Professional Documents

Culture Documents

Us4854065 PDF

Uploaded by

Jin SongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us4854065 PDF

Uploaded by

Jin SongCopyright:

Available Formats

United States Patent [19]

French et al.

[54]

[75]

HAMMER BLOCK DEVICE

2,758,404

2,832,167

Inventors: Kendrick L. French, Lebanon, Me.;

3,988,848 11/1976 Chatigny .

Mark C. Laney, Lee, N.H.

[73] Assignee: K.W. Thompson Tool Company, Inc.,

Rochester, NH.

[21] Appl. No.: 254,953

Oct. 7, 1988

[22] Filed:

[511

[52]

[58]

[56]

Patent Number:

Date of Patent:

[11]

[45]

Int. Cl.4 ..... ..

. ............. .. F41C 17/00

US. Cl. ............................ .. 42/65; 42/ 69.01

Field of Search .................... .. 42/65, 69.01, 69.03

References Cited

U.S. PATENT DOCUMENTS

66,072

600,337

6/1867 Blake .

3/1898 Richardson .

609,233

8/1898 Houghton .

811,807 2/1906 Wesson .

835,380 1l/l906 Wesson et a1. .

855,227 5/1907 Bull .

1,070,145 8/1913 Lewis .

1,297,859 3/1919 Johnson .

1,405,765 2/1922 Diehm .

4,854,065

Aug. 8, 1989

8/1956 Tabor .

4/1958 Fox .

FOREIGN PATENT DOCUMENTS

588225

5/1925

France .................................. .. 42/69

Primary Examiner-Deborah L. Kyle

Assistant Examiner-Richard W. Wendtland

Attorney, Agent, or Firm-Blodgett & Blodgett

[57]

ABSTRACT

A ?rearm having a frame, a barrel, a trigger which is

pivotally connected to the frame, a hammer which is

pivotally connected to the frame, and a hammer block

which is integral with the trigger and extends upwardly

from the trigger to prevent the hammer from reaching

it forward ?ring position when the trigger is in its for

ward position, and allowing the hammer to reach its

forward firing position when the trigger is in its rear

ward position. The trigger is biased to its forward posi

tion and the hammer is also biased to its forward ?ring

position.

10 Claims, 2 Drawing Sheets

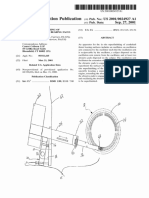

US. Patent

Aug. 8, 1989

Sheet 1 of2

4,854,065

US. Patent

FIG. 5

Aug. 8, 1989

Sheet 2 of2 '

FIG. 4

I 4,854,065

4,854,065

the hammer block, prevents the trigger from being

moved rearwardly from its forward position and causes

the trigger to move from its forward position to an

intermediate position when the hammer is moved to its

HAMMER BLOCK DEVICE

BACKGROUND OF THE INVENTION

The present invention relates in general to a ?rearm

in which ?ring is initiated by the strike of a hammer

which is controlled by a trigger mechanism. The inven

rearward cocked position. Thereafter, the trigger can

be pulled to its rearward position to release the hammer

tion is particularly directed to a ?rearm in which a

BRIEF DESCRIPTION OF THE DRAWINGS

to its forward ?ring position.

hammer block is employed to prevent the hammer from

The character of the invention, however, may be best

reaching its striking position for ?ring except under a

understood by reference to one of its structural forms as

predetermined set of conditions.

illustrated by the accompanying drawings, in which:

In the typical ?rearm which utilizes a hammer block,

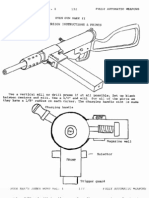

FIG. 1 is a front elevational view of a ?rearm em

the hammer block remains in a blocking position when

bodying the principles of the present invention,

the hammer alone is actuated. The hammer block is

moved from its blocking position through the action of 15 FIG. 2 is a fragmentary side elevational view of the

?rearm on an enlarged scale with portions broken

the trigger mechanism. In other ?rearms, a transfer

plate is used in place of a hammer block. In such a

away,

?rearm, the hammer is incapable of striking the percus

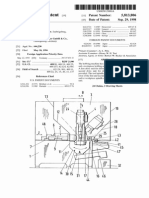

FIG. 3 is a diagrammatic view of the trigger and

sion element in its extreme forward position. The trans

hammer mechanisms in the normal non-operational

fer plate is interposed between the percussion element 20 condition,

and the hammer by the action of the trigger mechanism.

FIG. 4 is a view which is similar to FIG. 3, showing

The mechanism for activating the hammer block or

the trigger and hammer mechanisms in their cocked

transfer plate for each ?rearm involves a complicated

ready to ?re positions, and

lever and linkage arrangement. The parts which

FIG. 5 is a view which is similar to FIGS. 3 and 4,

makeup the actuating mechanism for the hammer block 25 showing the trigger and hammer in their ?ring posi

or transfer plate require a high degree of precision. The

tions.

plurality of moving parts which make up the hammer

DESCRIPTION OF THE PREFERRED

block actuating mechanism add considerably to the cost

of the ?rearm and are subject to wear. This, in turn,

EMBODIMENT

affects the long term reliability of the ?rearm. These 30 Referring ?rst to FIGS. 1 and 2 there is shown a

and other difficulties experienced with the prior art

?rearm embodying the principles of the present inven

?rearms have been obviated by the present invention.

tion and generally indicated by the reference numeral

It is, therefore, a principal object of the invention to

10. The ?rearm 10 is by way of example a black powder

provide a ?rearm having a hammer block which re

pistol

having a frame 12, a barrel 14, a nipple 13 which

quires no moving parts between the trigger mechanism 35

contains a percussion cap 15 which is mounted behind

and the hammer block.

the ?ring chamber of the ?rearm. The trigger 16 is

Another object of this invention is the provision of a

pivotally connected to the frame 12 by means of a pivot

?rearm having a hammer block in which the ?rearm

pin 18 and biased to the forward position shown in FIG.

cannot be ?red by pulling the trigger alone.

2 by a spring 22. A hammer 24 is pivotally connected to

A further object of the present invention is the provi

sion of a ?rearm having a hammer block which is also

utilized for holding the hammer in a cocked position

and for preventing release of the hammer to a ?ring

position except by operation of the trigger mechanism.

the frame 12 by means of a pivot pin 26.

Referring to FIGS. 15 a hammer block 20 is integral

with the trigger 16 and extends upwardly from the

pivot 18. The hammer block 20 normally occupies a

It is another object of the present invention to pro 45 rearward position when the trigger 16 is in its forward

position as shown in FIG. 3. The hammer block 20 has

a rearwardly facing surface 21 which has a rearwardly

ated, in part, by the hammer and, in part, by the trigger,

facing notch 23 for a purpose to be described. The

so that ?ring of the gun requires operation of both the

upper end of the hammer block has a rounded surface

trigger and hammer in a predeterminedsequence.

A still further object of the invention is a provision of 50 37, also for a purpose to be described. The hammer 24

has a forwardly facing striking surface 30 which is in

a ?rearm having a hammer block which is simple in

line

with the percussion cap 15 and a thumb grip 32 for

construction, inexpensive to manufacture, easy to oper

moving the hammer 24 about the pivot pin 26 from the

ate, and which provides a long life of useful service.

intermediate position shown in FIG. 3, to the rearward

With these and other objects in view, as will be ap

parent to those skilled in the art, the invention resides in 55 cocked position shown in FIG. 4. When the hammer 24

is in its intermediate position, as shown in FIG. 3, it is

the combination of parts set forth in the speci?cation

spaced from the percussion cap 15. An actuator ?nger

and covered by the claims appended hereto.

34 is integral with the hammer 24 and extends below the

SUMMARY OF THE INVENTION

pivot pin 26 in contact with the rearwardly facing sur

face 21 of the hammer block 20. A retaining ?nger 36 is

In general, the invention consist of a ?rearm having a

also integral with the hammer block 24 and extends

trigger which is pivoted to the frame and biased in the

forwardly above the hammer block 20 when the ham

forward position, a hammer which is pivoted to the

vide a ?rearm having a hammer block which is actu

mer block is in its rearward position as shown in FIG. 3.

frame and biased in a forward position and a hammer

The forward end of the retaining ?nger 36 has a

block which is ?xed to the trigger. The hammer block

extends from the pivot point of the trigger to a position 65 rounded surface 39 for a purpose to be described. The

hammer 24 is biased forwardly against the hammer

in which it blocks the hammer from reaching its for

ward ?ring position when the trigger is in its forward

position. More speci?cally, the hammer, acting through

block 20 by biasing means, generally indicated by the

reference numeral 38. The retaining ?nger 36 traps the

4,854,065

hammer block 20 in its rearward position as shown in

in?uence of the stronger spring 22 pushes the hammer

FIG. 3, and thereby prevents the trigger 16 from being

pulled rearwardly. Therefore, the ?rearm cannot be

?red by pulling the trigger alone. The outer end of the

24 rearwardly. The rounded surface 37 is rearward of

the pivot pin 18 so that rearward movement of the

hammer block 20 causes the surface 37 to move down

hammer block 20 has a lip 35 which strikes the under

wardly. The rounded surface 39 is forward of the pivot

pin 26 so that rearward movement of the retaining ?n

ger 36 causes the surface 39 to move upwardly. As the

hammer block 20 and the hammer 24 move rearwardly,

side of the retaining ?nger 36 when the trigger 16 is

pulled rearwardly a slight amount, thereby preventing

any further rearward movement of the trigger.

The biasing means 38 which biases the hammer 24

the surfaces 37 and 39 slide along each other until the lip

forwardly comprises a mounting block 44 which is ?xed 10 35 drops below the retaining ?nger 36 as shown in FIG.

to the frame 12 and a spring assembly generally iridi

3. The ?rearm 10 is now in condition for reloading and

cated by the reference numeral 43. The spring assembly

subsequent ?ring.

43 comprises a ?rst bracket 40 which is pivotally con

nected to the hammer 24 by means of a pivot pin 42, a

second bracket 47, a relatively strong helical compres

sion spring 50 which extends between the brackets 40

and 47, and a relatively weak helical spring 46 which is

located on the opposite side of the bracket 47 from the

It is obvious that minor changes may be made in the

form and construction of the invention without depart

ing from the material spirit thereof. It is not, however,

desired to con?ne the invention to the exact form herein

shown and described, but it is desired to include all such

as properly come within the scope claimed.

spring 50. The spring 46 is located within the mounting

The invention having been thus describe, what is

block 44. The outer end of the spring 46 rest against the

claimed as new and desired to secure by Letters Patent

bottom wall 45 of the mounting block 44. The upper

1s:

end of the spring 46 extends beyond the upper opening

1. A ?rearm:

49 of the mounting block, as shown in FIGS. 3 and 5. A

(a)

which has a frame and a barrel,

rod 48 is ?xed to the bracket 40 and extends down

(b)

a trigger which is pivotally connected to the

wardly along the helical axes of the springs 50 and 46. 25

frame

for pivoting movement relative to the frame

When the hammer 24 is in the intermediate position

about

a

?rst pivot point between a forward position

shown in FIG. 3, it is under the biasing in?uence of the

and

a

rearward

position,

relatively rearwardly, the spring 46 is compressed until

(c)

?rst

biasing

means

for biasing said trigger toward

the bracket 47 engages the top of the mounting block

said forward position,

44. This prevents any further downward movement of

(d) a hammer block which is ?xed to the trigger and

the bracket 47. Additional rearward movement of the

which extends from said ?rst pivot point in the

hammer 24 causes the bracket 40 to move towards the

opposite direction from said trigger so that when

bracket 47, thereby, compressing the relatively strong

the trigger is in said forward position, the hammer

spring 50. The hammer 24 is, thereby, under the in?u

block is in a rearward position and when the trig

ence of the biasing pressure of the spring 50 from a short

ger is in its rearward position, the hammer block is

distance rearwardly of the intermediate position shown

in

a forward position,

in FIG. 3, to the fully cocked position shown in FIG. 4.

(e) a hammer which is pivotally connected to the

Rearward movement of the hammer 24 from the inter

frame at a second pivot point which is rearward of

mediate position shown in FIG. 3 causes the actuator

said trigger for pivoting movement relative to the

?nger 34 to engage the rearwardly facing surface 21 of 40

frame between a forward ?ring position and a rear

the hammer block 20, and cause the hammer block 20 to

ward cocked position, said hammer engaging said

swing forwardly and the trigger 16 to swing rear

wardly. When the hammer 24 reaches its rearward

hammer block when said hammer block is in its

cocked position, as shown in FIG. 4, the actuator ?nger

34 engages the notch 23. This maintains the hammer 24 45

in the rearward or cocked position. The trigger 16 is in

position and said hammer is in an- intermediate

an intermediate position and is prevented from moving

forwardly by the actuator ?nger 34. The ?rearm 10 is,

thereby, cocked and ready to ?re. Firearm 10 is ?red by

moving the trigger 16 from its intermediate position 50

mer from reaching said forward ?ring position,

(f) second biasing means for biasing said hammer

toward its forward position,

shown in FIG. 4 to its rearward position shown in FIG.

(g) an actuator which is ?xed to said hammer and

5. This action causes the hammer block 35 to move

which extends from said second pivot point in the

opposite direction from said hammer for engaging

forwardly so that the notch 23 pulls away from the

actuator ?nger 34, thereby releasing the hammer 24 for

forward motion by the biasing means 38. When the 55

trigger 16 is pulled back to its rearward position, the

hammer block 20 is suf?ciently forward so that it is

clear of the hammer when the hammer moves to its

said rearward cocked position to prevent said ham

said hammer block and moving said hammer block

forwardly and said trigger rearwardly to an inter

mediate position between the forward and rear

ward positions of said trigger and said hammer

block when said hammer is moved to its rearward

(h) latching means associated with said hammer block

and said actuator for locking said hammer in its

rearward position against forward motion and said

charge. When the trigger 16 is released after ?ring of

trigger in its intermediate position against forward

the ?rearm 10, the rounded outer surface 37 of the

hammer block engages the rounded outer surface 39 of

mer 24 is under the biasing in?uence of the relatively

weak spring 46, the hammer block 20 which is under the

position between said forward ?ring position and

position, and

forward ?ring position as shown in FIG. 5. The percus

sion cap 15 is struck by the forward striking surface 30

of the hammer, thereby, causing the ?rearm to dis

the retaining ?nger 36. The relatively weak spring 46 is

substantially weaker than the spring 22. Since the ham

rearward position and said trigger is in its forward

65

motion, said latching means being rendered ineffec

tive to lock, said hammer in its rearward position

upon movement of said trigger to its rearward

position so that said hammer is moved to its for

ward ?ring position by said second biasing means.

4,854,065

pivoting movement about a ?rst pivot point rela

tive to the frame between a forward ?ring position

ing means comprises:

(a) a notch in one of said hammer block and said

actuator, and

and a rearward position

(b) a projection in the other of said hammer block and 5

said actuator for engaging said notch when said

trigger is in its intermediate position and said ham

mer is in its rearward position, said ?nger being

clear of said notch when said trigger is moved from

it intermediate position.

(b) a hammer which is mounted on the frame for

2. A ?rearm as recited in claim 1, wherein said latch

l0

3. A ?rearm as recited in claim 1, wherein said ham

(c) ?rst biasing means for biasing said hammer toward

said forward position,

(d) a trigger assembly which is mounted on the frame

for pivoting movement about a second pivot point

relative to the frame, said second pivot point being

spaced from said ?rst point, said trigger assembly

comprising:

mer comprises a retaining ?nger for preventing said

hammer block from moving forwardly and said trigger

from moving rearwardly when said hammer block is in

(1) a trigger which extends downwardly from said

second pivot point for movement about said

second pivot point between a forward position

its rearward position, said retaining ?nger being moved

and a rearward position, and

(2) a hammer block which is integral with said

out of engagement with said hammer block when said

hammer block is moved forwardly by said actuator to

permit rearward movement of said trigger.

4. A ?rearm as recited in claim 1, wherein said second 20

trigger and which extends upwardly from said

second pivot point so that when said trigger is in

its forward position said hammer block is in a

biasing means comprises:

(a) a relatively weak spring for biasing said hammer

between the intermediate position and the forward

position of said hammer, and

(b) a relative strong spring for biasing said hammer

rearward position and when said trigger is in its

between the intermediate position and the rear

ward position of said hammer.

5. A ?rearm as recited in claim 1, wherein said second

ward position, said hammer block allowing said

hammer to reach its forward ?ring position

when said hammer block is in its forward posi

tion and said trigger is in its rearward position,

biasing means comprises:

(a) a mounting block which is ?xed to the frame and

rearward position, said hammer block is in a

forward position, said hammer block preventing

said hammer from reaching its forward ?ring

position when said hammer block is in its rear

and

spaced from said hammer, said mounting block

(e) second biasing means for biasing said trigger

having an opposing surface which faces said ham

toward its forward position and said hammer block

toward its rearward position.

7. A ?rearm as recited in claim 6, wherein said ham

mer block has a rearwardly facing notch and said ?re

mer,

(b) a spring assembly which is located between said

hammer and said mounting block, said ?rst spring

assembly comprising:

(1) a ?rst bracket which is operatively connected to

said hammer,

(2) a second bracket which is located between said

?rst bracket and said mounting bracket and nor

mally spaced from said mounting bracket, and

(3) ?rst relatively strong helical compressing

arm has an actuator ?nger which is ?xed to said ham

mer and which extends from said ?rst pivot point in the

opposite direction from said hammer for engaging said

hammer block and moving said hammer block for

wardly ad said trigger rearwardly to an intermediate

position between the forward and rearward positions of

said trigger when said hammer reaches its rearward

position, wherein said actuator ?nger engages said

notch to prevent forward movement of said trigger and

spring which extends from said ?rst bracket to

said second bracket so that said spring is com

pressed when one of said brackets is moved 45 said hammer and to maintain said hammer in its rear

ward and cocked position, and wherein movement of

toward the other of said brackets, said helical

said trigger from its intermediate position to its rear

compression spring having a central longitudinal

axis which extends through said mounting block

and said spring assembly being movable along

said axis toward and away from said mounting

ward position disengages said notch from said actuator

?nger and releases said hammer for forward movement

by said ?rst biasing means to its forward ?ring position.

8. A ?rearm as recited in claim 7, wherein said ham

mer comprises a retaining ?nger which occupies a re

block, and

(4) a second relatively weak compression spring for

biasing said spring assembly away from said

mounting block and for biasing said hammer

from its intermediate position to its forward posi

position for preventing said hammer block from moving

forwardly and said trigger from moving rearwardly

tion, wherein rearward movement of said ham

when said hammer block is in its rearward position, said

mer compresses said second spring and causes

retaining ?nger being moved out of said retaining posi

taining position when said hammer is in its intermediate

tion when said hammer block is moved forwardly by

said spring assembly to move toward said

said actuator to permit rearward movement of said

mounting block until said second bracket en

gages said second bracket engages said opposing 60 trigger.

9. A ?rearm as recited in claim 6, wherein said ham

surface so that additional rearward movement of

mer comprises a retaining ?nger which occupies a re

said hammer causes said ?rst bracket to move

taining position when said hammer is in its intermediate

toward said second bracket and compressing

position for preventing sad hammer block from moving

said second spring, whereby said hammer i bi

ased toward its intermediate position by said 65 forwardly and said trigger from moving rearwardly

when said hammer block is in its rearward position, said

second spring.

retaining ?nger being moved out of said retaining posi

6. A ?rearm comprising:

tion when said hammer block is moved forwardly by

(a) a housing which has a frame and a barrel,

4,854,065

its rearward position after ?ring, said ?rst biasing means

causing said hammer block to push said hammer rear

said actuator to permit rearward movement of said

trigger.

10. A ?rearm as recited in claim 9, wherein said sec

wardly against the biasing effect of said ?rst relatively

ond biasing means comprises a ?rst relatively weak

spring which is weaker than said first biasing means for

biasing said hammer forwardly between the intermedi

ate position of said hammer and the forward position of

said hammer and a second relatively strong spring

weak spring, said ?rst rounded surface being rearward

of and above said ?rst pivot point and said second

rounded surface being forward of and above said sec

said hammer block has a rearwardly facing ?rst

rounded surface and said retaining ?nger has a for

reaches its rearward position, said retaining ?nger is

above said hammer block and in position for retaining

said hammer block against forward motion, and said

trigger against rearward motion.

ond pivot point so that as the hammer block moves

rearwardly, said ?rst rounded surface moves down

which is substantially stronger than said relatively weak

spring for biasing said hammer forwardly between the 10 wardly and as said hammer moves rearwardly, said

second rounder surface moves upwardly along said ?rst

intermediate position of said hammer and the rearward

rounded surface so that when said hammer block

position of said hammer, and, wherein the outer end of

wardly facing second rounded surface which is engaged

by said ?rst rounded surface when said hammer is at its

forward ?ring position and said trigger is released from '

20

25

35

45

50

55

65

II

You might also like

- Us 4407085Document5 pagesUs 4407085rte678No ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- Handgun Firing Mechanism with Independent Sear ReleaseDocument5 pagesHandgun Firing Mechanism with Independent Sear Releaseyuehan0% (1)

- Limited States Patent: LngramDocument7 pagesLimited States Patent: LngramJin SongNo ratings yet

- Oct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Document5 pagesOct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Юрий РуденкоNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- Us 4023499Document4 pagesUs 4023499ererNo ratings yet

- United States Patent 1111 3,595,128Document9 pagesUnited States Patent 1111 3,595,128rte678No ratings yet

- Byfwf p41 ': March 7, 1961 O. Danyluke 2,973,909Document5 pagesByfwf p41 ': March 7, 1961 O. Danyluke 2,973,909KrozeNo ratings yet

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- Us4467698 PDFDocument11 pagesUs4467698 PDFJin Song100% (1)

- Variable displacement compressor hinge mechanismDocument13 pagesVariable displacement compressor hinge mechanismSelvaraji MuthuNo ratings yet

- Us 4407085Document5 pagesUs 4407085Слэйтер Строительная компанияNo ratings yet

- Us 8210068us 8210068us 8210068us 8210068Document9 pagesUs 8210068us 8210068us 8210068us 8210068JameszouqunNo ratings yet

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocument7 pagesUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNo ratings yet

- 3/ Z7 VZMZM/ZZ : V. Holek 2,216,412Document3 pages3/ Z7 VZMZM/ZZ : V. Holek 2,216,412wererNo ratings yet

- Adjustable Handles for Riding or Walking Behind Lawn MowerDocument4 pagesAdjustable Handles for Riding or Walking Behind Lawn Mowerraseks1No ratings yet

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- Jurnal Bubut FixsafasfasfDocument6 pagesJurnal Bubut FixsafasfasfAdiBimaSanjaya100% (1)

- EP1321438B1Document10 pagesEP1321438B1Alessandro PatanèNo ratings yet

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- United States Patent (191Document10 pagesUnited States Patent (191PhanHathamNo ratings yet

- Us4358986 PDFDocument9 pagesUs4358986 PDFJin SongNo ratings yet

- Owen Sub Machine Gun PatentDocument11 pagesOwen Sub Machine Gun PatentBallistics67% (3)

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- Benet Mercie BreechDocument13 pagesBenet Mercie BreechAnonymous htRZ5zTMgNo ratings yet

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- US20010024927A1Document7 pagesUS20010024927A1MahnooshNo ratings yet

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- United States Patent 1191: MasuyamaDocument7 pagesUnited States Patent 1191: MasuyamaAbdullah AljabriNo ratings yet

- Thomosmm Donnell: T. M. McdonnellDocument3 pagesThomosmm Donnell: T. M. Mcdonnelledef345No ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- Us 3706152Document7 pagesUs 3706152rte678No ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- Us 6357155Document5 pagesUs 6357155edef345No ratings yet

- Raschel Machine With Stitch Comb and Knock-Over BarDocument6 pagesRaschel Machine With Stitch Comb and Knock-Over Barntd1011No ratings yet

- US3404552Document4 pagesUS3404552Prabal JindalNo ratings yet

- M2 HB Bolt Side Change US2529391Document4 pagesM2 HB Bolt Side Change US2529391apoorva singhNo ratings yet

- Us 3090578Document3 pagesUs 3090578mohamad zareNo ratings yet

- Us 3960084Document3 pagesUs 3960084rte678No ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- Benelli B76 US3893369Document4 pagesBenelli B76 US3893369apoorva singhNo ratings yet

- United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986Document3 pagesUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986wahaha06No ratings yet

- TEPZZZ89Z4 - 4B - T: European Patent SpecificationDocument25 pagesTEPZZZ89Z4 - 4B - T: European Patent Specificationzweisteine777No ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- 1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieDocument3 pages1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieVincent Grangé-PradérasNo ratings yet

- Title - Wood Chipper Disc and Knife MountingDocument5 pagesTitle - Wood Chipper Disc and Knife Mountingمحمد عبدالدايمNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- Diseño ElectricoDocument5 pagesDiseño ElectricoemernelsonmanNo ratings yet

- US Patent 4677897Document8 pagesUS Patent 4677897Mosin-NagantNo ratings yet

- Two-Axis Motion Mechanism with Reduced BacklashDocument10 pagesTwo-Axis Motion Mechanism with Reduced BacklashNile_JockeyNo ratings yet

- EP 1 262 663 A2 Rotor for Variable Displacement Swash Plate CompressorDocument16 pagesEP 1 262 663 A2 Rotor for Variable Displacement Swash Plate CompressorSelvaraji MuthuNo ratings yet

- United States Patent (19) (11) 4,298,078Document9 pagesUnited States Patent (19) (11) 4,298,078lfilippiniNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- United States Patent (191: Andersen Et A1Document5 pagesUnited States Patent (191: Andersen Et A1khoagleNo ratings yet

- US3173686 (Coin-Op Kiddie Ride)Document8 pagesUS3173686 (Coin-Op Kiddie Ride)ENo ratings yet

- Nun M.: BC BM 0000Document12 pagesNun M.: BC BM 0000shdhsjkNo ratings yet

- (GUNSMITHING) Sten Submachine Gun WWIIDocument7 pages(GUNSMITHING) Sten Submachine Gun WWIIMago Invisivel100% (10)

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- 枪炮声抑制器 PDFDocument11 pages枪炮声抑制器 PDFJin SongNo ratings yet

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongNo ratings yet

- 可调式双级触发机制半自动武器 PDFDocument12 pages可调式双级触发机制半自动武器 PDFJin SongNo ratings yet

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongNo ratings yet

- 块化插入触发器的方法和装置5 PDFDocument23 pages块化插入触发器的方法和装置5 PDFJin SongNo ratings yet

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Document13 pagesUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- Us6418655 PDFDocument17 pagesUs6418655 PDFJin SongNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Document15 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 pagesThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (121)

- 安装装置,枪支消声器 PDFDocument28 pages安装装置,枪支消声器 PDFJin Song100% (1)

- Us7946069 PDFDocument15 pagesUs7946069 PDFJin SongNo ratings yet

- Us4467698 PDFDocument11 pagesUs4467698 PDFJin Song100% (1)

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- Us6308609 PDFDocument18 pagesUs6308609 PDFJin SongNo ratings yet

- Us7676976 PDFDocument35 pagesUs7676976 PDFJin SongNo ratings yet

- Us5274939 PDFDocument7 pagesUs5274939 PDFJin SongNo ratings yet

- Us4358986 PDFDocument9 pagesUs4358986 PDFJin SongNo ratings yet

- Us4522106 PDFDocument13 pagesUs4522106 PDFJin Song100% (1)

- Us3276323 PDFDocument7 pagesUs3276323 PDFJin SongNo ratings yet

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Document6 pagesNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongNo ratings yet

- Fuji E Series MCCBDocument15 pagesFuji E Series MCCBFebri HandokoNo ratings yet

- WT198CDocument2 pagesWT198CaaquilNo ratings yet

- Logitech K330 KeyboardDocument148 pagesLogitech K330 Keyboardjdrivera188205No ratings yet

- Terminologies Used in Protective RelayingDocument2 pagesTerminologies Used in Protective RelayingMohammed Thofeek KhanNo ratings yet

- Sub-Circuit Monitoring: 11.3: Central Battery SystemsDocument1 pageSub-Circuit Monitoring: 11.3: Central Battery SystemsAnuraj VakavayalilNo ratings yet

- Failure Code of The PLC From SAUER For The BF / MF 571 C BF / MF 691 C CrawlerDocument15 pagesFailure Code of The PLC From SAUER For The BF / MF 571 C BF / MF 691 C CrawlerTeknik MakinaNo ratings yet

- Roland SH 09 Service Note PDFDocument7 pagesRoland SH 09 Service Note PDFNicola Dal saccoNo ratings yet

- Electric MotorsDocument11 pagesElectric MotorsAllan Gilbert Manalo JainNo ratings yet

- Ultra 2000Document216 pagesUltra 2000ElputoAmo XDNo ratings yet

- Question Bank in DC MotorsDocument13 pagesQuestion Bank in DC MotorsJoichiro NishiNo ratings yet

- Bulletin 700-HF: Miniature Square Base Ice-Cube RelayDocument2 pagesBulletin 700-HF: Miniature Square Base Ice-Cube RelayporterurmstonNo ratings yet

- C60N Marine PDFDocument2 pagesC60N Marine PDFViorel CatalinNo ratings yet

- Quick Start Guide Multilingual TitleDocument24 pagesQuick Start Guide Multilingual TitleAlucardNo ratings yet

- Primary-Side Transformer ProtectionDocument15 pagesPrimary-Side Transformer ProtectionRicarno Sei'koNo ratings yet

- Site Visit Report: Project Name - Proposed Educational Building of Degree CollegeDocument2 pagesSite Visit Report: Project Name - Proposed Educational Building of Degree CollegeRajshekhar KategarNo ratings yet

- m102 Service ManualDocument304 pagesm102 Service ManualAlejandroPáramoFandiño60% (5)

- BEKEBE Construction Catalogue Molds Contact Amin ZhangDocument35 pagesBEKEBE Construction Catalogue Molds Contact Amin ZhangSANDRO LUQUE ESPINOZANo ratings yet

- PF755 HHP Maintenance Manual - 8B5DDocument3 pagesPF755 HHP Maintenance Manual - 8B5DFranko Ney FélixNo ratings yet

- 8 - Precast Concrete Structures-Students PDFDocument17 pages8 - Precast Concrete Structures-Students PDFsitehabNo ratings yet

- Maserati QP 2006 - 2007 Workshop ManualDocument1,897 pagesMaserati QP 2006 - 2007 Workshop ManualDamien Jorgensen83% (12)

- Ssp431 Audi Rs 6Document44 pagesSsp431 Audi Rs 6gil_cs100% (1)

- DALI 4Ch RC EN D0016Document5 pagesDALI 4Ch RC EN D0016Mariuta VasilicaNo ratings yet

- Gasoline Direct InjectionDocument21 pagesGasoline Direct InjectionAadhith BalaNo ratings yet

- Drawing Silver Park TKJ630-2.0-18080612BDocument4 pagesDrawing Silver Park TKJ630-2.0-18080612BYeison GoyenecheNo ratings yet

- Schneider S56SW110 GRYDocument1 pageSchneider S56SW110 GRYAten HarisNo ratings yet

- Izbor Osigurača Odvodnika PrenaponaDocument5 pagesIzbor Osigurača Odvodnika PrenaponaMarko ŠuvačkiNo ratings yet

- LED Lighting Design GuideDocument34 pagesLED Lighting Design GuideFormerru100% (1)

- 7000 Series ATS Operator's ManualDocument11 pages7000 Series ATS Operator's ManualJimNo ratings yet

- VASHISTA AND S1 DEVELOPMENT ONSHORE TERMINALDocument8 pagesVASHISTA AND S1 DEVELOPMENT ONSHORE TERMINALKrm ChariNo ratings yet

- Catálogo Interruptor Siemens GMI PDFDocument20 pagesCatálogo Interruptor Siemens GMI PDFhesse21No ratings yet