Professional Documents

Culture Documents

Design Mega Columns-N-M Metric

Uploaded by

Damian Florin DanielCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Mega Columns-N-M Metric

Uploaded by

Damian Florin DanielCopyright:

Available Formats

DESIGN EXAMPLE OF A COLUMN WITH 4 ENCASED STEEL PROFILES

Andr Plumier

(Plumiecs & ULg) : a.plumier@ulg.ac.be (Main Contact)

Teodora Bogdan (ULg) : teodora.bogdan@ulg.ac.be

Herv Dege

(ULg) : h.degee@ulg.ac.be

Jean-Claude (JC) Gerardy ArcelorMittal Commercial Sections (Luxembourg) : jc.gerardy@arcelormittal.com

Abstract

Composite mega columns of tall buildings are currently designed with continuous built-up sections, welded in

the fabrication shop and spliced on the job site without any prequalified welding procedure. This leads to highly

restrained welds and splices which, under severe dynamic loadings, will likely crack before exhibiting any

ductile behavior. These tall buildings have not been submitted to severe earthquakes, but it will happen. The

1994 earthquake in Northridge, California, taught us that welding procedures, beam-to-column connections and

column splices have to be as simple as possible to properly and reliably work as anticipated.

Using multiple rolled sections encased into concrete is the solution for increasing the safety of tall buildings. It

leads to less welding, less fabrication works and reliable simple splices which have been used for decades in

high-rise projects.

AISC allows engineers to design composite sections built-up from two or more encased steel. But, it doesnt

explain how to perform and check the design. This paper offers a method to do it. The method is explained by

means of design examples covering combined axial compression, bending and shear.

Keywords

Composite columns, rolled sections, steel shapes, tall buildings, design method, mega-columns.

NOTATIONS

Aa = area of 1 steel profile.

Ac = area of concrete.

Ag = gross cross-sectional area of composite section.

As = total area of the steel profiles.

As1 = equivalent steel plate placed along the x-axis.

As2 = equivalent steel plate placed along the y-axis.

Asr = area of the continuous reinforcing bars.

Asri = cross-sectional area of reinforcing bar I.

Asrs = area of continuous reinforcing bars.

Avz = web area of the steel profile.

b = width of the steel profile.

h = height of the steel profile.

bs1 = width of As1 plate, mm.

bs2 = width of As2 plate, mm.

cx = concrete cover, on x direction.

cy = concrete cover, on y direction.

db = diameter of the longitudinal reinforcement.

dx = the distance between the two steel profiles HD 400x1299 (W14x16x873), on y - direction.

dy = the distance between the two steel profiles HD 400x1299 (W14x16x873), on x - direction.

dsx = the distance from the local centroid of the steel profile HD 400x1299 (W14x16x873) to the section neutral

axis, on x - direction.

dsy = the distance from the local centroid of the steel profile HD 400x1299 (W14x16x873) to the section neutral

axis, on y direction.

ds2x = the distance from the local centroid of As1 plate to the section neutral axis, on x - direction.

ds1y = the distance from the local centroid of As2 plate to the section neutral axis, on y - direction.

fc = compressive cylinder strength of concrete.

Fy = specified minimum yield stress of steel shape.

Fysr = yield stress of reinforcing steel.

Fu = specified minimum tensile strength of steel shape.

h1 = height of the concrete section.

h2 = width of the concrete section.

hs1 = height of As1 plate, mm.

hs2 = height of As2 plate, mm.

hnx = distance from centroidal axis (Y-Y) to neutral axis .

hny = distance from centroidal axis (X-X) to neutral axis .

Ic = moment of inertia of concrete.

Ir = moment of inertia of reinforcing steel.

Is = moment of inertia of steel shape.

Isr1x = moment of inertia about x axis of As1 plate, mm.

Isr2x = moment of inertia about x axis of As2 plate, mm.

Isr1y = moment of inertia about y axis of As1 plate, mm.

Isr2y = moment of inertia about y axis of As2 plate, mm.

Isrx = moment of inertia about x axis of equivalent plates, mm.

Isry = moment of inertia about y axis of equivalent plates, mm.

n = number of continuous reinforcing bars in composite section.

nx = number of continuous reinforcing bars on x direction.

ny = number of continuous reinforcing bars on y direction.

tf = steel profile flange thickness.

tw = steel profile web thickness.

Zr1x = full x-axis plastic modulus of As1 plate, mm.

Zr2x = full x-axis plastic modulus of As2 plate, mm.

Zr1y = full y-axis plastic modulus of As1 plate, mm.

Zr2y = full y-axis plastic modulus of As2 plate, mm.

Zsx = full x-axis plastic modulus of steel shape, mm.

Zsy = full y-axis plastic modulus of steel shape, mm.

Zcx = full x-axis plastic modulus of concrete shape, mm.

Zcy = full y-axis plastic modulus of concrete shape, mm.

Z cxn = x-axis plastic modulus of concrete section within the zone 2hn

Z r2xn = x-axis plastic modulus of As2 plates within the zone 2hn

Z cyn = y-axis plastic modulus of concrete section within the zone 2hn

Z r1yn = y-axis plastic modulus of As1 plates within the zone 2hn.

= steel contribution ratio.

Preface

Mega composite columns of tall buildings in Asia are typically designed with huge steel continuous caissons

built-up from heavy plates. They are welded together in the steel fabrication shop and spliced on the job site.

Internationally recognized welding codes such as AWS D1.1 (structural American welding code) and AWS

D1.8 (seismic welding code) or EN 1090-2:2008 (execution of steel structures) and EN 1011-2:2001

(recommendations for welding of metallic materials) impose the pre-qualification of the welding procedures of

such exotic joints, following strict welding sequences. Required preheating and interpass temperatures are

specified per the thickness of the steel (>32mm), its composition (CEV/grade), the type of electrode and the

level of restraint in the joint. Non-destructive tests (ultrasonic test, magnetic particle examination, radiographic

test) performed by certified inspectors are mandatory to guarantee sound welded connections and a safe

structure.

In practice, even when the welding codes are strictly followed, it is typical to have to repair up to 10% of the

welds in simple structures.

In the case of these huge caissons, the welding conditions are rather extreme. Heavy thick plates in typical grade

50 steel (ASTM A572Gr.50 or Q345) must be preheated at 110C in the steel fabrication shop as well as on the

job site prior and during the welding process. Any lack of preheating when welding these huge caissons induces

sensitive material conditions (hard and brittle zones) and high levels of restraint (post weld stresses) in all

directions starting in the steel fabrication shop and amplified on the job site after splicing two caissons together.

Applying adequate preheating during the whole welding process is difficult. How to preheat such joints at

110C? Correct welding takes days of work without interruption. Proper controlling and repair of all welds is so

expensive that this solution, when correctly executed, is not economical at all.

There is an economical and safer alternate to this configuration. AISC design codes allows designers to use

composite sections built-up from two or more encased steel shapes provided that the buckling of individual

shapes is prevented before the hardening of the concrete.

The Chinese Institute of Earthquake Engineering is also recommending the use of multiple jumbo H-shapes

rather than large continuous caissons. The welding procedures and the connection detailing of single rolled-Hsections are well described in the above mentioned codes. The use of correct beveling, the so-called "weldaccess-holes" associated to very precise welding sequences, including the removal of the backing bars and

appropriate grindings to clean-up the weld surface between passes minimize the amount of residual stresses after

splicing single rolled steel columns. W14x16 (HD400) rolled sections (jumbos) are today available up to 1299

kg/m (873 lbs/ft) with a flange thickness of 140 mm (5.5 in.) and W36 (HL920) are available up to 1377 kg/m

(925 lbs/ft). These sizes are not only available in classical grade 345 MPa (ASTM A992/Grade 345, Q345,

S355) which requires to be preheated for flange thicknesses above 32 mm (1.5 in.) but also in high tensile

modern steel produced by a quenching and self tempering process, namely ASTM A913 Grade 345 and 450, or

per ETA 10-156 (European Technical Approval) grades Histar 355 and Histar 460. Besides their higher yields,

the main advantages of these high performance steels are their weldability without preheating (above 0C and

with low hydrogen electrodes) as well as their outstanding toughness. (27J up to minus 50C). These high

performance steels are not only fully in compliance with American and European standards, they can also meet

the stringent requirements of the Chinese standards such as the 20% minimum elongation which is mandatory in

the Chinese seismic codes. These QST steels (ASTM A913) have already been successfully used in the

Shanghai World Financial Center.

In this paper, a method for the design of composite sections with multiple encased steel profiles is presented. It

make use of existing principles and calculations methods, but the fact is that the method as such does is not

presented up to now in books of structural design.

Introduction.

The design examples presented hereafter have as main references:

-

ANSI/AISC 360-10 Specification for Structural Steel Buildings, 2010

AISC DESIGN EXAMPLES Version 14.0,2011

Building Code Requirements for Structural Concrete ACI 318-08, 2008

Occasionally, reference is made to EN 1994-1-1:2004 Eurocode 4: Design of composite steel and concrete

structures, part 1-1, general rules and rules for buildings, European Committee for Standardization (CEN),

Brussels, Belgium.

Recall of AISC rules for design of composite members and introduction to

the design examples of composite columns with several steel profiles

encased.

Recall of AISC rule in I4. SHEAR.

For filled and encased composite members, either the shear strength of the steel section alone, the steel section

plus the reinforcing steel, or the reinforced concrete alone are permitted to be used in the calculation of available

shear strength.

The explanations and justifications of the design for shear resistance in the case of a composite column with 4

encased steel profiles are given within Examples I.X3 and I.X4.

Recall of AISC rule in I5. COMBINED FLEXURE AND AXIAL FORCE.

Design for combined axial force and flexure may be accomplished using the plastic-distribution method.

Several different procedures for employing the plastic-distribution method are outlined in the AISC

Commentary to I5.

Each of these procedures is applied for composite steel-concrete sections concrete with 4 encased steel profiles

in Example I.X1. and Example I.X2.

To help in following these design examples, the interaction curves which will be used are presented separately

in Fig. I-1e and I-1f. The equations correspond to different points selected on the interaction curves.

Calculations concerning the slenderness effect are not presented, because they would not be different of those

shown in detail in AISC Design Examples V14.0-2011. For design cases which would be different of the

examples presented (for instance a section with 6 encased steel profiles, this presentation in Figures I-1e and I1f shows the way to develop the appropriate interaction equations.

In the plastic-distribution method, the N-M interaction curves are convex, because it is assumed that the

concrete has no tensile strength.

Fig.I-1. Axial force (P) bending moment (M) diagram for a composite cross section.

For a composite cross-section symmetrical about the axis of bending, Roik and Bergmann (1992) have proposed

a simple method to evaluate its M-N interaction diagram. This method is adopted in AISC Specifications. As

shown in Figure I-1, this method does not determine a continuous N-M interaction curve, but only a few key

points. The N-M curve is then constructed by joining these key points by straight lines.

When evaluating these key points, rigid-plastic material behavior is assumed. Thus, steel is assumed to have

reached yield in either tension or compression. Concrete is assumed to have reached its peak stress in

compression and its tensile strength is zero. For one equivalent rectangular stress block the peak stress in

compression is:

0.85 f c' = 0.85 50MPa = 42.5 MPa

The key points in Fig.I-1are:

-

A - squash load point

B - pure flexural bending point

D - the maximum bending moment point

C - point with bending moment equal to the pure bending moment capacity

PLASTIC CAPACITIES FOR RECTANGULAR,

COLUMN WITH 4 ENCASED PROFILES

BENT ABOUT THE X X AXIS

Section

Stress distribution

Point Defining Equations

As1 = nx Asri = bs1 hs1

As 2 = ny Asr 2 = bs 2 hs 2

Asr = ( n x + n y ) Asri

nx no. of bars on x direction

ny no. of bars on y direction

bs1= width of As1 plate

hs1= height of As1 plate

bs2= width of As2 plate

hs2= height of As2 plate

As1 = area of top (bottom) plate

As2 = area of lateral plate

Asri = area of one longitudinal bar

A

PA = As Fy + As1 Fysr + As2 Fysr + 0.85 Ac f'c

MA = 0

As = 4 Aa

AC = h1 h2 As Asr

Aa = area of one steel profile

As = total area of the steel shape

C

PC = 0.85 Ac f'c

MC = M B

PD =

0.85 Ac f'c

2

1

M Dx = Z sx Fy + ( Z r1x + Z r2x ) Fysr + Z cx ( 0.85 f c' )

2

Zsx full x- axis plastic modulus of steel shape

Zr1x full x- axis plastic modulus of As1 plates

Zr2x full x- axis plastic modulus of As2 plates

Z r1x = 2 As1 d s1y

bs2 hs22

4

Z sx = 4 Aa d sy

Z r2x = 2

h1 h22

Z r1x Zr 2x Z sx

4

Fig. I -1e. Composite member with several encased steel profiles, X-X -axis anchor points.

Z cx =

PB = 0

Aa

h

where:

b* - the width of the equivalent steel rectangle bar

Aa area of one steel profile

b* =

h

For hnx between the two profiles hnx d sy :

2

PC

hnx =

2 h1 ( 0.85 f'c ) + 2 bs2 ( 2 Fyrs 0.85 f'c )

Z cxn = h1 hnx2 Z r2xn

Z r2xn = 2 bs2 hnx2

M Bx = M Dx Z r2xn Fyrs 1 Zcxn ( 0.85 f'c )

2

h

h

For hnx between the two profiles d sy < hnx d sy + :

2

2

PC + 4 d sy b* ( 2 Fy 0.85 f'c )

2

hnx =

2 h1 ( 0.85 f'c ) + 4 b* ( 2 Fy 0.85 f'c ) + 2 bs 2 ( 2 Fyrs 0.85 f'c )

Z r2xn = 2 bs2 hnx2

Z sxn = ( 2 d sx +b* ) h ( 2 d sx -b* ) h 2

2

nx

2

nx

b* ( 2 d sy h )

Z cxn = h1 hnx2 Z r2xn Z sxn

M Bx = M Dx Zr2xn Fyrs Z sxn Fy 1 Zcxn ( 0.85 f'c )

2

For hnx above the two profiles the height of vertical

h

h

equivalent layer d sy + <hnx s2 :

2

2

hnx =

PC As ( 2 Fy 0.85 f'c )

2 h1 ( 0.85 f'c ) + 2 bs2 ( 2 Fyrs 0.85 f'c )

Z r2xn = 2 bs2 hnx2

Z sxn = Z sx

Z cxn = h1 hnx2 Z r2xn Z sxn

M Bx = M Dx Z r2xn Fyrs Z sxn Fy 1 Z cxn ( 0.85 f'c )

2

Z sxn - x-axis plastic modulus of equivalent steel

rectangle bar within the zone 2hnx

Z cxn - x-axis plastic modulus of concrete section

within the zone 2hnx

Z r2xn - x-axis plastic modulus of As2 plate within the

zone 2hnx

Fig. I -1e. Composite member with several encased steel profiles, X-X -axis anchor points. (continued)

PLASTIC CAPACITIES FOR RECTANGULAR,

COLUMN WITH 4 ENCASED PROFILES

BENT ABOUT THE Y Y AXIS

Section

Stress distribution

Point Defining Equations

A

PA = As Fy + As1 Fysr + As2 Fysr + 0.85 Ac f'c

MA = 0

As = 4 Aa

AC = h1 h2 As Asr

Aa = area of one steel profile

As = total area of the steel shape

C

PC = 0.85 Ac f'c

MC = M B

PD =

0.85 Ac f'c

2

1

M Dy = Z sy Fy + ( Z r1y + Z r2y ) Fysr + Z cy ( 0.85 f c' ) Zsy

2

full y- axis plastic modulus of steel shape

Zr1y full y- axis plastic modulus of As1 plates

Zr2y full y- axis plastic modulus of As2 plates

b d2

Z r1y = 2 s1 s1

4

Z r2y = 2 As2 d s2x

Z sy = 4 Aa d sx

h12 h2

Z r1y Zr 2y Z sy

4

Fig. I -1f. Composite member with several encased steel profiles, Y-Y -axis anchor points.

Z cy =

10

PB = 0

Aa

b

where:

h* - the height of the equivalent steel rectangle bar

Aa area of one steel profile

h* =

b

For hny between the two profiles hny d sx :

2

PC

hny =

2 h2 ( 0.85 f'c ) + 2 bs1 ( 2 Fyrs 0.85 f'c )

Z cyn = h2 hny2 Z r1yn

Z r1yn = 2 bs1 hny2

M By = M Dy Z r1yn Fyrs 1 Z cyn ( 0.85 f'c )

2

b

b

For hny between the two profiles d sx < hny d sx + :

2

2

PC + 4 d sx h* ( 2 Fy 0.85 f'c )

2

hny =

2 h2 ( 0.85 f'c ) + 4 h* ( 2 Fy 0.85 f'c ) + 2 bs1 ( 2 Fyrs 0.85 f'c )

Z r1yn = 2 bs1 hny2

Z syn = ( 2 d sy +h* ) hny2 ( 2 d sy -h* ) hny2 2

h* ( 2 d sx b )

Z cyn = h1 hny2 Z r1yn Z syn

M By = M Dy Zr1yn Fyrs Z syn Fy 1 Zcyn ( 0.85 f'c )

2

For hny above the two profiles and the height of

h

b

vertical equivalent layer d sx + < hny s1 :

2

2

hny =

PC As ( 2 Fy 0.85 f'c )

2 h2 ( 0.85 f'c ) + 2 bs1 ( 2 Fyrs 0.85 f'c )

Z r1yn = 2 bs1 hny2

Z syn = Z sy

Z cyn = h1 hny2 Z r1yn Z syn

M By = M Dy Zr1yn Fyrs Z syn Fy 1 Zcyn ( 0.85 f'c )

2

Z syn - y-axis plastic modulus of equivalent steel

rectangle bar within the zone 2 hny

Z cyn - y-axis plastic modulus of concrete section

within the zone 2hny

Z r1yn - y-axis plastic modulus of As1 plates within

the zone 2hny

Fig. I -1f. Composite member with several encased steel profiles, Y-Y -axis anchor points (continued).

11

EXAMPLE I.X1 - COMPOSITE COLUMN WITH FOUR ENCASED STEEL PROFILES IN

COMBINED AXIAL COMPRESSION AND FLEXURE ABOUT (X-X) AXIS.

Given:

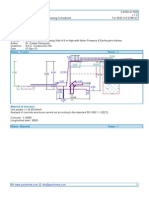

Determine for the encased composite member illustrates in Fig. I.X1-1 the axial force (P) bending moment

(M) diagram.

Fig. I.X1-1. Encased composite member section.

From ArcelorMittal classification, the steel material properties are:

ASTM A913- 11 Grade 65

Fy = 450MPa;

Fu = 550MPa;

12

From ArcelorMittal sections catalog, the geometric and material properties of one steel profile HD 400x1299

(W14x16x873) are:

Aa = 165000 mm2;

Avz = 505.2 cm2;

b = 476 mm;

h = 600 mm;

3

tw = 100 mm;

I HDx = 754600 10 mm

Zsx = 33250 cm ; Zsy = 16670 cm ;

tf = 140 mm;

4

I HDy = 254400 104 mm 4

From Fig. I.X1-1, additional geometric properties of the composite section used for force allocation and load

transfer are calculated as follows:

h1 = 3072mm;

h2 = 3072mm;

cx = 86mm -14mm = 72 mm;

cy = 86mm -14mm = 72 mm;

dx = 2500 mm;

dy = 2500mm;

dsx = 1012 mm;

dsy = 950mm;

ds1y = 1400 mm;

ds2x = 1450mm;

Ag = h1 h2 = (3072mm) (3072mm) = 9437184mm2 ;

db = 40mm for a T40 diameter bar;

Asri = 1256.637mm2 ;

n

Asr = Asri = 321699.09mm2 ;

i =1

As = Aa = 4 165000mm 2 = 660000mm 2

i =1

Ac = Ag Asr As = 9437184mm2 321699.09mm2 660000mm2 = 8.455 106 mm2

Ec = ( 0.043 wc1.5 )

f c' = 38007MPa for wc = 2500

kg

m3 ;

Es = 200000 MPa (AISC I1.3);

Asr + As 321699.09mm2 + 660000mm2

=

= 0.104

94371.84mm2

Ag

Pn = As Fy + Asr Fysr + 0.85 Ac f'c

= 6.6 105 mm 2 450MPa + 3.216 105 mm2 500MPa + 8.455 106 mm2 ( 0.85 50MPa )

= 817207.653kN

As Fy

Pn

660000mm2 450MPa

= 0.363

817207.653kN

where

h1 height of the concrete section, mm.

h2 width of the concrete section, mm.

cx concrete cover, on x direction, mm.

cy concrete cover, on y direction, mm.

dx the distance between the two steel profiles HD 400x1299 (W14x16x873), on y - direction, mm.

dy the distance between the two steel profiles HD 400x1299 (W14x16x873), on x - direction, mm.

dsx the distance from the local centroid of the steel profile HD 400x1299 (W14x16x873) to the

section neutral axis, on x - direction, mm.

13

dsy the distance from the local centroid of the steel profile HD 400x1299 (W14x16x873) to the

section neutral axis, on y direction, mm.

ds2x the distance from the local centroid of As1 plate to the section neutral axis, on x - direction, mm.

ds1y the distance from the local centroid of As2 plate to the section neutral axis, on y - direction, mm.

Solution:

A simplification of the composite section is made by replacing the reinforcement by equivalent steel plates, as

shown in Fig. I.X1-1. Horizontal plates include only reinforcement that belongs to the two main lines. One

horizontal plate, As1, replace 52 reinforcement rebars.

nx = 52

As1 = 52T40 = 52 1256.64mm2 = 65364mm 2

For hs1 = 3072mm (86mm +

d s1y =

100

mm) = 2800mm

2

bs1 = 23.338 mm;

hs1 2800mm

=

= 1400mm

2

2

Side plates includes besides the two lateral lines, the few additional rebars. The number of reinforcement which

corresponds to one lateral plate is 76.

ny = 30 + 30 + 3 2 + 5 2 = 76

As2 = 76T40 = 76 1256.64mm 2 = 95532mm 2

For hs2 = 3072mm 2 86mm = 2900mm

d s2x =

bs2 = 32.933 mm;

hs2 2900mm

=

= 1450mm

2

2

The moment of inertia of the reinforcing bars about the elastic neutral axis of the composite section, Isr, is

determined for the two equivalent plates As1 and As2, and is calculated as follows:

I sr1x =

hs1 bs13 2800mm ( 23.338mm )

=

= 2.966 106 mm4

;

12

12

I sr2x =

bs2 hs23 32.933mm ( 2900mm )

=

= 6.693 1010 mm4

;

12

12

2

I srx = 2 I sr1x + 2 I sr2x + 2 As1 d s1y

=

=2 2.966 106 mm 4 + 2 6.693 1010 mm 4 + 2 6.534 104 mm 2 (1400mm )

= 3.9 1011 mm 4

where

Isr1x moment of inertia about x axis of As1 plate, mm4.

Isr2x moment of inertia about x axis of As2 plate, mm4.

Isrx moment of inertia about x axis of equivalent plates, mm4.

hs1 height of As1 plate, mm.

bs1 width of As1 plate, mm.

14

hs2 height of As2 plate, mm.

bs2 width of As2 plate, mm.

The moment of inertia values of the entire steel section about X-X is determined as:

I sx = 4 Aa d sy2 + 4 I HDx = 4 165000mm 2 ( 950mm ) + 4 754600 10 4 mm 4 = 6.258 1011 mm 4

2

where

Isx moment of inertia about x axis of the steel profiles, mm4.

The moment of inertia values for the concrete about both axes axis is determined as:

h1 h23 3072mm ( 3072mm )

=

= 7.421 1012 mm 4

12

12

3

Ig =

I cx = I g I srx I sx = 7.421 1012 mm4 3.9 1011 mm4 6.058 1011 mm4 = 6.426 1012 mm4

where

Icx moment of inertia about x axis of the concrete part, mm4.

Material and Detailing Limitations

Material limits are provided in AISC Specification Sections I1.1 (2) and I1.3 as follows:

(1) Concrete strength:

f'c = 50MPa

21MPa f'c 70MPa

o. k.

(2) Specified yield stress of structural steel:

Fy = 450MPa

o. k.

(3) Specified yield stress of structural steel:

Fysr = 500MPa

Fy 525MPa

Fysr 525MPa

o. k.

Transverse reinforcement limitations are provided in AISC Specification Section I1.1 (3), I2.1a. (1), I2.1a. (2)

and ACI 318 as follows:

(1) Tie size and spacing limitations:

The AISC Specifications requires that either lateral ties or spirals be used for transverse reinforcement.

Where lateral ties are used, a minimum of either 10 mm (No. 3) bar placed at a maximum of 406 mm

(12 in.) on center, or a 13 mm (No. 4) bar or larger spaced at a maximum of 406 mm (16 in.) on center

shall be used.

14 mm lateral ties at 75 mm are provided.

o. k.

Note that AISC Specification Section I1.1 (1) specifically excludes the composite column provision of

ACI 318 Section 10.13, so it is unnecessary to meet the tie reinforcement provisions of ACI 318

Section 10.13.8. when designing composite columns using AISC Specifications Chapter I.

If spirals are used, the requirements of ACI 318 Sections 7.10 and 10.9.3 should be met according to

the User Note at the end of AISC Specification I2.1a.

15

(2) Additional tie size limitation:

ACI 318 Section 7.10.5.1 requires that all nonprestressed bars shall be enclosed by lateral ties, at least

10 mm (No. 3) in size for longitudinal bars 32 mm (No. 10) or smaller, and at least 13 mm (No. 4) in

size for 36 mm (No. 11), 43 mm (No. 14), 57 mm (No. 18), and bundled longitudinal bars.

14 mm lateral ties are provided for 40 mm longitudinal bars.

o. k.

(3) Maximum tie spacing should not exceed 0.5 times the least column dimension:

h = 3072mm

smax = 0.5 min 1

= 1536mm

h2 = 3072mm

s = 75mm smax = 1536mm

o. k.

(4) Concrete cover:

ACI 318 Section 7.7 contains concrete cover requirements. For concrete not exposed to weather or in

contact with ground, the required cover for column ties is 38 mm (1.5 in).

cover = 86mm -1T14 = 86mm -14mm = 72mm > 38mm

o. k.

(5) Provide ties as required for lateral support of longitudinal bars:

AISC Design Examples 2011 Part1, page I-96 indicates the following:AISC Specification Commentary

Section I2.1a references Chapter 7 of ACI 318 for additional transverse tie requirements. In accordance

with ACI 318 Section 7.10.5.3 and Fig. R7.10.5, ties are required to support longitudinal bars located

farther than 6 in. clear on each side from a laterally supported bar. For corner bars, support is typically

provided by the main perimeter ties. For intermediate bars, Fig. I.9-1illustrates one method for

providing support through the use of a diamond-shaped tie.

Longitudinal and structural steel reinforcements limits are provided in AISC Specification Section I1.1 (4), I2.1

and ACI 318 as follows:

(1) Structural steel minimum reinforcement ratio: As / Ag 0.01

6.6 105 mm2

= 0.070mm

9.437 106 mm 2

o. k.

(2) Minimum longitudinal reinforcement ratio: Asr / Ag 0.004

3.216 105 mm2

= 0.034mm

9.437 106 mm 2

o. k.

(3) Maximum longitudinal reinforcement ratio: Asr / Ag 0.08

3.216 105 mm2

= 0.034mm

9.437 106 mm 2

o. k.

(4) Minimum number of longitudinal bars:

ACI 318 Section 10.9.2 requires a minimum of four longitudinal bars within rectangular or circular

members with ties and six bars for columns utilizing spiral ties. The intent for rectangular sections is to

provide a minimum of one bar in each corner, so irregular geometries with multiple corners require

additional longitudinal bars.

256 bars provided

o. k.

(5) Clear spacing between longitudinal bars:

16

ACI 318 Section 7.6.3 requires a clear distance between bars of 1.5db or 38 mm (1.5in.).

1.5 db = 60mm

smin = max

= 60mm

38mm

s = 100mm 40mm = 60 smin

o. k.

(6) Clear spacing between longitudinal bars and the steel core:

AISC Specification Section I2.1e requires a minimum clear spacing between the steel core and

longitudinal reinforcement of 1.5 reinforcing bar diameters, but not less than 38 mm (1.5 in.).

1.5 db = 60mm

smin = max

= 60mm

38mm

The distance from the steel core and the longitudinal bars is determined from Fig. IX1-1, on x direction

as follows:

s = 524mm

b

60mm 2 40mm = 146mm smin

2

o. k.

The distance from the steel core and the longitudinal bars is determined from Fig. IX1-1, on y direction

as follows:

s = 586mm

h

60mm 2 40mm = 100mm smin

2

o. k.

where

h height of HD 400x1299 (W14x16x873) steel profile, mm.

b width of HD 400x1299 (W14x16x873) steel profile, mm.

(7) Concrete cover for longitudinal reinforcement:

ACI 318 Section 7.7 provides concrete cover requirements for reinforcement. The cover requirements

for column ties and primary reinforcement are the same, and the tie cover was previously determined to

be acceptable, thus the longitudinal reinforcement cover is acceptable by inspection.

Interaction of Axial Force and Flexure

AISC Design Examples 2011 Part1, page I-96 indicates the following:

The interaction between axial forces and flexure in composite members is governed by AISC

Specification Section I5 which, for compact members permits the use of a strain compatibility method

or plastic stress distribution method, with the option to use the interaction equations of Section H1.1.

The strain compatibility method is a generalized approach that allows for the construction of an

interaction diagram based upon the same concepts used for reinforced concrete design. Application of

the strain compatibility method is required for irregular/nonsymmetrical sections.

Plastic stress distribution methods are discussed in AISC Specification Commentary Section I5 which

provides three acceptable procedures for filled members. Plastic stress distribution methods are

discussed in AISC Specification Commentary Section I5. The procedure involves the construction of a

piecewise-linear interaction curve using the plastic strength equations provided in Fig. I-1-1 located

17

within the front matter of the Chapter I Design Examples. The method is a reduction of the piecewiselinear interaction curve that allows for the use of less conservative interaction equations than those

presented in Chapter H.

Thereafter are provided approaches following two methods: a plastic stress distribution method and a finite

element analysis.

Method1 - Interaction Curves from the Plastic Stress Distribution Model

Step 1: Construct nominal strength interaction surface A, B, C, and D without length effects, using the equations

provided in Fig. I-1e for bending about the X-X axis:

Point A (pure axial compression): the available compressive strength is calculated as illustrated in Design

Example I.9.

PA = As Fy + Asr Fysr + 0.85 Ac f'c

= 6.6 105 mm 2 450MPa + 3.216 105 mm2 500MPa + 8.455 106 mm2 ( 0.85 50MPa )

= 817207.653kN

M A = 0kNm

Point D (maximum nominal moment strength):

PD =

=

0.85 Ac f'c

=

2

8.455 106 mm 2 ( 0.85 50MPa )

2

=179679.054kN

The applied moment, illustrated in Fig. I -1e, is resisted by the flexural strength of the composite section about

its X-X axis. The strength of the section in pure flexure is calculated using the equations of Fig. I-1e found in

the front matter of the Chapter I Design Examples for Point B. Note that the calculation of the flexural strength

at Point B first requires calculation of the flexural strength at Point D as follows:

Z sr1x = 2 As1 d s1y = 2 6.534 104 mm 4 1400mm = 1.83 108 mm3

32.933mm ( 2900mm )

bs2 hs22

=2

= 1.385 108 mm3

;

4

4

2

Z sr2x = 2

Z srx = Z sr1x + Z sr1x = 1.83 108 mm3 + 1.385 108 mm3 = 3.21 108 mm3

Z sx = 4 Aa d sy = 4 1.65 105 mm 4 950mm = 6.27 108 mm3

h12 h2

Z sr1x Z sr2x Z sx

4

2

( 3072mm ) 3072mm

=

1.83 108 mm3 1.385 108 mm3 6.27 108 mm3 ;

4

= 6.299 109 mm3

Z cx =

where

Zsr1x full x-axis plastic modulus of As1 plate, mm3.

18

Zsr2x full x-axis plastic modulus of As2 plate, mm3.

Zsrx full x-axis plastic modulus of As1 and As2 plate, mm3.

Zsx full x-axis plastic modulus of steel shape, mm3.

Zcx full x-axis plastic modulus of concrete shape, mm3.

The bending moment of a composite cross-section is taken about the axis of symmetry. Therefore, the maximum

bending moment is obtained by placing the plastic neutral axis at the axis of symmetry of the composite crosssection. This conclusion can be obtained by examining the change in the bending moment of the composite

cross-section by making a small change in the position of the plastic neutral axis. The coefficient of in front

of the concrete part is a result on the assumption that concrete has no tensile strength and only the compressive

strength contributes to the bending moment capacity [Nethercot D.A., 2004].

1

M Dx = Z sx Fy + ( Z sr1x + Z sr2x ) Fysr + Z cx ( 0.85 f c' )

2

1

= 6.27 108 mm 3 450MPa + (1.83 108 mm 3 + 1.385 108 mm 3 ) 500MPa + 6.299 109 mm 3 ( 0.85 50MPa )

2

=5.767 105 kNm

Point B (pure flexure):

PB = 0kN

The stress distribution point C from Fig. I1e provides the same moment resistance as B, since the moment from

the stress resultants cancel each other. However, the resulting resistance to axial force is of the same magnitude

from the pure concrete part 0.85 f c' . This can be seen from adding up the stress distribution in B and C, with

regard to the equilibrium of forces, by example the resulting axial force. This follows because the resistance to

axial force in B is zero. Subtracting the stress distributions of B from that of C it results the value of hnx.

In order to determine the position of the neutral axis on X-X direction, the HD 400x1299 steel profile has been

considered as a rectangle bar (h x b*) with an equivalent area, as shown in Fig. I.X1-2a.

b*=

Aa 165000mm

=

= 275mm

;

h

600mm

where

h the height of the HD 400x1299 steel profile

19

Fig. I.X1-2a. Subtracting the components of the stress distribution combination at point B and C considering

normal force only, when the a.n.is between the profiles.

h

Assumption 1: the neutral axis is placed between the steel profiles hnx d sy :

2

PC PB = PC = 0.85 Ac f'c = 359358.109kN

= 2 hnx h1 ( 0.85 f'c ) + 2 hnx bs2 ( 2 Fyrs 0.85 f'c )

hnx =

=

PC

2 h1 ( 0.85 f'c ) + 2 bs2 ( 2 Fyrs 0.85 f'c )

359358.109kN

2 3072mm ( 0.85 50MPa ) + 2 32.933mm ( 2 500MPa 0.85 50MPa )

= 1.108m

h

Check assumption hnx d sy :

2

hnx = 1108mm d sy

h

= 650mm assumption not. k.

2

h

h

Assumption 2: the neutral axis is placed within the steel profiles d sy <hnx d sy + :

2

2

20

Fig. I.X1-2b. Subtracting the components of the stress distribution combination at point B and C considering

normal force only, when the a.n.is within the profiles.

PC PB = PC = 0.85 Ac f'c = 359358.109kN

= 2 hnx h1 ( 0.85 f'c ) + 4 hnx d sy b* ( 2 Fy 0.85 f'c ) + 2 hnx bs2 ( 2 Fyrs 0.85 f'c )

2

PC + 4 d sy b* ( 2 Fy 0.85 f'c )

2

hnx =

2 h1 ( 0.85 f'c ) + 4 b* ( 2 Fy 0.85 f'c ) + 2 bs 2 ( 2 Fyrs 0.85 f'c )

600mm

359358.109kN + 4 950mm

275mm ( 2 450MPa 0.85 f'c )

2

=

2 3072mm ( 0.85 50MPa ) + 4 275mm ( 2 450MPa 0.85 f'c ) + 2 32.933mm ( 2 500MPa 0.85 f'c )

= 767mm

h

h

Check assumption d sy <hnx d sy + :

2

2

d sy

h

h

= 650mm < hnx = 767mm < d sy + = 1250mm assumption o. k.

2

2

Z sr2xn = 2 bs2 hnx2

2

=2 32.933mm ( 767mm )

7

3

=3.878 10 mm

Z sxn = ( 2 d sx +b* ) h ( 2 d sx -b* ) h 2

2

nx

2

nx

b* ( 2 d sy h )

= ( 2 1012mm + 275mm ) ( 767mm ) ( 2 767mm - 275mm ) (1108mm ) 2

2

=9.141 10 7 mm 3

Z cxn = h1 hnx2 Z sr2xn Z sxn

=3072mm ( 767mm ) 3.878 10 7 mm 3 9.141 107 mm 3

2

=1.687 10 9 mm 3

275mm ( 2 950mm 600mm )

4

21

M Bx = M Dx Z r2xn Fyrs Z sxn Fy 1 Z cxn ( 0.85 f'c )

2

1

=576734.208kNm 3.878 107 mm3 500MPa 9.141 107 mm3 450MPa 1.687 109 mm3 ( 0.85 50MPa )

2

=480546kNm

where

Z cxn - x-axis plastic modulus of concrete section within the zone 2hn, mm3.

Z sxn - x-axis plastic modulus of equivalent rectangle bar within the zone 2hn, mm3.

Z sr2xn - x-axis plastic modulus of As2 plates within the zone 2hn, mm3.

Point C (intermediate point):

PC = 0.85 Ac f'c =

= 0.85 8.455 106 mm 2 50MPa

=359358.109kN

M Cx = M Bx = 480546kNm

The available compressive and flexural strengths are determined as follows:

LFRD

Design compressive strength:

ASD

Allowable compressive strength:

C = 0.75

C = 2.00

PX" = C PX

PX" =

where X = A,B,C or D

where X = A,B,C or D

P

PA" = A

PA" = C PA

= 0.75 817207.65kN = 612905.739kN

PB" = C PB

817207.65kN

=

= 408603.826kN

2

P

PB = B

= 0.75 0kN = 0kN

=

PC" = c PC

= 0.75 359358.109kN = 269518.582kN

PD" = c PD

= 0.75 179679.054kN = 134759.291kN

PX

PC" =

0kN

= 0kN

2

PC

359358.109kN

=

= 179679.055kN

2

P

PD" = D

179679.054kN

=

= 89839.53kN

2

22

Design flexural strength:

Allowable compressive strength:

B = 0.90

M X" = B M X

where X = A,B,C or D

b = 1.67

M

M X" = X

b

where X = A,B,C or D

M Ax" = B M Ax

M Ax" =

= 0.9 0kNm = 0kNm

M Bx" = B M Bx

= 0.9 480546kNm = 432491kNm

M Bx" =

M Ax

b

0kNm

= 0kNm

1.67

M Bx

480546kNm

=

= 287752kNm

1.67

M Cx" =

M Cx" = B M Cx

= 0.9 480546kNm = 432491kNm

M Dx" = B M Dx

= 0.90 576734.208kNm = 519060.787kNm

M Dx" =

M Cx

480546kNm

= 287752kNm

1.67

M Dx

576734.208kNm

=

= 345349.825kNm

1.67

The design and allowable strength values are plotted in Fig. I.X1-3.

Fig. I.X1 -3. Available and nominal interaction surfaces.

23

Method2 FEM Results

A numerical model using finite elements is considered with the purpose of comparison and validation of the

simplified method. The software package is FineLg, developed in collaboration between University of Lige

and Engineering office Greisch [FineLg Users Manual, V 9.2. 2011]. This numerical tool is continuously being

developed since the 70's and has been validated in a number of PhD theses and research reports. Specific

concrete beam elements have been developed by Ph. Boeraeve [Boeraeve P., 1991].

The chosen finite element is a 2D Bernoulli fiber element with 3 nodes and 7 degrees of freedom (DOF). The

total number of DOF corresponds to one rotational and two translational DOF for the nodes located at beam

element ends (nodes 1 and 3 in Fig. I.X1-4) and one relative longitudinal translational DOF for the node situated

at mid-length of the beam element (node 2 in Fig. I-X1-4). The relative translational DOF of the node at beam

mid-length has been proven necessary to take into account the strong variation of the centroid position along the

beam when the behaviour of the section is not symmetrical. Such a situation happens for instance in concrete

sections as soon as cracking occurs. The beam elements are able to simulate structures undergoing large

displacements but small deformations. They are developed following a co-rotational total description.

Fig. I.X1 -4. Strain Plane beam finite element with three nodes.

The model is built using an assembly of concrete (with appropriate reservations at the location of the steel

profiles) and steel fibre elements (see Fig. I.X1-6.b). In such fibre elements, only longitudinal strain and stresses

are explicitly modelled. The shear behaviour is supposed to remain elastic. Compatibility of longitudinal strains

is assumed at the interface between concrete and steel elements. This translates mathematically a perfectly rigid

longitudinal connection.

For both concrete and steel elements, internal forces in the elements are computed using a longitudinal and

transverse integration scheme. The integration along the beam length is performed using a classical Gauss

scheme with 4 integration points (see Fig. I.X1 -5.a). Nodal values are then extrapolated from this 4-point

scheme. At each longitudinal integration point (LIPi), a transverse integration is performed using a multilayer

scheme. The section is divided into a number of layers, in which the actual stress state is derived from the strain

state and assuming a uniaxial stress-strain relationship. In this case the cross-section is divided into 29 layers.

24

Fig. I.X1 -5. Integration scheme: a) longitudinal integration with 4-point Gauss scheme; b) transversal

integration with multilayer scheme

A parabola-rectangle constitutive law with tension stiffening is assumed for the concrete (EN 1992-1-1Eurocode 2, 2004), as shown in Fig. I.X1-6, and is analytically defined as follows:

c = f cc

ccu

c

2 ccu

c

c =

2 fc'

E

f ct = 0.3 f cc 3 = 4.072MPa .

where:

fcc = 50 MPa compressive strength of unconfined concrete (AISC I1.2b)

fct axial tensile strength of concrete;

ccu = 0.003 ultimate compressive strain of unconfined concrete (AISC I1.2b);

c strain at reaching maximum strength;

E = 38007MPa;

Fig. I.X1-6.Parabola-rectangle diagram for concrete in compression

An elastic perfectly plastic law is used to model the steel material (EN 1994-1-1-Eurocode 4 , 2004), as shown

in Fig. I.X1-7.

Fig. I.X1-7. Bi-linear steel material law.

where:

fy = 450MPA;

E = 200000MPa;

(AISC I1.3);

25

For both steel and concrete materials, the mechanical properties considered in the numerical simulations are the

nominal values. They should thus compare to the simplified AISC approach also considering nominal values of

the material properties. This comparison is done in Fig. I-XI-11.

The numerical M-N interaction curve is derived from the behaviour of a cantilever column with arbitrary length

l, as shown in Fig. I.X1-8. The column is chosen long enough to ensure that shear effects can be neglected but

not too long to avoid stability problems and second-order (i.e. buckling) effects.

Fig. I.X1-8. FineLg - numerical model.

Accounting for the symmetry of the cross-section, only half of the section is represented, as shown in Fig. I.X19. Results of the FEM analysis are then simply doubled for final post-processing and comparison. The total

height of the composite column is equal to l = 45m. The zone close to the support is the main zone of interest

and needs an accurate meshing. In total there are 17 nodes, 7 elements with a length of 6m, and 1 element

placed close to the support having 3 m. This shorter element allows a better localization of the plastic hinge.

26

Fig. I.X1-9. Meshing.

The column is initially loaded by a compressive axial force N. The compression force is kept constant while a

horizontal load is then increasingly applied until the bending resistance of the column is overcome (see Fig.

I.X1-10). The corresponding resisting moment in the plastic hinge is calculated by = H max l . The full curve

is then built by considering different values of the compression force N and by calculating the maximum

bending resistance M corresponding to each value of N.

Fig. I.X1-10. Example of pushover curves obtained with the numerical model for point C of the interaction

curve.

27

The following table summarizes the results obtained with the Simple method and the Finite Element model.

Point B

Point D

Point C

Point A

Nominal

LFRD

P

[kN] 0.75 P [kN]

0

0

179679

134759

359358

269518

817207

612905

P /2

ASD

[kN]

0

89839

179679

408603

Nominal

LFRD

ASD

Mx [kNm] 0.9 Mx [kNm] Mx/1.67 [kNm]

480546

432491

287752

576734

519060

345349

480546

432491

287752

0

0

0

FineLg

Mx

516060

604391

510177

0

Fig. I.X1-11. Comparison between the AISC - Plastic Distribution Method and the FEM method.

Conclusion

Design values of M-N interaction diagram have been obtained on the basis of a simple general methodology

proposed by AISC Specification and from which explicit expressions have been developed for the case of

composite sections with several encased steel profiles; these expressions have been presented in Figures I-1e

and I-1f.

The results of a study carried out with a more accurate FEM model confirm the validity of the results obtained

with the simple method in the case of composite sections with several encased steel profiles. Results obtained

with the simple AISC method using nominal values of the material properties and FEM results are compared on

Fig. I.XI-11. They are in excellent agreement for high compression level and the simple method is reasonably

accurate and safe-sided when bending becomes dominant. The simple method is thus felt sufficient to evaluate

design values of M-N interaction in the present context.

28

EXAMPLE I.X2 - COMPOSITE COLUMN WITH 4 STEEL PROFILES ENCASED IN COMBINED

AXIAL COMPRESSION AND FLEXURE OVER (Y-Y) AXIS.

Given:

Determine for the encased composite member illustrated in Fig. IX1-1 the axial force (P) bending moment

(M) diagram.

Fig. I.X2-1. Encased composite member section.

From ArcelorMittal classification, the steel material properties are:

ASTM A913- 11 Grade 65

Fy = 450MPa;

Fu = 550MPa;

29

From ArcelorMittal sections catalog, the geometric and material properties of one steel profile HD 400x1299

(W14x16x873) are:

Aa = 165000 mm2;

Avz = 505.2 cm2 ;

b = 476 mm;

h = 600 mm;

3

tw = 100 mm;

3

Zsx = 33250 cm ;

Zsy = 16670 cm ;

tf = 140 mm;

I HDx = 754600 10 mm I HDy = 254400 104 mm 4

4

From Fig. I.X1-1, additional geometric properties of the composite section used for force allocation and load

transfer are calculated as follows:

h1 = 3072mm;

h2 = 3072mm;

cx = 86mm -14mm = 72 mm;

cy = 86mm -16mm = 70 mm;

dx = 2500 mm;

dy = 2500mm;

dsx = 1012 mm;

dsy = 950mm;

ds1y = 1400 mm;

ds2x = 1450mm;

Ag = h1 h2 = (3072mm) (3072mm) = 9437184mm2 ;

db = 40mm for a T40 diameter bar;

Asri = 1256.637mm2 ;

n

Asr = Asri = 321699.09mm2 ;

i =1

4

As = Aa = 4 165000mm 2 = 660000mm 2

i =1

Ac = Ag Asr As = 9437184mm2 321699.09mm2 660000mm 2 = 8.455 106 mm2

Ec = ( 0.043 wc1.5 )

f c' = 38007MPa for wc = 2500

kg

m3 ;

Es = 200000 MPa (AISC I1.3);

Asr + As 321699.09mm2 + 660000mm2

=

= 0.104

94371.84mm2

Ag

Pn = As Fy + Asr Fysr + 0.85 Ac f'c

= 6.6 105 mm 2 450MPa + 3.216 105 mm2 500MPa + 8.455 106 mm2 ( 0.85 50MPa )

= 817207.653kN

As Fy

Pn

660000mm2 450MPa

= 0.363

817207.653kN

where

h1 height of the concrete section, mm.

h2 width of the concrete section, mm.

cx concrete cover, on x direction, mm.

cy concrete cover, on y direction, mm.

dx the distance between the two steel profiles HD 400x1299 (W14x16x873), on y - direction, mm.

dy the distance between the two steel profiles HD 400x1299 (W14x16x873), on x - direction, mm.

30

dsx the distance from the local centroid of the steel profile HD 400x1299 (W14x16x873) to the

section neutral axis, on x - direction, mm.

dsy the distance from the local centroid of the steel profile HD 400x1299 (W14x16x873) to the

section neutral axis, on y direction, mm.

ds2x the distance from the local centroid of As1 plate to the section neutral axis, on x - direction, mm.

ds1y the distance from the local centroid of As2 plate to the section neutral axis, on y - direction, mm.

Solution:

A simplification of the composite section is made by replacing the reinforcement by equivalent steel plates, as

shown in Fig. I.X2-1. Horizontal plates include only reinforcement that belongs to the two main lines. One

horizontal plate, As1, replace 52 reinforcement rebars.

nx = 52

As1 = 52T40 = 52 1256.64mm2 = 65364mm 2

For hs1 = 3072mm (86mm +

100

mm) = 2800mm

2

bs1 = 23.338 mm;

Side plates includes besides the two lateral lines, the few additional rebars. The number of reinforcement which

corresponds to one lateral plate is 76.

ny = 30 + 30 + 3 2 + 5 2 = 76

As2 = 76T40 = 76 1256.64mm 2 = 95532mm 2

For hs2 = 3072mm 2 86mm = 2900mm

bs2 = 32.933 mm;

The moment of inertia of the reinforcing bars about the elastic neutral axis of the composite section, Isr, is

determined for the two equivalent plates As1 and As2, and is calculated as follows:

I sr1y =

bs1 hs13 23.338mm ( 2800mm )

=

= 4.269 1010 mm 4

12

12

;

I sr2y =

hs2 bs23 2900mm ( 32.933mm )

=

= 8.632 106 mm 4

12

12

2

I sry = +2 I sr1y + 2 I sr2y + 2 As2 d s2x

= 2 4.269 1010 mm 4 + 2 8.632 106 mm 4 + 2 9.55 104 mm 2 (1450mm )

= 4.87 1011 mm 4

where

Isr1y moment of inertia about y axis of As1 plate, mm4.

Isr2y moment of inertia about y axis of As2 plate, mm4.

Isry moment of inertia about y axis of equivalent plates, mm4.

hs1 height of As1 plate, mm.

bs1 width of As1 plate, mm.

hs2 height of As2 plate, mm.

bs2 width of As2 plate, mm.

31

The moment of inertia values of the entire steel section about Y-Y axis is determined as:

I sy = 4 Aa d sx2 + 4 I HDy = 4 165000mm 2 (1012mm ) + 4 254400 104 mm 2 = 6.861 1011 mm 4

2

where

Isy moment of inertia about y axis of the steel profiles, mm.

The moment of inertia values for the concrete about both axes axis is determined as:

h2 h13 3072mm ( 3072mm )

=

= 7.421 1012 mm 4

12

12

3

Ig =

I cy = I g - I sry - I sy = 7.421 1012 mm4 4.87 1011 mm4 6.8611011 mm4 = 6.428 1012 mm4

where

Icy moment of inertia about y axis of the concrete part , mm4.

Material and Detailing Limitations

Material limits are provided in AISC Specification Sections I1.1 (2) and I1.3 as follows:

(1) Concrete strength:

f'c = 50MPa

21MPa f'c 70MPa

o. k.

(2) Specified yield stress of structural steel:

Fy = 450MPa

o. k.

(3) Specified yield stress of structural steel:

Fysr = 500MPa

Fy 525MPa

Fysr 525MPa

o. k.

Transverse reinforcement limitations are provided in AISC Specification Section I1.1 (3), I2.1a. (1), I2.1a. (2)

and ACI 318 as follows:

(1) Tie size and spacing limitations:

The AISC Specifications requires that either lateral ties or spirals be used for transverse reinforcement.

Where lateral ties are used, a minimum of either 10 mm (No. 3) bar placed at a maximum of 406 mm

(12 in.) on center, or a 13 mm (No. 4) bar or larger spaced at a maximum of 406 mm (16 in.) on center

shall be used.

14 mm lateral ties at 75 mm are provided.

o. k.

Note that AISC Specification Section I1.1 (1) specifically excludes the composite column provision of

ACI 318 Section 10.13, so it is unnecessary to meet the tie reinforcement provisions of ACI 318

Section 10.13.8. when designing composite columns using AISC Specifications Chapter I.

If spirals are used, the requirements of ACI 318 Sections 7.10 and 10.9.3 should be met according to

the User Note at the end of AISC Specification I2.1a.

(2) Additional tie size limitation:

ACI 318 Section 7.10.5.1 requires that all nonprestressed bars shall be enclosed by lateral ties, at least

10 mm (No. 3) in size for longitudinal bars 32 mm (No. 10) or smaller, and at least 13 mm (No. 4) in

size for 36 mm (No. 11), 43 mm (No. 14), 57 mm (No. 18), and bundled longitudinal bars.

32

14 mm lateral ties are provided for 40 mm longitudinal bars.

o. k.

(3) Maximum tie spacing should not exceed 0.5 times the least column dimension:

h = 3072mm

smax = 0.5 min 1

= 1536mm

h2 = 3072mm

s = 75mm smax = 1536mm

o. k.

(4) Concrete cover:

ACI 318 Section 7.7 contains concrete cover requirements. For concrete not exposed to weather or in

contact with ground, the required cover for column ties is 38 mm (1.5 in).

cover = 86mm 1T14 = 86mm 14mm = 72mm > 38mm

o. k.

(5) Provide ties as required for lateral support of longitudinal bars:

AISC Design Examples 2011 Part1, page I-96 indicates the following:

AISC Specification Commentary Section I2.1a references Chapter 7 of ACI 318 for additional

transverse tie requirements. In accordance with ACI 318 Section 7.10.5.3 and Fig. R7.10.5,

ties are required to support longitudinal bars located farther than 6 in. clear on each side from a

laterally supported bar. For corner bars, support is typically provided by the main perimeter

ties. For intermediate bars, Fig. I.9-1illustrates one method for providing support through the

use of a diamond-shaped tie.

Longitudinal and structural steel reinforcements limits are provided in AISC Specification Section I1.1 (4), I2.1

and ACI 318 as follows:

(1) Structural steel minimum reinforcement ratio: As / Ag 0.01

6.6 105 mm2

= 0.070mm

9.437 106 mm 2

o. k.

(2) Minimum longitudinal reinforcement ratio: Asr / Ag 0.004

3.216 105 mm2

= 0.034mm

9.437 106 mm 2

o. k.

(3) Maximum longitudinal reinforcement ratio: Asr / Ag 0.08

3.216 105 mm2

= 0.034mm

9.437 106 mm 2

o. k.

(4) Minimum number of longitudinal bars:

ACI 318 Section 10.9.2 requires a minimum of four longitudinal bars within rectangular or circular

members with ties and six bars for columns utilizing spiral ties. The intent for rectangular sections is to

provide a minimum of one bar in each corner, so irregular geometries with multiple corners require

additional longitudinal bars.

256 bars provided

o. k.

(5) Clear spacing between longitudinal bars:

ACI 318 Section 7.6.3 requires a clear distance between bars of 1.5db or 38 mm (1.5in.).

33

1.5 db = 60mm

smin = max

= 60mm

38mm

s = 100mm 40mm = 60 smin

o. k.

(6) Clear spacing between longitudinal bars and the steel core:

AISC Specification Section I2.1e requires a minimum clear spacing between the steel core and

longitudinal reinforcement of 1.5 reinforcing bar diameters, but not less than 38 mm (1.5 in.).

1.5 db = 60mm

smin = max

= 60mm

38mm

The distance from the steel core and the longitudinal bars is determined from Fig. I.X1-1, on x

direction as follows:

s = 524mm

b

60mm 2 40mm = 146mm smin

2

o. k.

The distance from the steel core and the longitudinal bars is determined from Fig. I.X2-1, on y

direction as follows:

s = 586mm

h

60mm 2 40mm = 100mm smin

2

o. k.

where

h height of HD 400x1299 (W14x16x873) steel profile, mm.

b width of HD 400x1299 (W14x16x873) steel profile, mm.

(7) Concrete cover for longitudinal reinforcement:

ACI 318 Section 7.7 provides concrete cover requirements for reinforcement. The cover requirements

for column ties and primary reinforcement are the same, and the tie cover was previously determined to

be acceptable, thus the longitudinal reinforcement cover is acceptable by inspection.

Interaction of Axial Force and Flexure

AISC Design Examples 2011 Part1, page I-104 indicates the following:

The interaction between axial forces and flexure in composite members is governed by AISC

Specification Section I5 which, for compact members permits the use of a strain compatibility method

or plastic stress distribution method, with the option to use the interaction equations of Section H1.1.

The strain compatibility method is a generalized approach that allows for the construction of an

interaction diagram based upon the same concepts used for reinforced concrete design. Application of

the strain compatibility method is required for irregular/nonsymmetrical sections.

Plastic stress distribution methods are discussed in AISC Specification Commentary Section I5 which

provides three acceptable procedures for filled members. Plastic stress distribution methods are

discussed in AISC Specification Commentary Section I5. The procedure involves the construction of a

piecewise-linear interaction curve using the plastic strength equations provided in Fig. I-1-1 located

within the front matter of the Chapter I Design Examples. The method is a reduction of the piecewise-

34

linear interaction curve that allows for the use of less conservative interaction equations than those

presented in Chapter H.

Thereafter are provided approaches following two methods: a plastic stress distribution method and a finite

element analysis.

Method1 - Interaction Curves from the Plastic Stress Distribution Model

Step 1: Construct nominal strength interaction surface A, B, C, and D without length effects, using the equations

provided in Fig. I-1f for bending about the Y-Y axis:

Point A (pure axial compression): the available compressive strength is calculated as illustrated in Design

Example I.9.

PA = As Fy + Asr Fysr + 0.85 Ac f'c

= 6.6 105 mm 2 450MPa + 3.216 105 mm2 500MPa + 8.455 106 mm2 ( 0.85 50MPa )

= 817207.653kN

M A = 0kNm

Point D (maximum nominal moment strength):

PD =

=

0.85 Ac f'c

=

2

8.455 106 mm 2 ( 0.85 50MPa )

2

=179679.054kN

The applied moment, illustrated in Fig. I-1f, is resisted by the flexural strength of the composite section about its

Y-Y axis. The strength of the section in pure flexure is calculated using the equations of Fig. I-1f found in the

front matter of the Chapter I Design Examples for Point B. Note that the calculation of the flexural strength at

Point B first requires calculation of the flexural strength at Point D as follows:

bs1 hs12 23.338mm ( 2800mm )

=

= 9.148 107 mm3

4

4

2

Z sr1y =

Z sr2y = 2 As2 d s2x = 2 9.55 10 4 mm 4 1450mm = 2.769 108 mm3 ;

Z sry = Z sr1y + Z sr1y = 9.148 107 mm3 + 2.769 108 mm3 = 3.684 108 mm3

Z sy = 4 Aa d sy = 2 1.65 105 mm 4 1012mm = 6.679 108 mm 3

h1 h

Z r1y Z r2y Z sy

4

2

3072mm ( 3072mm )

=

9.148 107 mm3 2.769 108 mm3 6.679 108 mm3

4

= 6.211 109 mm3

Z cy =

2

2

where

Zsr1y full y-axis plastic modulus of As1 plate, mm3.

35

Zsr2y full y-axis plastic modulus of As2 plate, mm3.

Zsy full y-axis plastic modulus of steel shape, mm3.

Zcy full y-axis plastic modulus of concrete shape, mm3.

The bending moment of a composite cross-section is taken about the axis of symmetry. Therefore, the maximum

bending moment is obtained by placing the plastic neutral axis at the axis of symmetry of the composite crosssection. This conclusion can be obtained by examining the change in the bending moment of the composite

cross-section by making a small change in the position of the plastic neutral axis. The coefficient of in front

of the concrete part is a result on the assumption that concrete has no tensile strength and only the compressive

strength contributes to the bending moment capacity.

1

M Dy = Z sy Fy + ( Z sr1y + Z sr2y ) Fysr + Z cy ( 0.85 f c' )

2

1

= 6.679 108 mm 3 450MPa + ( 9.148 107 mm 3 + 2.769 108 mm 3 ) 500MPa + 6.211 109 mm 3 ( 0.85 50MPa )

2

=6.168 105 kNm

Point B (pure flexure):

PB = 0kN

The stress distribution type C from Fig. I1f provides the same moment resistance as B, since the moment from

the stress resultants cancel each other. However, the resulting resistance to axial force is of the same magnitude

from the pure concrete part 0.85 f c' . This can be seen from adding up the stress distribution in B and C, with

regard to the equilibrium of forces, by example the resulting axial force. This follows because the resistance to

axial force in B is zero. Subtracting the stress distributions of B from that of C it results the value of hny.

In order to determine the position of the neutral axis, on Y-Y direction, the HD 400x1299 steel profile has been

considered as a rectangle bar (h* x b) with an equivalent area, as shown in Fig. I.X2-2a.

h*=

Aa 165000mm

=

= 346.639mm

;

b

476mm

where

b the width of the HD 400x1299 steel profile;

36

Fig. I.X2-2a. Subtracting the components of the stress distribution combination at point B and C considering

normal force only, when the a.n. is between the profiles.

PC PB = PC = 0.85 Ac f'c = 359358.109kN

= 2 hny h2 ( 0.85 f'c ) + 2 hny bs1 ( 2 Fyrs 0.85 f'c )

hny =

=

PC

2 h2 ( 0.85 f'c ) + 2 bs1 ( 2 Fyrs 0.85 f'c )

359358.109kN

2 3072mm ( 0.85 50MPa ) + 8 23.338mm ( 2 500MPa 0.85 50MPa )

= 1.175m

b

Check assumption hny d sx :

2

hny = 1175mm d sx

b

= 774mm

2

assumption not. k.

h

h

Assumption 2: the neutral axis is placed within the steel profiles d sy <hnx d sy + :

2

2

37

Fig. I.X2-2b. Subtracting the components of the stress distribution combination at point B and C considering

normal force only, when the a.n. is within the profiles.

PC PB = PC = 0.85 Ac f'c = 359358.109kN

= 2 hny h1 ( 0.85 f'c ) + As ( 2 Fy 0.85 f'c ) + 2 hny bs1 ( 2 Fyrs 0.85 f'c )

b

PC + 4 d sx h* ( 2 Fy 0.85 f'c )

2

hny =

2 h2 ( 0.85 f'c ) + 4 h* ( 2 Fy 0.85 f'c ) + 2 bs1 ( 2 Fyrs 0.85 f'c )

476mm

359358.109kN + 4 1012mm

346.639mm ( 2 450MPa 0.85 50MPa )

2

=

2 3072mm ( 0.85 50MPa ) + 4 346.639mm ( 2 450MPa 0.85 50MPa ) + 2 23.338mm ( 2 500MPa 0.85 50MPa )

= 856mm

h

h

Check assumption d sy <hnx d sy + :

2

2

d sx +

b

b

= 774mm < hny = 856mm d sx + = 1250mm assumption o. k.

2

2

Z sr1yn = 2 bs1 hny2

2

=2 23.338mm (856mm )

7

3

=3.421 10 mm

Z syn = ( 2 d sy +h* ) hny2 ( 2 d sy -h* ) hny2 2

h* ( 2 d sx b )

= ( 2 950mm + 346.639mm ) ( 856mm ) ( 2 950mm 346.639mm ) ( 856mm ) - 2

2

= 9.273 10 7 mm 3

Z cyn = h1 hny2 Z r1yn Z syn

=3072mm (1009mm ) 3.421 107 mm 3 9.273 107 mm 3

2

=2.124 109 mm 3

346.639mm ( 2 950mm - 476mm )

4

38

M By = M Dy Z r1yn Fyrs Z syn Fy 1 Z cyn ( 0.85 f'c )

2

1

=616779.059kNm 3.421 107 mm3 500MPa 9.273 107 mm3 450MPa 2.124 109 mm3 ( 0.85 50MPa )

2

=512804.327kNm

where

Z cyn - y-axis plastic modulus of concrete section within the zone 2hn,mm3.

Z syn - y-axis plastic modulus of equivalent rectangle bar within the zone 2hn,mm3.

Z sr1yn - y-axis plastic modulus of As1 plates within the zone 2hn,mm3.

Point C (intermediate point):

PC = 0.85 Ac f'c =

= 0.85 8.455 106 mm 2 50MPa

=359358.109kN

M Cy = M By = 512804.327kNm

The available compressive and flexural strengths are determined as follows:

LFRD

Design compressive strength:

ASD

Allowable compressive strength:

C = 0.75

C = 2.00

PX" = C PX

where X = A,B,C or D

PX

PX" =

where X = A,B,C or D

PA" = C PA

= 0.75 817207.65kN = 612905.739kN

PB" = C PB

= 0.75 0kN = 0kN

PA

PA" =

=

817207.65kN

= 408603.826kN

2

PB =

=

PC" = c PC

= 0.75 359358.109kN = 269518.582kN

PC" =

PB

c

0kN

= 0kN

2

PC

359358.109kN

=

= 179679.055kN

2

PD" = c PD

= 0.75 179679.054kN = 134759.291kN

PD" =

PD

179679.054kN

=

= 89839.53kN

2

39

Design flexural strength:

Allowable compressive strength:

B = 0.90

M X" = B M X

where X = A,B,C or D

b = 1.67

M

M X" = X

b

where X = A,B,C or D

M Ay" = B M Ay

M Ay" =

= 0.9 0kNm = 0kNm

M Ay

0kNm

=

= 0kNm

1.67

M By" = B M By

= 0.9 512804kNm = 461524kNm

M By" =

=

M Cy" = B M Cy

= 0.9 512804kNm = 461524kNm

M Cy" =

=

M Dy" = B M Dy

= 0.9 616779.059kNm = 555101.153kNm

M Dy" =

=

M By

b

512804kNm

= 307068kNm

1.67

M Cy

b

512804kNm

= 307068kNm

1.67

M Dy

b

616779.059kNm

= 369328.778kNm

1.67

The design and allowable strength values are plotted in Fig. IX2-3.

Fig. I.X2-3. ASD and LFRD interaction surfaces.

40

Method2 FEM Results

Table of results obtained with Simple method and Finite Element model.

Point B

Point D

Point C

Point A

Nominal

LFRD

P

[kN] 0.75 P [kN]

0

0

179679

134759

359358

269518

817207

612905

P /2

ASD

[kN]

0

89839

179679

408603

Nominal

LFRD

My [kNm] 0.9 My [kNm] My/1.67

512804

461524

616780

555102

512804

461524

0

0

ASD

[kNm]

307068

369329

307068

0

FineLg

My

528385

622210

524608

0

Fig. I.X2-4. Comparison between the Plastic Distribution Method and the FEM method.

Conclusion

Design values of M-N interaction diagram have been obtained on the basis of a simple method presented in

AISC Specification and for which explicit expressions have been developed for the case of composite sections

with several encased steel profiles; these expressions are presented in Figures I-1e and I-1f.

The results of the finite element study made with more refined models confirm the validity of the results

obtained by that the simple method in the case of composite sections with several encased steel profiles

(compare nominal and FinelG in Table above).

The simple method can be kept to evaluate design values of M-N interaction for that case.

41

EXAMPLE I.X3 COMPOSITE COLUMN WITH 4 ENCASED STEEL PROFILES IN SHEAR

DIRECTION Y.

Given:

Determine if the composite member with 4 encased steel profiles illustrated in Figure I.X4-1 is adequate for the

axial forces, shears and moments given hereunder, that have been determined in accordance with the direct

analysis method of AISC 2010 Specification Chapter C for the control of ASCE(2010)ASCE/SEI 7-10 load

combinations:

Factored bending moment:

Mu,X = 450000 kNm

Factored axial (compression) force:

Nu = 180000 kN

Factored transverse shear Vu,Y in direction Y:

Vu,Y= 20000 kN

The characteristics of the steel profile are:

h = 600 mm

b= 476 mm

2

A = 165000 mm

tf = 140 mm

4

Iy = 754600. 10 mm

tw = 100 mm

4

Iz = 254400.10 mm

Solution:

Fig. I.X3-1. Definition of notations.

Available Shear Strength

According to AISC Specification Section I4.1, there are three acceptable options for determining the available

shear strength of an encased composite member:

42

Option 1- Available shear strength of the steel section alone in accordance with AISC Specification Chapter G.

Option 2- Available shear strength of the reinforced concrete portion alone per ACI 318.

Option 3- Available shear strength of the steel section in addition to the reinforcing steel ignoring the

contribution of the concrete.

Option 1 clearly is a gross underestimation for the section with 4 encased steel profiles, because it would consist

in disregarding the contribution to shear resistance of a net area Ac of concrete equal to Ac = 8,45 m2. Option 1 is

not developed.

Option 2 is envisaged hereunder. Its application however requires one adaptation for composite sections with

several encased steel profiles, in comparison to, for instance, the procedure presented in Design Example I.11.

The principle of the adaptation is explained hereunder. It requires separate calculation of shear strength of subsections composing the complete section. This is presented in detail.

Option 3 will not be used because it would be unsafe for composite sections with several encased steel profiles.

This is explained below.

Principle of the adaptation of Option 2 to sections with several encased steel profiles.

The problem to solve in sections with several encased profiles is that concrete and steel components

contributing to shear resistance are not working in parallel, like in the case of one central steel profile encased in

concrete: they are, for some part, working in series or chain. This is easier to understand if one subdivides the

column section into 5 smaller sections, each providing resistance to shear. They are respectively the sections of

width bc3 (2 sections), bs (2 sections) and bc4 (1 section), all with height hz .

They are named section bc3, section bc4 and section bs in the following.

The applied shear force Vu,Y will distribute itself into Vu,bc3 , Vu,bc4 and Vu,bs between sections bc3, bc4 and bs,

proportionally to the stiffness of those sections.

Then each section should provide strength greater than the applied shear force in that section.

Sections bc3 and bc4 are regular reinforced concrete sections and can be treated as such.

But section bs is a composite steel-concrete section having 2 reinforced concrete flanges, 2 inner steel profiles

(the HD sections) and 1 reinforced concrete web. Section bs is a chain of components in concrete and steel; its

strength should be calculated on the basis of the weakest link, which is concrete. This is why the check for

transverse shear is made on one section bs homogenized in concrete. All components of that section are taken

into account. This is valid because the steel profile has more strength than its equivalent concrete section, as

shown by the following comparison of pure shear resistance:

-

for the steel profile: Vn = 0.6FyAwCv

For webs of rolled I-shaped members with

(Spec. Eq G2-1)

43

h/tw 2, 24

E

=> v = 1.00 and Cv = 1.0

Fy

The HD section height and web thickness are: h = 600 mm

h/tw = 6 2, 24

(Spec. Eq G2-2)

tw=100 mm

E

= 47,2

Fy

Aw = 100 x (600- 2 x 140) =32000 mm2

Vn HD = 0.6FyAwCv = 0,60x 450 x 32000 x 1 = 8640 kN

vVn = 8640 > Vu,t,S2= 2134 kN

where Vu,t,S2 is the transverse shear in the steel profile as calculated in the section Resistance to

transverse shear of the HD profile.

-

For a concrete section with same height and width of concrete equivalent to the steel profile, the shear

strength in case of pure shear applied to a section without transverse reinforcement is:

Vc = 2 fc bw d

ACI318-08 (11-3)

=1,0 for normal weight concrete

In international units (N, mm), ACI318-08 (11-3) expression becomes:

Vc =0,1693 fc bw d =1,1971 bw d

for fc=50MPa

A similar expression is defined, which takes into account longitudinal reinforcement with an upper

bound value:

Vc = 3,5 fc bw d

ACI318-08 (11-5)

In international units (N, mm), it becomes:

Vc = 0,2963 fc bw d = 2,095 bw d

for fc=50MPa

bw = 100 x 200000/38004 =526 mm

d = h1 = 600 mm

Vc = 2,095 bw d= 661 kN

Vc =0,75 x 661,1 = 496 kN

It results: vVn,HD = 0.6FyAwCv = 8640 kN > Vc = 496 kN

And it can be concluded that it is justified to make concrete only checks for shear resistance: the concrete part

of the section bs is weaker and would fail first. The extra strength of the steel profiles above concrete strength

has no use, as it would only intervene after crushing the concrete web.

[Note: the expression found in the provisory version of Eurocode 2 or ENV1992 indicated a value for the shear

resistance VRd very similar to Vc = 2,095 bw d :

VRd1 = Rd bw dk (1, 2 + 40 l ) =0,48 x(1,2 +40 x 0,104) bwd = 2,57 bwd

with l = 0,104 for the section defined

in this example].

Why Option 3 cannot be applied to sections with several encased steel profiles.

In option 3, the available shear strength would be found as the addition of the available shear strength of the

steel sections in addition to the available shear strength of the reinforcing steel, ignoring the contribution of the

concrete. In fact, this way to present things does not express clearly what is meant. The idea is that, due to

44

cracking, the contribution to shear resistance of concrete without transverse reinforcement Vc is equal to 0. In

such case, the shear resistance of reinforced concrete in shear can exist, due to transverse reinforcement and

equilibrium between inclined compression struts of concrete and tension in steel ties, the stirrups. In such

case, the available shear strength indicated in ACI318-08 is Vs , meaning that the total shear strength is only Vs

instead of being (Vc + Vs).

But Vs is limited to an upper bound value corresponding to crushing of concrete compression struts in the strut

and ties equilibrium recalled above. That limit is:

Vs = 8 fc bw d

ACI318-08 (11.4.7.9)

That expression expressed in international units, with the data of the section under consideration, becomes:

Vs = 0,676fc bw d = 4,78 bw d

for fc = 50MPa

[Note: it is remarkable that in option 3, the available shear strength is said to be the addition of the available

shear strength of the steel section to the available shear strength of the reinforcing steel, but the available shear

strength of the reinforcing steel is in fact a concrete strength].

However, in a section with several steel profiles, the applied shear force Vu,Y will distribute itself into Vu,bc3 ,

Vu,bc4 and Vu,bs between sections bc3, bc4 and bs, proportionally to the stiffness of those sections. Section bs

being made of components working in series or chain, the strength of the chain should be calculated on the

basis of its weakest link, which is concrete. So Option 3 has to be applied in the same way as Option 2 and

adding the shear strength of the steel profiles to a shear strength of the reinforcement would lead to an unsafe

design.

Distribution of transverse shear in the composite section.

The symbols are defined at Figure I.X3-2.

The width bc3, bs and bc4 are:

bc3 = 286mm

bs = 476 mm

bc4 = 3072 2 x (286+476) = 1548 mm

45

Fig. I.X3-2. Definition of sections bc3, bc4, and bs.

Fig. I.X3-3. Position of the reinforcement and the HD profiles.

The applied shear force Vu,Y is distributed between sections bc3, bc4 and bs proportionally to their stiffness:

Vu,bc3 = Vu,Y x (EIeff)bc3/EIeff

Vu,bc4 = Vu,Y x (EIeff)bc4/EIeff

Vu,bs = Vu,Y x (EIeff)bs/EIeff

The effective bending stiffness EIeff of the column is:

EIeff = Es Is + 0.5Esr Isr + C1Ec Ic

(Spec. Eq.I2-6)

C1= 0.1+ 2 [(As/(Ac+As)] 0,3

(Spec. Eq.I2-7)