Professional Documents

Culture Documents

S 1624

Uploaded by

Pankaj KambleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S 1624

Uploaded by

Pankaj KambleCopyright:

Available Formats

Natural gas generator

set QSV91 series

engine

1700 kW (2125 kVA) Standby

Description

Features

This Cummins Power Generation gas generator set

is a fully integrated power generation system

utilizing state of the art technology that results in

optimum performance and efficient use of fuel for

standby applications.

Exhaust emissions Lean burn technology provides

exhaust emissions levels as low as 1 g/hp-hr NOx.

This generator set is designed in

facilities certified to ISO 9001 and

manufactured in facilities certified to

ISO 9001 or ISO 9002.

The Prototype Test Support (PTS)

program verifies the performance

integrity of the generator set design.

Cummins heavy-duty engine Rugged 4-cycle lean burn

gas combustion engine utilizing full authority electronic engine

management and monitoring.

Permanent magnet generator (PMG) Offers enhanced

motor starting and fault clearing short circuit capability.

Alternator Several alternator sizes offer selectable voltage

and temperature rise with low reactance 2/3 pitch windings;

low waveform distortion with non-linear loads, fault clearing

short-circuit capability, class F or H insulation (see Alternator

Data Sheet for details), bearing and stator RTDs and anticondensation heater. Mechanically strengthened for use on

utility paralleling with unreliable grid.

Control system The PowerCommand 3.3 generator set

control is standard equipment and provides total genset

system integration including full paralleling capability in grid or

load share mode, precise frequency and voltage regulation,

alarm and status message display, AmpSentry protection,

output metering, auto-shutdown at fault detection and a user

interface panel installed onto the genset. Optional remote

operator panels are also available.

Cooling system The generator set is equipped with the

capability of interfacing with a remote radiator or heat

exchanger.

Warranty and service Backed by a comprehensive

warranty and worldwide distributor network that can provide all

levels of service from replacements parts to performance

guarantee programs.

60 Hz

Model

C1700 N6

kW (kVA)

1700 (2125)

Configuration

4 pole alternator through gearbox

*Genset is capable of operating between 0.8 lagging and 1.0 power factor. All fuel consumption and heat balance data is at 1.0 power factor.

2011 Cummins Power Generation Inc. All rights reserved. Cummins Power Generation and Cummins are registered trademarks of Cummins

Inc. PowerCommand, AmpSentry and Our energy working for you. are trademarks of Cummins Power Generation. Other company,

product, or service names may be trademarks or service marks of others. Specifications are subject to change without notice.

S-1624a (4/11)

Generator set specifications

Governor regulation class

Voltage regulation, no load to full load

Random voltage variation

Frequency regulation

Random frequency variation

Radio frequency emissions compliance

Single step load pickup

ISO 8528 Part 1, Class G1 with exceptions - see PTS (Prototype

Test Support) Data Sheet

0.5%

0.5%

Isochronous

0.25%

IEC 801.2 through IEC 801.5; MIL STD 461C, Part 9

See PTS data sheet for details

Engine specifications

Design

Bore

Stroke

Displacement

Cylinder block

Battery charging alternator

Starting voltage

Fuel system

Ignition system

Air cleaner type

Lube oil filter type(s)

Breather

4 cycle, V-block, turbocharged low temperature aftercooled

180 mm (7.09 in)

200 mm (7.87 in)

91.6 liters (5590 in3)

Cast iron, V18

None

24 volt negative ground

Lean burn

Individual coil on plug

Dry replaceable element

Full flow and bypass filters

Breather filter

Alternator specifications

Design

Stator

Rotor

Insulation system

Standard temperature rise

Exciter type

Phase rotation

Alternator cooling

AC waveform total harmonic distortion

Telephone influence factor (TIF)

Telephone harmonic factor (THF)

Brushless, 4 pole, revolving field

2/3 pitch

Two bearing

Class F or H see ADS (Alternator Data Sheet) for details

105 C (221 F) Continuous @ 40 C (104 F) ambient

PMG (Permanent Magnet Generator)

A (U), B (V), C (W)

Direct drive centrifugal blower fan

< 5% no load to full linear load, < 3% for any single harmonic

< 50 per NEMA MG1-22.43

<3

Available voltages

60 Hz Three phase lineneutral/line-line

240/416

254/440

277/480

347/600

Note: Some voltages may not be available on all models. Consult factory for availability.

Generator set options and accessories

Engine

NOx 1 g/hp-hr

Natural gas fuel methane index

as low as 77

Air starter

Alternator

125 C (257 F) rise alternator

105 C (221 F) rise alternator

Control panel

Remote operator panel with

HMI320

Accessories

Exhaust silencers

Gas Train

Radiators

Bladder Expansion Tank

Heat Exchanger

Exhaust Heat Recovery

Note: Some options may not be available on all models - consult factory for availability.

Our energy working for you.

www.cumminspower.com

2011 Cummins Power Generation Inc. All rights reserved. Cummins Power Generation and Cummins are registered trademarks of Cummins

Inc. PowerCommand, AmpSentry and Our energy working for you. are trademarks of Cummins Power Generation. Other company,

product, or service names may be trademarks or service marks of others. Specifications are subject to change without notice.

S-1624a (4/11)

PowerCommand 3.3 control system

PowerCommand control system is a microprocessorbased genset monitoring, metering and control system

designed to meet the demands of todays engine driven

gensets. The integration of all control functions into a

single control system provides enhanced reliability and

performance, compared to conventional genset control

systems. These control systems have been designed and

tested to meet the harsh environment in which gensets

are typically applied. Major features include:

- AmpSentry protection providing a full range of

alternator protection functions matched to the

alternator provided.

- Extended Paralleling (Peak Shave/Base Load)

regulates the genset real and reactive power output

while paralleled to the utility. Power can be regulated

at either the genset or utility bus monitoring point.

- Digital frequency synchronization and voltage

matching.

- Isochronous Load Share

- Droop KW and KVAR Control

- Real time clock for fault and event time stamping.

- Real time clock for start/stop to initiate a test with or

without load, or a Base Load or Peak Shave session.

- Digital voltage regulation. Three phase full wave FET

type regulator.

- Genset/Engine monitoring and protection.

- Utility/AC Bus metering and protection

- Modbus interface for interconnecting to customer

equipment.

Operator/display panel

- Auto/Manual/Run/Stop mode selectors

- Alpha-numeric display with pushbutton access for

viewing engine and alternator data and providing

setup, controls and adjustment

- Circuit breaker position indication and manual control

- 320 x 240 pixels graphic LED backlight LCD.

- Multiple language support

Engine Protection

- Engine vitals - oil temperature and pressure, coolant

temperature and levels

- Derate

- Configurable alarm and status inputs

- Emergency stop

- Low and high battery voltage warning

- Weak battery warning

Dead battery shutdown

Fail to start (overcrank) shutdown

Fail to crank shutdown

Cranking lockout

Engine Data

- Oil temperature and pressure

- Coolant temperature and pressure, HT and LT

- Intake manifold pressure and temperature

- Exhaust temperature and pressure

- Engine electronics temperature and DC voltage

- Gas inlet and downstream pressures, mass flow rate,

and control valve position

- Spark advance and knock level/count, per cylinder

- Lube oil status, priming status

- Oil and engine heater status

- Start system status

- Compressor and compressor bypass status

- Auxiliary power supply status

AmpSentry alternator protection

- Overcurrent and short circuit shutdown

- Single and three phase fault current regulation

- Over and under voltage shutdown

- Over and under frequency shutdown

- Overload warning and load shed alarm output

- Reverse power and Var shutdown

- Excitation fault

Alternator data

- AC voltage, line-to-line and line-to-neutral

- Three phase AC current

- Frequency

- Total and individual phase power factor, kW and KVA

- Alternator heater status

- Winding and bearing temperatures

Other data

- Genset hardware data

- Data logs operational data

- Fault history up to 32 events

- Start attempts, starts, running hours, kW hours

- Engine data operational data, monitored status

functions, auxiliary system inputs, etc.

- Service adjustments - operational, customer

configurable set up, calibration, etc.

Paralleling data, functions and protection

- Genset and Utility/AC Bus Source AC Metering

TM

- First Start Sensor System

- Active Digital phase lock loop synchronizer

- Sync check

- Isochronous kW and kVAR load share controls

- kW import/export and kVAR/PF control for extended

utility (mains) paralleling

- Multiple Genset Load Demand control

- Power Transfer Control

- Breaker Control and status monitoring/warning

- Inputs for remote kW and kVAR control

For further detail on PowerCommand 3.3 see

document S-1570

Our energy working for you.

www.cumminspower.com

2011 Cummins Power Generation Inc. All rights reserved. Cummins Power Generation and Cummins are registered trademarks of Cummins

Inc. PowerCommand, AmpSentry and Our energy working for you. are trademarks of Cummins Power Generation. Other company,

product, or service names may be trademarks or service marks of others. Specifications are subject to change without notice.

S-1624a (4/11)

Base load (continuous) rating definition

Applicable for supplying power continuously to a constant

load up to the full output rating for unlimited hours. No

sustained overload capability is available for this rating.

Consult authorized distributor for rating. (Equivalent to

Continuous Power in accordance with ISO 8528, ISO 3046,

AS2789, DIN6271, and BS5514).

Generator set data sheets

60 Hz pipeline gas

Model

C1700 N6

Data

sheet

D-3487

MN*

77

Emissions

g/hp-hr

1.0

LT

(oC)

50

HT

(oC)

95

* MN = Methane

This outline drawing is to provide representative

configuration details for Model series only.

See respective model data sheet for specific model

outline drawing number.

Do not use for installation design

Dimensions and weights

Model

C1700 N6

Dim A

mm (in)

7302 (287.5)

Dim B

mm (in)

1720 (67.7)

Dim C

mm (in)

3136 (123.5)

Weight wet

kg (lbs)

21069 (46449)

Weights represent a set with standard features. See outline drawings for weights of other configurations.

Americas

1400 73rd Avenue N.E.

Minneapolis, MN 55432 USA

Phone 763 574 5000

USA toll-free 877 769 7669

Fax 763 574 5298

Europe, CIS, Middle East and Africa

Manston Park Columbus Ave.

Manston Ramsgate

Kent CT 12 5BF United Kingdom

Phone 44 1843 255000

Fax 44 1843 255902

Asia Pacific

10 Toh Guan Road #07-01

TT International Tradepark

Singapore 608838

Phone 65 6417 2388

Fax 65 6417 2399

Warning: Back feed to a utility system can cause electrocution and/or property damage. Do not connect to any buildings electrical system

except through an approved device or after building main switch is open.

Our energy working for you.

www.cumminspower.com

2011 Cummins Power Generation Inc. All rights reserved. Cummins Power Generation and Cummins are registered trademarks of Cummins

Inc. PowerCommand, AmpSentry and Our energy working for you. are trademarks of Cummins Power Generation. Other company,

product, or service names may be trademarks or service marks of others. Specifications are subject to change without notice.

S-1624a (4/11)

You might also like

- Planning DetailsDocument4 pagesPlanning DetailsPankaj KambleNo ratings yet

- RedBus Ticket TK4584488458 BNG To Mum 7th MarchDocument2 pagesRedBus Ticket TK4584488458 BNG To Mum 7th MarchPankaj KambleNo ratings yet

- RAABTA - Ik Vaari Aa Chords and Lyrics - ChordZoneDocument2 pagesRAABTA - Ik Vaari Aa Chords and Lyrics - ChordZonePankaj KambleNo ratings yet

- TSI Rotostat Profile Latest1Document39 pagesTSI Rotostat Profile Latest1Pankaj KambleNo ratings yet

- Reconditioning Gas Turbine Components Cleaning BrazingDocument4 pagesReconditioning Gas Turbine Components Cleaning BrazingPankaj KambleNo ratings yet

- Reconditioning Gas Turbine Components Quality Control Assessment MethodDocument8 pagesReconditioning Gas Turbine Components Quality Control Assessment MethodPankaj KambleNo ratings yet

- Saarang TicketsDocument3 pagesSaarang TicketsPankaj KambleNo ratings yet

- Non Destructive Testing of Rotors From The BoreDocument2 pagesNon Destructive Testing of Rotors From The BorePankaj KambleNo ratings yet

- 5160DF PowerDocument7 pages5160DF PowerPankaj Kamble100% (1)

- Gas Power PlantsDocument9 pagesGas Power PlantsPankaj KambleNo ratings yet

- Ts EnglishDocument24 pagesTs EnglishPankaj KambleNo ratings yet

- Brochure Engine 51-60GDocument7 pagesBrochure Engine 51-60GAnonymous 0irJN2UINo ratings yet

- Process Plant Piping OverviewDocument133 pagesProcess Plant Piping Overviewskdalalsin100% (8)

- 3 TMF Crack InitiationDocument8 pages3 TMF Crack InitiationPankaj KambleNo ratings yet

- 4860TS PowerDocument7 pages4860TS PowerPankaj KambleNo ratings yet

- 4860 PowerDocument7 pages4860 PowerPankaj KambleNo ratings yet

- Ettes Power Biomass Gas Generator SetsDocument1 pageEttes Power Biomass Gas Generator SetsPankaj KambleNo ratings yet

- Natural Gas Generator 58Document4 pagesNatural Gas Generator 58Pankaj KambleNo ratings yet

- SFGLD560Document2 pagesSFGLD560Pankaj KambleNo ratings yet

- SFGLD480Document2 pagesSFGLD480Pankaj KambleNo ratings yet

- LEXE0839 00 - 1 UDocument2 pagesLEXE0839 00 - 1 UPankaj KambleNo ratings yet

- SFGLD180Document2 pagesSFGLD180Pankaj KambleNo ratings yet

- SFGLD360Document2 pagesSFGLD360Pankaj KambleNo ratings yet

- 3544G PowerDocument13 pages3544G PowerPankaj KambleNo ratings yet

- SFGLD240Document2 pagesSFGLD240Pankaj KambleNo ratings yet

- Datasheet of MWM-DeUTZ Gas Generator EM-1250NDocument1 pageDatasheet of MWM-DeUTZ Gas Generator EM-1250NPankaj KambleNo ratings yet

- EP 4page BrochureREV2013Document2 pagesEP 4page BrochureREV2013Pankaj KambleNo ratings yet

- Lexe7582 05Document44 pagesLexe7582 05Pankaj KambleNo ratings yet

- GU GasEnginesDocument2 pagesGU GasEnginesPankaj KambleNo ratings yet

- MWM DEUTZ Natural Gas Generator 63Document1 pageMWM DEUTZ Natural Gas Generator 63Pankaj KambleNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NEW GENERATION OVERCURRENT PROTECTION DEVICESDocument4 pagesNEW GENERATION OVERCURRENT PROTECTION DEVICESkarqu86No ratings yet

- Chapter 3Document16 pagesChapter 3manasb6342No ratings yet

- Certification of Engineering Calculation 2: I-FormDocument69 pagesCertification of Engineering Calculation 2: I-FormParantap RahaNo ratings yet

- 6 - Full Wave RectifierDocument8 pages6 - Full Wave RectifierAdel RaweaNo ratings yet

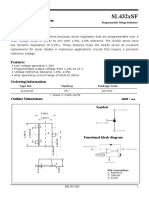

- SL432xSF: DescriptionDocument5 pagesSL432xSF: Descriptionserrano.flia.coNo ratings yet

- ABB ACS880 Regenerative Rectifier CTRL PRG FW C A4Document194 pagesABB ACS880 Regenerative Rectifier CTRL PRG FW C A4AhmadNo ratings yet

- Unit 4.2 Electrical Energy ManagementDocument61 pagesUnit 4.2 Electrical Energy ManagementJoeb DsouzaNo ratings yet

- Marathon Voltage Regulator DVR2000EPlus - IOM - GPN046Document92 pagesMarathon Voltage Regulator DVR2000EPlus - IOM - GPN046Khaled KamelNo ratings yet

- EPLAN Print JobDocument63 pagesEPLAN Print Jobjulian niko0% (1)

- Miele Coffee Maker Cva - 4070 - EncaDocument6 pagesMiele Coffee Maker Cva - 4070 - EncaJim LawlerNo ratings yet

- Chapter 3-Lossy CapacitorsDocument24 pagesChapter 3-Lossy Capacitorsmarceloassilva7992No ratings yet

- Ert BoqDocument10 pagesErt BoqAbhishek ShatagopachariNo ratings yet

- Luanshya Technical and Business College Management Board Diploma in Electrical Engineering Electrical Instrumentation (Dee 231)Document9 pagesLuanshya Technical and Business College Management Board Diploma in Electrical Engineering Electrical Instrumentation (Dee 231)Alfred K ChilufyaNo ratings yet

- Electrical Machines Tutorial on AC MotorsDocument2 pagesElectrical Machines Tutorial on AC MotorsEmerging TubeNo ratings yet

- c2000 Series PDFDocument630 pagesc2000 Series PDFEDUARDONo ratings yet

- LF Report - lf1S CompleteDocument15 pagesLF Report - lf1S CompleteAndres VergaraNo ratings yet

- LM723 LM723C PDFDocument14 pagesLM723 LM723C PDFPedro MalpicaNo ratings yet

- TP48300-A V100R001 Maintenance Guide 06Document52 pagesTP48300-A V100R001 Maintenance Guide 06Choubane LamineNo ratings yet

- Protection of SubstationDocument21 pagesProtection of Substationkvramanan_1100% (1)

- Ejercicios Rele DistanciaDocument17 pagesEjercicios Rele DistanciaRodrigo Octavio Valencia LealNo ratings yet

- Sie Bro ZP d43 PDFDocument4 pagesSie Bro ZP d43 PDFAsterix IDNo ratings yet

- Presentation Intern TNB DistributionDocument22 pagesPresentation Intern TNB Distributionsyakir yusriNo ratings yet

- Learning About ESD Part 7 - ESD StandardsDocument4 pagesLearning About ESD Part 7 - ESD Standardshyde2520015754100% (1)

- ELSB - Cat - Product News - 2020 - Preview - 21-10-2020Document242 pagesELSB - Cat - Product News - 2020 - Preview - 21-10-2020PRABHU SHANKAR MNo ratings yet

- Ets 05Document3 pagesEts 05Sivagurunathan SpNo ratings yet

- ASM Katalogus 2021 EN CL-616Document1 pageASM Katalogus 2021 EN CL-616Kdr PaxtonNo ratings yet

- WD05666 - A PDFDocument112 pagesWD05666 - A PDFSudarshan DhumalNo ratings yet

- List of Emc Tests Un Ece r10 Rev.6Document4 pagesList of Emc Tests Un Ece r10 Rev.6mirassouNo ratings yet

- DC To AC Inverter Card With Igbts: Construction and Performance Johannes ErikssonDocument26 pagesDC To AC Inverter Card With Igbts: Construction and Performance Johannes Erikssonarian bayu SugiantoNo ratings yet

- Group 2 Act 5Document6 pagesGroup 2 Act 5Quezza Phola S PatulinNo ratings yet