Professional Documents

Culture Documents

Cepalco (138 KV Live Tank PCB)

Uploaded by

gvdomingoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cepalco (138 KV Live Tank PCB)

Uploaded by

gvdomingoCopyright:

Available Formats

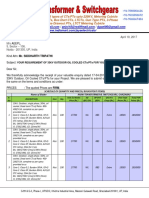

PCB-1

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

EVALUATION OF 138kV POWER CIRCUIT BREAKER

Description

B.1

B.1.1

Technical Characteristics and Requirements

Application

a. Breaker Application (general purpose, definite purposes)

B.1.2

Line, transformer and

capacitor

b. Individual pole operation (open and close):

No

c. Independent pole tripping

No

Circuit Breaker Electrical Characteristics

a. Nominal System Voltage, kV

138

b. Rated Maximum Voltage, kV

145

c. Rated Voltage range factor

d. Rated Insulation Level

1. Short-duration Power Frequency Withstand Voltage, 1 min. dry, kV rms

2. Lightning Impulse Withstand Voltage, kV, (peak value)

e. Rated continuous current at System Frequency, A rms

f. Rated Short Time Withstand Current, kA rms

g. Rated Interrupting Time, milliseconds (ms)

h. Maximum Permissible Tripping Time Delay, sec.

i. Rated closing and latching current, kA peak

j. Reclosing Duty Cycle

k. Maximum Permissible Tripping current

1. Voltage/Impedance

2. Cut-off Current

I. Minimum Dead Time to insure that closing time is not too short

m. Rated System Frequency, Hz.

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

Design Requirements

_______________________________________________

_______________________________________________

_______________________________________________

1

275

650

3,150

40

1

40 (108)

O-0.3s CO-3min CO

By Contractor

By Contractor

By Contractor

60

PCB-2

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

B.1.3

Circuit Breaker Physical Characteristics

a. Location (specify indoor, outdoor)

Three pole tank

c. Number of Interrupting Modules/Pole

d. Medium of Interrupting

e. Interrupting Module (specify Live tank or Dead tank)

1

SF6

Dead tank

g. Phase Spacing between centerline of single phase tanks, mm

h. Phase Spacing between tops of bushings (if provided in common enclosures)

Minimum distance between tops of bushings of same pole (if dead tank breakers are

i.

supplied)

B.1.5

3000

By Contractor

By Contractor

a. Rated Maximum Voltage, kV

b. Creepage length, mm

c. Color

d. Maximum cantilever strengh, kg

e. Must be suitable for live line washing (Yes, No)

f. Internal bushing insulation

Operating Mechanism and Auxiliaries

a. Operating mechanism

Motor-Spring Charged

b. Motor Operating mechanism voltage (AC, DC)

230 Vac, 1, 60Hz

138

Brown

By contractor

Yes

SF6 gas

125 Vdc

a. 138kV

2 electrically independent

trip coils

b. 69kV

2 electrically independent

trip coils

e. Tripping Mechanism Voltage, Vdc

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

Individual foundation

Bushing Characteristics

c. Closing coil voltage (AC, DC)

d. Tripping Mechanism

1. Number of trip coils (circuits) per pole

CONFORME

outdoor

b. Enclosures (specify single pole tank, three-pole tank)

f. Mounting on: (specify individual foundation, common foundation, frame)

B.1.4

Design Requirements

f.

Number of additional converitble auxiliary contacts above those normally required for

circuit breaker operation

g.

The operating mechanism shall be engineered for single pole closing and tripping

_______________________________________________

_______________________________________________

_______________________________________________

125 V dc

12A, 12B

No

PCB-3

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

The breakers if engineered for single pole actuation shall be provided with phase

h. discrepancy monitoring and control system for synchronized operation of individual pole

(closing and opening )

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

Design Requirements

N/A

PCB-4

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

For compressed gas or air blast circuit breakers, on decrease of gas pressure below

minimum value of the circuit breaker

1. If closed, shall be

PT - Prevented from Tripping

TA - Trip Automatically

2. If open, shall be

PC - Prevented from closing

CA - Close Automatically

Current Transformer (CT)

Design Requirements

i.

B.1.6

a. If dead tank type circuit breakers are to be supplied, bushing type current transformers

are to be provided on each bushing turret

If required, they shall be as mentioned in the specifications for current transformer of

b.

Section 6

c. No. of cores per PCB bushing turret

B.1.7

PC

Yes

Yes

Miscellaneous Accessories

a. Breaker Position Indicator (both mechanical & light)

b. Manual Closing Device

c. Operations Counter

Yes

Yes

Yes

d. Cable duct from the control cubicle down to cable trench to be provided by contractor

Yes

Type and size of Line terminal connectors to be furnished by Contractor on the terminals

e. of circuit breaker shall be suitable for (specify size/ampacity of conductor and no. of

conductors)

Refer to bid drawing

Type and size of ground terminal connectors to be furnished by the Contractor for the

circuit breaker shall be suitable for (specify size fo conductor)

>125 mm2 PVC insulated

tin-annealed stranded Cu

conductor PVC Insulated

f.

g. Required no. of ground terminal connectors on the structure of the breaker:

1. If mounted on individual structure

2. If mounted on common structure

B.1.8 Alarm Devices

B.1.8.1 All alarm indicating devices shall have (spdt, dpdt)

electrically independent contacts to be used on (volts dc) control system to open or close 0.1

amperes inductive circuit

Service

B.1.9and Maintenance

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

PT

_______________________________________________

_______________________________________________

_______________________________________________

1

2

DPDT

125 Vdc

PCB-5

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

Minimum permissible number of interruptions before any contact check or mechanical

a.

check with opening of gas compartment is necessary:

b. Leakage rate of SF6 per year, %

B.2

B.2.1

Test and Test Report(s) Requirements

Normal Test

Is breaker design new or previous design with substantial changes in design and/or rating

a.

(yes, no)

Note: If yes, certified design tests and reports are required

b. Design test and reports required (Yes, No)

Certified test design reports of prototype or duplicate production type are acceptable

c.

(Yes, No)

d. Test reports of licenser instead of contractor's manufacturer is:

e. Test frequency requirement (Power)

f. Factory Acceptance Tests (Routine) to be witnessed by Owner's Representative (s)

g. Required no. of personnel to witness Factory Acceptance Tests

B.2.2

Standard Field Test Requirement during Commissioning

a. Insulation Resistance Test

b. Static Contact Resistance Test

c. Timing Analysis

d. Insulation Powr Factor Test

e. SF6 Gas Analysis

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

Design Requirements

In accordance with the

operating endurance

capabilities for circuit

breakers

< 1 for all types of breakers

Yes, previous design

Yes

Yes

Yes

Not acceptable

60Hz

Yes

3

PCB-6

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

B.3

B.3.1

B.4

B.4.1

B.4.2

B.4.3

Auxiliary Power Supply

The items listed below shall be designed to receive the following auxiliary voltage source.

a. Dehumidifier for the control cubicle, Vac

230 Vac, 1, 60 Hz

b. Internal lights and convenience outlets

230 Vac, 1, 60 Hz

c. Motors

230 Vac, 1, 60 Hz

d. Controls

125 Vdc, +10%, -15%

e. Indicating lights for position indicator operating mechanism

125 Vdc, +10%, -15%

Spares and Spares Parts

The following parts aside from those Manufacturer's recommended spare parts shall be furnished for each applicable

substation:

a. 138kV

1. Set(s) of tripping coils for the circuit breaker

1

2. Set(s) of closing coils for the circuit breaker

1

3. Set(s) of pole discrepancy relay

1

4. Set(s) of indicating bulb

1

5. Set(s) of motor for the operating mechanism

1

All spare parts shall be interchangeable with and identical in all respect to the original parts.

All breakers of the same rating and type and all its components shall be fully intechangeable.

B.5

Tools

B.5.1

In addition to those tools and devices recommended by the Manufacturer for the circuit

breaker, the following tools and devices shall be supplied each for substation.

1.

B.6

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative C.

Designation

Design Requirements

Set(s) of SF6 handling equipment composing of but not limited to the following:

a. SF6 gas filling device

b. SF6 gas recovery and drying device

c. SF6 gas testing set for leakage, humidity O2 content and SO2 gas analysis

d. SF6 gas temperature measuring device

e. Measuring device for SF6 density

Other Techinical Requirements for the Circuit Breaker

The Power Circuit Breaker (PCB) shall be configured as shown in the Single Line Diagram (SLD).

The Contractor shall design the optimum arrangement of the switchgear which will suit the

available space for the proposed switchyards.

All operating mechanism with manual operation facility shall be positioned/arranged in such

manner that it could be operated from the ground level whenever possible. Otherwise, the

Contractor is required to provide suitable operating flat form of ladder.

Furthermore, the design and construction of the switchgear must allow readily replacement

of parts with minimum interruption

to the module and adjacent bays.

_______________________________________________

Other Technical Data to Be Filled-in

by Contractor

_______________________________________________

_______________________________________________

1 set

PCB-7

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

Design Requirements

C.1

The contractor furnished data and information are included in this specification to indicate

the guaranteed performance, interface requirements and construction features of all

Contractor furnished equipement. The accuracy and the compatibility of such information

with overall performance requirements specified by Employer are the sole responsibility of

the Contractor.

C.2

C.2.1

Environmental Considerations

In accordance with Paragraph 2.8 of the General Technical Requirements and the Technical

Data Sheets of Section 2, the operating environment for this installation (will, will not) affect

the life expectancey of the components used in this equipements. if there will be an effect,

the following components will be affected as follows:

Component

_______________________________

Effect

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

PCB-8

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

C.3

Design Requirements

Other Technical Data for Power Circuit Breaker

Contractor's Data

1. Country of Origin

2. Manufacturer

3. Type and Designation

4. Control Circuit

a. Closing voltage range, V

b. Maximum closing current, A

c. Tripping voltage range, V

d. Maximum tripping current, A

5. Breaker Operating Time (in ms) for Rated Control Voltage and Pressure

a. Opening time from energization of trip coil to contact parting

b. Arcing time

c. Break time

d. Close open time

e. Closing time

6. Gas Pressures

a. Pressure at 20C of interrupting medium

b. Pressure at 20C of insulating medium

7. Gas System

a. SF6 Gas shipment method in breaker or separate; (Yes, No)

b. If Yes, no. of containers, each

c. Weight per container, kg

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

PCB-9

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

d.

e.

f.

g.

h.

Gas per container, kg

Total quantity of SF6 gas to be supplied with the original equipment, kg

Total quantity of SF6 gas required per breaker, kg

Guaranteed maximum SF6 gas leakage rate in kg/yr

No. of gas monitoring systems included with the equipment

i.

In-service life of gaskets, years

j. Storage shelf life of gaskets, years

8. Maximum Foundation Loading during Operation

a. For horizontal breakers, N

b. For vertical breakers, N

9. Motor Capacity

a. Type

b. Horsepower, hp

c. Current, start/run

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

Design Requirements

PCB-10

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

EVALUATION OF 69kV POWER CIRCUIT BREAKER

Description

B.1

B.1.1

Technical Characteristics and Requirements

Application

a. Breaker Application (general purpose, definite purposes)

B.1.2

Line, transformer and

capacitor

b. Individual pole operation (open and close):

No

c. Independent pole tripping

No

Circuit Breaker Electrical Characteristics

a. Nominal System Voltage, kV

69

b. Rated Maximum Voltage, kV

72.5

c. Rated Voltage range factor

d. Rated Insulation Level

1. Short-duration Power Frequency Withstand Voltage, 1 min. dry, kV rms

2. Lightning Impulse Withstand Voltage, kV, (peak value)

e. Rated continuous current at System Frequency, A rms

f. Rated Short Time Withstand Current, kA rms

g. Rated Interrupting Time, milliseconds (ms)

h. Maximum Permissible Tripping Time Delay, sec.

i. Rated closing and latching current, kA peak

j. Reclosing Duty Cycle

k. Maximum Permissible Tripping current

1. Voltage/Impedance

2. Cut-off Current

I. Minimum Dead Time to insure that closing time is not too short

m. Rated System Frequency, Hz.

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

Design Requirements

_______________________________________________

_______________________________________________

_______________________________________________

1

140

325

3,150

40

2

40

O-0.3s CO-3min CO

By Contractor

By Contractor

By Contractor

60

PCB-11

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

B.1.3

Circuit Breaker Physical Characteristics

a. Location (specify indoor, outdoor)

Three pole tank

c. Number of Interrupting Modules/Pole

d. Medium of Interrupting

e. Interrupting Module (specify Live tank or Dead tank)

1

SF6

Dead tank

g. Phase Spacing between centerline of single phase tanks, mm

h. Phase Spacing between tops of bushings (if provided in common enclosures)

Minimum distance between tops of bushings of same pole (if dead tank breakers are

i.

supplied)

B.1.5

N/A

By Contractor

By Contractor

a. Rated Maximum Voltage, kV

b. Creepage length, mm

c. Color

d. Maximum cantilever strengh, kg

e. Must be suitable for live line washing (Yes, No)

f. Internal bushing insulation

Operating Mechanism and Auxiliaries

a. Operating mechanism

Motor-Spring Charged

b. Motor Operating mechanism voltage (AC, DC)

230 Vac, 1, 60Hz

72.5

2247.5

Brown

By Contractor

Yes

SF6 gas

125 Vdc

a.

138kV

2 electrically independent

trip coils

b.

69kV

2 electrically independent

trip coils

e. Tripping Mechanism Voltage, Vdc

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

Individual foundation

Bushing Characteristics

c. Closing coil voltage (AC, DC)

d. Tripping Mechanism

1. Number of trip coils (circuits) per pole

CONFORME

outdoor

b. Enclosures (specify single pole tank, three-pole tank)

f. Mounting on: (specify individual foundation, common foundation, frame)

B.1.4

Design Requirements

125 Vdc

f.

Number of additional converitble auxiliary contacts above those normally required for circuit

breaker operation

12A, 12B

g.

The operating mechanism shall be engineered for single pole closing and tripping

No

_______________________________________________

_______________________________________________

_______________________________________________

PCB-12

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

The breakers if engineered for single pole actuation shall be provided with phase

h. discrepancy monitoring and control system for synchronized operation of individual pole

(closing and opening )

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

Design Requirements

N/A

PCB-13

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

For compressed gas or air blast circuit breakers, on decrease of gas pressure below minimum

value of the circuit breaker

1. If closed, shall be

PT - Prevented from Tripping

TA - Trip Automatically

2. If open, shall be

PC - Prevented from closing

CA - Close Automatically

Current Transformer (CT)

Design Requirements

i.

B.1.6

a. If dead tank type circuit breakers are to be supplied, bushing type current transformers are

to be provided on each bushing turret

If required, they shall be as mentioned in the specifications for current transformer of

b.

Section 6

c. No. of cores per PCB bushing turret

B.1.7

Miscellaneous Accessories

a. Breaker Position Indicator (both mechanical & light)

b. Manual Closing Device

c. Operations Counter

d. Cable duct from the control cubicle down to cable trench to be provided by contractor

PT

PC

Yes

Yes

Three (3)

Yes

Yes

Yes

Yes

Type and size of Line terminal connectors to be furnished by Contractor on the terminals of

e. circuit breaker shall be suitable for (specify size/ampacity of conductor and no. of

conductors)

f.

Type and size of ground terminal connectors to be furnished by the Contractor for the circuit

breaker shall be suitable for (specify size fo conductor)

g. Required no. of ground terminal connectors on the structure of the breaker:

1. If mounted on individual structure

2. If mounted on common structure

B.1.8 Alarm Devices

B.1.8.1 All alarm indicating devices shall have (spdt, dpdt)

electrically independent contacts to be used on (volts dc) control system to open or close 0.1

amperes inductive circuit

Service

B.1.9 and Maintenance

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

>125 mm2 PVC insulated

tin-annealed stranded Cu

conductor PVC Insulated

1

2

DPDT

125 Vdc

PCB-14

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

Minimum permissible number of interruptions before any contact check or mechanical

a.

check with opening of gas compartment is necessary:

b. Leakage rate of SF6 per year, %

B.2

B.2.1

Test and Test Report(s) Requirements

Normal Test

Is breaker design new or previous design with substantial changes in design and/or rating

a.

(yes, no)

Note: If yes, certified design tests and reports are required

b. Design test and reports required (Yes, No)

Certified test design reports of prototype or duplicate production type are acceptable (Yes,

c.

No)

d. Test reports of licenser instead of contractor's manufacturer is:

e. Test frequency requirement (Power)

f.

Factory Acceptance Tests (Routine) to be witnessed by Owner's Representative (s)

g. Required no. of personnel to witness Factory Acceptance Tests

B.2.2

Standard Field Test Requirement during Commissioning

a. Insulation Resistance Test

b. Static Contact Resistance Test

c. Timing Analysis

d. Insulation Powr Factor Test

e. SF6 Gas Analysis

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

Design Requirements

In accordance with the

operating endurance

capabilities for circuit

breakers

< 1 for all types of breakers

Yes

Yes

Yes

Not acceptable

60Hz

Yes

Two (2)

PCB-15

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

B.3

B.3.1

B.4

B.4.1

B.4.2

B.4.3

Auxiliary Power Supply

The items listed below shall be designed to receive the following auxiliary voltage source.

a. Dehumidifier for the control cubicle, Vac

230 Vac, 1, 60 Hz

b. Internal lights and convenience outlets

230 Vac, 1, 60 Hz

c. Motors

230 Vac, 1, 60 Hz

d. Controls

125 Vdc, +10%, -15%

e. Indicating lights for position indicator operating mechanism

125 Vdc, +10%, -15%

Spares and Spares Parts

The following parts aside from those Manufacturer's recommended spare parts shall be furnished for each applicable

substation:

a. 138kV

1. Set(s) of tripping coils for the circuit breaker

1

2. Set(s) of closing coils for the circuit breaker

1

3. Set(s) of pole discrepancy relay

1

4. Set(s) of indicating bulb

1

5. Set(s) of motor for the operating mechanism

1 for each type used

All spare parts shall be interchangeable with and identical in all respect to the original parts.

All breakers of the same rating and type and all its components shall be fully intechangeable.

B.5

Tools

B.5.1

In addition to those tools and devices recommended by the Manufacturer for the circuit breaker,

the following tools and devices shall be supplied each for substation.

1.

B.6

CONFORME

Name of Bidder

Name SIgnature of Bidder's RepresentativeC.

Designation

Design Requirements

Set(s) of SF6 handling equipment composing of but not limited to the following:

a. SF6 gas filling device

b. SF6 gas recovery and drying device

c. SF6 gas testing set for leakage, humidity O2 content and SO2 gas analysis

d. SF6 gas temperature measuring device

e. Measuring device for SF6 density

Other Techinical Requirements for the Circuit Breaker

The Power Circuit Breaker (PCB) shall be configured as shown in the Single Line Diagram (SLD).

The Contractor shall design the optimum arrangement of the switchgear which will suit the

available space for the proposed switchyards.

All operating mechanism with manual operation facility shall be positioned/arranged in such

manner that it could be operated from the ground level whenever possible. Otherwise, the

Contractor is required to provide suitable operating flat form of ladder.

Furthermore, the design and construction of the switchgear must allow readily replacement of

parts with minimum interruption

to the module and adjacent bays.

_______________________________________________

Other Technical Data to Be Filled-in

by Contractor

_______________________________________________

_______________________________________________

1 set

PCB-16

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

C.1

C.2

C.2.1

Design Requirements

The contractor furnished data and information are included in this specification to indicate the

guaranteed performance, interface requirements and construction features of all Contractor

furnished equipement. The accuracy and the compatibility of such information with overall

performance requirements specified by Employer are the sole responsibility of the Contractor.

Environmental Considerations

In accordance with Paragraph 2.8 of the General Technical Requirements and the Technical Data

Sheets of Section 2, the operating environment for this installation (will, will not) affect the life

expectancey of the components used in this equipements. if there will be an effect, the following

components will be affected as follows:

Component

_______________________________

Effect

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

PCB-17

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

C.3

Design Requirements

Other Technical Data for Power Circuit Breaker

Contractor's Data

1. Country of Origin

2. Manufacturer

3. Type and Designation

4. Control Circuit

a. Closing voltage range, V

b. Maximum closing current, A

c. Tripping voltage range, V

d. Maximum tripping current, A

5. Breaker Operating Time (in ms) for Rated Control Voltage and Pressure

a. Opening time from energization of trip coil to contact parting

b. Arcing time

c. Break time

d. Close open time

e. Closing time

6. Gas Pressures

a. Pressure at 20C of interrupting medium

b. Pressure at 20C of insulating medium

7. Gas System

a. SF6 Gas shipment method in breaker or separate; (Yes, No)

b. If Yes, no. of containers, each

c. Weight per container, kg

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

PCB-18

POWER CIRCUIT BREAKER - CEPALCO SUBSTATION

Technical Data Sheet

Description

d. Gas per container, kg

e. Total quantity of SF6 gas to be supplied with the original equipment, kg

f. Total quantity of SF6 gas required per breaker, kg

g. Guaranteed maximum SF6 gas leakage rate in kg/yr

h. No. of gas monitoring systems included with the equipment

i. In-service life of gaskets, years

j. Storage shelf life of gaskets, years

8. Maximum Foundation Loading during Operation

a. For horizontal breakers, N

b. For vertical breakers, N

9. Motor Capacity

a. Type

b. Horsepower, hp

c. Current, start/run

CONFORME

Name of Bidder

Name SIgnature of Bidder's Representative

Designation

_______________________________________________

_______________________________________________

_______________________________________________

Design Requirements

You might also like

- Type PRS Programmable Resettable Sectionalizer Single-Phase: SectionDocument9 pagesType PRS Programmable Resettable Sectionalizer Single-Phase: SectionLuis MurilloNo ratings yet

- Cooper Nova Manual S280421 Part3Document7 pagesCooper Nova Manual S280421 Part3Arliel John GarboNo ratings yet

- " Power Details ": Project NameDocument11 pages" Power Details ": Project NameEdmar BataqueNo ratings yet

- Presentation 1Document43 pagesPresentation 1Arliel John GarboNo ratings yet

- System Design and Cost Estimation of Additional 100MVA Power Transformer at Balingueo SubstationDocument39 pagesSystem Design and Cost Estimation of Additional 100MVA Power Transformer at Balingueo SubstationMichael FontanillaNo ratings yet

- 110 TOP TRANSMISSION & DISTRIBUTION Objective QuestionsDocument22 pages110 TOP TRANSMISSION & DISTRIBUTION Objective QuestionsEarl Jenn AbellaNo ratings yet

- Decision 2015-213+RC COTELCODocument64 pagesDecision 2015-213+RC COTELCOEdza Mae HaguimitNo ratings yet

- Wefix Construction Services Incorporated: (Weekly Activity Report)Document4 pagesWefix Construction Services Incorporated: (Weekly Activity Report)Mark Kenneth P. OntejoNo ratings yet

- AN - PCD Assignable Phases and Bushing PolarityDocument5 pagesAN - PCD Assignable Phases and Bushing PolarityChristianM.LeandroYauriNo ratings yet

- ZAMCELCO CAPEX Program ApprovalDocument44 pagesZAMCELCO CAPEX Program ApprovalCoii Yee Jr.No ratings yet

- PCB Management Plan - LUECO Poro Point SubstationDocument5 pagesPCB Management Plan - LUECO Poro Point SubstationArmelita Tadifa DucusinNo ratings yet

- Existing Power Plant Evaluation: CEPALCO 1MW Photovoltaic Power PlantDocument34 pagesExisting Power Plant Evaluation: CEPALCO 1MW Photovoltaic Power PlantJChris EsguerraNo ratings yet

- DIAL TYPE TESTEDDocument2 pagesDIAL TYPE TESTEDPruthvi KrishnaNo ratings yet

- ABB Series V Expulsion Dropout FusesDocument4 pagesABB Series V Expulsion Dropout FusesmrhomNo ratings yet

- What It Takes To Become An APEC Engineer ISBN9781684898640Document531 pagesWhat It Takes To Become An APEC Engineer ISBN9781684898640YVES GONZALESNo ratings yet

- Maintenance Testing Price Actual Testing PriceDocument2 pagesMaintenance Testing Price Actual Testing PriceEdmar BataqueNo ratings yet

- 2021 Version of Electrical Shopwork I For Electrical Engineering and Technology Students Isbn 9781685642792Document94 pages2021 Version of Electrical Shopwork I For Electrical Engineering and Technology Students Isbn 9781685642792YVES GONZALESNo ratings yet

- E1 WH s1 s2 Electrical Rev2Document1 pageE1 WH s1 s2 Electrical Rev2kenneth molinaNo ratings yet

- IIEE Magazine 2019Document48 pagesIIEE Magazine 2019Harold TiczonNo ratings yet

- Introduction to Transformer Rated MetersDocument21 pagesIntroduction to Transformer Rated MetersLowell ValienteNo ratings yet

- Over Current Protection For The TransformersDocument9 pagesOver Current Protection For The TransformersSandipan MukherjeeNo ratings yet

- PHILEC Brand Distribution Transformers GuideDocument2 pagesPHILEC Brand Distribution Transformers Guideleantonato100% (1)

- CTS, PTS, Current Transformer, Potential Transformers, SMC LT Distribution BoxDocument4 pagesCTS, PTS, Current Transformer, Potential Transformers, SMC LT Distribution BoxSharafatNo ratings yet

- 1007Document1 page1007sivasankarNo ratings yet

- Rla Transformer by Furan TestDocument4 pagesRla Transformer by Furan TestRaja Bharath DonthiNo ratings yet

- 6.3kA PerformanceDocument36 pages6.3kA PerformanceedgarcooNo ratings yet

- Res.26s+2009 CAPEXDocument85 pagesRes.26s+2009 CAPEXCJ MillenaNo ratings yet

- Construction Electric Distribution StdsDocument299 pagesConstruction Electric Distribution Stdskenneth molinaNo ratings yet

- DecisionERCCaseNo2012 128RC PDFDocument24 pagesDecisionERCCaseNo2012 128RC PDFFranz Xyrlo Ibarra TobiasNo ratings yet

- Evolis Circuit Breaker CatalogueDocument21 pagesEvolis Circuit Breaker Cataloguepb21No ratings yet

- V16 - Malvar - Bulihan.r1Document14 pagesV16 - Malvar - Bulihan.r1Edmar BataqueNo ratings yet

- Jambaran Tiung Biru Project: Electrical Power and Control Cable Schedule - Substation No. 1Document2 pagesJambaran Tiung Biru Project: Electrical Power and Control Cable Schedule - Substation No. 1Alif AnsharNo ratings yet

- BM Power - AtsDocument4 pagesBM Power - AtsEdmar BataqueNo ratings yet

- 30 HILUX ELECTRICAL WIRING DIAGRAMDocument1 page30 HILUX ELECTRICAL WIRING DIAGRAMwilderNo ratings yet

- Riser Diagram: ComputationsDocument1 pageRiser Diagram: Computationsmark dominicNo ratings yet

- FLECO Operation Status and Proposed SolutionsDocument13 pagesFLECO Operation Status and Proposed SolutionsRamil F. De JesusNo ratings yet

- 34.5 KV Bus Single Line Diagram for Carmen Copper SubstationDocument6 pages34.5 KV Bus Single Line Diagram for Carmen Copper SubstationTabon SkiNo ratings yet

- 02 - Veif - 2019 - Updates - On - The - CNP - Interconnection - NGCP PDFDocument10 pages02 - Veif - 2019 - Updates - On - The - CNP - Interconnection - NGCP PDFBandivz BandivzNo ratings yet

- Substation Filter BankSpecsDocument7 pagesSubstation Filter BankSpecsTudor BostanNo ratings yet

- R-MAG Instruction Book 1VAL255101-MB Rev EDocument52 pagesR-MAG Instruction Book 1VAL255101-MB Rev Erian0201No ratings yet

- Ee423 Primary Distribution OverviewDocument41 pagesEe423 Primary Distribution OverviewCathryn FriasNo ratings yet

- Task Force Duterte - Abra Power (Tfd-Ap) Abra Electric CooperativeDocument26 pagesTask Force Duterte - Abra Power (Tfd-Ap) Abra Electric Cooperativefrancis erl ligsayNo ratings yet

- Drawings For MV Switchgear Unigear Zs3.2: Ampliacion Se Sur WSPDocument4 pagesDrawings For MV Switchgear Unigear Zs3.2: Ampliacion Se Sur WSPfrankrosseliNo ratings yet

- Order Code Sel 351 PDFDocument2 pagesOrder Code Sel 351 PDFMohammed shamaaNo ratings yet

- Transformer Testing For New 10mva Power Transfomer: Batangas Ii Electric Cooperative (Batelec Ii)Document4 pagesTransformer Testing For New 10mva Power Transfomer: Batangas Ii Electric Cooperative (Batelec Ii)Edmar BataqueNo ratings yet

- GLX24Document12 pagesGLX24asadijaz144100% (1)

- EE 104 Lecture 1 - Fundamental PrinciplesDocument31 pagesEE 104 Lecture 1 - Fundamental PrinciplesRogzJrBernzNo ratings yet

- 34.5 KV Bus Single Line Diagram for Carmen SubstationDocument6 pages34.5 KV Bus Single Line Diagram for Carmen SubstationTabon SkiNo ratings yet

- GVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantDocument15 pagesGVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantRohit100% (1)

- EPR Plan - LUECO Poro Point SubstationDocument10 pagesEPR Plan - LUECO Poro Point SubstationArmelita Tadifa DucusinNo ratings yet

- Lecture 5 Wiring Materials PDFDocument11 pagesLecture 5 Wiring Materials PDFAnonymous 3Ra3zVuMDNo ratings yet

- Pix-H: Metal-Clad Switchgear Up To 17.5kVDocument24 pagesPix-H: Metal-Clad Switchgear Up To 17.5kVCristian Martinez100% (1)

- Requirements For 69kV Transmission Line LatestDocument1 pageRequirements For 69kV Transmission Line LatestCatrina FedericoNo ratings yet

- 11kV SF6Document6 pages11kV SF6ahmadgce04No ratings yet

- Quotation CT PT Isolators AB Switches DO Fuse Set Horn Gap VCB SMC Boxes Deep Drawn BoxesDocument8 pagesQuotation CT PT Isolators AB Switches DO Fuse Set Horn Gap VCB SMC Boxes Deep Drawn BoxesShokautNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument11 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Technical Bid Evaluation for Electrical WorksDocument14 pagesTechnical Bid Evaluation for Electrical WorksNavneet SinghNo ratings yet

- 40MV Transformer TS 2791 FINALDocument12 pages40MV Transformer TS 2791 FINALRanchak KumarNo ratings yet

- Three Phase Power Converter Distribution TransformersDocument19 pagesThree Phase Power Converter Distribution Transformersali hamzaNo ratings yet

- Fiber's Role in Video Security & Surveillance NetworksDocument42 pagesFiber's Role in Video Security & Surveillance NetworksgvdomingoNo ratings yet

- Antenna Height Comparison for Line-of-Sight CalculationsDocument2 pagesAntenna Height Comparison for Line-of-Sight CalculationsgvdomingoNo ratings yet

- List of Protection and Control Schematic DiagramDocument5 pagesList of Protection and Control Schematic DiagramgvdomingoNo ratings yet

- Microwave ReportDocument44 pagesMicrowave ReportgvdomingoNo ratings yet

- T1/E1 Copper To FiberDocument3 pagesT1/E1 Copper To FibergvdomingoNo ratings yet

- Davao Topographic MapDocument1 pageDavao Topographic MapgvdomingoNo ratings yet

- AL7Document4 pagesAL7gvdomingoNo ratings yet

- Ohmic, Dielectric, and Radiation. The Ohmic Losses Are Caused by The Current Flowing inDocument15 pagesOhmic, Dielectric, and Radiation. The Ohmic Losses Are Caused by The Current Flowing in9999igiNo ratings yet

- R Rec P.838 1 199910 S!!PDF eDocument2 pagesR Rec P.838 1 199910 S!!PDF eTiếu Tam TiếuNo ratings yet

- Inspirational Quotes For WorkDocument3 pagesInspirational Quotes For WorkgvdomingoNo ratings yet

- Toril Topographic MapDocument1 pageToril Topographic MapgvdomingoNo ratings yet

- Antenna Details WTC12-W71DDocument2 pagesAntenna Details WTC12-W71DgvdomingoNo ratings yet

- Telephone System PresentationDocument3 pagesTelephone System PresentationgvdomingoNo ratings yet

- Telephone System DesignDocument1 pageTelephone System DesigngvdomingoNo ratings yet

- 7GHz Channel PlanDocument1 page7GHz Channel PlangvdomingoNo ratings yet

- Microwave Transmission GuideDocument20 pagesMicrowave Transmission Guidek_muange897100% (2)

- Wireless Path ProfilingDocument19 pagesWireless Path ProfilinggvdomingoNo ratings yet

- Ohmic, Dielectric, and Radiation. The Ohmic Losses Are Caused by The Current Flowing inDocument15 pagesOhmic, Dielectric, and Radiation. The Ohmic Losses Are Caused by The Current Flowing in9999igiNo ratings yet

- Microwave Design FormulaDocument1 pageMicrowave Design FormulagvdomingoNo ratings yet

- Special Design ConsiderationDocument1 pageSpecial Design ConsiderationgvdomingoNo ratings yet

- Telephone SystemDocument5 pagesTelephone SystemgvdomingoNo ratings yet

- Rainfall ChartDocument1 pageRainfall ChartgvdomingoNo ratings yet

- Fundamentals On Microwave Communication With Microwave Planning Guide by Manny RuleDocument67 pagesFundamentals On Microwave Communication With Microwave Planning Guide by Manny Rulegvdomingo100% (1)

- Setting Crossovers in An AVR - Pre-Pro With Dirac Live 2 Room CorrectionDocument5 pagesSetting Crossovers in An AVR - Pre-Pro With Dirac Live 2 Room CorrectionstudskirbyNo ratings yet

- Lecture 2Document26 pagesLecture 2alessio8No ratings yet

- Irfp4227pbf PDFDocument8 pagesIrfp4227pbf PDFTyron DsouzaNo ratings yet

- Philips HFC 141 ManualDocument52 pagesPhilips HFC 141 ManualvvmacNo ratings yet

- Com4 Satellite Communications ReviewersDocument6 pagesCom4 Satellite Communications ReviewersKristine Ella BaduriaNo ratings yet

- The Von Neumann ArchitectureDocument27 pagesThe Von Neumann ArchitectureArun SharmaNo ratings yet

- Panasonic Txl42etf62Document0 pagesPanasonic Txl42etf62Doru DariusNo ratings yet

- Top 30+ Most Asked VLSI Interview Questions (2021) : 1) What Do You Understand by Boolean Logic?Document11 pagesTop 30+ Most Asked VLSI Interview Questions (2021) : 1) What Do You Understand by Boolean Logic?Nic JonesNo ratings yet

- Xiaomi becomes world's third largest smartphone makerDocument8 pagesXiaomi becomes world's third largest smartphone makerBodaKatalinNo ratings yet

- 427Document56 pages427Taca BerenjiNo ratings yet

- Human Auditory System Response To Modulated Electromagnetic EnergyDocument4 pagesHuman Auditory System Response To Modulated Electromagnetic EnergyChris HardingNo ratings yet

- Canon Speedlite MT-24EX PLDocument19 pagesCanon Speedlite MT-24EX PLVampulaNo ratings yet

- 3 Operation Instructions, PLC SystemDocument25 pages3 Operation Instructions, PLC SystemheemaNo ratings yet

- Overview of OFDM Modulation TechniqueDocument15 pagesOverview of OFDM Modulation TechniqueDishant KhoslaNo ratings yet

- DPP - (5) 11th (P) IOC (E) - Ans PDFDocument2 pagesDPP - (5) 11th (P) IOC (E) - Ans PDFRishabh GuptaNo ratings yet

- Evolution of Computers: 5 Generations from Abacus to AIDocument7 pagesEvolution of Computers: 5 Generations from Abacus to AIOscarLopezHernandez100% (1)

- 3.6.2 Radiation 00-10Document16 pages3.6.2 Radiation 00-10Murray PhysicsNo ratings yet

- Midac Li-Ion BatteriesDocument8 pagesMidac Li-Ion Batteriescrash2804No ratings yet

- Intel 945g Manual de UsuarioDocument39 pagesIntel 945g Manual de UsuarioDavid NavarroNo ratings yet

- Registrador TR3000Document4 pagesRegistrador TR3000ParramanuelNo ratings yet

- DSC QuickUserGuide PC1616 PC1832 PC1864Document4 pagesDSC QuickUserGuide PC1616 PC1832 PC1864Marko MarkovicNo ratings yet

- Rru5905&Rru5905w&Rru5305 (1.4g) Installation Guide (10) (PDF) - enDocument130 pagesRru5905&Rru5905w&Rru5305 (1.4g) Installation Guide (10) (PDF) - enНатальяNo ratings yet

- Moxa-Imc-101-Series-Datasheet-V1.3.pdf CONVERTIDOR DE MEDIOS PDFDocument4 pagesMoxa-Imc-101-Series-Datasheet-V1.3.pdf CONVERTIDOR DE MEDIOS PDFEduardo QuintanaNo ratings yet

- SICON-4000MZi in English (Rev1 8) PDFDocument116 pagesSICON-4000MZi in English (Rev1 8) PDFAdjie89% (9)

- Mini Ag - ENGLISH MANUAL - Rev - ADocument23 pagesMini Ag - ENGLISH MANUAL - Rev - AMadalina PalagaNo ratings yet

- PS 438903221 T4900-T41200 enDocument2 pagesPS 438903221 T4900-T41200 enjamirvillarroelNo ratings yet

- Introducing Samsung DVD Recorder (DVD-R128 - R129)Document74 pagesIntroducing Samsung DVD Recorder (DVD-R128 - R129)tomverstratenNo ratings yet

- RK310-01 Atmospheric Temperature SensorDocument2 pagesRK310-01 Atmospheric Temperature SensorJAIRO ANDRES CAMACHO GUERRERONo ratings yet

- TD Spread spectrum Aerospace School exercisesDocument4 pagesTD Spread spectrum Aerospace School exercisesAssia Naja0% (1)

- WhirlpoolDocument23 pagesWhirlpoolmrfarhatNo ratings yet