Professional Documents

Culture Documents

Influence of Electrical Process Parameters

Uploaded by

siddy_777Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Influence of Electrical Process Parameters

Uploaded by

siddy_777Copyright:

Available Formats

ACME-201; No.

of Pages 8

archives of civil and mechanical engineering xxx (2014) xxxxxx

Available online at www.sciencedirect.com

ScienceDirect

journal homepage: http://www.elsevier.com/locate/acme

Review

A review on inuence of electrical process

parameters in EDM process

T. Muthuramalingam a,*, B. Mohan b

a

b

Department of Production Technology, M.I.T. Campus, Anna University, Chennai, India

Department of Mechanical Engineering, CEG Campus, Anna University, Chennai, India

article info

abstract

Article history:

Since the thermal energy produced in electrical discharge machining process is due to the

Received 12 July 2013

applied electrical energy, it is very important to enhance the electrical process parameters to

Accepted 16 February 2014

improve the process efciency. The present study discusses about having an overview of the

Available online xxx

EDM process, modeling of process parameters, and inuence of process parameters such as

input electrical variables, pulse shape, and discharge energy on performance measures such

Keywords:

as material removal rate, surface roughness and electrode wear rate. This study also

EDM

discusses about controlling the electrical process parameters, and empirical relationships

EWR

between process parameters and optimization of process parameters in EDM process. From

Discharge

the review results, it has been observed that the efcacy of the machining process can be

MRR

improved by electrical process parameters, and only less attention has been given for

Surface

enhancing such parameters.

# 2014 Politechnika Wrocawska. Published by Elsevier Urban & Partner Sp. z o.o. All

rights reserved.

1.

Introduction

Electrical discharge machining (EDM), otherwise known as

thermal erosion process, is one of the non-conventional

machining processes, where tool and workpiece do not come

into contact with each other during the machining process. The

progression of events constituting the process of material

erosion from the work surfaces by an electrical discharge

machining can be explained in the following way. If an

appropriate voltage is developed across the tool electrode

(normally cathode) and the workpiece (normally anode), the

breakdown of dielectric medium between them happens due to

the growth of a strong electrostatic eld. Owing to the electric

eld, electrons are emitted from the cathode toward the anode

on the electrode surfaces having the shortest distance between

them. These electrons impinge on the dielectric molecules of

the insulating medium, breaking these dielectric uid molecules into positive ions and electrons. These secondary

electrons travel along on the same ionization path. This event

causes an increase in the electric eld strength across the work

surfaces and liberates a large number of electrons. It creates an

ionized column in the shortest spark gap between the tool

electrode and the workpiece, thereby decreasing the resistance

of the uid column and causing an electrical discharge in the

shortest distance point between the tool and the workpiece. The

* Corresponding author. Tel.: +91 9994872013; fax: +91 4422232403.

E-mail addresses: muthu1060@gmail.com, muthu_456@yahoo.com (T. Muthuramalingam), mohan@mitindia.edu (B. Mohan).

http://dx.doi.org/10.1016/j.acme.2014.02.009

1644-9665/# 2014 Politechnika Wrocawska. Published by Elsevier Urban & Partner Sp. z o.o. All rights reserved.

Please cite this article in press as: T. Muthuramalingam, B. Mohan, A review on inuence of electrical process parameters in EDM process,

Archives of Civil and Mechanical Engineering (2014), http://dx.doi.org/10.1016/j.acme.2014.02.009

ACME-201; No. of Pages 8

archives of civil and mechanical engineering xxx (2014) xxxxxx

3.

Enhancing the performance of pulse

generator

Fig. 1 Basic mechanism involved in EDM.

enormous thermal energy melts and vaporizes the material

from the workpiece, which creates a small crater over the work

surface. There happened a collapse of the ionized column with

the termination of the electrical energy by means of the

switching circuit and then surrounding dielectric uid occupies

its place. The melted debris is removed by the ushing process.

The conduction of dielectric medium can be determined by the

current, duration and pulse energy [1]. Fig. 1 explains the

formation of ionized column in the shortest distance of work

surfaces using the EDM process [1].

2.

State of art in EDM process

Since the electrical discharge machining process is of with

non-linear nature, it requires a lot of improvements on it.

Many authors have discussed about the research works for

improving process efciency of the EDM process. The fundamentals of EDM process mechanism and research works

carried out from the inception to the development of the diesinking EDM process within the past decade have been

discussed by Ho and Newman [2]. It has been reported and

discussed about the EDM researches relating to improve the

process performance measures, optimizing the process variables, and monitoring and control of the sparking process.

Abbas et al. presented the recent research trends to improve

the performance characteristics involved in all the aspects of

electrical discharge machining process. They discussed about

the need for controlling the process parameters to enhance the

machining process efciency of the EDM process [3]. The

development of new technologies for improving the surface

quality of workpiece is a signicant research area in EDM

process. Kumar et al. presented a review on the phenomenon

of surface modication by EDM and future trends of its

applications [4]. It has been observed that most of the research

works concentrated on surface modication using the powder

mixed dielectric medium in EDM process. The study of the

impact of the electrical process parameters on surface

modication of the workpiece has been taken up by very

few researchers.

Since the electrical energy is supplied to the EDM process

informing the DC pulses, the pulse generator needs to be

upgraded to improve the performance measures in the

machining process. The lower energy pulses enhance the

surface nish of the workpiece whereas the higher energy

pulses improve the material removal rate.

Jahan et al. conducted a detailed experimental investigation to nd out the inuence of major operating parameters on

surface quality of tungsten carbide with both transistor and

RC-type generators in EDM process [5]. It has been proved that

RC pulse generator has produced a smoother surface nish

than the transistor pulse generator due to its lower discharge

energy distribution over the surface of tungsten carbide. Han

et al. designed and developed a modied transistor pulse

generator with pulse frequency of 1 MHz to produce higher

material removal rate than the RC pulse generator in the

electrical discharge machining process [6]. They found that the

transistor pulse generator has provided two or three times

higher machining speed than the conventional RC pulse

generator while machining tungsten workpiece with brass

electrode.

A pulse generator based on xed pulse width modulation

has been developed by Yan and Liu to generate the high

frequency 4.4 MHz and short duration pulse control signals to

reduce surface roughness of the workpiece tungsten carbide in

the EDM process [7]. From the experimental results, it has been

observed that the very low discharge energy pulse applied

between tool and electrode has improved the surface quality of

workpiece during the machining process. Yan and Chiang

discussed about the development and application of a new

power supply in wire electrical discharge machining process

[8].

A transistor-controlled power supply composed of a low

energy discharge circuit has been designed to provide the

functions of high frequency and lower energy pulse control.

The experimental results have shown that the low peak

current has been resulted in better surface nish in EDM

process. Muthuramalingam and Mohan discussed about effect

of uniform distribution for improving the surface quality using

iso current pulse generator in EDM process [9]. Fig. 2 shows the

surface quality of workpiece made by three different pulse

generators. It has been observed that the iso current pulse

generator could produce better surface nish than the

conventional pulse generators such as RC pulse generator

and transistor pulse generator.

Han et al. designed and developed a new transistor type

pulse generator with high frequency response to produce

higher erosion rate of the workpiece in the electrical discharge

machining process [10]. From the experimental results, it has

been observed that the modied transistor pulse generator has

produced 24 times higher material removal rate than the RC

pulse generator in the EDM process. Yan and Lai presented the

development of a ne-nish power supply with high frequency in EDM process [11]. This power supply has been composed

with full bridge circuit, two snubber circuits and a pulse control

circuit. It has been found that the proposed power supply has

Please cite this article in press as: T. Muthuramalingam, B. Mohan, A review on inuence of electrical process parameters in EDM process,

Archives of Civil and Mechanical Engineering (2014), http://dx.doi.org/10.1016/j.acme.2014.02.009

ACME-201; No. of Pages 8

archives of civil and mechanical engineering xxx (2014) xxxxxx

Fig. 2 Surface topography of machined surface using different pulse generators.

produced lower discharge energy and thus contributed to

lower surface roughness. Muthuramalingam and Mohan

developed a semiconductor based pulse switching circuit to

produce lower energy discharge pulses during nishing level

of the process for enhancing the EDM performance characteristics [12]. Casanueva et al. attempted to establish a new EDM

impulse generator based on high frequency switched DC-toDC series-parallel resonant converter [13]. It has been claimed

that the capacitance effect has affected the overall impedance

of the EDM arrangement and thus altered the machining

characteristics of EDM process.

4.

Inuence of pulse shape on performance

measures

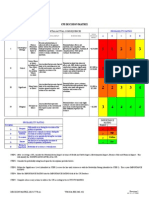

Studying the variation of the EDM process response characteristics due to change in shape of the generated pulse is one

of the research aspects in the EDM process. The discharge

pulse shape affects the average spark energy which is

delivered on the surface. Since the machining characteristics

in EDM process depend on the electrical energy, the pulse

shape which has an effect on the machining characteristics

such as material removal rate, surface quality and electrode

wear rate as shown in Fig. 3.

The effects of the voltage excitation of the pre-ignition

spark pulse on the performance measures such as material

removal rate, electrode wear rate and average surface

roughness have been discussed by Ghoreishi and Tabari

[14]. Based on the results, it is clear that applying voltage

excitation of the pulse has produced an effective pulse which

in turn increased material erosion and surface quality. The

inuence of the current impulse on machining tungsten

carbide and SKD die steel with electrolytic copper tool

electrode in the EDM process has been investigated by Tsai

and Lu [15]. From the experimental results, it has been found

that the material removal rate and tool wear rate have been

affected by the energy density. Muthuramalingam and Mohan

discussed about inuence of discharge current impulse on the

performance measures in EDM process [16].

Son et al. investigated the inuences of electrical pulse

condition on the machining characteristics in the EDM process

[17]. It has been found that the duration of pulse considerably

affects the machining characteristics such as material removal

rate, tool wear rate and surface accuracy. It has also been

realized that the shorter EDM pulse could be efcient to make a

precision part. Liu et al. described the inuence of the EDM

discharge pulse shape on the machining characteristics such

as material removal mechanism of Si3N4TiN [18]. The surface

texture of machined workpiece has been investigated with

different form of discharge pulse such as relaxation and iso

current pulse. It has been proved that uniform discharge

energy has produced good surface topography. Janardhan and

Samuel analyzed the effect of machining parameters on

material removal rate and average surface roughness using

the pulse train data acquired at the spark gap with the help of

MATLAB software package [19]. It has been observed that the

material erosion rate has been increased with decrease in the

pulse off time in EDM process. Yeo et al. proposed a new pulse

discriminating technique for monitoring electrical discharge

machining process [20]. This system has employed the current

pulse as the main detecting parameter as it has been

considered to be a better representation of the spark energy

inside the plasma channel as compared to the voltage. There

should be less arcing effect to enhance the surface nish for an

ideal EDM process. Muthuramalingam and Mohan discussed

and proved that the uniform duration pulse shape for the

discharging phenomenon in EDM process has improved the

surface quality of the workpiece with less arcing effect [21].

5.

Inuence of electrical process parameters

on performance measures

Fig. 3 Relation between pulse shape and machining

characteristics in EDM process.

There are many research works that have been conducted to

nd the inuence of process parameters especially electrical

Please cite this article in press as: T. Muthuramalingam, B. Mohan, A review on inuence of electrical process parameters in EDM process,

Archives of Civil and Mechanical Engineering (2014), http://dx.doi.org/10.1016/j.acme.2014.02.009

ACME-201; No. of Pages 8

archives of civil and mechanical engineering xxx (2014) xxxxxx

Fig. 4 SEM images of surface using EDM process.

process parameters on EDM process. Most of the research

works reveal that the discharge current and machining time

have the most inuencing nature on the EDM performance

measures. Fig. 4 shows the SEM images of EDM surface while

machining AISI 202 stainless steel with tungsten carbide tool

electrode.

Gostimirovic et al. investigated the effects of electrical

process parameters on the performances of die-sinking

electrical discharge machining process with RC pulse generator

while machining manganese-vanadium tool steel workpiece

using graphite tool electrode. They found that the discharge

current and pulse duration have highly inuenced the material

removal rate of the EDM process [22]. Mohan et al. analyzed the

effect of EDM process parameters such as electrode material,

polarity, pulse duration, current and rotation of the electrode on

the material removal rate, tool wear rate and surface roughness

[23]. It has been found that the material removal rate and tool

wear rate have been increased with the discharge current during

machining process. Nowicki et al. analyzed the effects

individual electrical discharge on the crater volume of the

workpiece in EDM process [24]. They found that the crater

surface exhibits strong interaction with the electrical discharge

spark. Mohan et al. investigated the surface roughness of the

SiC/6025Al composite surface using electrical discharge machining process with brass as the tool electrode [25]. From the

experimental results, it has been observed that increasing peak

current has resulted in higher surface roughness during the

machining process.

Seo et al. discussed about the drilling process of a

functionally graded 1535 vol.% of silicon carbide particulate

reinforced Al359 metal matrix composite by electrical discharge

machining process to assess the machinability and workpiece

quality [26]. It has been observed that the peak current and pulse

on time have increased the material removal rate. It has also

been reported that increase in percentage SiC particles has

increased the material removal rate and electrode wear rate.

Puertas et al. carried out a study on the inuence of the factors of

current intensity, pulse time and duty cycle over the material

removal rate, surface quality and electrode wear rate [27]. They

modeled the relationship between the input parameters and

response parameters in the die-sinking EDM process using

response surface methodology. It has been concluded that the

lower values of the current intensity and the machining time

have to be used in order to obtain a good surface nish. The use

of the dimensional analysis for investigating the effects of the

electrical and the physical parameters on the material removal

rate of a die-sinking EDM process has been described by Yahya

and Manning [28]. From the experimental results, it has been

found that the material removal rate has been increased with

discharge current, gap voltage and pulse on time.

Huang et al. made an attempt to unveil the inuence of the

process parameters on the machining performances in the EDM

process [29]. It has been found that the pulse on time and spark

gap have the most signicant nature to affect the performance

measures such as surface roughness and white layer depth

using numerical analysis. Kuppan et al. reported about the

experimental investigation of small deep hole drilling of Inconel

718 with electrolytic copper tool electrode using the electrical

discharge machining process [30]. The experimental results

have shown that the material removal rate has been increased

with the increase in the peak current and duty factor. Patel et al.

investigated the feasibility of fabricating micro holes in SiCpAl

composites using electrical discharge machining with a rotary

tube electrode [31]. They have investigated the material removal

rate, electrode wear rate and hole tapper as the responses for the

study. The experimental results have revealed that pulse on

duration has signicantly affected the response characteristics

involved in EDM process. Pelicer et al. focused on investigating

the inuence of EDM process parameters and electrode

geometry on feature micro accuracy on tool steel for mold

fabrication purposes [32]. A set of designed experiments with

varying process parameters such as pulse current, open voltage

and pulse duration have been carried out in H13 steel using

different shaped copper electrodes. It has been concluded that

the triangular shaped electrode would produce highly inefcient output, since the fast wearing nature of the electrode

edges. Wang et al. carried out a series of experiments to

investigate the impacts of machining polarity, electrode

rotation speed and nominal capacitance on the material

removal rate and tool wear rate with poly crystalline diamond

[33]. It has been demonstrated that favorable machining

performance of EDM process on the workpiece could be

achieved in tool with negative polarity as compared to the

positive polarity.

Tosun et al. presented an investigation on the effect and

optimization of machining parameters on kerf and material

removal rate in wire EDM process with Taguchi method [34]. The

experimental studies have been conducted under varying pulse

duration, gap voltage, wire speed and ushing pressure with

AISI 4140 steel as workpiece material. Based on the ANOVA

method, the high effective parameter on both kerf and material

removal rate has been found as pulse duration. Ji et al. presented

a new process of machining SiC ceramics using electrical

discharge milling process [35]. The effects of tool polarity, pulse

duration, voltage and peak current on the process performances

such as material removal rate, electrode wear rate and surface

roughness have been investigated. It has been found that the

negative polarity tool electrode with longer pulse duration has

produced high material removal rate and surface roughness.

Rebelo et al. presented an experimental study on the effect of

Please cite this article in press as: T. Muthuramalingam, B. Mohan, A review on inuence of electrical process parameters in EDM process,

Archives of Civil and Mechanical Engineering (2014), http://dx.doi.org/10.1016/j.acme.2014.02.009

ACME-201; No. of Pages 8

archives of civil and mechanical engineering xxx (2014) xxxxxx

electric discharge machining parameters on material removal

rate and surface quality with high strength copperberyllium

alloys [36]. They found that the plasma diameter has been

decreased with pulse duration and discharge current during the

machining process.

Yu et al. examined the use of electrical discharge machining on machining poly-crystalline silicon [37]. The effects of

different WEDM process parameters on machining characteristics have been explored. From the experimental results, it

has been indicated that the pulse on time has the great

inuence on the cutting speed in Wire EDM process. Batish

et al. investigated the effect of process parameters and

mechanism of material deposition in electric discharge

machining on surface properties of EN31, H11 and high carbon

high chromium die steel materials [38]. It has been discussed

about material transfer mechanism involved in EDM process.

It has been found that die steels have been machined

effectively with copper tool electrode using EDM process.

Patel et al. presented a detailed experimental investigation of

machining characteristics such as surface integrity and

material removal mechanisms of advanced ceramic composite Al2O3SiCwTiC with EDM process [39]. It has been

concluded that the surface roughness and material removal

rate have been increased with pulse duration in EDM process.

6.

Inuence of discharge energy on

performance measures

In view of the fact that when the discharge energy is converted

into the thermal energy to melt and vaporize the material in

EDM process, it is unavoidable to discuss the inuence of the

pulse energy on the machining characteristics in such a

process.

Jahan et al. conducted an experimental investigation with

the view of obtaining ne surface nish in die-sinking EDM

process of tungsten carbide using different tool electrodes

such as tungsten, copper tungsten and silver tungsten [40]. It

has been found that the surface nish has been inuenced by

the discharge energy during machining process. It has been

realized that the lower discharge energy has produced good

surface nish. Yeo et al. discussed about the machining of

zirconium based bulk metallic glass by EDM process with

different tool electrodes such as copper, brass and tungsten

rod electrode [41]. The experimental results have shown

that the usage of lower input energy has produced the

lower surface roughness and electrode tool wear. Khanra

et al. investigated the inuence of energy input on the

workpiece surface during the machining in the EDM process.

In this experimental investigation, a well-polished mild steel

(C 0.18%) plate has been used for machining by EDM [42]. It has

been observed that the energy input has inuenced the debris

particle size in the EDM process.

Popa et al. showed the importance of optimizing the

process parameters that could inuence the quality of the EDM

process [43]. They formulated the equation of crater depth in

terms of discharge energy in EDM process. From the relation, it

has been observed that the crater depth has been increased

with the discharge current owing through the workpiece and

tool electrode. Kojima et al. described about the spectroscopic

measurement of arc plasma diameter in EDM [44]. They found

that the arc plasma has been increased with increasing

discharge current. It has been veried that crater diameter and

depth decrease with increasing gap width due to the increased

plasma diameter. The arc plasma diameter has been increased

with increasing spark gap and thus claried the reason for

lower material removal rate and smoother surface nish with

longer spark gap. Wong et al. developed a single spark pulse

generator using resistancecapacitance arrangement to study

the erosion characteristics in the EDM process from the crater

size [45].

The volume and size of the craters have been found to be

more consistent at lower energy discharge sparks than the

higher energy discharge sparks. The higher energy pulse leads

to the micro surface crack on the work surface. Guu et al.

aimed to investigate the machining characteristics of manganesezinc ferrite magnetic materials using electrical discharge

machining process [46]. The experimental results have

indicated that the morphology of debris revealed the mechanism of material removal. It has been observed that the better

machined surface has been obtained by setting process

parameters at low pulse energy. Nowicki et al. made an

attempt to machine supercial layer of the workpiece using

brush EDM process by modifying the spark energy [47]. The

theoretical modeling of the EDM process based upon the heat

transfer equations has been established by Singh [48]. In the

study, the input energy equation has been developed as a

function of pulse duration, current, polarity of electrode and

properties of the workpiece and tool electrodes. This model

has been helpful to calculate the optimal process parameters

for obtaining optimum discharge energy.

7.

Monitoring and control of the EDM process

The EDM process parameters have to be monitored during the

machining process so that the controlling of those parameters

can be done to obtain the required response parameters. The

main action of monitoring and controlling the process is to

observe and measure process parameters to reduce the

deviation of performance measures from the expected level.

An adaptive control system for process monitoring,

identication and control in the wire electrical discharge

machining process has been developed by Yan [49]. It has been

realized that the wire breaking has been controlled by

adjustment of pulse interval of each pulse cycle of supply.

Caydas et al. developed an adaptive neuro-fuzzy inference

system model for the prediction of the surface roughness of

machined surface using wire EDM process as a function of

process parameters such as open circuit voltage, pulse

duration and wire feed rate [50]. From the experimental

results, it has been found that the proposed control system has

improved the surface quality in EDM process.

Yilmaz et al. introduced a used friendly intelligent system

based on the knowledge of the skilled operators for the

selection of the EDM process parameters for machining AISI

4340 stainless steel [51]. The system has been provided with a

compact selection tool based on expert rules and enabled an

unskilled user to select necessary parameters which lead to

lower electrode wear rate and better surface quality. Zhou and

Please cite this article in press as: T. Muthuramalingam, B. Mohan, A review on inuence of electrical process parameters in EDM process,

Archives of Civil and Mechanical Engineering (2014), http://dx.doi.org/10.1016/j.acme.2014.02.009

ACME-201; No. of Pages 8

archives of civil and mechanical engineering xxx (2014) xxxxxx

Han developed an adaptive control system which directly and

automatically has regulated the tool down time for improving

the process performance in EDM process [52]. It has been

observed that this adaptive system would improve the

machining rate, due to the automatic adjustment of spark

gap. Yan and Chien developed a new pulse discriminating and

control system for process monitoring in EDM process [53]. The

effects of pulse interval, machining feed rate and workpiece on

the variation of the proportion of normal spark, arc and short

circuit in the total spark have been discussed. The experimental results have indicated that the developed control system

has signicantly reduced the arc discharge in EDM process to

achieve stable machining.

Chang designed a proportional derivative controller of the

spark gap between an electrode and a workpiece to analyze the

non-linearity involved in EDM process [54]. They concluded

that this non-linearity has reduced the effective discharge in

electrical discharge machining process. Behrens and Ginzel

proposed a neuro-fuzzy based gap width controller for a highly

efcient removal mechanism in EDM process [55]. The

experimental results have indicated that the proposed

controller has enhanced EDM process to achieve the better

surface nish of workpiece. Kao and Shih monitored the

discharge current in electrical discharge machining using high

speed data acquisition with high frequency response [56].

From the experimental results, it has been found that decrease

in air gap between tool and workpiece has improved the

material removal rate in EDM process.

Tong et al. designed an experimental system with a macro/

micro dual feed spindle to improve the machining performance of servo scanning micro EDM process, which utilized an

ultrasonic linear motor as the macro drive and a piezoelectric

actuator as micro feeding mechanism [57]. Based on LabVIEW

software package, a real time control system has been

developed to control coordinately the dual-feed spindle to

drive the tool electrode. Fenggou and Dayong presented a

method to automatically determine and optimize the process

parameters on the EDM sinking process with the application of

articial neural network [58]. The experimental results have

proved that automatic determination of current value would

be the efcient method on improving EDM performance.

8.

Modeling of EDM process parameters

The process parameters modeling helps to analyze the

inuence process parameters on the machining characteristics in any of the machining process. This section is

discussed about the mathematical modeling of process

parameters and simulation models in the EDM process.

8.1.

Theoretical modeling of EDM process

Since the two electrical conductors such as tool electrode and

workpiece are separated by a dielectric medium, the EDM

arrangement can be modeled as a capacitor. Liu et al.

constructed a plate capacitor model for electrical discharge

machining process [59]. The correlation actions of process

parameters and energy distribution have been discussed

based on the eld electron emission theory. It has been

observed that machining time plays a major role to improve

the process efciency. Das and Joshi developed a comprehensive mathematical model to predict the spark erosion rate

involved in EDM process [60]. They found that the plasma

current and plasma radius have been increased with pulse

duration. Salonitis et al. developed the thermal based model

for the determination of the material removal rate and average

surface roughness achieved as a function of the process

parameters in the EDM process [61]. Spadlo et al. developed a

thermo model for brush electrical discharge alloying process

[62]. It has been realized that material removal depends on the

discharge current pulse owing through the dielectric medium.

8.2.

Optimization of EDM process

Most of the research works have been carried out to optimize

the electrical process parameters in EDM process. Marafona

and Wykes described an investigation into the optimization of

material removal rate in the electric discharge machining

process with copper tungsten tool electrode [63]. From the

experimental results, it has been proved that large current

intensity would result in higher material removal rate.

Matoorian et al. presented the application of the Taguchi

robust design methods to optimize the precision and accuracy

of the EDM process for machining of precise cylindrical forms

on hard and difcult-to-machine materials [64]. They found

that the current intensity of the EDM process affects the

material removal rate greatly. Muthuramalingam and Mohan

developed Taguchi-DEAR methodology based optimization of

electrical process parameters [65]. Tzeng and Chen described

about the application of the fuzzy logic analysis coupled with

Taguchi methods to optimize the precision and accuracy of the

high speed electrical discharge machining process [66]. The

most important factors affecting the precision and accuracy of

the high speed EDM process have been identied as duty cycle

and peak current. Kuriakose and Shunmugam developed a

multiple regression model to represent relationship between

the input and output process variables [67]. They have done

the multi objective optimization method based on nondominated sorting genetic algorithm to optimize the EDM

process parameters.

9.

Conclusion

The present study discussed about the review of contribution

of electrical process parameters for efcient EDM process in

various aspects such as state of art, inuence of the discharge

energy, modeling of EDM process parameters, pulse generators, pulse shape, monitoring the parameters and optimization of EDM process parameters. The review has been carried

out in all aspects and types of EDM process such as die-sinking

EDM, wire EDM and micro EDM. The following conclusions can

be mainly made based on the literatures:

(i) Most of the literatures have discussed about inuence of

process parameters on the performance measures,

modeling and optimization of process parameters involved in the electro erosion process.

Please cite this article in press as: T. Muthuramalingam, B. Mohan, A review on inuence of electrical process parameters in EDM process,

Archives of Civil and Mechanical Engineering (2014), http://dx.doi.org/10.1016/j.acme.2014.02.009

ACME-201; No. of Pages 8

archives of civil and mechanical engineering xxx (2014) xxxxxx

(ii) It has been found that peak current and pulse duration are

dominating the performance measures in EDM process.

(iii) It has been observed that only less attention has been

given for enhancing the electrical process parameters in

EDM process in terms of pulse modication, monitoring

and adaptive controlling of the process parameters.

(iv) It has also been observed that only very few literatures are

available describing the hybrid modern manufacturing

techniques such as electro chemical discharge machining

(ECDM).

references

[1] E.C. Jameson, Electrical Discharge Machining, rst ed.,

Society of Manufacturing Engineers, Michigan, 2001.

[2] K.H. Ho, S.T. Newman, State of the art electrical discharge

machining (EDM), International Journal of Machine Tools and

Manufacture 43 (2003) 12871300.

[3] N.M. Abbas, D.G. Solomon, M. Fuad Bahari, A review on

current research trends in electrical discharge machining,

International Journal of Machine Tools and Manufacture 47

(2007) 12141228.

[4] S. Kumar, R. Singh, T.P. Singh, B.L. Sethi, Surface modication

by electrical discharge machining: a review, Journal of

Materials Processing Technology 209 (2009) 36753687.

[5] M.P. Jahan, Y.S. Wong, M. Rahman, A study on the ne-nish

die-sinking micro EDM of tungsten carbide using different

electrode materials, Journal of Materials Processing

Technology 209 (2009) 39563967.

[6] F. Han, L. Chen, D. Yu, X. Zhou, Basic study on pulse

generator for micro EDM, International Journal of Advanced

Manufacturing Technology 33 (2007) 474479.

[7] M.T. Yan, Y.T. Liu, Design analysis and experimental study of

a high frequency power supply for nish cut of wire EDM,

International Journal of Machine Tools and Manufacture 49

(2009) 793796.

[8] M.T. Yan, T.L. Chiang, Design and experimental study of a

power supply for micro wire EDM, International Journal of

Advanced Manufacturing Technology 40 (2009) 11111117.

[9] T. Muthuramalingam, B. Mohan, Enhancing the surface

quality process by iso pulse generator in EDM process,

Advanced Materials Research 622/623 (2013) 375380.

[10] F. Han, S. Wachi, M. Kunieda, Improvement of machining

characteristics of micro-EDM using transistor type iso pulse

generator and servo feed control, Precision Engineering 28

(2004) 378385.

[11] M.T. Yan, Y.P. Lai, Surface quality improvement of wire-EDM

using a ne-nish power supply, International Journal of

Machine Tools and Manufacture 47 (2007) 16861694.

[12] T. Muthuramalingam, B. Mohan, Design and fabrication of

control system based iso pulse generator for electrical

discharge machining, International Journal of Mechatronics

and Manufacturing Systems 6 (2013) 133143.

[13] R. Casanueva, F.J. Azcondo, S. Bracho, Series-parallel

resonant converter for an EDM power supply, Journal of

Materials Processing Technology 149 (2004) 172177.

[14] M. Ghoreishi, C. Tabari, Investigation into the effect of

voltage excitation of pre-ignition spark pulse on the electrodischarge machining process, Materials and Manufacturing

Processes 22 (2007) 833841.

[15] Y.Y. Tsai, C.T. Lu, Inuence of current impulse on machining

characteristics in EDM, Journal of Mechanical Science and

Technology 21 (2007) 16171621.

[16] T. Muthuramalingam, B. Mohan, Inuence of discharge

current pulse on machinability in electrical discharge

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

[32]

[33]

[34]

machining, Materials and Manufacturing Processes 28

(2013) 375380.

S.M. Son, H.S. Lim, A.S. Kumar, M. Rahman, Inuences of

pulsed power condition on the machining properties in micro

EDM, Journal of Materials Processing Technology 190 (2007)

7376.

K. Liu, D. Reynaerts, B. Lauwers, Inuence of the pulse shape

on the EDM performance of Si3N4TiN ceramic composite,

CIRP Annals Manufacturing Technology 58 (2009) 217220.

V. Janardhan, G.L. Samuel, Pulse train data analysis to

investigate the effect of machining parameters on the

performance of wire electro discharge turning process,

International Journal of Machine Tools and Manufacture 50

(2010) 775788.

S.H. Yeo, E. Aligiri, P.C. Tan, H. Zarepour, A new pulse

discriminating system for micro-EDM, Materials and

Manufacturing Processes 24 (2009) 12971305.

T. Muthuramalingam, B. Mohan, Experimental investigation of

iso energy pulse generator on performance measures in EDM,

Materials and Manufacturing Processes 28 (2013) 11371142.

M. Gostimirovic, P. Kovac, B. Skoric, M. Sekulic, Effect of

electrical process parameters on the machining performance

in EDM, Indian Journal of Engineering and Materials Sciences

18 (2012) 411415.

B. Mohan, A. Rajadurai, K.G. Satyanarayana, Effect of SiC and

rotation of electrode on electric discharge machining of Al

SiC composite, Journal of Materials Processing Technology

124 (2002) 297304.

B. Nowicki, A. Dmowska, A.P. Lejtas, Morphology of traces

made by individual electric discharge in the EDM, Advances

in Manufacturing Science and Technology 33 (2009) 524.

B. Mohan, A. Rajadurai, K.G. Satyanarayana, Electric

discharge machining of AlSiC metal matrix composites

using rotary tube electrode, Journal of Materials Processing

Technology 153/154 (2004) 978985.

Y.W. Seo, D. Kim, M. Ramulu, Electrical discharge machining

of functionally graded 1535 vol% SiCp/Al composites,

Materials and Manufacturing Processes 21 (2006) 479487.

I. Puertas, C.J. Luis, L. Alvarez, Analysis of the inuence of

EDM parameters on surface quality, MRR and EW of WC-Co,

Journal of Materials Processing Technology 153/154 (2004)

10261032.

A. Yahya, C.D. Manning, Determination of material removal

rate of an electro discharge machine using dimensional

analysis, Journal of Physics D: Applied Physics 37 (2004)

14671471.

J.T. Huang, Y.S. Liao, W.J. Hsue, Determination of nishcutting operation number and machining parameters setting

in wire electrical discharge machining, Journal of Materials

Processing Technology 87 (1999) 6981.

P. Kuppan, A. Rajadurai, S. Narayanan, Inuence of EDM

process parameters in deep hole drilling of Inconel 718,

International Journal of Advanced Manufacturing Technology

38 (2008) 7484.

K.M. Patel, P.M. Pandey, P.V. Rao, Understanding the role of

weight percentage and size of silicon carbide particulate

reinforcement on electro-discharge machining of aluminium

based composites, Materials and Manufacturing Processes 23

(2008) 665673.

N. Pelicer, J. Ciurana, T. Ozel, Inuence of process parameters

and electrode geometry on feature micro-accuracy in electro

discharge machining of tool steel, Materials and Manufacturing

Processes 24 (2009) 12821289.

D. Wang, W.S. Zhao, L. Gu, X.M. Kang, A study on micro hole

machining of poly crystalline diamond by micro- electrical

discharge machining, Journal of Materials Processing

Technology 211 (2011) 311.

N. Tosun, C. Cogun, G. Tosun, A study on kerf and material

removal rate in wire electrical discharge machining based on

Please cite this article in press as: T. Muthuramalingam, B. Mohan, A review on inuence of electrical process parameters in EDM process,

Archives of Civil and Mechanical Engineering (2014), http://dx.doi.org/10.1016/j.acme.2014.02.009

ACME-201; No. of Pages 8

archives of civil and mechanical engineering xxx (2014) xxxxxx

[35]

[36]

[37]

[38]

[39]

[40]

[41]

[42]

[43]

[44]

[45]

[46]

[47]

[48]

[49]

[50]

Taguchi method, Journal of Materials Processing Technology

152 (2004) 316322.

R. Ji, Y.H. Liu, Y.Z. Zhang, B.O. Cai, X.P. Li, High speed end

electric discharge milling of silicon carbide ceramics,

Materials and Manufacturing Processes 26 (2011) 10501058.

J.C. Rebelo, A.M. Dias, R. Mesquita, P. Vassalo, M. Santos, An

experimental study on electro-discahrge machining and

polishing of high strength copperberyllium alloys, Journal

of Materials Processing Technology 103 (2000) 389397.

P.H. Yu, H.K. Lee, Y.X. Lin, S.J. Qin, Machining characteristics

of poly crystalline silicon by wire electrical discharge

machining, Materials and Manufacturing Processes 26

(2011) 14431450.

A. Batish, A. Bhattacharya, V.K. Singla, G. Singh, Study of

material transfer mechanism in die steels using powder

mixed electric discharge machining, Materials and

Manufacturing Processes 27 (2012) 449456.

K.M. Patel, P.M. Pandey, P.V. Rao, Surface integrity and

material removal mechanisms associated with the EDM of

Al2O3 ceramic composite, International Journal of Refractory

Metals and Hard Materials 27 (2009) 892899.

M.P. Jahan, Y.S. Wong, M. Rahman, A study on the quality

micro-hole machining of tungsten carbide by micro-EDM

process using transistor and RC-type pulse generator, Journal

of Materials Processing Technology 209 (2009) 17061716.

S.H. Yeo, P.C. Tan, E. Aligiri, S.B. Tor, N.H. Loh, Processing of

zirconium based bulk metallic glass using micro electrical

discharge machining, Materials and Manufacturing Processes

24 (2009) 12421248.

A.K. Khanra, L.C. Pathak, M.M. Godkhindi, Micro analysis of

debris formed during electrical discharge machining, Journal

of Materials Science 42 (2007) 872877.

M.S. Popa, G. Contiu, G. Pop, P. Dan, New technologies and

applications of EDM process, The International Journal of

Material Forming 2 (2009) 633636.

A. Kojima, W. Natsu, M. Kunieda, Spectroscopic

measurement of arc plasma diameter in EDM, CIRP Annals

Manufacturing Technology 57 (2008) 203207.

Y.S. Wong, M. Rahman, H.S. Lim, H. Han, N. Ravi,

Investigation of micro-EDM material removal characteristics

using single RC-pulse discharges, Journal of Materials

Processing Technology 140 (2003) 303307.

Y.H. Guu, K.L. Tsai, L.K. Chen, An experimental study on

electrical discharge machining of manganesezinc ferrite

magnetic material, Materials and Manufacturing Processes 22

(2007) 6670.

B. B. Nowicki, R. Pierzynowski, S. Spadlo, The supercial layer

of parts machined by brush electro discharge mechanical

machining (BEDMM), Proceedings of the Institution of

Mechanical Engineers Part B: Journal of Engineering

Manufacture 218 (2004) 18.

H. Singh, Experimental study of distribution of energy during

EDM process for utilization in thermal models, International

Journal of Heat and Mass Transfer 55 (2012) 50535064.

M.T. Yan, An adaptive control system with self organizing

fuzzy sliding mode control strategy for micro wire EDM

machine, International Journal of Advanced Manufacturing

Technology 50 (2010) 315328.

U. Caydas, A. Hascalik, Modeling and analysis of electrode

wear and white layer thickness in die-sinking EDM process

[51]

[52]

[53]

[54]

[55]

[56]

[57]

[58]

[59]

[60]

[61]

[62]

[63]

[64]

[65]

[66]

[67]

through response surface methodology, International Journal

of Advanced Manufacturing Technology 38 (2008) 11481156.

O. Yilmaz, O. Eyercioglu, N.N.Z. Gindy, A user friendly fuzzy

based system for the selection of electro discharge

machining process parameters, Journal of Materials

Processing Technology 172 (2006) 363371.

M. Zhou, F. Han, Adaptive control for EDM process with a self

tuning regulator, International Journal of Machine Tools and

Manufacture 49 (2009) 462469.

M.T. Yan, H.T. Chien, Monitoring and control of the micro

wire-EDM process, International Journal of Machine Tools

and Manufacture 47 (2007) 148157.

X.F. Chang, Mixed H2/H1 optimization approach to gap control

on EDM, Control Engineering Practice 13 (2005) 95104.

A. Behrens, J. Ginzel, Neuro-fuzzy processes control system

for sinking EDM, Journal of Manufacturing Processes 5 (2003)

3339.

C.C. Kao, A.J. Shih, Sub-nano second monitoring of microhole electrical discharge machining pulses and modeling of

discharge ringing, International Journal of Machine Tools and

Manufacture 46 (2006) 19962008.

H. Tong, Y. Li, Y. Wang, D. Yu, Servo scanning 3D micro-EDM

based on macro/micro dual feed machine, International

Journal of Machine Tools and Manufacture 48 (2008) 858869.

C. Fenggou, Y. Dayong, The study of high efciency and

intelligent optimization system in EDM sinking process,

Journal of Materials Processing Technology 149 (2004) 8387.

S. Liu, Y. Huang, Y. Li, A plate capacitor model of the EDM

process based on the eld emission theory, International

Journal of Machine Tools and Manufacture 51 (2011) 653659.

S. Das, S.S. Joshi, Modelling of spark erosion rate in micro

wire-EDM, International Journal of Advanced Manufacturing

Technology 48 (2010) 581596.

K. Salonitis, A. Stournaras, P. Stavropoulos, G. Chryssolouris,

Thermal modeling of the material removal rate and surface

roughness for die-sinking EDM, International Journal of

Advanced Manufacturing Technology 40 (2009) 316323.

S. Spadlo, J. Kozak, P. Mlynarczyk, Mathematical modelling of

the electrical discharge mechanical alloying process,

Procedia CIRP 6 (2013) 423427.

J. Marafona, C. Wykes, A new method of optimizing material

removal rate using EDM with coppertungsten electrodes,

International Journal of Machine Tools and Manufacture 40

(2000) 153164.

P. Matoorian, S. Sulaiman, M.M.H.M. Ahmed, An

experimental study for optimization of electrical discharge

turning process, Journal of Materials Processing Technology

204 (2008) 350356.

T. Muthuramalingam, B. Mohan, Multi response optimization

of electrical process parameters on machining characteristics

in EDM using Taguchi-DEAR methodology, Journal of

Engineering Technology 3 (2013) 5760.

Y.F. Tzeng, F.C. Chen, Multi objective optimisation of high

speed electrical discharge machining process using Taguchi

fuzzy based approach, Materials and Design 28 (2007)

11591168.

S. Kuriakose, M.S. Shunmugam, Multi-objective optimization

of wire-electrical discharge machining process by nondominated sorting genetic algorithm, Journal of Materials

Processing Technology 170 (2005) 133141.

Please cite this article in press as: T. Muthuramalingam, B. Mohan, A review on inuence of electrical process parameters in EDM process,

Archives of Civil and Mechanical Engineering (2014), http://dx.doi.org/10.1016/j.acme.2014.02.009

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Decision MatrixDocument12 pagesDecision Matrixrdos14No ratings yet

- Chapter 3 - Basic Logical Concepts - For Students PDFDocument65 pagesChapter 3 - Basic Logical Concepts - For Students PDFTiên Nguyễn100% (1)

- What Is Science Cornell Notes ExampleDocument3 pagesWhat Is Science Cornell Notes Exampleapi-240096234No ratings yet

- Bhagavadgita With Samkara's CommentaryDocument199 pagesBhagavadgita With Samkara's Commentarysiddy_777No ratings yet

- Manyu Suktam EnglishDocument2 pagesManyu Suktam EnglishvedavakNo ratings yet

- Non Rgvedic Citations in The Asvalayana Srautasutra A StudyDocument442 pagesNon Rgvedic Citations in The Asvalayana Srautasutra A Studysiddy_777No ratings yet

- EDM of Inconel 718 Using Hollow ToolDocument10 pagesEDM of Inconel 718 Using Hollow Toolsiddy_777No ratings yet

- The First Volume of The Encyclopedic Compendium On The Shrauta SystemDocument572 pagesThe First Volume of The Encyclopedic Compendium On The Shrauta Systemsiddy_777No ratings yet

- On The Succession of The Hindu Priesthood. The B Rigus, Añgiras, and Atharvans, and The Historical Evidence Thence DerivedDocument80 pagesOn The Succession of The Hindu Priesthood. The B Rigus, Añgiras, and Atharvans, and The Historical Evidence Thence Derivedsiddy_777No ratings yet

- Index Verborum To The Published Text of The Atharva VedaDocument384 pagesIndex Verborum To The Published Text of The Atharva Vedasiddy_777No ratings yet

- Part One of The Second Volume of The Kosha On ShrautamDocument425 pagesPart One of The Second Volume of The Kosha On Shrautamsiddy_777100% (1)

- Citations in Sabara BhasyaDocument310 pagesCitations in Sabara Bhasyasiddy_777No ratings yet

- Complete EDM Handbook - 12 PDFDocument0 pagesComplete EDM Handbook - 12 PDFds_srinivasNo ratings yet

- Abhāvapramā A and Error in Kumārila's CommentatorsDocument29 pagesAbhāvapramā A and Error in Kumārila's Commentatorssiddy_777No ratings yet

- Kumarila's Notion of PauruseyavacanaDocument17 pagesKumarila's Notion of Pauruseyavacanasiddy_777No ratings yet

- Action, Desire and the Emergence of Subjectivity in Prābhākara MīmāṃsāDocument28 pagesAction, Desire and the Emergence of Subjectivity in Prābhākara Mīmāṃsāsiddy_777No ratings yet

- Free Will in Mīmā SāDocument21 pagesFree Will in Mīmā Sāsiddy_777No ratings yet

- The Nations of India at The Battle Between The Pandavas and KauravasDocument30 pagesThe Nations of India at The Battle Between The Pandavas and Kauravassiddy_777No ratings yet

- Political History of Ancient IndiaDocument381 pagesPolitical History of Ancient Indiasiddy_777100% (2)

- Kumārila's Defence of RealismDocument12 pagesKumārila's Defence of Realismsiddy_777No ratings yet

- VazihistaDocument33 pagesVazihistasiddy_777No ratings yet

- Kuru KingsDocument10 pagesKuru Kingssiddy_777No ratings yet

- The Pandyan KingdomDocument256 pagesThe Pandyan KingdomSharmalan ThevarNo ratings yet

- A Comment On Sankara's Commentary On Bhagavadgita Xviii.1 PDFDocument11 pagesA Comment On Sankara's Commentary On Bhagavadgita Xviii.1 PDFsiddy_777No ratings yet

- Clinic Management System (24 PGS)Document24 pagesClinic Management System (24 PGS)pranithNo ratings yet

- The Stolen Bacillus - HG WellsDocument6 pagesThe Stolen Bacillus - HG Wells1mad.cheshire.cat1No ratings yet

- 62046PSYCHICSDocument1 page62046PSYCHICSs0hpokc310No ratings yet

- HAU Theology 103 Group Goal Commitment ReportDocument6 pagesHAU Theology 103 Group Goal Commitment ReportEM SagunNo ratings yet

- Digital Logic Design: Dr. Oliver FaustDocument16 pagesDigital Logic Design: Dr. Oliver FaustAtifMinhasNo ratings yet

- Vocabulary Prefixes ExercisesDocument2 pagesVocabulary Prefixes ExercisesMarina García CarrascoNo ratings yet

- Space Gass 12 5 Help Manual PDFDocument841 pagesSpace Gass 12 5 Help Manual PDFNita NabanitaNo ratings yet

- Mind MapDocument1 pageMind Mapjebzkiah productionNo ratings yet

- Menggambar Dengan Mode GrafikDocument30 pagesMenggambar Dengan Mode GrafikkurniawanNo ratings yet

- Policarpio 3 - Refresher GEODocument2 pagesPolicarpio 3 - Refresher GEOJohn RoaNo ratings yet

- The Basics of Hacking and Pen TestingDocument30 pagesThe Basics of Hacking and Pen TestingAnonNo ratings yet

- Honey Commission InternationalDocument62 pagesHoney Commission Internationallevsoy672173No ratings yet

- Neptune Sign House AspectDocument80 pagesNeptune Sign House Aspectmesagirl94% (53)

- Reich Web ADocument34 pagesReich Web Ak1nj3No ratings yet

- A Personality Trait-Based Interactionist Model of Job PerformanceDocument18 pagesA Personality Trait-Based Interactionist Model of Job PerformanceAlvina AhmedNo ratings yet

- DELA PENA - Transcultural Nursing Title ProposalDocument20 pagesDELA PENA - Transcultural Nursing Title Proposalrnrmmanphd0% (1)

- SYS600 - Visual SCIL Application DesignDocument144 pagesSYS600 - Visual SCIL Application DesignDang JinlongNo ratings yet

- BUDDlab Volume2, BUDDcamp 2011: The City of Euphemia, Brescia / ItalyDocument34 pagesBUDDlab Volume2, BUDDcamp 2011: The City of Euphemia, Brescia / ItalyThe Bartlett Development Planning Unit - UCLNo ratings yet

- Manzano's and Kendall Taxonomy of Cognitive ProcessesDocument5 pagesManzano's and Kendall Taxonomy of Cognitive ProcessesSheena BarulanNo ratings yet

- Learn Six Sigma Process and Methodology BasicsDocument4 pagesLearn Six Sigma Process and Methodology BasicsGeorge MarkasNo ratings yet

- Tabelas Normativas DinDocument2 pagesTabelas Normativas DinDeimos PhobosNo ratings yet

- Embedded Systems - RTOSDocument23 pagesEmbedded Systems - RTOSCheril MehtaNo ratings yet

- Configuring Nagios On Client For OSSIMDocument10 pagesConfiguring Nagios On Client For OSSIMMaixender NganareNo ratings yet

- Bluehill BrochureDocument24 pagesBluehill BrochureGeorge SingerNo ratings yet

- Grammar Booster: Lesson 1Document1 pageGrammar Booster: Lesson 1Diana Carolina Figueroa MendezNo ratings yet

- (MCQ) - Arithmetic ProgressionDocument5 pages(MCQ) - Arithmetic Progressionrahul aravindNo ratings yet

- Lasers OpDocument6 pagesLasers OpAndrian PrimadyaNo ratings yet