Professional Documents

Culture Documents

Aluminum Welding Proceedure

Uploaded by

GregEverett2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum Welding Proceedure

Uploaded by

GregEverett2Copyright:

Available Formats

Matls IM 566 Revised Apr 16, 2013

Page 1 of 14

****COMPLETE RE-WRITE. PLEASE READ CAREFULLY.****

ALUMINUM WELDING

GENERAL REQUIREMENTS

The welding qualification requirements for fabrication and/or repair of any aluminum sign support

structures for highway signs, light poles and traffic signals shall be in accordance with the requirements

of the Structural Welding Code Aluminum AWS D1.2/D1.2M: 2003, Aluminum Welding Code for

Class III Structures and the requirements of Article 2423 of the standard specifications.

WELDING PROCESS

All welding shall be done by the following process:

GMAW - Gas Metal Arc Welding

Other processes may be approved by the Engineer.

BASE METAL

Base Metal shall conform to ASTM B221, Alloy Group 6061-T6.

PROCEDURE QUALIFICATION

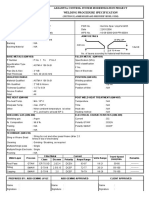

A Welding Procedure Specification (WPS) shall be required and shall be submitted for approval. WPS

shall be prepared in accordance with Section 3 and Annex E of the AWS D1.2 Structural Welding

Code.

Qualification of the WPS shall be in accordance with Section 3, Part C using the Base Metal, Procedure

Qualification Record (PQR), joint preparation, surface preparation, cleaning and limiting variables from

Part C, Section 3.14 of the AWS D1.2 Structural Welding Code.

ELECTRODES

Electrodes shall be of the type specified on the plans or in the AWS D1.2/D1.2M: 2003 as listed in

Table 4.2. Certificate of Conformation shall be required and shall be submitted for review and

verification.

ACCEPTANCE CRITERIA GROOVE WELDS PLATE & PIPE (AWS D1.2, 3.6.2)

The visual examination of the test weldment shall satisfy the following acceptance criteria:

1. Both the face and the root surfaces shall be free of cracks.

2. All craters shall be filled to the full cross section of the weld.

3. The edges of the weld shall blend smoothly with the base metal.

4. Underfill shall not exceed 0.01 (0.25mm)

5. The root shall show:

a. Complete fusion for CJP groove welds.

b. Penetration equal to or greater than the weld size specified for PJP groove welds.

6. The maximum melt through on groove welds in pipe or in tubing shall not exceed 1/8 (3 mm).

7. The root cavity shall not exceed 1 1/16 (2 mm).

8. Total weld thickness shall be equal to or greater than the thickness of the base metal but the

http://www.iowadot.gov/erl/current/IM/content/566.htm

10/2/2013

Matls IM 566 Revised Apr 16, 2013

Page 2 of 14

weld reinforcement shall not exceed the following values:

Thickness

Maximum Reinforcement

inch

mm

inch

mm

t 3/8

t 10

3/32

2

3/8 < t 3/4

10 < t 19

1/8

3

t > 3/4

1 > 19

3/16

5

note: The above indicated values for a given plate thickness joint welded from both sides.

t 1/4

t6

3/23

2

1/4 < t 1/2

6 < t 13

1/8

3

1/2 < t 1

13 < t 25

5/32

4

t>1

1 > 25

3/16

5

note: The above indicated values for a given plate thickness joint welded from one side.

The tensile and yield strength for temper T6, Alloy 6061 shall be as follows: 38 Ksi (Tensile), 35 Ksi

(Yield).

When fracture occurs in the weld metal, a minus 5% tolerance shall be allowed, if fracture occurs

outside the weld metal.

ACCEPTANCE CRITERIA FILLET WELDS FOR PLATE AND PIPE (AWS D1.2, 3.6.3)

The visual examination of the test weldment shall satisfy the following acceptance criteria:

1. Surface of the welds shall be free from any cracks.

2. All craters shall be filled to the full cross section of the weld.

3. The edges of the weld shall blend smoothly with the base metal.

4. Underfill shall not exceed 0.01 (0.25 mm).

5. The weld shall exhibit complete fusion in the root and to the base metal by the macroetech test.

6. The leg length shall meet the requirements of the WPS.

7. Root surface concavity (suck-back) shall not exceed 1/32 (1 mm).

GROOVE WELDS PLATE, PIPE AND CASTINGS

z

Visual examination of the test weldment shall conform to the requirements of Part B Section 3.6

of the AWS D1.2/D1.2M: 2003.

{ Note: Macroetching of the cut sections shall be included in the examination of fillet welds

and PJP Groove Welds.

Tension test specimens shall conform to the requirements of Part B, Section 3.7 of the D1.2 AWS

Code.

Bend test specimens shall conform to the requirements of Part B, Section 3.8 of the D1.2 AWS

Code.

Soundness Test Castings shall conform to the requirements of Part B, Section 3.9 of the D1.2

AWS Code.

Soundness Tests Fillet Welds for Plates and Pipes shall conform to the requirements of Part B,

Section 3.10 Option 1 (Fillet Weld Fracture Test Pipe and Plate), and Option 2 (Fillet Weld Root

Bend Test Plate).

POSITION AND TESTS FOR PROCEDURE WELDS

Each WPS shall be qualified by positioning and welding test plates as follows:

http://www.iowadot.gov/erl/current/IM/content/566.htm

10/2/2013

Matls IM 566 Revised Apr 16, 2013

Page 3 of 14

Note: These positions are classified as (1) Flat, (2) Horizontal, (3) Vertical, or (4) Overhead

Note: Plate Groove 1G (Flat), 2G (Horizontal), 3G (Vertical), 4G (Overhead)

Plate Fillet 1F (Flat) 2F (Horizontal), 3F (Vertical), 4F (Overhead)

Pipe Groove 1G (Horizontal Rotated), 2G (Vertical Fixed), 5G (Horizontal Fixed), 6G

(Inclined Fixed)

Pipe Fillet 1F (Inclined Rotated), 2F (Vertical Fixed), 2FR (Horizontal Rotated), 4F

(Overhead Fixed), 5F (Horizontal Fixed)

http://www.iowadot.gov/erl/current/IM/content/566.htm

10/2/2013

Matls IM 566 Revised Apr 16, 2013

Page 4 of 14

WELDER PERFORMANCE

z

All shop welders, welding operators and tack welders shall be qualified and certified prior to

welding on any Iowa Department of Transportation Bridge or sign support structure. The

qualification of welders, welding operators, and tackers shall be in accordance with the

instructions of this IM. Certification shall be for a period of 1 year. However, shop welders

certification may be extended annually based on a verification, notorized letter from the

fabricator, certifying that the welder or tack welder has been engaged in the welding process for

which he is qualified without interruption of more than six months during the preceding twelve

months.

All field welders shall be qualified for a period of one year. Those welders who have successfully

passed their qualification tests without failure for two consecutive years, requalification will only

be required every two years.

Welder re-qualification/re-certification may be required at any time there is a specific reason to

question his/her ability to make sound welds.

LIMITATION OF VARIBLE

z

z

When welding in vertical position, a change in direction of welding shall require a re-qualification.

Qualification of a tack welder. Tack welder shall be qualified as a welder of fillet welds in the

qualified position.

FILLET WELD QUALIFICATION

Fillet welds between parts having dihedral angle of less than 75 degrees, the welder shall be required

to weld a groove weld test plate. Parts having a dihedral angle of 75 degree to 135 degrees, shall be

required to weld a fillet weld test plate.

http://www.iowadot.gov/erl/current/IM/content/566.htm

10/2/2013

Matls IM 566 Revised Apr 16, 2013

http://www.iowadot.gov/erl/current/IM/content/566.htm

Page 5 of 14

10/2/2013

Matls IM 566 Revised Apr 16, 2013

Page 6 of 14

Performance Accepting Criteria for Groove welds:

Visual examination shall be required for appearance and dimensions shall be in accordance with Part

B, Section 3.6.3

The guided bend surface of the weld and the heat affected zone shall have no discontinuities

exceeding the following dimensions:

a. 1/8 (3mm) measured in any direction

b. 3/8 (10mm) for the sum of all the discontinuities exceeding 1/32 (0.8 mm), but less than or

equal to 1/8 (3mm) for 1 (38 mm) wide specimens.

c. (6mm) maximum for corner cracks, except when this crack has resulted from a visible

inclusion or other fusion type of discontinuities, then 1/8 (3mm) maximum shall apply.

Fillet Welds Fracture Test Requirements:

The 6 inch (150mm) performance specimen, center section shall be examined visually on the broken

surface. In order to pass, it must show complete fusion to the root and have no inclusion or porosity

larger than 3/32 (2mm) in the greatest dimension. The sum of greatest dimensions of all inclusions and

porosity combined shall not exceed (19mm) in the 6 (150mm) length.

Note: The macroetch specimen for the fillet weld test (option #1) shall show complete penetration to

the root of the joint.

http://www.iowadot.gov/erl/current/IM/content/566.htm

10/2/2013

Matls IM 566 Revised Apr 16, 2013

http://www.iowadot.gov/erl/current/IM/content/566.htm

Page 7 of 14

10/2/2013

Matls IM 566 Revised Apr 16, 2013

http://www.iowadot.gov/erl/current/IM/content/566.htm

Page 8 of 14

10/2/2013

Matls IM 566 Revised Apr 16, 2013

http://www.iowadot.gov/erl/current/IM/content/566.htm

Page 9 of 14

10/2/2013

Matls IM 566 Revised Apr 16, 2013

http://www.iowadot.gov/erl/current/IM/content/566.htm

Page 10 of 14

10/2/2013

Matls IM 566 Revised Apr 16, 2013

http://www.iowadot.gov/erl/current/IM/content/566.htm

Page 11 of 14

10/2/2013

Matls IM 566 Revised Apr 16, 2013

http://www.iowadot.gov/erl/current/IM/content/566.htm

Page 12 of 14

10/2/2013

Matls IM 566 Revised Apr 16, 2013

http://www.iowadot.gov/erl/current/IM/content/566.htm

Page 13 of 14

10/2/2013

Matls IM 566 Revised Apr 16, 2013

http://www.iowadot.gov/erl/current/IM/content/566.htm

Page 14 of 14

10/2/2013

You might also like

- Welding Procedure 6GDocument5 pagesWelding Procedure 6GTrinh DungNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Technical Specs PDFDocument12 pagesTechnical Specs PDFcsolanki6586100% (1)

- E0900048-V4 LIGO UHV Welding SpecDocument7 pagesE0900048-V4 LIGO UHV Welding SpecBenjamin BrownNo ratings yet

- 01 - WELDING DEFECTS (Surface) - May 2021Document28 pages01 - WELDING DEFECTS (Surface) - May 2021Gerry Dan ChanliongcoNo ratings yet

- Destructive Test ReportDocument5 pagesDestructive Test ReportAnonymous r4Pd1KR0100% (1)

- Welding AISI 4130 PDFDocument5 pagesWelding AISI 4130 PDFDarioNo ratings yet

- Weld DefectsDocument45 pagesWeld Defectsanon_256154377No ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Filler MetalsDocument28 pagesFiller MetalsPeerasak ArunNo ratings yet

- Cajon-001 WPSDocument2 pagesCajon-001 WPSDanem HalasNo ratings yet

- Butt weld imperfections and defects guideDocument47 pagesButt weld imperfections and defects guidearash59_4uNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Miller Welding TitaniumDocument20 pagesMiller Welding TitaniumrcpretoriusNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- QA-QC Welding Program evaluation TestDocument2 pagesQA-QC Welding Program evaluation TestSatish KeskarNo ratings yet

- AWS A5.10 Specification For Bare Aluminum and Aluminum Alloy Welding Electrodes and Rods (1999)Document38 pagesAWS A5.10 Specification For Bare Aluminum and Aluminum Alloy Welding Electrodes and Rods (1999)Jairo Contreras100% (1)

- Special Alloys and Overmatched Welding Products SolveDocument14 pagesSpecial Alloys and Overmatched Welding Products SolveBhanu Pratap ChoudhuryNo ratings yet

- Metrode P92TP Welding ConsumablesDocument23 pagesMetrode P92TP Welding Consumablespipedown456No ratings yet

- Aws 1208Document80 pagesAws 1208ndrarlyNo ratings yet

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- Cwi Program Information: Faxed Applications Are Not AcceptedDocument7 pagesCwi Program Information: Faxed Applications Are Not Acceptedfeihung20120% (1)

- Brazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Document3 pagesBrazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Joyce GordonioNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- MIG-MAG Welding Course OverviewDocument10 pagesMIG-MAG Welding Course OverviewGanesanGovindarjNo ratings yet

- Welding School DisplayDocument10 pagesWelding School DisplaySunilNo ratings yet

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- AWS C5.10/C5.10M:2003 - Guide to Shielding GasesDocument6 pagesAWS C5.10/C5.10M:2003 - Guide to Shielding GasesBoby ThomasNo ratings yet

- 05-Welder Certification PDFDocument11 pages05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- 125 Welding-Inspection-Technology-M11-Q-A PDFDocument88 pages125 Welding-Inspection-Technology-M11-Q-A PDFmoonstar_dme100% (1)

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Welding Processes Used in Saudi AramcoDocument62 pagesWelding Processes Used in Saudi AramcoAnand RaoNo ratings yet

- WPS RegisterDocument2 pagesWPS RegisterdaveswinburneNo ratings yet

- GMAW Transfer Modes GuideDocument1 pageGMAW Transfer Modes GuideNathanLaertePiai100% (1)

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNo ratings yet

- SEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding RodDocument2 pagesSEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding Rodsoft4gsmNo ratings yet

- Interpretations: ASME Boiler and Pressure Vessel Code Section IxDocument48 pagesInterpretations: ASME Boiler and Pressure Vessel Code Section Ixjuan ninaNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- A5 32-A5 32M-97Document5 pagesA5 32-A5 32M-97mon3embo7No ratings yet

- Fermi Lab Orbital Welding ProcedureDocument2 pagesFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- A1010 WeldingDocument20 pagesA1010 WeldingCurious RajNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- WPS - 021Document13 pagesWPS - 021MAT-LIONNo ratings yet

- Welder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationDocument1 pageWelder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationPerminder SinghNo ratings yet

- Selection of Welding ConsumablesDocument13 pagesSelection of Welding ConsumablesbassemaeNo ratings yet

- Asme Sec 9 - ADocument144 pagesAsme Sec 9 - Anidhinchandranvs67% (3)

- Welding: Munther DiyabDocument113 pagesWelding: Munther DiyabMunther MohdNo ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- Factors in Selection of Filler Metals in WeldingDocument2 pagesFactors in Selection of Filler Metals in WeldingBalakumarNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- Unitor Maintenance and Repair Welding: The Solutions GuideDocument1 pageUnitor Maintenance and Repair Welding: The Solutions GuideNuzhat Ali100% (1)

- Flux Cored and MIG Pipe WeldingDocument59 pagesFlux Cored and MIG Pipe Weldingcentaury2013No ratings yet

- AWS Welder Certification ApplicationDocument5 pagesAWS Welder Certification Applicationfallalovaldes61No ratings yet

- Welding Consumables Flyer D2wDocument4 pagesWelding Consumables Flyer D2wGregEverett2No ratings yet

- Hand BookDocument300 pagesHand BookGregEverett2No ratings yet

- API 582 The Welding Solution PDFDocument21 pagesAPI 582 The Welding Solution PDFRemmy Torres Vega75% (8)

- WPW 3-3 ShortDocument8 pagesWPW 3-3 ShortGregEverett2No ratings yet

- Specification For Air Craft Warning LightsDocument5 pagesSpecification For Air Craft Warning Lightsgeverett2765No ratings yet

- 334488-T-1005-2-7646 - 02 HDPE ButweldingDocument14 pages334488-T-1005-2-7646 - 02 HDPE ButweldingGregEverett2No ratings yet

- 334488-T-1005-2-7650 - 01 WPS & PQR For STG PipingDocument4 pages334488-T-1005-2-7650 - 01 WPS & PQR For STG PipingGregEverett2No ratings yet

- EE BA 54 001 Stack Lighting DrawingDocument1 pageEE BA 54 001 Stack Lighting Drawinggeverett2765No ratings yet

- Specification For Air Craft Warning LightsDocument5 pagesSpecification For Air Craft Warning Lightsgeverett2765No ratings yet

- EK-BA-23-001 Three-Tube Steel Stack Structure DrawingDocument1 pageEK-BA-23-001 Three-Tube Steel Stack Structure Drawinggeverett2765No ratings yet

- Inspection of Unfired Pressure VesselsDocument35 pagesInspection of Unfired Pressure Vesselstbmari100% (7)

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- CE QB - All Units PDFDocument38 pagesCE QB - All Units PDFkurian georgeNo ratings yet

- Industrial Applications of Olefin MetathesisDocument7 pagesIndustrial Applications of Olefin Metathesisdogmanstar100% (1)

- Catalogo Novik NeoDocument32 pagesCatalogo Novik NeorafaelciceliniNo ratings yet

- Alpha 10 Mini Manual Rev1Document2 pagesAlpha 10 Mini Manual Rev1k4gw100% (1)

- PDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressDocument15 pagesPDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressJosé LuisNo ratings yet

- C ProgDocument29 pagesC ProgaishwaryaNo ratings yet

- In The Shadow of The CathedralDocument342 pagesIn The Shadow of The CathedralJoy MenezesNo ratings yet

- High Current Transistor SpecsDocument5 pagesHigh Current Transistor SpecsamernasserNo ratings yet

- Article 680 Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsDocument13 pagesArticle 680 Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsDocente 361 UMECITNo ratings yet

- Coal Gasification, Liquid Fuel Conversion (CTL), and CogenerationDocument66 pagesCoal Gasification, Liquid Fuel Conversion (CTL), and CogenerationVăn Đại - BKHNNo ratings yet

- COE 107.04 Cathodic Protection Monitoring Instruments and ProceduresDocument42 pagesCOE 107.04 Cathodic Protection Monitoring Instruments and ProceduresMo'tasem Serdaneh100% (1)

- Resultados de La Web: GDDS - Traducción Al Español - Ejemplos Inglés - Reverso ..Document3 pagesResultados de La Web: GDDS - Traducción Al Español - Ejemplos Inglés - Reverso ..Jo PaterninaNo ratings yet

- Spe 143287 MS PDocument11 pagesSpe 143287 MS PbvkvijaiNo ratings yet

- IRCTC Next Generation Eticketing SystemDocument4 pagesIRCTC Next Generation Eticketing Systemsivagokul526No ratings yet

- Student Graduation Using DataMiningDocument207 pagesStudent Graduation Using DataMiningDanielNo ratings yet

- Yoshimi Advanced User ManualDocument297 pagesYoshimi Advanced User Manualfby999No ratings yet

- L1Document7 pagesL1Francisco Roberto Trujillo LeonNo ratings yet

- Public Speaking RulesDocument12 pagesPublic Speaking RulesAnonymous 0ejRGUpmo1No ratings yet

- ECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnDocument33 pagesECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnJosé Bonifácio Marques de AmorimNo ratings yet

- EEG Signal Classification Using K-Means and Fuzzy C Means Clustering MethodsDocument5 pagesEEG Signal Classification Using K-Means and Fuzzy C Means Clustering MethodsIJSTENo ratings yet

- Regulation of AlternatorDocument6 pagesRegulation of Alternatorkudupudinagesh100% (1)

- George B Dantzig PDFDocument19 pagesGeorge B Dantzig PDFKeith BoltonNo ratings yet

- Secondary SourcesDocument4 pagesSecondary SourcesKevin NgoNo ratings yet

- Example4 FatigueTools WS01-SNDocument23 pagesExample4 FatigueTools WS01-SNJosé Luciano Cerqueira CesarNo ratings yet

- Calicut University: B. A PhilosophyDocument6 pagesCalicut University: B. A PhilosophyEjaz KazmiNo ratings yet

- Automatic Helmet DetectDocument4 pagesAutomatic Helmet Detectvasanth100% (1)

- E02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaDocument6 pagesE02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaSALMANNo ratings yet

- Steam Technical InfoDocument2 pagesSteam Technical InfoAnonymous 7z6OzoNo ratings yet

- Work Instruction For Coil Taping Process of EE14 (1&4 Pin)Document6 pagesWork Instruction For Coil Taping Process of EE14 (1&4 Pin)k.mehaboob bashaNo ratings yet