Professional Documents

Culture Documents

Reliability of 996 Engines Excellence Magazine October 2005

Uploaded by

turbobrik100%(1)100% found this document useful (1 vote)

233 views3 pagesp

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentp

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

233 views3 pagesReliability of 996 Engines Excellence Magazine October 2005

Uploaded by

turbobrikp

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Questions& Answers

BY JIM PASHA

Do you think the 996 engines will be as

reliable as previous 911 engines were?

Is the construction of the new-gen flat six

robust enough to last over 200,000

miles, or 300,000 kilometers?

Easily. The first thing to consider about

the Irquid-cooled 91 1 engine is that the

internal design was intended to make the

rotating engine pieces solid In relationship to all other rotat~ngmasses. What

that means in English is that the crank-

shaft, connecting rods, and pistons were

supposed to be located better.

In earlier Porsche flat sixes, the case

halves provided both the "holder" and reference for the crankshaft and other, critical parts. But, because of the size of the

components and the space available,

some compromises were made - both

in the web sizes and case design. One

traditional weakness in the all-aluminum

Porsche engines was main-web strength.

This goes all the way back to the original

four-cylinder 3561912 englnes.

Over time, normal usage weakens and

distorts the main webs - no matter how

well balanced the rotating masses are. It

may take many miles of use before these

problems show up, but they will occur.

Many 356ers know exactly what I'm talking about - as well as what it costs to

replace a worn-out case. Harry Pellow

had a number of crankcases he used to

This article reprinted with permission of Jim Pasha.

RennTech.org

OCTOBER 2005

excellence 165

show off. These cases looked good, but

they had main webs with so much fatlgue

that they weren't worth salvaging X-ray

inspections revealed most of this.

Porsche has nearly eliminated this possibility in the 996lBoxster engine by utilizing a unique main-case design wlth an

iron main-bearing saddle. The main portion of the case is cast around each set of

pieces In aluminum. Porsche AG decided

to make the cylinders part of the outer

crankcase to simplify the manufacturing

166

excellence

OCTOBER 2005

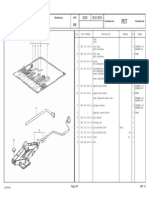

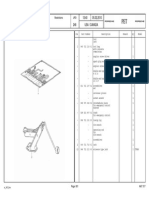

toS of a used Or failed 996 engine have

been rarely, if ever, published and few

the manfacturing process. Connecting rod

independent shops have pulled one of

(top, right) for a 3.4-liter 996 engine; piston

these engines apart. That's partly because

is dished for the four-valve heads. Partially

PorscheAG doesn't make internal pieces

disassembled 996 engine seen in prafile,

available and partly because it offers a

with the iron main-bearing saddle clearly

factory rebuild and exchange program evident (above, left). Another view of the

wlth enough of an incentive that few ownmain-bearing saddle (above, right). Fourers do anythlng other than turn in thelr brovalve 996 cylinder head (left) showed little

ken motors as cores. In this case, though,

wear after 100,000+ miles, though the

our 996 owner opted to purchase a lowchain ramps for the 996's VarioCam timing

mileage engine from a dismantler instead

system did show their age...

of an exchange motor. That left his old 3 4

as a core that we were able to photograph

process. This makes it a complex piece, wlth the help of Wickie Laurie of Renntag

with cylinder liners cast into the alum~num Motorwerks of Nashville, Tennessee.

alloy outer case during the manufacturing

The 296-hp water-cooled, DOHC flat

process. This method of assembly and

six had well over 100,000 miles when it

manufacture is new to Porsche, but it began to exhiblt a compression probyields a robust engine - though there

lem. It was removed from the car and

appears to be ev~dencethat the weak link disassembly revealed upper cylinder

is a need to better locate the rear end of

crack~ngdue to the fuel contamination.

the crankshaft. Time will tell.

Otherwise, the englne was in good conWe recently inspected a 996 engine dition when it was disassembled. The

that suffered serious damage due to (pur- first thing we noticed was that cylinder

posely) contaminated fuel. Internal pho- wear was almost non-existent. The bearCombined cylinder bank/outer crankcase

casting (top, left) was chosen to simplify

This article reprinted with permission of Jim Pasha.

RennTech.org

ings and rings also showed very little

wear, even at 100,000 miles. The chain

ramps for the VarioCam, however,

seemed to have heavy grooving that's

similar to what we've seen on 944S, 944

52, 968, and 928 S4 engines that use

similar tensioner arrangements. The 996

camshaft-drive chains did not appear to

be stretched or damaged, though. At

least these items can be replaced without totally disassembling the engine.

Except for the valid complaints over

rear main seals in both Boxster and 996

models and some early manufacturing

problems, these all-new engines are surprisingly trouble-free - especially in

comparison with Porsche engines of the

early 1970s. We witnessed terrible failures with the air-cooled flat sixes in those

days, from crankcase issues to chain

tensioners to head studs. There have

also been failures in the later air-cooled

engines, from premature valve-guide

wear to cylinder-head sealing issues to

secondary air/CEL failures. Any criticism

of the "new-gen" motors must take these

air-cooled foibles into account, too.

This article reprinted with permission of Jim Pasha.

RennTech.org

OCTOBER 2005

excellence 167

You might also like

- Porsche 356: The Engine Handbook: An Engine Assembly GuideFrom EverandPorsche 356: The Engine Handbook: An Engine Assembly GuideNo ratings yet

- 2014 1 Porsche Turbo Nemturbo 50 EvDocument8 pages2014 1 Porsche Turbo Nemturbo 50 EvBenedek Zoltán100% (1)

- The Mercedes W108, W109 V8 With Buyer's Guide, Chassis Number And Data Card ExplanationFrom EverandThe Mercedes W108, W109 V8 With Buyer's Guide, Chassis Number And Data Card ExplanationNo ratings yet

- Road & Track Iconic Cars: BMW M SeriesFrom EverandRoad & Track Iconic Cars: BMW M SeriesLarry WebsterNo ratings yet

- 911 (996), 1998 - 2005 PDFDocument777 pages911 (996), 1998 - 2005 PDFRadovan NikolcicNo ratings yet

- Porsche 911 Carrera 4S ManualDocument114 pagesPorsche 911 Carrera 4S Manualgraig27100% (1)

- Porsche OptionsDocument16 pagesPorsche OptionsRichard Scotti100% (1)

- L Jetronic For Porsche 912EDocument28 pagesL Jetronic For Porsche 912EAtone Romeo100% (1)

- Porsche 911 Carrera (Type 996) Service Manual: 1999-2005 - Complete IndexDocument11 pagesPorsche 911 Carrera (Type 996) Service Manual: 1999-2005 - Complete IndexBentley Publishers33% (12)

- Porsche 993 Workshop ManualsDocument1,481 pagesPorsche 993 Workshop ManualsAnonymous HyecU1cl386% (22)

- Ferrari Mondial PDFDocument11 pagesFerrari Mondial PDFBennyLouPlummerNo ratings yet

- Porsche Approved Engine OilsDocument5 pagesPorsche Approved Engine OilsRenee Rodriguez100% (1)

- P 996 WSM Diagnosis To 45Document345 pagesP 996 WSM Diagnosis To 45finnishfox100% (1)

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesFrom EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNo ratings yet

- 996 gt3 mk1 - mk2Document4 pages996 gt3 mk1 - mk2Jeff Chin100% (1)

- E 964 KatalogDocument578 pagesE 964 KatalogDoru IacovescuNo ratings yet

- User Manual Porsch 996Document263 pagesUser Manual Porsch 996otttiii90% (10)

- AfterSales Training - Air Cooled Engine RepairDocument72 pagesAfterSales Training - Air Cooled Engine RepairPaul Williams100% (2)

- Porsche 911:The Practically Free Supercar: Practically Free PorscheFrom EverandPorsche 911:The Practically Free Supercar: Practically Free PorscheRating: 5 out of 5 stars5/5 (1)

- 928 Diagnostics Manual v2.0Document56 pages928 Diagnostics Manual v2.0Andreas LetnikNo ratings yet

- Porsche Scheduled Maintenance Plan BrochureDocument2 pagesPorsche Scheduled Maintenance Plan BrochureDavid LusignanNo ratings yet

- BMW 3 Series - E36 Restoration Tips & TechniquesFrom EverandBMW 3 Series - E36 Restoration Tips & TechniquesRating: 5 out of 5 stars5/5 (4)

- Porsche Classic ORIGINALE 01Document46 pagesPorsche Classic ORIGINALE 01scorpia88100% (2)

- 996 Wiring 1999-2000Document30 pages996 Wiring 1999-2000Van Nguyen100% (3)

- Porsche 914 Manual PDFDocument202 pagesPorsche 914 Manual PDFOscar Hamer100% (1)

- Porsche 944 Transmission Workshop ManualDocument369 pagesPorsche 944 Transmission Workshop ManualJose Garcia100% (3)

- Porsche Workshop Manual 911 1972Document1,005 pagesPorsche Workshop Manual 911 1972kolmschot100% (5)

- 911 Turbo Carrera Repair ManualDocument407 pages911 Turbo Carrera Repair Manualelianeah100% (4)

- Porsche by Robert WalkerDocument67 pagesPorsche by Robert WalkerConceição FerreiraNo ratings yet

- Porsche 996TT Repair ManualDocument2,099 pagesPorsche 996TT Repair Manualcoconutkilt100% (5)

- 986 Group 7 Body InteriorDocument80 pages986 Group 7 Body InteriorSebestyen FridvalszkyNo ratings yet

- 993 Usa KatalogDocument446 pages993 Usa KatalogGenocea CfoNo ratings yet

- 11 PDFDocument124 pages11 PDFMarcinNo ratings yet

- 2015 Tool Catalog 7 15Document272 pages2015 Tool Catalog 7 15Ed Morales100% (1)

- WM Porsche 928 Factory Manual - Vol 1Document315 pagesWM Porsche 928 Factory Manual - Vol 19TECHNIKNo ratings yet

- 997 2005-08 Workshop ManualDocument5,222 pages997 2005-08 Workshop Manualdann089100% (2)

- P30 Drivetrain Repair - Sports CarDocument104 pagesP30 Drivetrain Repair - Sports CarAllan Cancino100% (1)

- Porsche - Origin of The Species - by Karl Ludvigsen - ExcerptDocument16 pagesPorsche - Origin of The Species - by Karl Ludvigsen - ExcerptBentley PublishersNo ratings yet

- Porsche 911 Workshop Manual 1972-1981 enDocument1,005 pagesPorsche 911 Workshop Manual 1972-1981 engbesze100% (4)

- WM Porsche 928 Factory Manual - Vol 7Document4 pagesWM Porsche 928 Factory Manual - Vol 79TECHNIKNo ratings yet

- The Ultimate Preowned 996 Buying GuideDocument6 pagesThe Ultimate Preowned 996 Buying GuideturbobrikNo ratings yet

- Porsche VIN Decoder - StuttcarsDocument3 pagesPorsche VIN Decoder - StuttcarsslowmosquitoNo ratings yet

- The Porsche Quiz Book: 100 Questions on the History of PorscheFrom EverandThe Porsche Quiz Book: 100 Questions on the History of PorscheNo ratings yet

- 1990 Porsche 928 Service Repair Manual PDFDocument24 pages1990 Porsche 928 Service Repair Manual PDFhfjskemmdmNo ratings yet

- WM Porsche 928 Factory Manual - Vol 2Document398 pagesWM Porsche 928 Factory Manual - Vol 29TECHNIK100% (1)

- BMW 3-Series (E30) Performance Guide: 1982-1994From EverandBMW 3-Series (E30) Performance Guide: 1982-1994Rating: 4.5 out of 5 stars4.5/5 (18)

- Porsche DownloadDocument33 pagesPorsche DownloadManuel Larrosa Marquez50% (2)

- Saab - Binder1 PDFDocument479 pagesSaab - Binder1 PDFmnbvqwert67% (3)

- Road Design With Autocad Civil 3d 0912 enDocument26 pagesRoad Design With Autocad Civil 3d 0912 enAMTRIS33% (3)

- Chocolate Lasagna - OMG Chocolate DessertsDocument21 pagesChocolate Lasagna - OMG Chocolate Dessertsturbobrik100% (1)

- 7 Buildings That Defy The Laws of PhysicsDocument9 pages7 Buildings That Defy The Laws of PhysicsturbobrikNo ratings yet

- CAD Clinic - Introduction To Civil 3D Corridors - CadalystDocument11 pagesCAD Clinic - Introduction To Civil 3D Corridors - CadalystturbobrikNo ratings yet

- What's Really New in Android 4.4.1 and 4.4Document13 pagesWhat's Really New in Android 4.4.1 and 4.4turbobrikNo ratings yet

- Porsche 911 997 runs on autogasDocument6 pagesPorsche 911 997 runs on autogasturbobrikNo ratings yet

- LPG On A Subaru Impreza WRX - ScoobyNetDocument6 pagesLPG On A Subaru Impreza WRX - ScoobyNetturbobrikNo ratings yet

- Geometric Design of Roads - Wikipedia, The Free EncyclopediaDocument14 pagesGeometric Design of Roads - Wikipedia, The Free EncyclopediaturbobrikNo ratings yet

- Road Design Tutorial For Civil 3dDocument22 pagesRoad Design Tutorial For Civil 3dPRINCE PAUL CHAKANYUKA60% (5)

- The Ultimate Preowned 996 Buying GuideDocument6 pagesThe Ultimate Preowned 996 Buying GuideturbobrikNo ratings yet

- Porsche 911 997 runs on autogasDocument6 pagesPorsche 911 997 runs on autogasturbobrikNo ratings yet

- Fine enn en Mustang - og billigereDocument6 pagesFine enn en Mustang - og billigereturbobrikNo ratings yet

- Bentley Maxsurf Enterprise V8i (SELECTSeries 3) 20.00.03Document8 pagesBentley Maxsurf Enterprise V8i (SELECTSeries 3) 20.00.03turbobrikNo ratings yet

- EVO - Buyer's Guide - Porsche 996 Turbo - Page 4 - TeamspeedDocument4 pagesEVO - Buyer's Guide - Porsche 996 Turbo - Page 4 - TeamspeedturbobrikNo ratings yet

- Buster Merryfield AutobiographDocument20 pagesBuster Merryfield AutobiographturbobrikNo ratings yet

- Avocado Sauce RecipeDocument6 pagesAvocado Sauce RecipeturbobrikNo ratings yet

- Avocado Sauce RecipeDocument6 pagesAvocado Sauce RecipeturbobrikNo ratings yet

- Water Tower Turned Into Dream Home BoligmaniDocument9 pagesWater Tower Turned Into Dream Home BoligmaniturbobrikNo ratings yet

- Volvo 740 - This Old Volvo Costing Nearly NOK 200,000 - BroomDocument7 pagesVolvo 740 - This Old Volvo Costing Nearly NOK 200,000 - BroomturbobrikNo ratings yet

- Board & Care - Harstad Motorsport Centre and NMK HarstadDocument6 pagesBoard & Care - Harstad Motorsport Centre and NMK HarstadturbobrikNo ratings yet

- 10 Killer New Features in Word 2013 - PCWorldDocument14 pages10 Killer New Features in Word 2013 - PCWorldturbobrikNo ratings yet

- 10 Fabulous Spa in Gran Canaria - ABC NewsDocument7 pages10 Fabulous Spa in Gran Canaria - ABC NewsturbobrikNo ratings yet

- Volvo V70 - Large Wagon That Cost Little - BroomDocument10 pagesVolvo V70 - Large Wagon That Cost Little - BroomturbobrikNo ratings yet

- Test Volvo V70 1.6d 2009Document8 pagesTest Volvo V70 1.6d 2009turbobrikNo ratings yet

- Architecture in Norway - This Is Norway's Toughest Concrete House - HyttelivDocument5 pagesArchitecture in Norway - This Is Norway's Toughest Concrete House - HyttelivturbobrikNo ratings yet

- Volvo 740 - This Old Volvo Costing Nearly NOK 200,000 - BroomDocument7 pagesVolvo 740 - This Old Volvo Costing Nearly NOK 200,000 - BroomturbobrikNo ratings yet

- Subaru Outback - How To Create It A Whole New Trend - BroomDocument5 pagesSubaru Outback - How To Create It A Whole New Trend - BroomturbobrikNo ratings yet

- Board & Care - Harstad Motorsport Centre and NMK HarstadDocument6 pagesBoard & Care - Harstad Motorsport Centre and NMK HarstadturbobrikNo ratings yet

- Bilimport - Own Import Car Can Pay Off - DinSide NORWAY IMPORT CARDocument6 pagesBilimport - Own Import Car Can Pay Off - DinSide NORWAY IMPORT CARturbobrikNo ratings yet

- Knowing Annelida: Earthworms, Leeches and Marine WormsDocument4 pagesKnowing Annelida: Earthworms, Leeches and Marine WormsCherry Mae AdlawonNo ratings yet

- Cdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFDocument87 pagesCdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFMilciades MurilloNo ratings yet

- Ninoy Aquino Parks and Wildlife CenterDocument7 pagesNinoy Aquino Parks and Wildlife CenterNinia Richelle Angela AgaNo ratings yet

- LOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorDocument1 pageLOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorHorizon 99No ratings yet

- Shapes FlashcardsDocument5 pagesShapes FlashcardsHome Organising by JRNo ratings yet

- Bill No. 1 - General Items PreliminariesDocument24 pagesBill No. 1 - General Items PreliminariesNorazreen NorAzharNo ratings yet

- Digital B&W Copiers (D154/D155-NA) Parts CatalogDocument118 pagesDigital B&W Copiers (D154/D155-NA) Parts Catalogkhoi vuNo ratings yet

- P&id BoilerDocument1 pageP&id BoilerBagus AryowibowoNo ratings yet

- Kendriya vidyalaya reading comprehension and grammar questionsDocument7 pagesKendriya vidyalaya reading comprehension and grammar questionsRaam sivaNo ratings yet

- Clinical Ultrasound A How-To GuideDocument146 pagesClinical Ultrasound A How-To GuideNacko Stavreski67% (3)

- Ampersand MenuDocument5 pagesAmpersand MenuJozefNo ratings yet

- Cricothyroidotomy and Needle CricothyrotomyDocument10 pagesCricothyroidotomy and Needle CricothyrotomykityamuwesiNo ratings yet

- Vrio Analysis Slide Template 16x9 1Document8 pagesVrio Analysis Slide Template 16x9 1Alt HrishiNo ratings yet

- CLIC Catalogue PDFDocument28 pagesCLIC Catalogue PDFsangram patilNo ratings yet

- GPS and The Quest For Pizza: National Aeronautics and Space AdministrationDocument1 pageGPS and The Quest For Pizza: National Aeronautics and Space Administrationvijay maddiNo ratings yet

- Appendix C: Time Value of MoneyDocument15 pagesAppendix C: Time Value of MoneyrockerNo ratings yet

- NASA Technical Mem Randum: E-Flutter N78Document17 pagesNASA Technical Mem Randum: E-Flutter N78gfsdg dfgNo ratings yet

- Specs Mantilla UV BT8800 Oct 2014Document2 pagesSpecs Mantilla UV BT8800 Oct 2014Julio MendezNo ratings yet

- Heradesign Brochure 2008Document72 pagesHeradesign Brochure 2008Surinder SinghNo ratings yet

- Desiderata: by Max EhrmannDocument6 pagesDesiderata: by Max EhrmannTanay AshwathNo ratings yet

- Electrical Machines Multiple Choice Questions - Mcqs - QuizDocument10 pagesElectrical Machines Multiple Choice Questions - Mcqs - Quiztooba mukhtarNo ratings yet

- Business PlanDocument63 pagesBusiness PlanKristine BalanayNo ratings yet

- Pump Course Material Chapter 2Document16 pagesPump Course Material Chapter 2engr victorNo ratings yet

- Tap Yourself FreeDocument134 pagesTap Yourself Freenguyenhavn100% (2)

- The Quill Vol. LVIII Issue 1 1-12Document12 pagesThe Quill Vol. LVIII Issue 1 1-12Yves Lawrence Ivan OardeNo ratings yet

- Personality Types and Character TraitsDocument5 pagesPersonality Types and Character TraitspensleepeNo ratings yet

- Goat Milk Marketing Feasibility Study Report - Only For ReferenceDocument40 pagesGoat Milk Marketing Feasibility Study Report - Only For ReferenceSurajSinghalNo ratings yet

- Revised fire drill performance standardsDocument47 pagesRevised fire drill performance standardsKartikeya GuptaNo ratings yet

- IMRAD - G1 PepperDocument13 pagesIMRAD - G1 PepperRomero, Ken Angelo B.No ratings yet

- Pentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessDocument156 pagesPentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessStanley JohnsonNo ratings yet