Professional Documents

Culture Documents

Welding Electrode Chart

Uploaded by

Zaheed ManooCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Electrode Chart

Uploaded by

Zaheed ManooCopyright:

Available Formats

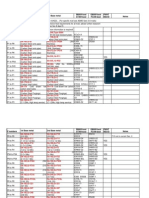

TABLE OF RECOMMENDED WELDING PRACTICES

CS

A/B

1-A

CS

C-1/2Mo

11/4Cr-1/2Mo

21/4Cr-1Mo

5Cr-1/2Mo

9Cr-1Mo

12Cr

C- 11/4Cr- 21/4Cr- 5Cr- 9CrSS SS SS

12Cr

1/2Mo 1/2Mo 1Mo 1/2Mo 1Mo

304 316 321

B/C

1-A

C

1-A

B

2-B

C

2-B

D

2-C

B

2-B

C

2-B

D

2-C

E

2-C

B

2-C

C

2-C

D

2-C

E

2-C

F

2-C

B

3-C

C

3-C

D

3-C

E

3-C

F

3-C

G

3-C

B/K

3-C

C/K

3-C

D/K*

3-C

E/K*

3-C

F/K*

3-C

G/K*

3-C

O/M

3-C

SS304

SS316

SS321

SS309

SS310

HK

HT

SS

347

SS SS

309 310

HK

HT

INCOLOY

800

M/K

1-N

M/K

1-N

M/K

2-N

M/K

2-N

M/K

1-N

M/K

1-N

M/K

2-N

M/K

2-N

M/K

1-N

M/K

1-N

M/K

2-N

M/K

2-N

M/E312

1-N

M/E312

1-N

M/E312

2-N

M/E312

2-N

M/K

1-N

M/K

1-N

M/K

2-N

M/K

2-N

M/L

1-N

M/L

1-N

M/L

2-N

M/L

2-N

M

1-N

M

1-N

M

2-N

M

2-N

M

1-N

M

1-N

M

2-N

M

2-N

M

1-N

M

1-N

M

2-N

M

2-N

H

1-D

H

1-D

I

1-D

H

1-D

I

1-D

J

1-D

H

1-D

I

1-D

J

1-D

K

1-D

H

1-D

I

1-D

J

1-D

K

1-D

K

1-D

K/L

1-D

K/L

1-D

K/L

1-D

L

1-D

K/M

1-D

K/M

1-D

K/M

1-D

K/M

1-D

L/M

1-D

K/M

1-D

K/M

1-D

K/M

1-D

K/M

1-D

K/M

1-D

L/M

1-D

M

1-D

M

1-D

M

1-D

M

1-D

M

1-D

M

1-D

M

1-D

M

1-D

M

1-D

M

1-D

INCOLOY800

Note :

1.

2.

3.

*A

B

C

D

E

F

G

H

I

J

K

L

M

N

+O

In the box Top line indicates welding consumables (Refer Appendix A)

Bottom line left indicates preheat requirements (Refer Appendix B)

Bottom line right indicates post weld heat requirements (Refer Appendix C)

( * ) These combinations may be joined by welding, Heat treatment may however, adversely affect the

properties of one of the base matels. Contact EIL-HMTD for further information.

( * ) PWHT may affect the corrosion resistance properties of the austenitic stainless steel weld metal

under some conditions. Confirm with EIL/HMTD before use.

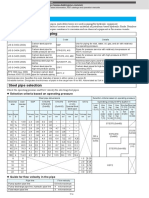

APPENDIX-A (WELDING CONSUMABLES)

E-6010 for Root and E-7018 for Cover passes

E7016 , E7018 , ER70S-2 Bare Wire

E7016-A1 , E7018-A1 , ER80S-D2

E8016-B2 , E8018-B2 , ER80S-B2 , ER80S-B2L

NOTES:

E9016-B3 , E9018-B3 , ER80S-B3 , E312

* For pipe or tube sizes upto 4"O.D. or

1/2"wall thickness maximum.

E8018 B6, ER 80 S B6 Bare Wire

E8018 B8, ER 80 S B8 Bare Wire

+ For special requirements of impact

test and BHN, Chroloy No.414 is

E308-15 , E308-16 , ER308 Bare Wire

recommended.

E316-15 , E316-16 , ER316 Bare Wire

E347-15 , E347-16 , Bare Wire

E309-15 , E309-16 , Bare Wire ER309

E310-15 , E310-16 , Bare Wire ER310

ENiCrFe-3 (inconel 182) , ERNiCr-3 (inconel 82) Bare Wire

E310-15 HG

E410-15 , E410-16 , ER410 Bare Wire

Page 1 of 2

1.

2.

3.

APPENDIX-B (PREHEAT REQUIREMENTS)

50F(10C) for Carbon Steel with thickness less than 1" and minimum specified tensile strength not to

exceeding 71000 psi.

50F(10C) for Carbon-moly Steel upto 1/2" thickness and minimum specified tensile strength not to

exceeding 71000 psi.

50F(10C) for all thickness of alloys 304,316,321,347,309,310,HK and Incoloy800.

175F(79C) for Carbon-moly Steel over 1/2" thickness or with minimum specified tensile strength

exceeding 71000 psi.

175F(79C) for Carbon Steel 1" and over or with minimum specified tensile strength exceeding 71000

psi.

300F(149C) for 1 1/4 Cr - 1/2 Mo Steel ; 350F for 2 1/4 Cr - 1 Mo & 5 Cr - 1/2 Mo steels

400F(204C) for 9 Cr - 1 Mo and 12 Cr steels.

APPENDIX-C (POST WELD HEAT TREATMENT REQUIREMENTS)

1100F(593C) - 1200F(649C)

See Note 1

1250F(676C) - 1350F(732C)

See Note 1

1325F(718C) - 1350F(732C)

See Note 1

See Note 2

Not required where the ferritic member is within the limits shown in Note1. For situations outside these

limits, EIL-HMTD will provide specific instructions.

Note 1:

PWHT not required for the followings conditions :

a.

Carbon Steel Tubing or Piping of less than 3/4" wall thickness

b.

Carbon - moly tubing or piping upto 3/4" wall thickness and min.specified tensile strength not

exceeding 71,000 psi.

c.

Chrome - moly tubing or piping that meets all of the following requirements :

i)

A maximum specified chromium content of 3%

ii)

A maximum wall thickness of 1/2"

iii)

A minimum preheat of 350F(176C) {300F(149C) for Cr content not exceeding 2%}

d.

Fillet welds attaching external non-pressure parts such as lugs or other pipe supporting elements to

carbon steel, carbon-moly, 1 1/4Cr - 1/2Mo, 2 1/4Cr - 1Mo pipe or tube provided the throat thickness of

the fillet weld does not exceed.

i)

1/2" for attachments to carbon steel and carbon moly

ii)

1/4" for attachments to Chrome - Moly pipe or Tubes.

The minimum preheat temperature shall be as specified in Appendix B based on the pipe or tube wall

thickness.

e.

Fillet welds used in slip-on and socket welding flanges and connections, as follows :

i)

Carbon steel materials, regardless of thickness, when the weld throat thickness does not

exceed 5/8".

ii)

Carbon -moly steel and chrome-moly steel (upto 3% max.chrome content), regardless of the

thickness, when the weld throat thickness does not exceed 1/2".

iii)

The min. preheat temperature shall be as specified in Appendix B based on the pipe or tube

wall thickness.

No post weld heat treatment normally required. However, when service conditions require post weld

Note 2 :

treatment, EIL-HMTD will provide specific instructions.

A)

B)

C)

D)

N)

The above table prepared based on the EIL standard specification of coils for fired heaters, specification 6-17-03 Rev.01

Page 2 of 2

You might also like

- Piping Release Report (Spool For Paint)Document2 pagesPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- Electroplating in The Home WorkshopDocument21 pagesElectroplating in The Home WorkshopcdslicNo ratings yet

- Engineer Guide Summary DEC 2020Document25 pagesEngineer Guide Summary DEC 2020AMALENDU PAULNo ratings yet

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- A320 Generic CCOMDocument816 pagesA320 Generic CCOMBobi GuauNo ratings yet

- Mold Maintenance ProgramDocument6 pagesMold Maintenance Programमनोज चौधरी100% (1)

- ASME P Material NumbersDocument1 pageASME P Material Numbersmahi1437100% (1)

- Gaseous Hydrogen Piping SpecificationDocument5 pagesGaseous Hydrogen Piping SpecificationAndri DoemeriNo ratings yet

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Material and electrode selection guideDocument1 pageMaterial and electrode selection guideVijayabaraniNo ratings yet

- Electrodes ConsumablesDocument2 pagesElectrodes Consumablesranjith_007100% (2)

- Assignment 2Document21 pagesAssignment 2anthonyunisaNo ratings yet

- Welding Chart The Complete Reference Guide To WeldingDocument2 pagesWelding Chart The Complete Reference Guide To WeldingJitu JenaNo ratings yet

- SMAW & GTAW Filler Metal Selection GuideDocument2 pagesSMAW & GTAW Filler Metal Selection GuideShanmuga Navaneethan100% (1)

- Seafaring LN The Bronze Age MediterraneanDocument10 pagesSeafaring LN The Bronze Age MediterraneanHermes AegeanNo ratings yet

- PoopDocument1 pagePoopVance HurdNo ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- ElectrodosDocument14 pagesElectrodosanon-635614100% (6)

- Marine Engine Genset Product GuideDocument104 pagesMarine Engine Genset Product GuideAngga Ardiansyah86% (7)

- ASME P Material NumbersDocument2 pagesASME P Material NumbersAbdullah100% (1)

- Electrode Selection Excel SheetDocument1 pageElectrode Selection Excel Sheetchandrakit047No ratings yet

- Welding Electrode Specification ChartDocument2 pagesWelding Electrode Specification ChartMahesh Kumar100% (2)

- Electrodes and filler wires for welding various steel materialsDocument1 pageElectrodes and filler wires for welding various steel materialsMurugananthamParamasivam100% (1)

- Electrode SelectionDocument15 pagesElectrode SelectionkarthikeyanNo ratings yet

- Specification For Piping FabricationDocument24 pagesSpecification For Piping FabricationSanjay SenNo ratings yet

- WPS - EngineerDocument20 pagesWPS - Engineerhunghoanglong100% (1)

- Electrode SelectionDocument85 pagesElectrode SelectionShaheen Andre Chikku100% (2)

- Material With Electrode SelectionDocument2 pagesMaterial With Electrode SelectionJithuJohn100% (3)

- Kati List 2020Document114 pagesKati List 2020Zeeshan Ahmed80% (5)

- WPSASMEDocument76 pagesWPSASMERama TamaNo ratings yet

- PIPING MATERIALS COMPARISON TABLEDocument12 pagesPIPING MATERIALS COMPARISON TABLEJay Vinoth100% (2)

- Bill of Lading DetailsDocument3 pagesBill of Lading DetailsThamaa Nagh' GhemblezzNo ratings yet

- Metrode Dissimilar Consumable SelectorDocument7 pagesMetrode Dissimilar Consumable SelectorClaudia MmsNo ratings yet

- En-006-Compatibilita OssigenoDocument24 pagesEn-006-Compatibilita OssigenoMauro Costa100% (1)

- VettingCreteria - Conoco PhilipDocument11 pagesVettingCreteria - Conoco PhilipDennis BellNo ratings yet

- AES-W-016 welding filler metalsDocument2 pagesAES-W-016 welding filler metalsmalika_00No ratings yet

- Shell's Post-Weld Heat Treatment GuideDocument17 pagesShell's Post-Weld Heat Treatment GuideSiva RamNo ratings yet

- Essar Group PresentationDocument59 pagesEssar Group PresentationchetanpatelhNo ratings yet

- BRIDGE Steel Welding GuideDocument2 pagesBRIDGE Steel Welding GuideANTONYLEONo ratings yet

- GB-T8163-1999 英文版Document11 pagesGB-T8163-1999 英文版saasim_1100% (1)

- Welding RodDocument368 pagesWelding Rodjrod91586% (29)

- Astm B187Document9 pagesAstm B187Plata Elpidio100% (3)

- Balancing Off-Hire Clauses and Charterparty DisputesDocument4 pagesBalancing Off-Hire Clauses and Charterparty DisputesParthiban NagarajanNo ratings yet

- New Piping Flexibility Rules in ASME B31.3 AppendixP - Becht & Diehl - ASME - 2006Document5 pagesNew Piping Flexibility Rules in ASME B31.3 AppendixP - Becht & Diehl - ASME - 2006Alvin SmithNo ratings yet

- Material With Electrode SelectionDocument2 pagesMaterial With Electrode SelectionAhmadiBinAhmadNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- Carbon Steel Pipes - Comparing AmericanDocument2 pagesCarbon Steel Pipes - Comparing AmericanKazi Anwarul Azim SohelNo ratings yet

- Mild Steel Welding ElectrodeDocument12 pagesMild Steel Welding ElectrodeVĩnh NguyễnNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- 7 classes of dissimilar steel filler metalsDocument1 page7 classes of dissimilar steel filler metals911targa100% (1)

- Material Comparison Tables (ASTM KS, JIS, DIN, BS, NBN, NF, UNI)Document12 pagesMaterial Comparison Tables (ASTM KS, JIS, DIN, BS, NBN, NF, UNI)mihailspiridonNo ratings yet

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 pagesSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNo ratings yet

- FILL COURSE ENROLMENT FORMDocument3 pagesFILL COURSE ENROLMENT FORMRaja Guru100% (1)

- 3 05 A Welding Specification of Carbon Steel Alloy SteelDocument40 pages3 05 A Welding Specification of Carbon Steel Alloy SteelvancongthanhNo ratings yet

- Din 2393-2Document0 pagesDin 2393-2Yalavarthi ChandrasekharNo ratings yet

- 20 2690fittingsforco21942Document11 pages20 2690fittingsforco21942Eugen StangaNo ratings yet

- Cs Welded Pipes - 1Document7 pagesCs Welded Pipes - 1albejo_r9No ratings yet

- 1729Document52 pages1729praj24083302No ratings yet

- Reg. 353 Flanges Types and RequirementsDocument5 pagesReg. 353 Flanges Types and RequirementsRajivharolikarNo ratings yet

- ASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesDocument4 pagesASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesAnibal QuezadaNo ratings yet

- A 313 - A 313M - 98 Qtmxmy9bmzezts1sruq - PDFDocument7 pagesA 313 - A 313M - 98 Qtmxmy9bmzezts1sruq - PDFTiến Lượng NguyễnNo ratings yet

- Piping: Material SpecificationDocument2 pagesPiping: Material SpecificationGABRIELA310No ratings yet

- Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater TubesDocument4 pagesElectric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater TubesVishal SharmaNo ratings yet

- Valve DetailDocument5 pagesValve DetailRakesh RanjanNo ratings yet

- KOGAS Natural Gas Ball Valve SpecificationDocument25 pagesKOGAS Natural Gas Ball Valve Specification윤병택No ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- Hydraulic PipingDocument1 pageHydraulic Pipingpandunugraha04No ratings yet

- AISI CSP Durability GuideDocument4 pagesAISI CSP Durability Guiderhonald2000No ratings yet

- Rolf Rolf: Engg. Solutions IncDocument6 pagesRolf Rolf: Engg. Solutions IncPham Huu Loc HoNo ratings yet

- BIS Hume PipeDocument7 pagesBIS Hume PipeShiv Pratap SinghNo ratings yet

- Astm A 178 A 178M 2002Document4 pagesAstm A 178 A 178M 2002AnamulKabir0% (1)

- T000003407 - FileName1 - 6079A-B-590-006 Vol-2Document32 pagesT000003407 - FileName1 - 6079A-B-590-006 Vol-2kanchanabalajiNo ratings yet

- ASTM A333 Grade 6 Pipe Specification and DimensionsDocument10 pagesASTM A333 Grade 6 Pipe Specification and DimensionsArmandito ZamudioNo ratings yet

- QW 423.1 InterpretationDocument1 pageQW 423.1 InterpretationZaheed ManooNo ratings yet

- Module 6Document35 pagesModule 6Zaheed ManooNo ratings yet

- Module 4Document38 pagesModule 4Zaheed ManooNo ratings yet

- Module 3Document23 pagesModule 3Zaheed ManooNo ratings yet

- Module 5Document19 pagesModule 5Zaheed ManooNo ratings yet

- Documents Guiding Welding InspectionDocument11 pagesDocuments Guiding Welding InspectionZaheed ManooNo ratings yet

- Module 1Document10 pagesModule 1Zaheed ManooNo ratings yet

- Weld Process Cheat SheetDocument1 pageWeld Process Cheat SheetZaheed ManooNo ratings yet

- FLOORING - Installation ManualDocument28 pagesFLOORING - Installation ManualAlex GeronaNo ratings yet

- Innovative Financing of Metro Rail ProjectsDocument8 pagesInnovative Financing of Metro Rail ProjectsNivesh ChaudharyNo ratings yet

- T.Y.B.COM. ResultsDocument913 pagesT.Y.B.COM. ResultsROhan KaDamNo ratings yet

- Lightning Protection Codes & Earthing StructuresDocument6 pagesLightning Protection Codes & Earthing Structuresan_iboreg8720No ratings yet

- Mdpe PipeDocument14 pagesMdpe PipeMann Gurpreet100% (2)

- Lecture7 - Equipment and Material HandlingDocument52 pagesLecture7 - Equipment and Material HandlingAkimBiNo ratings yet

- Adva Flow 411Document2 pagesAdva Flow 411Doug WeirNo ratings yet

- MilStd 161FDocument17 pagesMilStd 161FThomas M RiddleNo ratings yet

- VDF Vs Laser ScreedSaver TechDocument2 pagesVDF Vs Laser ScreedSaver TechYogendra Bastakoti100% (1)

- Composite Masonry1Document17 pagesComposite Masonry1Bibek Basnet0% (1)

- Railway Track FasteningsDocument20 pagesRailway Track FasteningsFaisal RasoolNo ratings yet

- Caso - Organizing Fo Innovation at GlenmarkDocument13 pagesCaso - Organizing Fo Innovation at GlenmarkGiancarlo RenzoNo ratings yet

- NPDC AssetsDocument1 pageNPDC AssetsAustinNo ratings yet

- SMED Case Study PDFDocument3 pagesSMED Case Study PDFBagus DhakaNo ratings yet

- Bombardier Commercial Aircraft Q400 Factsheet enDocument2 pagesBombardier Commercial Aircraft Q400 Factsheet endismalmusic100% (1)

- Closed MillsDocument104 pagesClosed MillsDa DelivererNo ratings yet

- Introduction To Supply Chain Management: Mcgraw-Hill/IrwinDocument60 pagesIntroduction To Supply Chain Management: Mcgraw-Hill/Irwintariq_jamil99No ratings yet