Professional Documents

Culture Documents

DDT Konstract Inc. Silk Residences Project Quality Management

Uploaded by

John AurélioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DDT Konstract Inc. Silk Residences Project Quality Management

Uploaded by

John AurélioCopyright:

Available Formats

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

PROJECT QUALITY

MANAGEMENT

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Project Quality Management

The project quality management procedure is an assurance that the activities involved in

the construction project would comply with the terms of the approved drawings, necessary designs,

specifications and methodologies. Inspection and testing of materials and methodology shall be

performed in accordance with the Project Quality Control Plan which is a set standard under the

supervision of the Project Quality Control Engineer. On the other hand, the quality of work

supervision is under the Project Quality Assurance Engineer.

Process Flow Chart

A. Concrete

Start

Inspection

Batching

Receiving

Slump Test &

Temperature

Result

NO

Y

NO

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

Add

Admixture

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Result

YES

Sample for

Y

Compressive

NO

Strength

Test

NO

Add

Admixture

Y

NO

YES

Result

NO

NO

Return to

Y

Batching

NO

Plant

Result

NO

YES

Concrete

YPouring

YES

NO

NO

Leveling

Retest the

Reserve sample

Result

NO

NO

Remove the

concrete

Y

poured section

NO

Finishing

Curing

End

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

B. Reinforcement Bars

Start

Material

Delivery

Material

Testing

Result

YES

Fabrication

Installation

of Material

Inspection

of Installed

Material

End

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

NO

Y

NO

Return to

Supplier

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

C. Formworks

Start

Survey

Layout

Rebar

Work

Form Enclosure

Request

Inspection

Concrete

Works

Form Stripping

Request

End

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Major Work in Construction

1. Concrete Activity

a. Inspection

This activity is done by check listing. Each reinforcement and formwork is

checked if it is ready for pouring of concrete. Otherwise, the problem should be

addressed, then it must be fixed to be able to pour the concrete and resume the

immediate activities.

b. Batching

This activity is done when the project site calls the attention of the

batching plant for the delivery of the concrete mix which would be used for

certain structural members which are ready for concrete pouring.

c. Receiving

When the concrete mixer arrives in the site, they should receive and notify

the Concrete Engineer. The condition of concrete should be first checked before

the pouring activity should happen.

d. Slump Test and Temperature Test

Before pouring of concrete, concrete slump test and temperature testing

should be conducted. Temperature test is done to know if the concrete is already

in its ideal pouring temperature; otherwise, premature concrete pouring would

cause problems. On the other hand, Slump Test is done to know and check the

workability of the concrete.

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure1.1 Slump Test of Delivered Concrete

e. Sample for Compressive Strength

A four sample specimen of concrete cylinder should be attained to be able

to conduct a compressive strength test. The samples represent the 7-day, 14-day,

28-day and 56-day specimen which all are to be tested. If the first specimen fails,

the following specimen should be tested for compressive strength.

f. Concrete Pouring

If all the samples are obtained and passed all the necessary tests, (Slump

and Temperature Test, Compressive Strength Test) concrete should then be

poured on the members which are ready to be poured on. In the case of Silk

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Residences, DDT Konstract Inc. used concrete bucket and concrete pump for

pouring

Figure 1.2 Concrete Pouring Using a Bucket

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

g. Levelling

Levelling is applicable for slabs in which the levelness of the slab is

checked for each poured section.

h. Finishing

Power trowel is used for finishing of concrete slab to have a smooth finish.

i. Curing

Curing process is done by spraying a chemical in the cured member of

the structure.

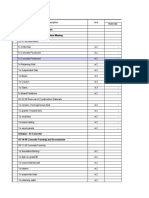

Forms needed in Concrete Activity

Figure 1.A Concrete Placement Monitoring

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

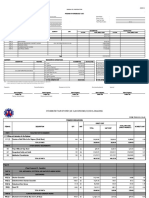

Figure 1.B Concrete Pouring Request Permit

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 1.C Material Delivery Inspection Request

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 1.D Testing Inspection Request

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

2. Reinforcement Bars

a. Material Delivery

Once the rebar is ordered, it is delivered in the site. Visual inspection

shall be done by the Project Quality Assessment Engineer. The primary

inspections is the diameter of the bar or of there are impurities, rusts on the

delivered rebar. The quantity of the delivered rebar is also checked if it matches

the quantity ordered. DDT Konstract, Inc. has an official form for this kind of

Request named as Material Delivery Inspection Request. The form includes the

description of the material, quantity, location of usage and remarks.

b. Material Testing

After the material is inspected, a four sample specimen for each delivered

order is obtained. The sample is 500 mm in length and they obtain three for each

batch of deliver. The four sample represent the 7-days, 14-days, 28-days, and 56days specimen that is to be tested. The sample is tested with accordance of

PNS49:2002. The test methods are ASTM A370-09 (Standard Test Methods and

Definitions for Mechanical Testing of Steel Products) and PNS823/ ASTM E41508 (Standard Test Method for Atomic Emission Vacuum Spectrometric Analysis

of Carbon and Low-Alloy Steel). They also have form for testing entitled Testing

Request (Off-Site) in which they have the instruction to testing laboratory.

c. Fabrication

When the rebar passed the material testing and complied with the

standard, the rebar can then be used. It can be fabricated into what is used and in

accordance with the cutting list.

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 2.1 Fabrication of Ties

d. Installation of Rebar

After the fabrication procedure, installation of the fabricated rebar should

take place. The form used is Inspection & Work Request/Permit. In this form, it is

the nature of work is written and the signature for the approval for each engineer.

e. Inspection of Installed Rebar

In inspection of the installed reinforcement bars, the project Quality

Assessment and Quality Control Engineer should check the arrangement and the

number of reinforcement bar for each member. Checking of the spacing for each

ties is also done.

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 2.2 Inspection of Coupler and Rebar for Beams and Girders

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Forms needed in Reinforcement Bar Activity

Figure 2.A Inspection & Work Request/Permit

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 2.B Inspection Checklist (Rebar)

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 2.C Material Delivery Inspection Request

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 2.D Request for Inspection

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 2.E Testing Inspection Request

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

3. Formworks Activity

a. Survey Layout

The Survey Layout has the actual location for the member and it conforms

the elevation and level of the member. It has also a a form which has the actual

survey location.

Figure 3.1a Survey and Layout Request Form

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

b. Rebar Work

The rebar work is the inspected rebar installation that is passed the

inspection. It is also the process in the rebar for major work.

c. Form Enclosure Request

It is the request for the formwork to be installed on the certain structural

member that is ready for concrete pouring.

d. Concrete Work

It is the time when the structural member is ready to be poured.

e. Form Stripping Request

It is the request when the poured concrete is passes on the certain hours

after poured depending on the structural member.

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Forms needed in Formwork Activity

Figure 3.A Form Enclosure Form

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 3.B Form Stripping Request Permit

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 3.C Inspection Checklist (Manpower)

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 3.D Request for Inspection

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 3.E Survey Layout Request

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Test for Rebars

Steel, just like concrete, plays also a very significant role in any

structural element. Since this backs concrete up, steel that will be used in any

portion of a structure should have properties that are specified in the plan.

Failure to have standard steel will cause weaker reinforcements and will make

the structure fail under small external forces. Buildings that collapsed through

the years are mainly caused by sub-standard reinforcements. To prevent this,

the steel that will be used in any construction site is subjected to different test.

Unlike concrete however, the tests are done in different laboratories and

samples of each steel are only delivered to be examined. Tensile test is one of

the most popular tests done on steel.The deliver rebar is tested by the supplier

but the project is still get sample for the testing the tensile strength,

mechanical properties and the chemical composition of the rebar. Whenever

there is a delivered of rebar, they get a random sample. The rebar must passed

all the test before using it. It is usually in the warehouse. The sample is tested

in the testing company in which they will be given the result. When the rebars

passed the test, the batch of rebars that is tested is already can be used but if

the rebars failed, the batch of the rebars is returned to the supplier.

Figure 3.1 Steel samples that will be delivered to a testing center to determine

if its properties will match that of the standard.

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

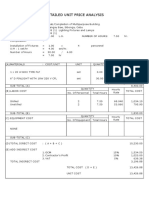

Figure 3.2 Sample Result of the Rebar Test

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Test for Concrete

Concrete pouring is one of the most crucial methods in construction.

Failure to successfully conduct this method will surely affect the schedule of

the project and will later extend its duration that will surely significantly affect

its cost. Likewise, the concrete used will dictate the strength of the building

as a whole. If substandard mix will be used, it will definitely be a big problem.

Preventive measures are therefore done before the concrete pouring is started.

There are two tests done in the field before the said method: Compressive

strength test and slump test. The former will tell them the strength of the

concrete mix delivered as its name implies. It will be the basis of whether or

not the concrete exhibits strength properties that are the same of that specified

on the plan. The latter, on the other hand, shows the workability of the

concrete. Different height of the slump is required for each particular purpose

of the concrete. When the concrete mix delivered in the project site, it gets a

sample for compressive strength of the concrete. It ensures that the delivered

mix is correct. First they put oil on the mold then get a part of concrete on the

mixture. After, the mold is fill 3 layers of equal volume and stomp it 25 times

each with a rounded end of the rod. We used a rubber mallet to vibrate the

side of the mold to avoid honeycombs to the concrete samples and also scrape

the excess concrete sample at the top of the mold. After 24 hours, the mold is

labeled and submerged on the curing tank. It is ideal to use potable water for

curing and it must be protected from direct sunlight and contamination of the

rain water. When its time to test, it is delivered on the testing company. The

result will be given to the company. If the specimen passed the test, the pour

concrete is good for use. But if the specimen failed, they used the back-up of

the 56 days specimen and test it. If the retest is failed, they will rectify the

whole section of the poured concrete.

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 3.3 Sample Compressive Strength Result

Slump Test done on site before the actual

pouring.

Figure 3.4 Samples that are subjected to Compressive Strength Test

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Figure 3.5 Slump Test Samples

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

DDT KONSTRACT, INC: SILK RESIDENCES

PROJECT QUALITY MANAGEMENT

Site Instruction

The site instruction is used by the Engineers whenever a work is not

properly done and a certain member. If the subcontractor does not follow or

fixed the inspected error in the work, the engineer will written this site

instruction and the worker or the foreman must comply on the commitment

date that is on the form. It is also in the form the observation of the quality

assurance Engineer and the specific location where he/ she sees this defect.

Also, it is on the form the proposed corrective action that is required on the

specific problem.

Figure 3.6 Sample form of Site Instruction

CE PRACTICUM 2: AGATON, AMATA, BALMACEDA, CORTEZ, LATINA

You might also like

- Note: Use For The Whole Project DurationDocument15 pagesNote: Use For The Whole Project DurationMichelle anne EscabarteNo ratings yet

- Bill of Materials SampleDocument5 pagesBill of Materials SampleJayteeNo ratings yet

- K7 PROJECT COST ESTIMATES 011822 11amDocument49 pagesK7 PROJECT COST ESTIMATES 011822 11amfrancis sebastian lagamayoNo ratings yet

- Proposed Two - Storey Residential BuildingDocument7 pagesProposed Two - Storey Residential BuildingBJ MadzNo ratings yet

- Productivity RateDocument10 pagesProductivity RateRodelNo ratings yet

- Construction Labor RatesDocument12 pagesConstruction Labor RatesJoseph AlcanseNo ratings yet

- BOQ Housing - MyCitiHomesDocument4 pagesBOQ Housing - MyCitiHomesAnjo BalucasNo ratings yet

- Unit Price List for Construction MaterialsDocument98 pagesUnit Price List for Construction MaterialsYonasNo ratings yet

- Construction Labor Productivity PhilippinesDocument40 pagesConstruction Labor Productivity PhilippinesNico Jaylo100% (1)

- Material Schedule of Two Storey BuildingDocument1 pageMaterial Schedule of Two Storey BuildingOreoluwaNo ratings yet

- Unit Rates and Cost Per ItemDocument213 pagesUnit Rates and Cost Per ItemDesiree Vera GrauelNo ratings yet

- Unit Cost AnalysisDocument20 pagesUnit Cost AnalysisJoseph Crister PracullosNo ratings yet

- Mobile Equipment Parking Area and Non Revenue Stores ConstructionDocument1 pageMobile Equipment Parking Area and Non Revenue Stores ConstructionZachNo ratings yet

- Supply and Installation of Telecom Tower Lean Concrete Mix DesignDocument2 pagesSupply and Installation of Telecom Tower Lean Concrete Mix Designbhct1987No ratings yet

- Annex A Program of Works Budget Cost for 4-Storey School BuildingDocument152 pagesAnnex A Program of Works Budget Cost for 4-Storey School BuildingAl Patrick Dela CalzadaNo ratings yet

- Bridge Construction Boq Item Cost AnalysisDocument405 pagesBridge Construction Boq Item Cost Analysis朱叶凡No ratings yet

- BS 8110-1 1997Document168 pagesBS 8110-1 1997Ibrahim abdullahiNo ratings yet

- BOQ - Civil, Structural and ArchitecturalDocument46 pagesBOQ - Civil, Structural and ArchitecturalVincent SaysonNo ratings yet

- Estimating PaintDocument7 pagesEstimating PaintMartin AtigaNo ratings yet

- PM BOQ Construction Material Estimate SheetDocument12 pagesPM BOQ Construction Material Estimate SheetXozanNo ratings yet

- The Vertical Concrete Mix MenuDocument56 pagesThe Vertical Concrete Mix Menusemperfidelis61No ratings yet

- Grillage Analysis ThesisDocument78 pagesGrillage Analysis ThesisAnonymous 0eBKSRNo ratings yet

- RCC Rate AnalsysisDocument39 pagesRCC Rate AnalsysisAnonymous YmINeSIFNo ratings yet

- Weekly Progress Report - No. 06: Sai Gon Binh An Urban AreaDocument15 pagesWeekly Progress Report - No. 06: Sai Gon Binh An Urban AreaMinh Thuận100% (1)

- Boq Rate Brgy. Binlod Argao Cebu For Contstruction Type A Perimeter Fence With Catwalk As of 1 3 21 PDFDocument11 pagesBoq Rate Brgy. Binlod Argao Cebu For Contstruction Type A Perimeter Fence With Catwalk As of 1 3 21 PDFJohn Rhey Lofranco TagalogNo ratings yet

- Name/Location of Project: Department of Public Works and HighwaysDocument32 pagesName/Location of Project: Department of Public Works and HighwaysCelsoRapiNo ratings yet

- Breakdown Estimate Land CoDocument2 pagesBreakdown Estimate Land CoNick OperarioNo ratings yet

- PG Timbers Mega Promotion HouseDocument12 pagesPG Timbers Mega Promotion HouseByron MabodzaNo ratings yet

- BoQ For Water TankDocument10 pagesBoQ For Water TankMenaka GurusingheNo ratings yet

- Pep of Superstructure 04 043014-EditedfDocument71 pagesPep of Superstructure 04 043014-EditedfJholo BuctonNo ratings yet

- Cutting ListDocument2 pagesCutting ListWilson S. UntalanNo ratings yet

- Cico Office: Qatar Decoration Offices & ShowroomsDocument13 pagesCico Office: Qatar Decoration Offices & ShowroomsJhay ManeclangNo ratings yet

- SEPTIC TANK BILL OF QUANTITIESDocument212 pagesSEPTIC TANK BILL OF QUANTITIESEphremHailu100% (1)

- Properties of Fresh Concrete PresentationDocument38 pagesProperties of Fresh Concrete PresentationKannan KandappanNo ratings yet

- Contruction Manual Estimate - MST Connect 2022Document192 pagesContruction Manual Estimate - MST Connect 2022Orion PaxNo ratings yet

- Labor Production Table PDFDocument6 pagesLabor Production Table PDFFroilan EspinosaNo ratings yet

- 1 PDF Revised National Plumbing Code of The Philippinespdf El Niña Jude B PDFDocument141 pages1 PDF Revised National Plumbing Code of The Philippinespdf El Niña Jude B PDFKevinDataHilaNo ratings yet

- Pice Lecture Quantification - Cost AnalysisDocument56 pagesPice Lecture Quantification - Cost AnalysisAaRichard ManaloNo ratings yet

- Custodio Perimeter Fence CostingDocument2 pagesCustodio Perimeter Fence CostingJohn Carl Salas100% (1)

- Cost Breakdown Template 03-19-13Document3 pagesCost Breakdown Template 03-19-13api-162282755No ratings yet

- Kest 5th Septic Tank & Soak Away MT 1Document166 pagesKest 5th Septic Tank & Soak Away MT 1EphremHailuNo ratings yet

- Gantt Chart DEMOLITION & CONSTRUCTION WORKS 2PERIODSDocument1 pageGantt Chart DEMOLITION & CONSTRUCTION WORKS 2PERIODSDAP Ysabelle Marie FuentesNo ratings yet

- Gcrc5510 Iss 2Document50 pagesGcrc5510 Iss 2임동우No ratings yet

- Seminar Report PDFDocument40 pagesSeminar Report PDFAnusha RNo ratings yet

- BOQ-Phase 2 Slope Protection CCDocument26 pagesBOQ-Phase 2 Slope Protection CCEden Mae de GuzmanNo ratings yet

- Mechanical Engineer with 3+ years experience seeking challenging positionDocument6 pagesMechanical Engineer with 3+ years experience seeking challenging positiondavidgeorge143No ratings yet

- Brian - Gantt ChartDocument2 pagesBrian - Gantt Chartchristian100% (1)

- Gumpp Priority Investment Project in Two Secondary Cities in Ghana Additional Two (2) Cells Landfill Cells at The Oti Landfill Site in KumasiDocument19 pagesGumpp Priority Investment Project in Two Secondary Cities in Ghana Additional Two (2) Cells Landfill Cells at The Oti Landfill Site in KumasiIsaac Ekow MensahNo ratings yet

- BoskiDocument118 pagesBoskiJohnNo ratings yet

- Detailed Estimates For Implementation-OlivieraDocument19 pagesDetailed Estimates For Implementation-OlivieraGarlic FernandezNo ratings yet

- Material Delivery ScheduleDocument20 pagesMaterial Delivery ScheduleBarnabas UdehNo ratings yet

- Interim Payment For Interior Plastering WorksDocument14 pagesInterim Payment For Interior Plastering Worksarchie_728No ratings yet

- S Curve Panlasian Revised 1Document18 pagesS Curve Panlasian Revised 1Anna TumbaliNo ratings yet

- SL - No Location/Area Work DescriptionDocument2 pagesSL - No Location/Area Work Descriptionshyamsundar_ceNo ratings yet

- M303 Pricing and Bid ProceduresDocument2 pagesM303 Pricing and Bid ProceduresSJKNo ratings yet

- Design of ConcreteDocument146 pagesDesign of ConcreteMhariecriszReazo100% (1)

- Final-Corrected Calculation (Concrete)Document6 pagesFinal-Corrected Calculation (Concrete)ChungHuiPingNo ratings yet

- National Cancer Institute Egypt Resources Calculation SheetDocument3 pagesNational Cancer Institute Egypt Resources Calculation SheetShady Cookies MonsterNo ratings yet

- Plan Take OffDocument44 pagesPlan Take OfftinNo ratings yet

- Project SpecsDocument15 pagesProject SpecsYsaiNo ratings yet

- 9184 Contract AgreementDocument4 pages9184 Contract AgreementCristina Melloria100% (1)

- Estimating Costing VDocument4 pagesEstimating Costing Vशंकर थापाNo ratings yet

- Train on plastering and anti-crack application standardsDocument13 pagesTrain on plastering and anti-crack application standardsJOHN CARLO AZORESNo ratings yet

- Labour Productivity - PlasterDocument1 pageLabour Productivity - PlasterInfo Oasis GroupNo ratings yet

- REPAIR OF DAYCARE CENTER, COMFORT ROOM AND BRGY. HALLDocument18 pagesREPAIR OF DAYCARE CENTER, COMFORT ROOM AND BRGY. HALLRamil S. ArtatesNo ratings yet

- ACI PRC-132.1-22: Responsibility For The Care of Test Specimens For Acceptance of Concrete-TechnoteDocument5 pagesACI PRC-132.1-22: Responsibility For The Care of Test Specimens For Acceptance of Concrete-TechnoteMoGHNo ratings yet

- Residential Beam DesignDocument104 pagesResidential Beam DesignTewodros AbateNo ratings yet

- ILNAS-EN 12390-3:2019: Testing Hardened Concrete - Part 3: Compressive Strength of Test SpecimensDocument8 pagesILNAS-EN 12390-3:2019: Testing Hardened Concrete - Part 3: Compressive Strength of Test SpecimensXuan DTNo ratings yet

- Aci 212.3R - 2004 PDFDocument30 pagesAci 212.3R - 2004 PDFBhavanishankar ShettyNo ratings yet

- VicRoads Restraint GuideDocument36 pagesVicRoads Restraint Guidevahur_s100% (1)

- Experimental Study On Bacterial Concrete With Replacement of Cement by Using Flyash M. DinushaDocument5 pagesExperimental Study On Bacterial Concrete With Replacement of Cement by Using Flyash M. DinushaGR DesignsNo ratings yet

- EEE-Speaker3 - Engr. CLEMENTE - Full Paper-2022 PICE MNCTC PDFDocument6 pagesEEE-Speaker3 - Engr. CLEMENTE - Full Paper-2022 PICE MNCTC PDFShy AbuizaNo ratings yet

- Strengthening of Concrete Structures With Textile Reinforced Mortars - State-Of-The-Art ReviewDocument20 pagesStrengthening of Concrete Structures With Textile Reinforced Mortars - State-Of-The-Art ReviewEdward TsaiNo ratings yet

- New Procedures For Materials 2020Document700 pagesNew Procedures For Materials 2020Mengalvio GraçaNo ratings yet

- Project: Residential House Retrofitting Location: Purok Magsaysay, Loakan Proper, Baguio CityDocument4 pagesProject: Residential House Retrofitting Location: Purok Magsaysay, Loakan Proper, Baguio CityLemuel Kim Cera TabinasNo ratings yet

- Constructions Material - AmetheusDocument34 pagesConstructions Material - AmetheusAmetheus // GKSahaNo ratings yet

- Analysis of RatesDocument12 pagesAnalysis of RatesVenkatesha HebbarNo ratings yet

- DPI Jan-Feb 17 ScribdDocument68 pagesDPI Jan-Feb 17 Scribdratninp9368No ratings yet

- Building Technology 5 ReviewerDocument5 pagesBuilding Technology 5 ReviewerNicole De VeraNo ratings yet

- Bedding Sand Selection For Interlocking Concrete Pavements in Vehicular ApplicationsDocument8 pagesBedding Sand Selection For Interlocking Concrete Pavements in Vehicular Applicationsgonzalez_m_aNo ratings yet

- Method of Statement For GunitingDocument3 pagesMethod of Statement For Gunitingsyed syahidieNo ratings yet

- Amm 423-426 1159Document6 pagesAmm 423-426 1159damiendamNo ratings yet

- TEPZZ 79 - Z77B - T: European Patent SpecificationDocument23 pagesTEPZZ 79 - Z77B - T: European Patent SpecificationLong An DoNo ratings yet

- Conplast CNDocument2 pagesConplast CNMoatz HamedNo ratings yet

- Rheobuild 2000 PFDocument2 pagesRheobuild 2000 PFFrancois-No ratings yet

- Xplorer: Operating ManualDocument130 pagesXplorer: Operating ManualDaniel ArmasNo ratings yet

- 09 r00 57 C Deha HalfenDocument26 pages09 r00 57 C Deha HalfenVagany7No ratings yet

- Knowledge FailuresDocument6 pagesKnowledge Failuresကိုနေဝင်းNo ratings yet

- Schaum's Outline of Theory and Problems of Reinforced - Everard, Noel J., 1933 - 1993 - New York - McGraw-Hill - 9780070197725 - Anna's ArchiveDocument392 pagesSchaum's Outline of Theory and Problems of Reinforced - Everard, Noel J., 1933 - 1993 - New York - McGraw-Hill - 9780070197725 - Anna's ArchiveJoshua NicholasNo ratings yet

- Concrete mix design for strength and workabilityDocument11 pagesConcrete mix design for strength and workabilityCebo QinisoNo ratings yet