Professional Documents

Culture Documents

SC1164

Uploaded by

thongleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SC1164

Uploaded by

thongleCopyright:

Available Formats

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

TEL:805-498-2111 FAX:805-498-3804 WEB:http://www.semtech.com

October 25, 1999

DESCRIPTION

The SC1164/5 combines a synchronous voltage mode

controller with two low-dropout linear regulators

providing most of the circuitry necessary to implement

three DC/DC converters for powering advanced

microprocessors such as Pentium II.

The SC1164/5 switching section features an integrated

5 bit D/A converter, pulse by pulse current limiting,

integrated power good signaling, and logic compatible

shutdown. The SC1164/5 switching section operates at

a fixed frequency of 200kHz, providing an optimum

compromise between size, efficiency and cost in the

intended application areas. The integrated D/A converter provides programmability of output voltage from

2.0V to 3.5V in 100mV increments and 1.30V to 2.05V

in 50mV increments with no external components.

The SC1164/5 linear sections are low dropout regulators. The SC1164 supplies 1.5V for GTL bus and 2.5V

for non-GTL I/O.

For the SC1165 both LDOs are adjustable.

FEATURES

Synchronous design, enables no heatsink solution

95% efficiency (switching section)

5 bit DAC for output programmability

On chip power good function

Designed for Intel Pentium ll requirements

1.5V, 2.5V or Adj. @ 1% for linear section

APPLICATIONS

Pentium ll or Deschutes microprocessor supplies

Flexible motherboards

1.3V to 3.5V microprocessor supplies

Programmable triple power supplies

ORDERING INFORMATION

(1)

Part Number

Package

SC1164CSW

SO-24

SC1165CSW

SO-24

Linear

Voltage

Temp.

Range (TJ)

1.5V/2.5V 0 to 125C

Adj.

0 to 125C

Note:

(1) Add suffix TR for tape and reel.

PIN CONFIGURATION

BLOCK DIAGRAM

REF.

Top View

AGND

GATE1

LDOS1

LDOS2

VCC

OVP

PWRGOOD

CSCS+

PGNDH

DH

PGNDL

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

GATE2

LDOV

VID0

VID1

VID2

VID3

VID4

VOSENSE

EN

BSTH

BSTL

DL

FET

CONTROLLER

2.5V/ADJ.

1.265V

REF.

FET

CONTROLLER

1.5V/ADJ.

(24 Pin SOIC)

LDOV

Pentium is a registered trademark of Intel Corporation

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

ABSOLUTE MAXIMUM RATINGS

Parameter

VCC to GND

PGND to GND

BST to GND

Operating Temperature Range

Symbol

VCC

Junction Temperature Range

Storage Temperature Range

Lead Temperature (Soldering) 10 seconds

Thermal Impedance Junction to Ambient

Thermal Impedance Junction to Case

TA

Maximum

-0.3 to +7

1

-0.3 to +15

0 to +70

Units

V

V

V

C

TJ

TSTG

0 to +125

-65 to +150

C

C

TL

300

80

25

C

C/W

C/W

JA

JC

ELECTRICAL CHARACTERISTICS

Unless specified: VCC = 4.75V to 5.25V; GND = PGND = 0V; VOSENSE = VO; 0mV < (CS+-CS-) < 60mV; LDOV = 11.4V to 12.6V; TA = 25C

PARAMETER

Switching Section

Output Voltage

Supply Voltage

Supply Current

Load Regulation

Line Regulation

Current Limit Voltage

Oscillator Frequency

Oscillator Max Duty Cycle

Peak DH Sink/Source Current

Peak DL Sink/Source Current

Output Voltage Tempco

Gain (AOL)

OVP threshold voltage

OVP source current

Power good threshold voltage

Dead time

Linear Sections

Quiescent current

Output Voltage (LDO1 SC1164)

Output Voltage (LDO2 SC1164)

Reference Voltage (SC1165)

Feedback Pin Bias Current (SC1165)

Gain (AOL)

Load Regulation

Line Regulation

Output Impedance

Notes: (1) See Output Voltage table.

(2) In application circuit.

1999 SEMTECH CORP.

CONDITIONS

MIN

IO = 2A

VCC

VCC = 5.0V

IO = 0.8A to 15A

BSTH-DH = 4.5V, DH-PGNDH = 3V

BSTL-DL = 4.5V, DL-PGNDL = 3V

55

175

90

1

1

LDOS (1,2) to GATE (1,2)

(2)

IO = 0 to 8A

8

1

0.5

70

200

95

7

15

85

225

65

35

120

10

85

50

LDOV = 12V

MAX

UNITS

See Note 1.

4.5

VOSENSE to VO

VOVP = 3.0V

TYP

115

100

5

2.475 2.500 2.525

1.485 1.500 1.515

1.252 1.265 1.278

10

90

0.3

0.3

1

V

mA

%

%

mV

kHz

%

A

A

o

ppm/ C

dB

%

mA

%

ns

mA

V

V

V

uA

dB

%

%

K

2

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

PIN DESCRIPTION

Pin

1

2

3

4

5

6

Pin Name

AGND

GATE1

LDOS1

LDOS2

VCC

OVP

7

8

9

10

11

12

13

14

15

16

PWRGOOD

CSCS+

PGNDH

DH

PGNDL

DL

BSTL

BSTH

(1)

EN

17

18

19

20

21

22

23

24

VOSENSE

(1)

VID4

(1)

VID3

(1)

VID2

(1)

VID1

(1)

VID0

LDOV

GATE2

(1)

Pin Function

Small Signal Analog and Digital Ground

Gate Drive Output LDO1

Sense Input for LDO1

Sense Input for LDO2

Input Voltage

High Signal out if VO>setpoint +20%

Open collector logic output, high if VO

within 10% of setpoint

Current Sense Input (negative)

Current Sense Input (positive)

Power Ground for High Side Switch

High Side Driver Output

Power Ground for Low Side Switch

Low Side Driver Output

Supply for Low Side Driver

Supply for High Side Driver

Logic low shuts down the converter;

High or open for normal operation.

Top end of internal feedback chain

Programming Input (MSB)

Programming Input

Programming Input

Programming Input

Programming Input (LSB)

+12V for LDO section

Gate Drive Output LDO2

Top View

AGND

GATE1

LDOS1

LDOS2

VCC

OVP

PWRGOOD

CSCS+

PGNDH

DH

PGNDL

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

GATE2

LDOV

VID0

VID1

VID2

VID3

VID4

VOSENSE

EN

BSTH

BSTL

DL

(24 Pin SOIC)

Note:

(1) All logic level inputs and outputs are open

collector TTL compatible.

3

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

OUTPUT VOLTAGE

Unless specified: VCC = 5.00V; GND = PGND = 0V; VOSENSE = VO; 0mV < (CS+-CS-) < 60mV; TA = 25oC

PARAMETER

Output Voltage

CONDITIONS

IO = 2A in Application Circuit

VID

MIN

43210

01111

01110

01101

01100

01011

01010

01001

01000

00111

00110

00101

00100

00011

00010

00001

00000

11111

11110

11101

11100

11011

11010

11001

11000

10111

10110

10101

10100

10011

10010

10001

10000

1.274

1.323

1.372

1.421

1.470

1.527

1.576

1.625

1.675

1.724

1.773

1.822

1.871

1.921

1.970

2.019

1.940

2.058

2.156

2.254

2.352

2.450

2.548

2.646

2.744

2.842

2.940

3.038

3.136

3.234

3.332

3.430

TYP

1.300

1.350

1.400

1.450

1.500

1.550

1.600

1.650

1.700

1.750

1.800

1.850

1.900

1.950

2.000

2.050

2.000

2.100

2.200

2.300

2.400

2.500

2.600

2.700

2.800

2.900

3.000

3.100

3.200

3.300

3.400

3.500

MAX

UNITS

1.326

1.377

1.428

1.479

1.530

1.573

1.624

1.675

1.726

1.776

1.827

1.878

1.929

1.979

2.030

2.081

2.060

2.142

2.244

2.346

2.448

2.550

2.652

2.754

2.856

2.958

3.060

3.162

3.264

3.366

3.468

3.570

4

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

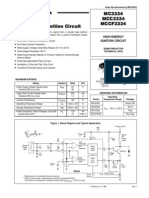

1999 SEMTECH CORP.

2

4

VID2

VID3

C22

330uF

(NORMALLY 3.3V)

PWRGD

VID4

24

12

VID1

VID0

VINLIN

330uF

C21

19

20

21

22

C5

0.1uF

U1

R14 *

R18 **

100k

SC1164/5CSW

LDOS2

GATE1

GATE2

PGNDL

AGND

EN

VID3

VID2

VID1

VID0

OVP

VCC

CS+

Q4

BUK556

R15 *

LDOS1

VDD

BSTL

DL

PGNDH

DH

BSTH

VID4

PWRGOOD

VO SENSE

CS-

C9

330uF

23

14

13

10

11

15

18

17

0.1uF

C13

R17 **

100k

BUK556

Q3

R13 *

R4

5mOhm

1.00k

R6

C14

1500uF

C12

330uF

C17

1500uF

C16

1500uF

C11

330uF

C15

1500uF

2.32k

R5

C18

0.1uF

VLIN2

VLIN1

VCC_CORE

** R17, R18 REQUIRED IF VINLIN CAN BE PRESENT WITHOUT 12V BEING

PRESENT.

* SEE "SETTING LDO OUTPUT VOLTAGE" TABLE

NOTE: FOR SC1164, R12, R13, R14 AND R14 ARE NOT REQUIRED,

CONNECT LDOS1 (PIN3) DIRECTLY TO VLIN1 TO GENERATE 2.5V OUTPUT.

CONNECT LDOS2 (PIN4) DIRECTLY TO VLIN2 TO GENERATE 1.5V OUTPUT.

4uH

L1

Q1

BUK556

R12 *

C10

330uF

Q2

BUK556

TBD

10

R16

R1

OVP

C3

1500uF

16

C2

1500uF

EN

C1

0.1uF

5V

12V

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

APPLICATION CIRCUIT

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

MATERIALS LIST

Qty. Reference

Part/Description

Vendor

Notes

C1,C5,C13,C 0.1F Ceramic

18

Various

C2,C3,C14C17

1500F/6.3V

SANYO

C9-C12,

C21, C22

330F/6.3V

Various

L1

4H

Q1,Q2,Q3,

Q4

See notes

See notes

FET selection requires trade-off between efficiency and

cost. Absolute maximum RDS(ON) = 22 m for Q1,Q2

R4

5m

IRC

OAR-1 Series

R5

2.32k, 1%, 1/8W

Various

R6

1k, 1%, 1/8W

Various

R1

10, 5%, 1/8W

Various

R12

1%, 1/8W

Various

See Table Below (Not required for SC1164)

R13

1%, 1/8W

Various

See Table Below (Not required for SC1164)

R14

1%, 1/8W

Various

See Table Below (Not required for SC1164)

R15

1%, 1/8W

Various

See Table Below (Not required for SC1164)

R17,R18

100k, 5%,1/8W

Various

Required if Voltage is applied to the linear FET(s) without

12V applied to SC1164/5

U1

SC1164/5CSW

SEMTECH

MV-GX or equiv. Low ESR

8 Turns 16AWG on MICROMETALS T50-52D core

SETTING LDO OUTPUT VOLTAGE

1.265 (R A + R B )

+ (IFB R A )

RB

RB

RA

VOUT LDO1 (LDO2)

R12 (R14)

R13 (R15)

3.45V

105

182

3.30V

105

169

3.10V

102

147

2.90V

100

130

See layout diagram for clarification

2.80V

100

121

R A and R B must be low enough so

2.50V

100

97.6

that the (IFB R A ) term does not cause

1.50V

100

18.7

significant error

VOUT =

Where :

IFB = Feedback pin bias current

R A = Top feedback resistor

R B = Bottom feedback resistor

6

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

95%

95%

90%

90%

85%

85%

Efficiency

Efficiency

October 25, 1999

80%

3.5V Std

3.5V Sync

3.5V Sync Lo Rds

75%

80%

2.8V Std

2.8V Sync

2.8V Sync Lo Rds

75%

70%

70%

0

10

12

14

16

10

12

14

16

10

12

14

16

Typical Efficiency at Vo=2.8V

95%

95%

90%

90%

85%

85%

Efficiency

Efficiency

Typical Efficiency at Vo=3.5V

80%

2.5V Std

2.5V Sync

2.5V Sync Lo Rds

75%

8

Io (Amps)

Io (Amps)

80%

2.0V Std

2.0V Sync

2.0V Sync Lo Rds

75%

70%

70%

0

8

Io (Amps)

10

12

14

16

8

Io (Amps)

Typical Efficiency at Vo=2.5V

Typical Efficiency at Vo=2.0V

Typical Ripple, Vo=2.8V, Io=10A

Transient Response Vo=2.8V, Io=300mA to 10A

7

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

as small as possible. This loop contains all the high current, fast transition switching. Connections should be as

wide and as short as possible to minimize loop inductance. Minimizing this loop area will a) reduce EMI, b)

lower ground injection currents, resulting in electrically

cleaner grounds for the rest of the system and c) minimize source ringing, resulting in more reliable gate

switching signals.

LAYOUT GUIDELINES

Careful attention to layout requirements are necessary

for successful implementation of the SC1164/5 PWM

controller. High currents switching at 200kHz are present in the application and their effect on ground plane

voltage differentials must be understood and minimized.

1). The high power parts of the circuit should be laid out

first. A ground plane should be used, the number and

position of ground plane interruptions should be such

as to not unnecessarily compromise ground plane integrity. Isolated or semi-isolated areas of the ground

plane may be deliberately introduced to constrain

ground currents to particular areas, for example the input capacitor and bottom FET ground.

3). The connection between the junction of Q1, Q2 and

the output inductor should be a wide trace or copper

region. It should be as short as practical. Since this

connection has fast voltage transitions, keeping this

connection short will minimize EMI. The connection between the output inductor and the sense resistor should

be a wide trace or copper area, there are no fast voltage or current transitions in this connection and length

is not so important, however adding unnecessary

impedance will reduce efficiency.

2). The loop formed by the Input Capacitor(s) (Cin), the

Top FET (Q1) and the Bottom FET (Q2) must be kept

12V IN

5V

10

1

2

3

4

0.1uF

5

6

0.1uF

7

8

9

10

11

12

AGND

GATE2

GATE1

LDVO

LDOS1

VID0

LDOS2

VID1

VCC

VID2

OVP

VID3

PWRGOOD

VID4

CS-

VOSENSE

CS+

EN

PGNDH

BSTH

DH

BSTL

PGNDL

DL

24

23

2.32k

22

Cin

21

Q1

1.00k

20

5mOhm

Vout

19

4uH

18

Q2

Cout

17

16

15

14

13

SC1164/5

RA1

5V

Vo Lin1

Q3

+

Heavy lines indicate

high current paths.

RB1

Cout Lin1

Cin Lin

For SC1164, RA1, RA2, RB1 and RB2

are not required. LDOS1 connects to

Vo Lin1, LDOS2 connects to Vo Lin2

RA2

Vo Lin2

Q4

RB2

Cout Lin2

Layout diagram for the SC1164/5

8

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

4) The Output Capacitor(s) (Cout) should be located

as close to the load as possible, fast transient load

currents are supplied by Cout only, and connections

between Cout and the load must be short, wide copper areas to minimize inductance and resistance.

5) The SC1164/5 is best placed over a quiet ground

plane area, avoid pulse currents in the Cin, Q1, Q2

loop flowing in this area. PGNDH and PGNDL should

be returned to the ground plane close to the package.

The AGND pin should be connected to the ground

side of (one of) the output capacitor(s). If this is not

possible, the AGND pin may be connected to the

ground path between the Output Capacitor(s) and the

Cin, Q1, Q2 loop. Under no circumstances should

AGND be returned to a ground inside the Cin, Q1, Q2

loop.

5V supply through a 10 resistor, the Vcc pin should

be decoupled directly to AGND by a 0.1F ceramic

capacitor, trace lengths should be as short as possible.

7) The Current Sense resistor and the divider across

it should form as small a loop as possible, the traces

running back to CS+ and CS- on the SC1164/5 should

run parallel and close to each other. The 0.1F capacitor should be mounted as close to the CS+ and

CS- pins as possible.

8) Ideally, the grounds for the two LDO sections

should be returned to the ground side of (one of) the

output capacitor(s).

6) Vcc for the SC1164/5 should be supplied from the

5V

Vout

+

Currents in various parts of the power section

9

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

COMPONENT SELECTION

SWITCHING SECTION

OUTPUT CAPACITORS - Selection begins with the

most critical component. Because of fast transient load

current requirements in modern microprocessor core

supplies, the output capacitors must supply all transient

load current requirements until the current in the output

inductor ramps up to the new level. Output capacitor

ESR is therefore one of the most important criteria. The

maximum ESR can be simply calculated from:

R ESR

ILRIPPLE=

V

t

It

Vt = Maximum transient voltage excursion

It = Transient current step

For example, to meet a 100mV transient limit with a

10A load step, the output capacitor ESR must be less

than 10m. To meet this kind of ESR level, there are

three available capacitor technologies.

Each Capacitor

C

(F)

ESR

(m)

C

(F)

ESR

(m)

Low ESR Tantalum

330

60

2000

10

OS-CON

330

25

990

8.3

1500

44

7500

8.8

Low ESR Aluminum

The choice of which to use is simply a cost/performance issue, with Low ESR Aluminum being the

cheapest, but taking up the most space.

INDUCTOR - Having decided on a suitable type and

value of output capacitor, the maximum allowable

value of inductor can be calculated. Too large an inductor will produce a slow current ramp rate and will

cause the output capacitor to supply more of the transient load current for longer - leading to an output voltage sag below the ESR excursion calculated above.

The maximum inductor value may be calculated from:

POWER FETS - The FETs are chosen based on several

criteria with probably the most important being power

dissipation and power handling capability.

TOP FET - The power dissipation in the top FET is a

combination of conduction losses, switching losses and

bottom FET body diode recovery losses.

a) Conduction losses are simply calculated as:

PCOND = IO2 RDS( on )

Total

Qty.

Rqd.

VIN

4L fOSC

Ripple current allowance will define the minimum permitted inductor value.

Where

Technology

fast enough to reduce the voltage dropped across the

ESR at a faster rate than the capacitor sags, hence ensuring a good recovery from transient with no additional

excursions.

We must also be concerned with ripple current in the

output inductor and a general rule of thumb has been to

allow 10% of maximum output current as ripple current.

Note that most of the output voltage ripple is produced

by the inductor ripple current flowing in the output capacitor ESR. Ripple current can be calculated from:

R ESR C

(VIN VO )

It

The calculated maximum inductor value assumes 100%

duty cycle, so some allowance must be made. Choosing

an inductor value of 50 to 75% of the calculated maximum will guarantee that the inductor current will ramp

where

= duty cycle

VO

VIN

b) Switching losses can be estimated by assuming a

switching time, if we assume 100ns then:

PSW = I O V IN 10 2

or more generally,

PSW =

IO VIN ( t r + t f ) fOSC

4

c) Body diode recovery losses are more difficult to estimate, but to a first approximation, it is reasonable to assume that the stored charge on the bottom FET body

diode will be moved through the top FET as it starts to

turn on. The resulting power dissipation in the top FET

will be:

PRR = Q RR VIN f OSC

To a first order approximation, it is convenient to only

consider conduction losses to determine FET suitability.

For a 5V in; 2.8V out at 14.2A requirement, typical FET

losses would be:

10

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

FET type

RDS(on) (m) PD (W)

Package

BUK556H 22

2.48

TO220

IRL2203

7.0

0.79

D PAK

Si4410

13.5

1.53

SO-8

BOTTOM FET - Bottom FET losses are almost entirely

due to conduction. The body diode is forced into conduction at the beginning and end of the bottom switch conduction period, so when the FET turns on and off, there

is very little voltage across it, resulting in low switching

losses. Conduction losses for the FET can be determined by:

INPUT CAPACITORS - since the RMS ripple current in

the input capacitors may be as high as 50% of the output current, suitable capacitors must be chosen accordingly. Also, during fast load transients, there may

be restrictions on input di/dt. These restrictions require

useable energy storage within the converter circuitry,

either as extra output capacitance or, more usually,

additional input capacitors. Choosing low ESR input

capacitors will help maximize ripple rating for a given

size.

PCOND = I O2 R DS ( on ) (1 )

For the example above:

FET type

RDS(on) (m) PD (W)

Package

BUK556H 22

1.95

TO220

IRL2203

7.0

0.62

D PAK

Si4410

13.5

1.20

SO-8

Each of the package types has a characteristic thermal

impedance, for the TO-220 package, thermal impedance

is mostly determined by the heatsink used. For the surface mount packages on double sided FR4, 2 oz printed

o

circuit board material, thermal impedances of 40 C/W

2

o

for the D PAK and 80 C/W for the SO-8 are readily

achievable. The corresponding temperature rise is detailed below:

o

Temperature rise ( C)

FET type

Top FET

(1)

Bottom FET

(1)

BUK556H 49.6

39.0

IRL2203

31.6

24.8

122.4

96

Si4410

o

(1) With 20 C/W Heatsink

It is apparent that single SO-8 Si4410 are not adequate for

this application, but by using parallel pairs in each position, power dissipation will be approximately halved and

temperature rise reduced by a factor of 4.

11

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

PROGRAMMABLE SYNCHRONOUS DC/DC

CONVERTER, DUAL LOW DROPOUT

REGULATOR CONTROLLER

SC1164/5

October 25, 1999

OUTLINE DRAWING - SO-24

JEDEC MS-013AD

B17104B

ECN 99-667

12

1999 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

You might also like

- Skhi 22B DatasheetDocument9 pagesSkhi 22B DatasheetRakesh RoyNo ratings yet

- Isolated Flyback Switching Regulator W - 9V OutputDocument16 pagesIsolated Flyback Switching Regulator W - 9V OutputCasey DialNo ratings yet

- Datasheet for Inverter GH214A(P1Document27 pagesDatasheet for Inverter GH214A(P1TvcrepairNo ratings yet

- LCT B85TDU22H Service ManualDocument59 pagesLCT B85TDU22H Service ManualCristina NistorNo ratings yet

- FAN8082 (KA3082N) : Bi-Directional DC Motor DriverDocument13 pagesFAN8082 (KA3082N) : Bi-Directional DC Motor DriverFrancisco Hernandez MartinezNo ratings yet

- Voltage-Controlled Oscillator: ... The Analog Plus CompanyDocument24 pagesVoltage-Controlled Oscillator: ... The Analog Plus CompanyMoltrevNo ratings yet

- LT1076 5Document8 pagesLT1076 5Marquis DavidNo ratings yet

- Ka3082 Controlador de Motores CCDocument12 pagesKa3082 Controlador de Motores CCshibatoyanNo ratings yet

- Delta PLC DVP SS ModelDocument4 pagesDelta PLC DVP SS ModelTarun SonwaneNo ratings yet

- IC 3842 para FonteDocument8 pagesIC 3842 para FonteTomNedscNo ratings yet

- STP9NK65ZFPDocument16 pagesSTP9NK65ZFPJacson FagundesNo ratings yet

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument12 pages3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesGiovanni Carrillo VillegasNo ratings yet

- LCD221SD Service ManualDocument41 pagesLCD221SD Service Manual1cvbnmNo ratings yet

- ST 232Document11 pagesST 232Negru P. PlantatieNo ratings yet

- CPWRAN10Document5 pagesCPWRAN10Vasco RodriguesNo ratings yet

- An 1599Document20 pagesAn 1599nisha770No ratings yet

- HV9910BDB7 HV9910B PFC 40W LED Driver Demoboard: Specifications General DescriptionDocument5 pagesHV9910BDB7 HV9910B PFC 40W LED Driver Demoboard: Specifications General DescriptionNT372No ratings yet

- Datasheet (LT1074)Document16 pagesDatasheet (LT1074)HermesSanchezNo ratings yet

- CA3102Document11 pagesCA3102bonaparteCWBNo ratings yet

- AM5898NDocument11 pagesAM5898NGabriel Cosme VazquezNo ratings yet

- LG - 32lb9rta Me Eay41970901 PDFDocument139 pagesLG - 32lb9rta Me Eay41970901 PDFLuděk CsibaNo ratings yet

- LC75816E, 75816W: 1/8 To 1/10 Duty Dot Matrix LCD Display Controllers/Drivers With Key Input FunctionDocument44 pagesLC75816E, 75816W: 1/8 To 1/10 Duty Dot Matrix LCD Display Controllers/Drivers With Key Input FunctionajitajimalNo ratings yet

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDocument10 pagesNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânNo ratings yet

- NCV47821 3.3 V To 20 V Adjustable Dual LDO With Adjustable Current Limit and Diagnostic FeaturesDocument15 pagesNCV47821 3.3 V To 20 V Adjustable Dual LDO With Adjustable Current Limit and Diagnostic FeaturesTestronicpartsNo ratings yet

- Modbus-1 3eDocument4 pagesModbus-1 3ekelpiusNo ratings yet

- Data SheetDocument6 pagesData SheetTuấn Âm Thanh Hi-endNo ratings yet

- UDN2916Document10 pagesUDN2916ejoaomelchiorsNo ratings yet

- DVP20SX211RDocument8 pagesDVP20SX211RcurielvicNo ratings yet

- Uc 3845Document23 pagesUc 3845Bahram RN100% (1)

- Transformer Driver For Isolated Power Supplies: Features ApplicationsDocument29 pagesTransformer Driver For Isolated Power Supplies: Features Applicationsngongpro27No ratings yet

- AM5888SDocument10 pagesAM5888SproctepNo ratings yet

- DRV 8811Document22 pagesDRV 8811nelson_loboNo ratings yet

- TB6560AHQ 4-Axis CNC Driver PDFDocument7 pagesTB6560AHQ 4-Axis CNC Driver PDFMai HuyNo ratings yet

- Ibm Lenovo E420 COMPAL LA-1331Document83 pagesIbm Lenovo E420 COMPAL LA-1331Abubakar SidikNo ratings yet

- Ldrxxyy: Very Low Drop Dual Voltage RegulatorDocument14 pagesLdrxxyy: Very Low Drop Dual Voltage RegulatorCaterine OliveiraNo ratings yet

- Data SheetDocument8 pagesData SheetMauro VianaNo ratings yet

- Ucc 28220Document32 pagesUcc 28220urpublicNo ratings yet

- UC3825ADWDocument15 pagesUC3825ADWmichaelliu123456No ratings yet

- ADC0804 DatasheetDocument48 pagesADC0804 DatasheetSaurabh AnmadwarNo ratings yet

- RD 2015-05-001-V01 Evaluation Board For M909 ModulesDocument24 pagesRD 2015-05-001-V01 Evaluation Board For M909 ModulesasokanenNo ratings yet

- FAN7314 LCD Backlight Inverter Drive IC: Features DescriptionDocument3 pagesFAN7314 LCD Backlight Inverter Drive IC: Features DescriptionMaha DevanNo ratings yet

- MAX1858 Evaluation Kit: General Description FeaturesDocument7 pagesMAX1858 Evaluation Kit: General Description Features9183290782No ratings yet

- Ucc2800 PDFDocument22 pagesUcc2800 PDFgarrycNo ratings yet

- Single Ended Active Clamp/Reset PWM: Features DescriptionDocument16 pagesSingle Ended Active Clamp/Reset PWM: Features Descriptioncatsoithahuong84No ratings yet

- 35W DVD Power Supply With ICE2A265Document12 pages35W DVD Power Supply With ICE2A265BUDINo ratings yet

- Viper 100Document8 pagesViper 100SeanNo ratings yet

- OFF-LINE SWITCH MODE TRANSFORMERSDocument9 pagesOFF-LINE SWITCH MODE TRANSFORMERSSunil SonavaneNo ratings yet

- Elevador VoltajeDocument10 pagesElevador VoltajeFernando AugustoNo ratings yet

- 2.7V 4-Channel/8-Channel 10-Bit A/D Converters With SPI™ Serial InterfaceDocument20 pages2.7V 4-Channel/8-Channel 10-Bit A/D Converters With SPI™ Serial Interfacejoseleomi_limaNo ratings yet

- 180w SourceDocument2 pages180w SourceMustata AlexandruNo ratings yet

- Irams 06 Up 60 ADocument18 pagesIrams 06 Up 60 AAndré Roberto EvangelistaNo ratings yet

- Datasheet MC3334Document6 pagesDatasheet MC3334odipasNo ratings yet

- IRAMX16UP60ADocument18 pagesIRAMX16UP60Atheylor1990No ratings yet

- 74 Ls 121Document10 pages74 Ls 121krlossnNo ratings yet

- MCP3040 DatasheetDocument40 pagesMCP3040 Datasheetjiajun898No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Santak Tg500 SchematicDocument1 pageSantak Tg500 Schematictestlass100% (1)

- Description Features: Programmable Synchronous DC/DC Converter, Dual Low Dropout Regulator ControllerDocument12 pagesDescription Features: Programmable Synchronous DC/DC Converter, Dual Low Dropout Regulator ControllerthongleNo ratings yet

- Three-Phase Buck PWM Controller With Integrated MOSFET Drivers For VRM9, VRM10, and AMD Hammer Applications FeaturesDocument28 pagesThree-Phase Buck PWM Controller With Integrated MOSFET Drivers For VRM9, VRM10, and AMD Hammer Applications FeaturesthongleNo ratings yet

- KA7500BDocument8 pagesKA7500BGheorghe PaiusanNo ratings yet

- NCP1203 Advance Information PWM Current-Mode Controller For Universal Off-Line Supplies Featuring Standby and Short Circuit ProtectionDocument12 pagesNCP1203 Advance Information PWM Current-Mode Controller For Universal Off-Line Supplies Featuring Standby and Short Circuit ProtectionthongleNo ratings yet

- KA7500BDocument8 pagesKA7500BGheorghe PaiusanNo ratings yet

- Description Features: Programmable Synchronous DC/DC Converter, Dual Low Dropout Regulator ControllerDocument12 pagesDescription Features: Programmable Synchronous DC/DC Converter, Dual Low Dropout Regulator ControllerthongleNo ratings yet

- NCP1203 Advance Information PWM Current-Mode Controller For Universal Off-Line Supplies Featuring Standby and Short Circuit ProtectionDocument12 pagesNCP1203 Advance Information PWM Current-Mode Controller For Universal Off-Line Supplies Featuring Standby and Short Circuit ProtectionthongleNo ratings yet

- Agilent ADNS-2051 Optical Mouse Sensor: Data SheetDocument40 pagesAgilent ADNS-2051 Optical Mouse Sensor: Data Sheetthongle100% (1)