an arc gate. This lifting of the lip effectively reduces

the angle of the entire chute arrangement to the point

where this angle is less than the natural angle of

repose of the material

Feeders are chutes inclined at an angle higher than the

angle of repose of the material. Material flow is

restrained by a set of heavy circular chains. When flow

has to be restored, the chains are rotated, letting the

material slide beneath them.

T

r

a

n

s

a

c

t

i

o

n

P

a

p

e

r

Ore pass practice in Canadian mines

Ore pass monitoring

Figure 5Sections draw control infrastructures for Quebec mines

(153 sections)

Table III

Performance of ore passes in Quebec mines

Q Rating

Non-supported

# Sections

% Failed

> 5 (fair)

< 5 (poor)

Total

4

3

7

Ore pass management necessitates the use of reliable

monitoring techniques. Those systems can be either direct or

indirect and range from very simple (visual inspections) to

fully automated systems (laser). Several mines try to keep an

ore pass full as this practice mitigates the results of impact

loads on the side walls, and provides a degree of

confinement that contributes to the stability of the ore pass.

Keeping an ore pass full, or to a certain predefined level,

requires strict procedures. Several techniques are available to

monitor the level of muck in an ore pass, Table IV.

The available techniques to monitor the integrity of an

ore pass are listed in Table V. These are not used on a regular

basis but they are often used in response to reported

problems of frequent ore pass hang-ups.

The performance of liners in ore passes also has to be

monitored on a regular basis. The fact that liners are used in

response or in anticipation of problems should justify the use

of the monitoring techniques listed in Table VI.

0

100

43

Table IV

Q Rating

Reinforced

# Sections

% Failed

43

50

93

0

60

32

> 5 (fair)

< 5 (poor)

Total

Muck level monitoring systems in Canadian ore

passes

Type

System

Comments

Direct

Visual

Evaluation of the muck level is performed

periodically by supervising personnel.

Inaccurate. Cannot be automated

A weighted tape is used by supervising

personnel to periodically record the muck level.

Cannot be automated.

Laser systems can provide real time

muck level readings.

Very accurate. Can be automated.

High capital cost. Sensitive to dust.

Measuring

Tape

Reinforcement

Hadjigeorgiou et al. (2004) addressed the issues associated

with reinforcement and support. In Quebec mines the

majority of vertical or inclined excavations are constructed

using Alimak, thus facilitating the installation of

reinforcement and support.

Resin-grouted rebar constitutes the most popular

reinforcement type for ore pass systems. Nevertheless, the

most recently developed excavations are reinforced by resin

grouted short cable bolts. More recently several Canadian

Mines have used resin grouted short cable bolts, for example

the Strand-Lok Cable bolt system, as they have been found to

dissipate impact shock more efficiently than rigid support

systems.

Liners

The relationship between rock mass and ore pass operational

failure was addressed for 10 Quebec mines, Hadjigeorgiou

and Lessard (2003). Cavity monitoring surveys, volume

reconciliation from actual tonnage capacity and/or comments

from mine operators were used to quantify the expansion of

an ore pass. An ore pass section is considered to have failed

if it had expanded to twice its initial volume as recorded in

the original layout. The Q system, Barton et al. (1974) was

used to quantify rock mass quality. The results are

summarized in Table III.

Referring to Table III, there is no incidence of

uncontrolled ore pass failure in any rockpass section that had

a Q value greater than 5. It is suggested that liners should be

considered for ground conditions where Q is less than 5.

812

DECEMBER 2005

VOLUME 105

REFEREED PAPER

Laser

Indirect

Tonnage

Reconciliation

Subtracting pass capacity and pass

output to pass input (scoop buckets).

Highly inaccurate

Table V

Wall degradation monitoring systems in Canadian

ore passes

Type

System

Comments

Direct

Visual

Evaluation of wall degradation from the

upper access.

Inaccurate. Pass must be emptied

Drilling into the pass from nearby drifts to

determine an approximate profile.

Pass can be kept full.

Provides only localized data.

Necessitates access.

A camera is lowered into the pass

Necessitates the use of a buggy.

Pass must be emptied.

A cavity monitoring system provides a

full 3D profile of the pass

Accurate (occasional blind spots).

High capital cost. Necessitates access.

Pass must be emptied.

Drilling

Camera

CMS

Indirect

Tonnage

reconciliation

Subtracting pass output to

pass input (scoop buckets).

Pass can be kept full.

Highly inaccurate

The Journal of The South African Institute of Mining and Metallurgy

Ore pass practice in Canadian mines

Type

System

Comments

Direct

Visual

Visual evaluation of liner wear is

performed from the upper access

Inaccurate. Requires access.

Pass must be emptied.

A system of nails of different lengths

is added to the liner during installation.

As the liner wears, nails are exposed.

Provides only localized data.

Pass must be emptied for reading

unless the nails are instrumented

Wear

nails

Indirect

Mill

performance

Liner materials such as silica and

calcium aluminate can be detrimental

to metals recuperation at the mill. Poor

recuperation can be caused by

liner material failing.

Pass can be kept full.

Difficult to track in a multi-pass system

Ore pass problems

Analysing the causes of degradation is a complex process

due to the potential interaction of several mechanisms.

Table VII demonstrates the level of degradation observed in

the mines. An interesting observation was that seven of the

eight ore pass sections that reported a tenfold enlargement

from the design volume were used to transfer ore of unit

weight greater than 30 kN/m3. Only 4 of the 31 sections

showing an enlargement of two to four times the initial

volume came from mines handling ore with a unit weight of

27 kN/m3. Only two waste pass sections have exhibited an

enlargement of two times the initial volume and those

examples were located in high stress environments. It is quite

possible that there is a relationship between the material unit

weight and the degree of observed degradation.

Figure 6 summarizes the perceived degradation

mechanisms observed in ore and waste passes in Quebec

mines. These have been identified based on information

collected at each site. It is noted that quite often there is more

than one mechanism at work.

Morrison and Kazakidis (1995) have used data from the

Sudbury mining camp to provide a qualitative assessment of

the dominant degradation mechanisms. These include:

structural failures facilitated by material flow; scaling of walls

due to high stresses; wear due to impact loading caused by

material flow; wear due to abrasion and blast damage caused

by the hang-ups clearing methods.

The importance of driving the rockpasses against the

foliation dip has been recognized by Stacey and Swart

(1997). The wisdom of this simple design rule has been

proven at several sites. Perhaps the most striking example is

two ore passes, at two mines in the same structural regime

characterizing by steep bedding, Figure 7. The first ore pass

excavated at a favourable orientation with respect to the

bedding did not run into problems. The second ore pass

excavated along the bedding experienced severe degradation.

A cavity survey indicated that the ore pass expanded to close

to 20 times its original diameter and was subsequently

abandoned.

The Journal of The South African Institute of Mining and Metallurgy

Material flow problems

Some types of material flow problems are reported in every

mine operating an ore pass system. Hambley (1987)

suggests that the transfer of coarse material can result in

hang-ups due to interlocking arches, while the transfer of

fine material results in hang-ups due to cohesive arches,

Figure 9. If flow is not restored there can be significant

consequences for the operation. A distinction is made in this

paper between blockages: localized in the vicinity of the

chute and hang-ups, which are found in the ore pass. This

distinction is not universally accepted in Canadian mines.

Hang-ups

In Quebec mines, interlocking hang-ups were more common

than cohesive arches, Table VIII. Cohesive hang-ups were

Table VII

Level of enlargement caused by wall degradation

(153 sections)

Degree of degradation

Ore pass sections

Negligible

> 2x original volume

2x original volume

5x original volume

10x original volume

Not defined

38.6%

9.8%

7.8%

12.4%

5.2%

26.1%

Comments

Operational failure

Operational failure

Operational failure

Figure 6Probable failure mechanisms (153 sections)

VOLUME 105

REFEREED PAPER

DECEMBER 2005

813

Table VI

Liner wear monitoring systems in Canadian ore

passes

Wall damage attributed to impact loading is most often

localized at the intersection of finger raises to the ore pass,

Figure 8. In practice it is sometimes difficult to differentiate

among damage due to impact, wear or the presence of

structural defects in the rock. It is most probable that the

presence of structural defects in the rock mass accentuates

the influence of impact loading, resulting in more pronounced

degradation. The use of rock boxes can reduce impact

damage but in most cases impact damage is localized on the

ore pass wall facing the finger raise. Constructing a rock box

at this location would be impractical, if not unfeasible.

Damage due to wear appears to be of lesser concern in

the examined mines. Abrasion rate depends on the

abrasiveness of the material and the rockpass walls

resistance to abrasion. In ore passes with relatively few

fractures, wear of the walls did not seem to endanger the

structural integrity of an ore pass.

T

r

a

n

s

a

c

t

i

o

n

P

a

p

e

r

Ore pass practice in Canadian mines

Poor Orientation

Favourble Orientation

66%

65%

55%

Figure 7Case studies of ore pass development with respect to bedding

Impact

damage zone

Wear zone

Wear zone

Impact damage

zone

Figure 8Damage zones in an ore pass

Cohesive

arches

Interlocking

arches

a)

b)

Figure 9Hang-ups caused by: (a) interlocking arches (b) cohesive arches

814

DECEMBER 2005

VOLUME 105

REFEREED PAPER

The Journal of The South African Institute of Mining and Metallurgy

Ore pass practice in Canadian mines

Table VIII

Frequency of reported hang-up occurrences in

Quebec mines

Frequency

Interlocking

hang-ups

(number of mines)

Cohesive

arches

(number of mines)

2

3

4

1

0

6

1

2

1

0

Never encountered

Rare (1 < per month)

Not frequent (1 to 4 per month)

Frequent ( >1 per week)

Very frequent ( > 1 per day)

Most hang-ups lower than 20 m are brought down by

attaching explosive charges on wood or aluminium poles

used to push the charge up to the hang-up. A buggy can also

be used to facilitate the pushing, Figure 10.

Hang-ups located higher in the pass can be blasted using

a Sputnik, an air-propelled device that can carry a 12 kg

explosive charge up to 100 m high, Figure 11. As a last

resort, holes drilled toward the hang-up can be driven and

explosive charges set inside the hole, near the supposed

hang-up location, Figure 12. If the location of the hang-up is

not clearly identified, it may take more than one attempt to

restore flow.

Table IX

observed when mining zinc-rich stopes (often referred to as

sticky ore) or when the dilution due to the paste fill is high.

A comprehensive review further revealed the interdependence of the frequency of hang-ups and wall degradation.

Blockages

Blockages are the most commonly encountered type of flow

disruption in ore pass systems, Table IX. All mines report

some type of blockage problems. Flow disruption near the

chute may be due to blocks wedged at the restriction caused

by the chute throat. Another source of problems is caused by

the accumulation of fine or sticky material in or near the

chute, on the ore pass floor. This reduces the effective crosssectional area and results in further blockages.

Frequency of blockage occurrences in Quebec mines

Frequency

Interlocking

Cohesive

blockage

blockage

(number of mines) (number of mines)

Never encountered

Rare (1 < per month)

Not frequent (1 to 4 per month)

Frequent ( >1 per week)

Very frequent ( > 1 per day)

0

1

4

4

1

1

1

1

5

2

Table X

Methods employed in Canadian mines to restore

flow in ore passes

Hang-up release mechanisms

Category

Restoring material flow is a priority in operating mines.

There are several methods employed in Canadian mines and

they can be classified as those that employ water and those

that rely on explosives, Table X. A complete review of hangup release techniques is provided by Hadjigeorgiou and

Lessard (2004).

Methods that

employ water

Methods to restore flow

Introduction of water from above the

hang-up or blockages

Introduction of water from a point below the blockage

Explosive-based

methods

Close range drilling and use of explosives

Drilling from a distance and use of explosives

Use of Sputnik or Flying Pumpkin

Use of blasting poles

Explosive charges

Aluminium or

wooden poles

Detonating cord

The Journal of The South African Institute of Mining and Metallurgy

VOLUME 105

REFEREED PAPER

DECEMBER 2005

815

Figure 10Use of a buggy to drive explosive charges up an ore pass, after Hadjigeorgiou and Lessard (2004)

T

r

a

n

s

a

c

t

i

o

n

P

a

p

e

r

Ore pass practice in Canadian mines

Conclusions

This paper illustrates some practices employed in Canadian

mines. An analysis of this data has revealed that there is no

unique Canadian strategy for Canadian mines. The field data

has, however, provided the foundations for developing a

series of guidelines for the design and operation of ore pass

systems. This information complements numerical

experiments investigating hang-up phenomena, Lessard

Hadjigeorgiou (2003).

Acknowledgements

1m

Figure 11Application of Sputnik to clear an ore pass, after

Hadjigeorgiou and Lessard (2004)

The authors would like to thank the Institut de Recherche

Robert Sauv en Sant et en Scurit du Travail (IRSST) for

its financial support. The authors would also like to

acknowledge and thank the ground control committee of the

Quebec Mining Association and mine personnel at the

following operations: Louvicourt, Bell-Allard, BouchardHbert, Langlois, Niobec, Agnico-Eagle Division Laronde,

Kiena, Mouska, Doyon and Bousquet II.

References

ATLAS COPCO, 1997. Guide to Underground Mining : Methods and

Applications, Document no. 9851 5073 01d.

BARTON, N., LIEN, R., and LUNDE, J. Engineering classification of rock masses for

the design of tunnel support, Rock Mechanics, vol. 6, 1974. pp. 189236.

BEUS, M.J., PARISEAU, W.G., STEWARD, B.M., and IVERSON. S.R. Design of Ore

Passes. Underground Mining Methods, W A Hustrulid and R.L. Bullock

(eds.), (Society of Mining Engineers, New York). pp. 627634.

HADJIGEORGIOU, J. and LESSARD, J.-F. Conception des chemines minerai et

strile. R-380; Institut de Recherche Robert Sauv en Sant et en Scurit

du Travail (IRSST). 2004.

HADJIGEORGIOU, J., LESSARD, J.F., and MERCIER-LANGEVIN, F. Issues in selection and

design of ore pass support. Fifth International Symposium on Ground

Support in Mining and Underground Construction. Villaescusa and Potvin,

(eds.) Perth WA. Balkema, 2004. pp. 491497.

HAMBLEY, D.F. Design of Ore Pass Systems for Underground Mines, CIM

Bulletin, vol. 897, 1987. pp. 2530.

LESSARD, J.F. and HADJIGEORGIOU, J. Design tools to prevent ore pass hang-ups.

10th Congress of the International Society for Rock Mechanics, Sandton,

South Africa. vol. 2, 2003. pp 757762.

HADJIGEORGIOU, J. and LESSARD, J. F. The Case for Liners in Ore Pass Systems.

3rd International Seminar on Surface Support Liners, Quebec City, Section

1m

4, 2003. p. 14.

Figure 12Use of explosives to clear hang-ups high in an ore pass,

after Hadjigeorgiou and Lessard (2004)

LESSARD, J.F. and HADJIGEORGIOU. J. Current Practice in Ore Pass Design in

Quebec Underground Mines. Mine Planning and Equipment Selection,

Kalgoorlie, WA, CD-Rom. 2003.

Cohesive hang ups are difficult to dislodge using

explosives. Some operations resort to blowing compressed air

through a PVC pipe raised up to the hang-up location or

dumping a predetermined amount of water from a point

above the hang-up. All mines have strict procedures about

the use of water in order to avoid the risks of mud rushes.

816

DECEMBER 2005

VOLUME 105

REFEREED PAPER

MORRISON, D.M. and KAZAKIDIS, V.N. Orepasses in Burst-Prone Ground : Current

Practice and Alternatives. 12th Mine Operators Conference, CIM, Timmins,

1995.

STACEY, T.R. and SWART, A.H. Investigation into Drawpoints, Tips Orepasses

and Chutes Vol. 1. Report to the Safety in Mines Research Advisory

Committee, Project OTH 303. 1997.

The Journal of The South African Institute of Mining and Metallurgy

You might also like

- EM202357MAR510ENGGDocument9 pagesEM202357MAR510ENGGRosalie BachillerNo ratings yet

- Methods of MiningDocument5 pagesMethods of MiningJunel Alapa0% (1)

- SHRINKAGE STOPING MINING METHODDocument6 pagesSHRINKAGE STOPING MINING METHODRiuRiversNo ratings yet

- Colgaduras en Piques - Investigacion NumericaDocument15 pagesColgaduras en Piques - Investigacion NumericaNajiv AleuyNo ratings yet

- Mining Narrow Steeply Dipping VeinsDocument31 pagesMining Narrow Steeply Dipping Veinstd__1985No ratings yet

- Open Stope Mining in Canada: January 2000Document20 pagesOpen Stope Mining in Canada: January 2000Aliocha BouldresNo ratings yet

- Surface and UGDocument26 pagesSurface and UGsunilsinghmNo ratings yet

- Sluice Design - Wyatt Yeager MSC PDFDocument42 pagesSluice Design - Wyatt Yeager MSC PDFWyattYeager100% (8)

- Recent Minefill Developments in AustraliaDocument7 pagesRecent Minefill Developments in Australiaalvaroaac4No ratings yet

- Metodos de Lavra SubterraneaDocument4 pagesMetodos de Lavra SubterraneaAmilton filhoNo ratings yet

- Sublevel Stoping Olympic DamDocument6 pagesSublevel Stoping Olympic DamYorky Edgardo CastilloNo ratings yet

- Midsem Merged Surface MiningDocument414 pagesMidsem Merged Surface MiningSamarth ShuklaNo ratings yet

- Advantages and Limitation of Chain TrencherDocument2 pagesAdvantages and Limitation of Chain TrencherZivadin LukicNo ratings yet

- MassMin2000 OpenStopeMininginCanadaDocument20 pagesMassMin2000 OpenStopeMininginCanadadiego19ahgNo ratings yet

- Underground Mining-Supported OpeningsDocument13 pagesUnderground Mining-Supported OpeningsPuvanendran GajananNo ratings yet

- Opencast Mining MethodDocument7 pagesOpencast Mining MethodjaypadoleNo ratings yet

- Mine barricade design reviewDocument9 pagesMine barricade design reviewSai Teja NadellaNo ratings yet

- Anglais Technique II PDFDocument50 pagesAnglais Technique II PDFFranck Einstein100% (1)

- Black Mountain MiningDocument13 pagesBlack Mountain MiningnylravatNo ratings yet

- Planning For Narrow Vein Mines: G GemellDocument4 pagesPlanning For Narrow Vein Mines: G GemellBendigo BanksNo ratings yet

- Utilization of blast movement measurements in grade controlDocument6 pagesUtilization of blast movement measurements in grade controlChrisCusackNo ratings yet

- Shaft Collar in Deep Overburden - Aur Resources - LouvicourtDocument8 pagesShaft Collar in Deep Overburden - Aur Resources - LouvicourtEEPNo ratings yet

- Mining of NarrowDocument31 pagesMining of NarrowWilliam HinostrozaNo ratings yet

- Grade Control For Australian Open Pit Gold MinesDocument14 pagesGrade Control For Australian Open Pit Gold Mineswaldo100% (1)

- Resue Firing and Dilution Control in Narrow Vein MiningDocument3 pagesResue Firing and Dilution Control in Narrow Vein MiningMostafaOmid0% (1)

- Surface Mining - Mechanical Extraction MethodDocument61 pagesSurface Mining - Mechanical Extraction MethodZUBAID HASAN 1907026No ratings yet

- Bamber 2004Document12 pagesBamber 2004manuelgltNo ratings yet

- Vocational Training ReportDocument32 pagesVocational Training ReportManish KujurNo ratings yet

- Ore Dilution in Sublevel StopingDocument131 pagesOre Dilution in Sublevel StopingRicardo Salas Iparraguirre100% (1)

- Surface Mining Assignment ReportDocument9 pagesSurface Mining Assignment ReportAshik RehmanNo ratings yet

- Lecture 3-Types of Underground Mining Methods - Lecture 3.Document9 pagesLecture 3-Types of Underground Mining Methods - Lecture 3.HILLARY FRANCIS SHENJERENo ratings yet

- Measuring Blast Movement To Reduce Ore Loss and DilutionDocument11 pagesMeasuring Blast Movement To Reduce Ore Loss and DilutionwileduingNo ratings yet

- Mine LayoutDocument7 pagesMine LayoutRavikumar mahadevNo ratings yet

- IntroductionDocument5 pagesIntroductionGabryel FotsoNo ratings yet

- Selective Blast in Gold MinesDocument4 pagesSelective Blast in Gold Minespleasure masango100% (1)

- 82 Tetteh CawoodDocument13 pages82 Tetteh CawoodJoao2014No ratings yet

- Trabarp 40Document22 pagesTrabarp 40jardelbrunoNo ratings yet

- Stowing in Ug MinesDocument55 pagesStowing in Ug Minesbecome ambani100% (5)

- Carter PaperDocument13 pagesCarter Paperronan2000No ratings yet

- Lec 51Document4 pagesLec 51Rishquez DCVNo ratings yet

- SPE 60690 CT FracturingDocument7 pagesSPE 60690 CT FracturingwongphengkitNo ratings yet

- (2009) Current Status and Future Prospects of Mining Subsidence and GrouDocument7 pages(2009) Current Status and Future Prospects of Mining Subsidence and GrouRizto SaliaNo ratings yet

- MAD455 - Surface MiningDocument115 pagesMAD455 - Surface MiningAbet Nego,CS.T100% (4)

- A New Automated Safe Environmentally Sustainable ADocument8 pagesA New Automated Safe Environmentally Sustainable Amukherjeemohul25No ratings yet

- Sample Mine EssayDocument3 pagesSample Mine EssayHeli Senn VentenillaNo ratings yet

- Sub-Level Caving: Where Is It Headed?Document8 pagesSub-Level Caving: Where Is It Headed?anon_747293279No ratings yet

- Interpretation of Flotation Data For The Design of Process PlantsDocument28 pagesInterpretation of Flotation Data For The Design of Process PlantshNo ratings yet

- Mechanical Extraction Methods: Rodríguez Lavado Isaac ManuelDocument14 pagesMechanical Extraction Methods: Rodríguez Lavado Isaac ManuelIsaac Manuel Rodriguez LavadoNo ratings yet

- Li - Determination of The Minimum Thickness of Crown Pillar For Safe Exploitation of A Subsea Gold Mine Based On Numerical Modelling - 2013Document15 pagesLi - Determination of The Minimum Thickness of Crown Pillar For Safe Exploitation of A Subsea Gold Mine Based On Numerical Modelling - 2013krainajackaNo ratings yet

- 1mining Through Adit, Incline, Decline and ShaftDocument11 pages1mining Through Adit, Incline, Decline and ShaftAkhil Sai KrishnaNo ratings yet

- Pit Planning and LayoutDocument7 pagesPit Planning and LayoutMarlinaTogumaJuniartiNapitupulu0% (1)

- Engineering Minerals Environment: Mining Engineering Is AnDocument6 pagesEngineering Minerals Environment: Mining Engineering Is AnMahtab Munir ButtNo ratings yet

- Channel Sampling: Channel Sampling Is Laborious, Tedious, Time Consuming and ExpensiveDocument7 pagesChannel Sampling: Channel Sampling Is Laborious, Tedious, Time Consuming and ExpensivelovelyNo ratings yet

- Oak Ridge National Laboratory: DirtDocument8 pagesOak Ridge National Laboratory: DirtHilmanNo ratings yet

- Mining Geomechanics - AWestern. AustraliaDocument6 pagesMining Geomechanics - AWestern. AustraliaAlonso ValerianoNo ratings yet

- Coal Pillar Extraction Experiences inDocument10 pagesCoal Pillar Extraction Experiences inBicá Valgy de SousaNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Reservoir Characterization of Tight Gas Sandstones: Exploration and DevelopmentFrom EverandReservoir Characterization of Tight Gas Sandstones: Exploration and DevelopmentNo ratings yet

- Green energy? Get ready to dig.: Environmental and social costs of renewable energies.From EverandGreen energy? Get ready to dig.: Environmental and social costs of renewable energies.Rating: 5 out of 5 stars5/5 (1)

- Central or Girth Gear Drive For Ball Mills - 1Document26 pagesCentral or Girth Gear Drive For Ball Mills - 1Vishnu Vardhan . C100% (3)

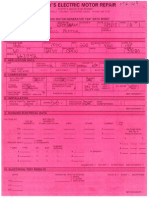

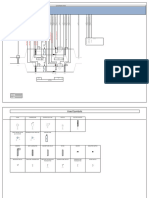

- 17K-169 Motor General Arrangement DrawingDocument3 pages17K-169 Motor General Arrangement DrawingRicardo MartinezNo ratings yet

- 17K-169 Scotty Electric Report On GE 1000 HP 225 RPM Synchronous MotorDocument2 pages17K-169 Scotty Electric Report On GE 1000 HP 225 RPM Synchronous MotorRicardo MartinezNo ratings yet

- Supply, Installation, & Commissioning of The World'S Largest Grinding MillDocument12 pagesSupply, Installation, & Commissioning of The World'S Largest Grinding MillRicardo MartinezNo ratings yet

- Steel Penstocks - 11 ManufactureDocument10 pagesSteel Penstocks - 11 ManufactureRicardo MartinezNo ratings yet

- Code of Practice for Micro Hydro Power ProjectsDocument64 pagesCode of Practice for Micro Hydro Power ProjectsRicardo MartinezNo ratings yet

- EC8702 Ad Hoc and Wireless Sensor NetworksDocument2 pagesEC8702 Ad Hoc and Wireless Sensor NetworksPraveen KumarNo ratings yet

- 4.DC Biasing - BJTsDocument77 pages4.DC Biasing - BJTsNimra AftabNo ratings yet

- Plastic Fines in Graded Aggregates and Soils by Use of The Sand Equivalent TestDocument2 pagesPlastic Fines in Graded Aggregates and Soils by Use of The Sand Equivalent TestDiana MoscosoNo ratings yet

- DPP No. 41: PhysicsDocument6 pagesDPP No. 41: PhysicsGajanan PurudNo ratings yet

- Short ChemistryDocument121 pagesShort ChemistryNAVEEN KUMAR SINGHNo ratings yet

- Technical Guide Pigment&Coating Colour PreparationDocument18 pagesTechnical Guide Pigment&Coating Colour PreparationHuy NguyenNo ratings yet

- The White Lotus by OSHODocument450 pagesThe White Lotus by OSHODillip Kumar MahapatraNo ratings yet

- The ONE Invisible Code - An Uncommon Formula To Breakthrough Mediocrity and Rise To The Next Level (Sharat Sharma)Document139 pagesThe ONE Invisible Code - An Uncommon Formula To Breakthrough Mediocrity and Rise To The Next Level (Sharat Sharma)Santhosh ReddyNo ratings yet

- Beginner's Guide To Centrifugal Compressor Design and SimulationDocument17 pagesBeginner's Guide To Centrifugal Compressor Design and Simulationvijay_jvNo ratings yet

- CPDprogram MECHENG-91018Document43 pagesCPDprogram MECHENG-91018PRC Board100% (1)

- Allyza Diane SauzaDocument60 pagesAllyza Diane SauzaAllyza Diane SauzaNo ratings yet

- MANET: Performance: Performance Comparison of Two On-Demand Routing Protocols For Ad Hoc NetworksDocument49 pagesMANET: Performance: Performance Comparison of Two On-Demand Routing Protocols For Ad Hoc NetworksSayed AlhussainiNo ratings yet

- HPLC Flowmeter Calibration and MaintenanceDocument9 pagesHPLC Flowmeter Calibration and MaintenanceDCG CandyNo ratings yet

- Apex NC Fence OrdinanceDocument28 pagesApex NC Fence OrdinanceKeith BloemendaalNo ratings yet

- Mathematics QuizDocument18 pagesMathematics QuizIyarna YasraNo ratings yet

- DowsingDocument76 pagesDowsingBacean Aurel IoanNo ratings yet

- Motor Insurance - Two Wheeler Package Policy ScheduleDocument1 pageMotor Insurance - Two Wheeler Package Policy SchedulePriya RNo ratings yet

- Predictive MaintenanceDocument17 pagesPredictive Maintenancejimmy_d_nasutionNo ratings yet

- Managing Microgrids with Multiple DER UnitsDocument3 pagesManaging Microgrids with Multiple DER UnitsSnehamoy DharNo ratings yet

- AHU Cable Termination 2 1Document2 pagesAHU Cable Termination 2 1naing linNo ratings yet

- Ea (Dyn)Document9 pagesEa (Dyn)Dr.Biswajit jenaNo ratings yet

- How To Configure A 3COM SwitchDocument5 pagesHow To Configure A 3COM Switchama1738No ratings yet

- Hydraulic Guidelines Bridge Design ProjectsDocument15 pagesHydraulic Guidelines Bridge Design ProjectsUmmi Ummi Ummi0% (1)

- Chapter-3 Water ResourcesDocument9 pagesChapter-3 Water ResourcesPranvi AroraNo ratings yet

- Environmental Sustainability of Ateneo de Naga University in S/Y 2018-2019Document12 pagesEnvironmental Sustainability of Ateneo de Naga University in S/Y 2018-2019Ludwig Claude LelisNo ratings yet

- Self HRMDocument372 pagesSelf HRMSaad NazeerNo ratings yet

- Fuel Transfer Pump - Disassemble: Shutdown SISDocument3 pagesFuel Transfer Pump - Disassemble: Shutdown SISjasleenNo ratings yet

- APP Modified Bituminous Waterproofing ManualDocument9 pagesAPP Modified Bituminous Waterproofing ManualMohan Kumar JayaramanNo ratings yet

- A Novel Op-Amp Based LC Oscillator For Wireless CommunicationsDocument6 pagesA Novel Op-Amp Based LC Oscillator For Wireless CommunicationsblackyNo ratings yet

- AC Circuit Analysis TechniquesDocument7 pagesAC Circuit Analysis TechniquesEduardo ReyesNo ratings yet