Professional Documents

Culture Documents

DIN Material Equivalent PDF

Uploaded by

MuralitclOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN Material Equivalent PDF

Uploaded by

MuralitclCopyright:

Available Formats

7.

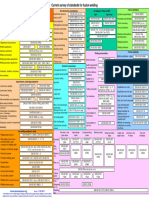

1 | Material data sheets

7.1 | Material data sheets

Designations, available types, temperature limits

Strength values at room temperature (RT)

(guaranteed values 1))

Material

group

Unalloyed

steel

Material no. Short name

to

to

DIN EN 10 027 DIN EN 10 027

1.0254

1.0255

P235TR1

P235TR2

Short name

to

DIN

(old)

Semi-finished

product

Documentation

St 37.0

Welded tube

Seamless tube

St 37.4

Documentation old

Upper

temp.

limit C

DIN EN 10217-1

DIN 1626

300

DIN EN 10216-1

DIN 1629

Welded tube

DIN EN 10217-1

Seamless tube

DIN EN 10216-1

Material no.

to

DIN EN 10 027

Yield point

min. ReH

N/mm2

Tensile strength

Rm

N/mm2

1.0254

235

360-500

23

1.0255

235

360-500

23

Breaking elongation, min.

A5

%

A80

%

at 0 C: 27

1.0427

C22G1

C 22.3

Flanges

VdTV-W 364

350

1.0427

240

410-540

20 (transverse)

S235JRG2

RSt 37-2

Steel bar, flat

DIN EN 10025

300

1.0038

235

340-470

21-26 1)

17-21 3)

1.0050

E295

St 50-2

products, wire rod,

1.0050

295

470-610

16-20 1)

12-16 3)

1.0570

S355J2G3

St 52-3

profiles

AD W1

1.0570

355

490-630

18-22 1)

14-18 3)

Heat

resistant

unalloyed

steel

1.0460

C22G2

C 22.8

Flanges

VdTV W 350

450

1.0460

240

410-540

Heat

resistant

steel

1.0345

P235GH

HI

480

1.0345

235

235

Sheet

DIN EN 10028

Seamless tube

DIN EN 10216

DIN 17155

450

s 16

at RT: 31

s 70

at RT: 27

3 s 100 (Rm)

10 s 150 (KV)

at -20 C: 27

s < 16 (ReH)

20

at RT: 31

s 70

360-480

25

at 0 C: 27

s 16

360-500

23

at 0 C: 27

s 16

1.0425

P265GH

HII

Sheet

DIN EN 10028

DIN 17155

480

1.0425

265

410-530

23

at 0 C: 27

s 16

1.0481

P295GH

17 Mn 4

Sheet

DIN EN 10028

DIN 17155

500

1.0481

295

460-580

22

at 0 C: 27

s 16

Seamless tube

DIN 17175

440-590

24

at RT: 31

s 16

440-600

20

at RT: 31

s 16

480-630

18

at RT: 31

s 16

1.5415

1.7335

1.7380

1.0305

16Mo3

13CrMo4-5

10CrMo9-10

P235G1TH

15 Mo 3

13 CrMo 4 4

Sheet

DIN EN 10028

Seamless tube

DIN 17175

Sheet

DIN EN 10028

Seamless tube

DIN 17175

Sheet

DIN EN 10028

Seamless tube

DIN 17175

St 35.8

Seamless tube

DIN 17175

DIN EN 10028

10 CrMo 9 10

270

DIN 17155

530

1.5415

DIN 17155

570

1.7335

300

290

DIN 17155

600

1.7380

310

280

480

1.0305

235

360-480

23

at RT: 34

s 16

1.0562

355

490-630

22

at 0 C: 47

s 16

at 0 C: 47

s 16

1.0566

at 0 C: 55

s 16

1.1106

at 0 C: 90

s 16

1.0562

P355N

StE 355

Sheet

heat resist.

1.0565

P355NH

WStE 355

Strip

400

1.0565

cold resist.

1.0566

P355NL1

TStE 355

Steel bar

(-50) 1)

special

1.1106

P355NL2

EStE 355

(-60) 1)

1) Cold resistant limit

275

270

Fine-grained

structural

steel

Standard

174

Remarks

s 16

1.0038

Common

structural

steel

Notched bar

impact strength

min. AV (KV 2))

J

DIN 17102

1) Smallest value of longitudinal or transverse test

2) New designation to DIN EN 10045; average of 3 specimens in DIN EN standards

3) Dependent on product thickness

175

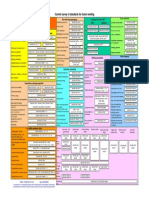

7.1 | Material data sheets

7.1 | Material data sheets

Designations, available types, temperature limits

Strength values at room temperature (RT)

(guaranteed values 3))

Material

group

Stainless

ferritic steel

Material no.

to

DIN EN 10 027

Short name

to

DIN EN 10 027

1.4511

X3CrNb17

1.4512

X2CrTi12

Semi-finished product Documentation Documentation

old

Strip

Strip

DIN EN 10088

DIN 17441 2)

Upper

temp.

limit C

Yield points min. Tensile strength

Breaking

elongation, min.

Rp1,0

Rp0,2

> 3 mm

< 3 mm

Rm

N/mm2 N/mm2

Thickness A5 Thickness A80

N/mm2

%

%

Material no.

to

DIN EN 10 027

Notched bar

impact strength

> 10 mm thickness,

transverse min. KV in J

Remarks

1.4511

230

420-600

23

s6

350

1.4512

210

380-560

25

s6

550 / 300 1)

1.4301

200

VdTV-W422

nach VdTV

DIN EN 10088

SEW 400

Stainless

austenitic

steel

1.4301

X5CrNi18-10

Strip

DIN EN 10088

1.4306

X2CrNi19-11

Strip

DIN EN 10088

X6CrNiTi18-10

Strip

DIN EN 10088

X6CrNiMoTi17-12-2

Strip

DIN EN 10088

X2CrNiMo17-12-2

Strip

DIN EN 10088

X2CrNiMo18-14-3

Strip

DIN EN 10088

1.4565

X2CrNiMnMoNbN25-18-5-4

Strip, Strip Sheet

SEW 400 / 97

1.4539

X1NiCrMoCu25-20-5

Strip Sheet, Strip

DIN EN 10088

X1NiCrMoCuN25-20-7

550 / 400 1)

1.4541

DIN 17441/97

550 / 400 1)

1.4571

DIN 17441/97

550 / 400 1)

1.4404

DIN 17441/97

550 / 400 1)

1.4435

DIN 17440/96

Strip Sheet

1.4529

DIN 17441/97

DIN 17440/96

Strip Sheet

1.4435

1.4306

DIN 17440/96

Strip Sheet

1.4404

550 / 350 1)

DIN 17440/96

Strip Sheet

1.4571

DIN 17441/97

DIN 17440/96

Strip Sheet

1.4541

DIN 17441/97

DIN 17440/96

Strip Sheet

SEW 400 / 91

230

260

215

245

220

250

205

235

220

250

205

235

240

270

225

255

240

270

225

255

240

270

225

255

1.4919

X6CrNi18-10

X6CrNiMo17-13

520-720

540-690

530-680

550-700

45

43

40

45

45

43

40

40

40

38

35

40

40

38

35

40

40

38

35

40

40

38

35

at RT: 60

s6

at RT: 60

s6

at RT: 60

s6

at RT: 60

s6

at RT: 60

s6

at RT: 60

s6

550 / 400 1)

1.4565

420

460

800-1000

30

25

at RT: 55

s 30

1.4539

240

270

530-730

35

35

at RT: 60

s6

225

255

33

30

220

250

520-720

40

40

300

340

650-850

40

40

285

325

38

35

300

340

600-800

40

40

at RT: 84

230

260

530-740

45

45

at RT: 60

s6

195

230

490-690

35

at RT: 60

s 250

185

225

500-700

30

205

245

490-690

35

Seamless tube

VdTV-W421

400

Strip Sheet, Strip

DIN EN 10088

400

1.4529

VdTV-W 502

1.4948

520-670

45

550 / 400 1)

Seamless tube

Austenitic

steel of

high heat

resistance

540-750

Strip Sheet

DIN EN 10028-7

DIN 17460

600

strip Forgin

DIN EN 10222-5

DIN 17460

600

Seamless tube

DIN 17459

600

Sheet, strip, bar

DIN 17460

600

Seamless tube

DIN 17459

600

Sheet, strip, bar

DIN 17460

600

DIN 17459

600

1.4948

q

1.4919

at RT: 60

s 75

at RT: 60

30

at RT: 60

Forging

1.4958

X5NiCrAlTi31-20

1.4958

205

245

490-690

30

170

200

500-750

35

170

200

500-750

35

at RT: 60

30

at RT: 80

Forging

Seamless tube

1) Temperature limit where risk of intercrystalline corrosion

2) Earlier standard DIN 17441 7/85

176

at RT: 80

s 50

3) Smallest value of longitudinal or transverse test, q = tensile test, transverse, l = tensile test, longitudinal

177

7.1 | Material data sheets

7.1 | Material data sheets

Designations, available types, temperature limits

Strength values at room temperature (RT)

(guaranteed values 3))

Material

group

Material no.

to

DIN EN 10 027 1)

Short name

to

DIN EN 10 027

Heat

resistant

steel

1.4828

X15CrNiSi20-12

Trade name

Semi-finished product

Documentation

Upper

temp.

limit C

Strip Sheet, Strip,

DIN EN 10095

900

Yield points min. Tensile strength Breaking

Material no.

elongation, min.

Rp1,0

Rp0,2

A80

A5

Rm

to

%

%

N/mm2

DIN EN 10 027 1) N/mm2 N/mm2

1.4828

230

270

Notched bar

impact strength

min. KV

J

1.4876

X10NiCrAlTi32-21

2.4858

NICr21Mo

INCOLOY 800

INCOLOY 800 H

INCOLOY 825

Strip Sheet, Strip

SEW470

all

VdTV-W412

Strip Sheet, Strip

VdTV-W434

all

DIN EN 10095

all

DIN 17750/02

Strip Sheet, Strip

VdTV-W432

Remarks

s 3 mm

500-750

solution annealed

(SEW470)

X10NiCrAlTi32-21 H

Nickelbased

alloys

1.4876

170

210

450-680

22

INCOLOY 800

210

240

500-750

30

(1.4876 H)

170

200

450 -700

30

INCOLOY 800H

170

210

450-680

2.4858

240

270

550

INCOLOY 825

235

265

550-750

600

950

900

450

1000

2.4816

240

Soft annealed

at RT: 150 4)

solution annealed (AT)

28

Soft annealed

30

at RT: 80

s 30 mm

DIN 17744 2)

2.4816

NiCR15Fe

INCONEL 600

DIN EN 10095

Strip Sheet, Strip

INCONEL 600 H

DIN 17750/02

VdTV-W305

450

DIN 17742 2)

2.4819

NiMo16Cr15W

HASTELLOY C-276

Strip Sheet, Strip

DIN 17750/02

VdTV-W400

450

Annealed (+A)

500-850

180

210

550

INCONEL 600

200

230

550-750

30

INCONEL 600 H

180

210

500-700

35

2.4819

310

330

690

30

HASTELLOY C-276

310

330

730-1000

30

NiCr22Mo9Nb

INCONEL 625

Flat products

DIN EN 10095

Strip Sheet, Strip

DIN 17750/02

INCONEL 625 H

at RT: 150 4)

Soft annealed

30

at RT: 150 4)

solution annealed

30

at RT: 96

s 5 mm, solution annealed (F69)

30

DIN 17744 2)

2.4856

solution annealed (F50)

28

900

450

(VdTV-W499)

s 3 mm, Annealed (+A)

2.4856

415

INCONEL 625 H

275

305

690

INCONEL 625

400

440

830-1000

30

2.4610

305

340

690

40

HASTELLOY-C4

280

315

700-900

40

820-1050

at RT: 100

solution annealed (F69)

s 3 mm; Soft annealed

DIN 17744 2)

2.4610

NiMo16Cr16Ti

HASTELLOY-C4

Strip Sheet, Strip

DIN 17750/02

Strip Sheet, Strip

VdTV-W424

400

NiCu30Fe

MONEL

Strip, Strip Sheet

DIN 17750/02

VdTV-W 263

at RT: 96

s 5, solution annealed

at RT: 96

5 < s 30

30

DIN 17744 2)

2.4360

30

425

2.4360

175

MONEL

175

205

450

30

450-600

30

s 50, Soft annealed

at RT: 120

Soft annealed

Seamless tube

Forging

1) In the case of nickel-based alloys, DIN 17007 governs the material number

2) Chemical composition

178

DIN 17743 2)

3) Smallest value of longitudinal or transverse test

4) Value ak in J/cm2

179

7.1 | Material data sheets

7.1 | Material data sheets

Designations, available types, temperature limits

Strength values at room temperature (RT)

(guaranteed values 2))

Material

group

Material designation

DIN EN 1652 (new)

DIN 17670 (old

Number Short name Number Short name

Copper CW354H

based alloy

CuNi30Mn1Fe 2.0882 CuNi30Mn1Fe

Copper

Cu-DHP

CUNIFER 30 1) Strip Sheet

2.0090

CW452K

CuSn6

2.1020

Copper-zinc

alloy

CW503L

DIN 17664

AD-W 6/2

DIN 17670

CW508L

CuZn20

2.0250

120

350-420

CuZn37

CW024A

100

200-250

42 6)

R200 (F20) 4) s > 5 mm

2.0090

140

220-260

33 7) / 42 6)

R220 (F22) 4) 0.2 s 5 mm

CuSn6

Strip,

DIN-EN 1652

DIN 17662

CW452K

300

350-420

45 7)

R350 (F35) 4) 0.1 s 5 mm

Bronze

Strip Sheet

DIN 17670

2.1020

DIN 17660

CW503L

DIN 17670

2.0250

DIN 17660

CW508L

DIN 17670

2.0321

CuZn 20

CuZn 37

Strip,

Brass

Strip Sheet

2.0402 CuZn40Pb2

DIN EN 485-2 (new)

Number

Strip,

DIN-EN 1652

Strip Sheet

2.0321

DIN-EN 1652

Strip,

DIN 17670

Strip Sheet

DIN 17660

DIN 1745-1 (old)

Semi-

Short Name Number Short Name

finished

EN AW-6082 EN AW-AlSi1MgMn 3.2315

AlMg 3

3.7025

LC-Ni 99

Ti 1

AlMgSi 1

LC-Ni 99

Ti 1

Ta

2.0402

Documentation Documenta-

Upper

tion

temp.

old

limit C

Material no.

55 6)

150

270-320

180

300-370

DIN 1745

EN AW-5754

Strip Sheet

DIN EN 575-3

DIN 1725

3.3535

300

380

(F38) 5) 0.3 s 5 mm

35

Yield points min. Tensile strength Breaking elongation, min.

Rp1,0

80

Rm

A5

N/mm2

190-240

14 (A50)

0.5 < s 1.5 mm

State: O / H111

85

150

0.4 s 1.5 mm

14 (A50)

DIN-EN 485-2

DIN 1745

EN AW-6082

DIN-EN 573-3

DIN 1725

3.2315

Strip, Strip

VdTV-W 345

600

2.4068

80

105

340-540

40

Sheet

DIN 17 850

250

3.7025

180

200

290-410

30 / 24 8)

Strip,

DIN 17 860

Strip Sheet

VdTV-W 230

250

TANTAL - ES

140

225

35 3)

State: O ; DIN EN values

62

0.4 < s 8 mm

0.1 s 5.0

Electron beam melted Sintered

Strip,

in vacuum

Strip Sheet

TANTAL - GS

180

Remarks

DIN EN-values

Strip,

VdTV-W382

KNotched bar

impact strengthmin. KV

J

150 (AD-W)

Strip Sheet

Ta

R300 (F30) 4) 0.2 s 5 mm

38 7)

48 6)

N/mm2 N/mm2

DIN EN 485-2

R270 (F27) 4) 0.2 s 5 mm

38 7)

48 6)

Rp0,2

Strip,

AD-W 6/1

2.4068

250

DIN 1787

product

1) Trade name

R350 (F35) 4) 0.3 s 15

35 6)

2.0882

DIN 17670

CW354H

Remarks

AD-W 6/2

Wrought

EN AW-5754 EN AW-Al Mg3 3.3535

aluminium

alloy

Tantalum

Yield points min. Tensile strength Breaking elongation, min. Notched bar

Rp1,0

Rp0,2

Rm

A5

impact strength

N/mm2 N/mm2

N/mm2

%

min. KV

J

DIN-EN 1652

Pure nickel

Titanium

350

Material no.

Strip,

DIN-EN 1652

Upper

temp.

limit C

Strip Sheet

SF-Cu

Strip,

Documentation Documentation

old

CW024A

Copper-tin

alloy

Semifinished

product

200

280

2) Smallest value of longitudinal or transverse test

3) Measured length lo = 25 mm

4) State designation to DIN EN 1652 or (--) to DIN

5) To DIN, material not contained in the DIN EN

30 3)

6) Specification in DIN EN for s > 2.5 mm

7) Breaking elongation A50, specification in

DIN EN for s 2.5 mm

8) A50 for thicknesses 5 mm

181

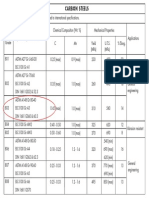

7.1 | Material data sheets

7.1 | Material data sheets

Chemical composition

(percentage by mass)

Chemical composition

Material

group

Material Short name

no.

(percentage by mass)

C1)

Si

max.

Mn

P

max.

S

max.

0.16

0.35

1.20

0.025

0.020

Cr

Mo

Ni

Other elements

Material

group

Material Short name

no.

C

max.

Si

max.

Mn

P

max.

S

max.

Cr

Mo

Ni

0.20

0.50

0.90 -

0.030

0.025

0.3

0.8

0.5

Other elements

Unalloyed

steel

1.0254

P235TR1

0.30 0.08

Cu 0.30

0.30

Cr+Cu+Mo+Ni 0.70

1.0255

P235TR2

0.16

0.35

1.20

0.025

0.020

0.30 0.08

0.30

Cu 0.30

Finegrained

structural

steel

1.0562

P355N

1.70

1.0565

P355NH

0.20

0.50

Cr+Cu+Mo+Ni 0.70

C22G1

0.18 - 0.15 0.23

Common

structural

steel

1.0038

Heat resist.

unalloyed

steel

Heat

resistant

steel

S235JRG2

0.35

0.17

0.40 -

0.035

0.030

0.30

0.045

0.045

0.045

0.045

N 0.009

0.035

0.035

Alges 0.015

C22G2

0.18 - 0.15 -

0.40 -

0.035

0.030

0.30

0.23

0.35

0.90

P235GH

0.16

0.35

0.40 -

0.030

0.025

0.30 0.08

S355J2G3

1.0460

1.0345

0.20

0.025

0.3

0.8

0.5

0.18

0.50

0.90 -

0.030

0.020

0.3

0.8

0.5

1.1106

P355NL2

0.18

0.50

0.90 -

0.025

0.015

0.3

0.8

0.5

0.040

0.015

16.0 -

Cu, N, Nb, Ti, V

1.70

Stainless

ferritic

steel

1.4511

X3CrNb17

0.05

1.00

1.00

Nb,Ti,V

1.0425

P265GH

0.20

0.40

0.50

0.030

0.025

0.30 0.08

0.30

1.0481

P295GH

0.08 -

0.40

0.90 -

0.030

0.025

0.30 0.08

0.30 Cr+Cu+Mo+Ni 0.70

16Mo3

0.12 -

X2CrTi12

0.03

1.00

1.00

0.040

0.015

10.5 -

Alges 0.020

Stainless

austenitic

steel

1.4301

X5CrNi18-10

0.07

1.00

2.00

0.045

0.015

17.0 -

0.35

1.7335

13CrMo4-5 0.08 10 CrMo9-10 0.08 -

0.35

P235G1TH

0.17

0.025

0.30

0.40 -

0.50

0.40 -

0.030

0.025

0.030

0.025

0.80

0.10 -

0.40 -

0.35

0.80

0.30

0.25 -

Cu 0.3

0.040

0.70 -

0.40 -

1.15

0.60

0.03

1.00

2.00

0.045

0.015

18.0 20.0

12.0

1.4541

X6CrNiTi18-10

0.08

1.00

2.00

0.045

0.015

17.0 -

9.0 -

19.0

12.0

1.4571

2.00 -

0.90 -

2.50

1.10

1.4404

0.08

1.00

Cu 0.3

1.4435

0.045

0.015

X2CrNiMo

0.03

1.00

2.00

0.045

0.015

X2CrNiMo

0.03

1.00

2.00

0.045

0.015

18 14 3

1.4565

X2CrNiMuMo

0.04

1.00

1.4539

X1NiCrMoCu

4.50 -

0.030

0.015

6.50

NbN2518-5-4

2.00

17 12 2

0.040

1) Carbon content dependent on thickness. Values are for a thickness of 16mm.

X6CrNiMoTi

17 12 2

Cu 0.3

0.02

0.70

2.00

0.030

0.010

25-20-5

1.4529

X2NiCrMoCuN

25-20-7

182

10.50

10.0 -

X2CrNi19-11

0.35

1.00

0.14

1.0305

0.030

0.90

0.18

1.7380

0.40 -

8.00 -

19.5

1.4306

1.50

0.20

-1,00

Ti: 6 x (C+N) - 0.65

1.4512

Cu 0.30

1.5415

Nb: 12 x % C

18.0

12.5

0.30

1.20

0.20

Nb + Ti + V 0.12

1.70

1.60

E295

1.0570

P355NL1

N 0.009

0.55

1.0050

1.0566

Alges 0.015

0.90

1.40

0.030

1.70

Alges 0.02

1.0427

0.90 -

Alges 0.020

(s. DIN EN 10028-3)

0.02

0.50

1.00

0.030

0.010

Ti: 5 x % C - 0.7

Ti: 5 x % C - 0.7

16.5 -

2.0 -

10.5 -

18.5

2.5

13.5

16.5 -

2.0 -

10.0 -

18.5

2.5

13.0

17.0 -

2.5 -

12.5 -

19.0

3.0

15.0

21.0 -

3.0 -

15.0 -

Nb 0.30, N: 0.04

25.0

4.5

18.0

- 0.15

19.0 -

4.0 -

24.0 -

Cu,

21.0

5.0

26.0

N: 0.15

19.0 -

6.0 -

24 -

Cu: 0.5 - 1

21.0

7.0

26.0

N: 0.15 - 0.25

N 0.11

183

7.1 | Material data sheets

7.1 | Material data sheets

Chemical composition

(percentage by mass)

Chemical composition

(percentage by mass)

Material

group

Ni

Material

no.

Short name

Trade name

Si

Mn

P

max.

S

max.

Cr

1.4948

X6CrNi18-10

0.04 -

1.00

2.0

0.035

0.015

17.0 -

8.0 -

19.0

11.0

Mo

Other elements

Material

group

Material Short name

no.

Copper

CW024A

Cu DHP

(2.0090)

(SF-Cu)

Copper-tin

alloy

CW452K

CuSn 6

(2.1020)

Bronze

Copper-zinc

alloy

CW503L

CuZn 20

79.0 -

CW508L

CuZn 37

62.0 -

(2.0321)

Brass

64.0

Cu

Al

Zn

Sn

Pb

Ni

Ti

Ta

Other elements

Austenitic

steel of

high heat

resistance

0.08

1.4919

X6CrNiMo 17-13

0.04 -

0.75

2.0

0.035

0.015

0.08

Heat

resistant

steel

1.4828

X15CrNiSi 20-12

0.20

1.50 -

2.0

0.045

0.015

2.00

1.4876

X10NiCrAlTi32-21

0.12

1.00

2.0

0.030

0.015

(DIN EN 10095) INCOLOY 800H

Nickel-based

alloy

2.4858

NiCr21Mo

0.025 0.50

1.0

0.020

0.015

INCOLOY 825

2.4816

NiCr15Fe

0.05 -

INCONEL 600

0.10

0.50

1.0

0.020

0.015

16.0 -

2.0 -

12.0 -

18.0

2.5

14.0

19.0 -

11.0 -

21.0

13.0

N: max 0.11

19.0 -

30.0 -

Al: 0.15 - 0.60

23.0

34.0

Ti: 0.15 - 0.60

19.5 -

2.5 -

38.0 -

Ti, Cu, Al,

23.5

3.5

46.0

Co 1.0

> 72

Ti, Cu, Al

14.0 -

0.08

1.0

0.020

0.015

14.5 16.5

NiCr22Mo9Nb

0.03 -

0.50

0.5

0.020

0.015

20.0 -

INCONEL 625

0.10

23.0

10.0

14.0 -

14.0 -

18.0

17.0

HASTELLOY C-276

2.4856

V, Co, Cu, Fe

17.0

Remainder

8.0 -

> 58

Ti, Cu, Al

15.0 -

NiMo16Cr16Ti

NiCu30Fe

1.0

0.025

0.015

0.15

0.50

2.0

0.020

Remainder

> 63

184

2.0882

CuNi 30 Mn1 Fe

CUNIFER 30

Si1MgMn

2.4068

LC-Ni 99

0.2

P: 0.01 - 0.4

0.02

0.10

Re-

Fe: 0.1

0.1

0.05

0.1

0.10

0.3

0.3

1.50 -

0.4

mainder

0.05

Remainder

0.10

Remainder

Re-

2.50

0.1

0.15

Si, Mn, Mg

0.2

0.1

Si, Mn, Mg

mainder

0.10

Remainder

0.025

99

0.1

C 0.02

Mg 0.15

Si 0.2

Titanium

3.7025

Ti

Re-

N 0.05

mainder

H 0.013

Ti, Cu,

C 0.06

Co 2,0

Fe 0.15

Cu: 28 - 34%

Tantalum

Ta

0.01

0.01

Rem.

Ti, Al, Co 1.0

MONEL

Copperbased

alloy

CuZn 40 Pb 2 57.0 -

(3.2315)

0.20

7.0

81.0

Wrought

EN AW-5754 EN AW-Al

aluminium

(3.3535)

Mg3

alloy

EN AW-6082 EN AW-Al

5.5 -

Co 1,0

0.015 0.08

HASTELLOY C4

2.4360

0,2

Rest

S 0.01

Nb/Ta: 3.15 - 4.15

INCONEL 625 H

2.4610

P: 0.015 - 0.04

59.0

Pure nickel

0.01

NiMo16Cr15W

2.0402

17.0

INCONEL 600 H

2.4819

2.0250

99.9

0.05

0.5 -

1.5

0.050

30.0

-32.0

Cu: Rest,

Pb, Zn

185

7.1 | Material data sheets

7.1 | Material data sheets

Strength values at elevated temperatures

Strength values at elevated temperatures

Material strength values in N/mm2

Material no.

to DIN Type of value

1.0254

1.0255

1.0427

1.0038

1.0570

1.0460

1.0345

1.0425

1.0481

1.5415

1.7335

Rp 0,2

Rp 0,2

Rp 0,2

Rp 0,2

Rp 0,2

Rp 0,2

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rp 0,2

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rm 200000

Rp 0,2

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rm 200000

Rp 0,2

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rm 200000

Rp 0,2

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rm 200000

Rp 0,2

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rm 200000

Material strength values in N/mm2

Temperatures in C

RT1)

235

235

220

205

315

240

206

234

272

275

1) Room temperature values valid up to 50 C

100

150 200

250 300

350

400 450

500 550 600 700 800

Material no.

to DIN Type of value

1.7380

210

187

254

230

190

215

250

190 170

161

226

210 185

180 170

205 195

235 225

215

230

150

143

206

165

130

122

186

145

150 130

175 155

205 185

200 170

220 205

110

125

100

136

95

191

132

110

136

95

191

132

115

130

136

95

191

132

115

155

167

118

243

179

157

150

80

80

49

113

69

(53)

(30)

(75)

(42)

80

49

113

69

57

(53)

(30)

(75)

(42)

(33)

80

49

113

69

57

(53)

(30)

(75)

(42)

(33)

93

59

143

85

70

145

216

167

298

239

217

170

245

191

370

285

260

49

29

74

41

30

140

132

73

171

101

84

165

157

98

239

137

115

(values to AD W1)

120

140

170

160

190

180

1.0305

() = values at 480 C

() = values at 480 C

1.0565

1.4511

1.4512

1.4301

() = values at 480 C

1.4306

1.4541

1.4571

(84)

(36)

(102)

(53)

(45)

(53)

(24)

(76)

(33)

(26)

1.4404

1.4435

() = values at

530 C

1.4565

1.4539

() = values at

570 C

Temperatures in C

RT1) 100

1.4529

Rp 0,2

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rm 200000

Rp 0,2

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rm 200000

Rp 0,2

Rp 0,2

Rp 0,2

Rp 0,2

Rp 1

Rm 10000

Rm 100000

Rp 0,2

Rp 1

Rp 0,2

Rp 1

Rm 10000

Rm 100000

Rp 0,2

Rp 1

Rp 0,2

Rp 1

Rp 0,2

Rp 1

Rp 0,2

Rp 1

Rp 0,2

Rp 1

Rm (VdTV)

Rp 0,2

Rp 1

150

235

336

230

210

215

205

205

225

200

245

185

304

230

200

157

191

147

181

176

208

185

218

225 166

199

225 165

200

420 350

460 400

220 205

235

520 440

300 230

340 270

284

220

195

142

172

132

162

167

196

177

206

152

181

150

180

310

355

190

220

420

210

245

245

205

190

127

157

118

147

157

186

167

196

137

167

137

165

270

310

175

205

400

190

225

250

230

165

226

190

186

118

145

108

137

147

177

157

186

127

157

127

153

255

290

160

190

390

180

215

300

220

140

216

180

180

110

135

100

127

136

167

145

175

118

145

119

145

240

270

145

175

380

170

205

350

210

120

400

200

110

136

95

191

132

115

167

450

190

240

166

306

221

201

105

80

49

113

69

57

500

180

147

103

196

135

120

(53)

(30)

(75)

(42)

(33)

550

600 700 800

83

49

108

68

58

44

22

61

34

28

() = values at 480 C

196

165

160

104 98 95 92 90

129 125 122 120 120

(approx. values to DIN 17441) 122

74

94 89 85 81 80

121 116 112 109 108

130 125 121 119 118

161 156 152 149 147

(approx. values to DIN 17441) 115

65

140 135 131 129 127

169 164 160 158 157

113 108 103 100 98

139 135 130 128 127

113 108 103 100 98

139 135 130 128 127

225 210 210 210 200

255 240 240 240 230

135 125 115 110 105

165 155 145 140 135

370 360

165 160

195 190

48

23

(17)

(5)

45

22

(17)

(8)

1) Room temperature values valid up to 50 C

187

7.1 | Material data sheets

7.1 | Material data sheets

Strength values at elevated temperatures

Strength values at elevated temperatures

Material strength values in N/mm2

Material strength values in N/mm2

Material no.

to DIN Type of value

1.4948

1.4919

1.4828

DIN EN 10095

1.4876

DIN EN 10095

Incoloy 800H

2.4858

2.4816

DIN EN 10095

Rp 0,2

Rp 1

Rm

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rm 200000

Rp 0,2

Rp 1

Rp 1/10000

Rp 1/100000

Rm 10000

Rm 100000

Rp 0,2

Rm

Rp 1/1000

Rp 1/10000

Rm 1000

Rm 10000

Rm 100000

Rp 0,2

Rp 1

Rm

Rp 1/1000

Rp 1/10000

Rm 1000

Rm 10000

Rm 100000

Rp 0,2

Rp 1

Rm

Rp 0,2

Rm

Rp 0,2

Rm

Rp 1/10000

Rp 1/100000

Rm 1000

Rm 10000

Rm 100000

Temperatures in C

RT1)

230

260

530

100

157

191

440

150

142

172

410

200

127

157

390

250

117

147

385

300

108

137

375

205

245

177

211

147

177

127

157

230

550

332

653

318

632

300

600

170

210

450

235

265

550

200

550

-750

180

500

-700

185

205

425

205

235

530

180

520

170

190

190

220

160

180

400

150

170

350

103

132

375

450

93

122

370

118

147

279

550

165

190

500

88

118

360

147

114

250

192

176

108

137

600 700 800 900

78

108

300

94 35

74 22

132 55

89 28

78 22

98

128

125 46

85 25

175 65

120 34

218 (Manufacturers

figures)

421

8

120 50 20

4

80 25 10

190 75 35 15

120 36 18 8.5

65 16 7,5 3.0

115

(Manufacturers

135

figures)

300

130 70 30 13

5

90 40 15

200 90 45 20

152 68 30 10

8

114 48 21

550

83

113

330

121

96

191

140

125

103

132

180

125

250

175

253

489

130

150

380

145

165

390

180 175 170

205 200 195

500

515

155

165

485

500

400

98

127

375

125

145

360

160

185

490

150

480

155

180

485

145

475

150

440

145

435

120

140

2.4819

VdTV-W 400

2.4856

DIN EN 10095

2.4610

2.4360

CW354H

2.0882

CW024A

2.0090

3.3535

EN-AW 5754

2.4068

Nickel

3.7025

Titan

(Soft annealed)

Material no.

to DIN

Tantal

170

480

1) Room temperature values valid up to 50 C

160

460

150

445

(solution annealed)

153

126

297

215

91

66

160

138

97

43

28

96

63

42

18

12

38

29

17

8

4

22

13

7

Temperatures in C

Type of value

Rp0,2

Rp1

Rp 0,2

Rp 1/100000

Rm 100000

Rm 1000

Rm 10000

Rp 0,2

Rp 1

Rp 0,2

Rm

Rp 1/10000

Rp 1/100000

K/S

Rp 1

Rp 1/10000

Rp 1/100000

K/S

Rp 1

Rm

Rp 2/10000

Rp 2/100000

K/S

K/S

Rp 0,2

Rm 100000

Rp 0,2

Rp 1

Rm

Rp 1/10000

Rp 1/100000

Rp 1

Rm 10000

Rm 100000

Rp 0,2

Rm

A 30[%]

Rp 0,2

Rm

A 30[%]

RT

310

330

410

100

280

305

350

150

305

340

175

450

285

315

150

420

140

400

93

140

87

130

84

126

93

65 58

220 220

58

56

57 57

67 63

80 70

(80)

80 70

105 95

340 290

87

58

195

53

49

50

56

200 250

240

275

320

255

285

135

390

107

102

82

123

107

102

84

132

385

99

94

80

120

99

94

82

170

46

40

43

49

145

37

30

36

41

300 350 400 450 500 550 600

195

220

200

215

280

300

170

Manufacturers figures

250

for Inconel 625 H

290

245

270

130 130

380 375

92 84

86 78

78 75

117 112

92 84

86 78

80 78

90

135

260

190

10

18

34

20

30

45

107

63

( S <= 5 )

() = values at 425 C

Permissible tension to AD-W 6/2 fr 105 h

75

Permissible tension to AD-W 6/2 fr 105 h

(F 20)

(F 22)

Permissible tension to AD-W6/1

45

60

85

260

65

90

275

85

200 180

220 160

200 145

140 100

225 200

35

200 160

280 270

25

225

260

130 (130)

370 (360)

700 800 900

90

110

90

70

160

150

150

130

90

185

110

130

120

80

175

150

260

140 130

240 230

150

55

80

240

75

60

55

40

50

75

210

35

23

19

11

40

65

150

10

6

Electron beam melted

Sintered in vacuum

1) Room temperature values valid up to 50 C

189

7.1 | Material data sheets

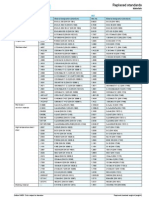

7.1 | Material data sheets

Material designations according to international specifications

Material designations according to international specifications

Material

no. to

DIN EN

1.0254

Standard

ASTM A 53-01

USA

UNS Semi-finished product

designation a pplications / title

K02504 Welded and seamless

black-oxidized and

A 53

Standard

JIS G 3445

(1988)

JAPAN

Designation Semi-finished product

applications

STKM 12 A Tubes

Material

no. to

DIN EN

1.0254

Standard

KS D 3583

(1992)

KOREA

Designation Semi-finished product

applications

SPW 400 Welded tubes of

Standard

CHINA

Designation Semi-finished product

applications

carbon steel

galvanized steel tubes

ASTM A 106-99

1.0255

1.0038

ASTM A 135-01

ASTM A 500-01

1.0050

1.0570

ASTM A 694-00

K02501 Seamless tubes of highA 106 temperature unalloyed steel

K03013 Electric resistance

A 135 welded tubes

K03000 Welded and seamless

A 500 fittings of cold-formed unal loyed steel

K03014 Forgings of unalloyed

A 694 and alloyed steel for pipe

flanges, fittings, valves and

other parts for high-

JIS G 3454

(1988)

JIS G 3457

(1988)

JIS G 3455

(1988)

STPG 370 Pipes under pressure

STPY 400 Welded tubes

STS 370

Pipes subjected to high

1.0255

pressures

1.0038

JIS G 3101

(1995)

JIS G 3106

(1999)

JIS G 3106

(1999)

SS 490

General structural steels

SM 490 A Steels for welded con-

1.0050

1.0570

structions

KS D 3503

(1993)

KS D 3517

(1995)

SS 490

General structural steels

STKM 16C Unalloyed steel tubes for general mechanical engineering

SM 520 B

GB T 700

(1988)

Q 235 B; (unalloyed structural

U12355 steels)

GB T 700

(1988)

GB T 713

(1997)

GB T 8164

(1993)

Q 275;

U12752

16Mng; Plate for steam boilers

L20162

16Mn; Strip for welded tubes

L20166

pressure drive systems

1.0345

ASTM A 414-01

1.0425

ASTM A 414-01

1.0481

ASTM A 414-01

1.5415

ASTM A 204-99

1.7335

1.7380

1.0305

190

ASTM A 387-99

ASTM A 387-99

ASTM A 106-99

K02201 Sheet of unalloyed steel

A 414 for pressure tanks

K02505

A 414

K02704

A 414

K12320 Sheet of molybdenum alloyed

A 204 steel for pressure tanks

K11789 Sheet of Cr-Mo alloyed

A 387 steel for pressure tanks

K21590

22 (22L)

K02501 Seamless tubes of highA 106 temperature unalloyed steel

JIS G 3115

(2000)

JIS G 3118

(2000)

JIS G 3118

(2000)

JIS G 3458

(1988)

JIS G 3462

(1988)

JIS G 4109

(1987)

JIS G 3461

(1988)

1.0345

SGV 480

1.0425

SGV 410

1.0481

SPV 450

Heavy plate for pressure

vessels

STPA 12

STBA 22

Tubes

Boiler and heat exchanger

1.5415

1.7335

1.7380

pipes

SCMV 4

Heavy plate for pressure

vessels

STB 340

Boiler and heat exchanger

KS D 3521

(1991)

KS D 3521

(1991)

SPPV 450 Heavy plate for pressure vessels

KS D 3572

(1990)

KS D 3572

(1990)

KS D 3543

(1991)

STHA 12 Tubes for boilers and heat

for medium application temp.

SPPV 315

exchangers

STHA 22

SCMV 4 Cr-Mo steel for pressure

vessels

GB 5310

(1995)

YB T 5132

(1993)

GB 5310

(1995)

15MoG; Seamless tubes for

A65158 pressure vessels

12CrMo; Plate of alloyed

A30122 structural steels

12Cr2MoG; Seamless tubes for

A30138 pressure vessels

1.0305

pipes

191

7.1 | Material data sheets

7.1 | Material data sheets

Material designations according to international specifications

Material designations according to international specifications

Material

no. to

DIN EN

1.0562

Standard

ASTM A 299-01

ASTM A 714-99

USA

UNS

designation

(AISI)

K02803

A 299

K12609

A 714 (II)

Semi-finished product

applications / title

Plate of C-Mn-Si steel

for pressure tanks

Welded and seamless

tubes of high-strength

Standard

JIS G 3106

(1999)

JIS G 3444

(1994)

JAPAN

Designation Semi-finished product

applications

SM 490 Steels for welded conA;B;C; structions

STK 490 Steels for welded con-

Material

no. to

DIN EN

1.0562

Standard

KOREA

Designation Semi-finished product

applications / title

Standard

CHINA

Designation Semi-finished product

applications

structions

low-alloy steel

1.0565

ASTM A 633-01

ASTM A 724-99

K12037

A633(D)

Normalized high-strength

K12037

A724(C)

Plate of tempered unal-

1.0565

low-alloy structural steel

loyed steel for welded

pressure tanks of layered

construction

1.0566

ASTM A 573-00

K02701

A 573

Plate of unalloyed structural steel with improved

JIS G 3126

(2000)

SLA 365 Heavy plate for pressure

JIS G 3444

(1994)

STK 490 Tubes for general use

1.0566

vessels (low temperature)

KS D 3541

(1991)

SLA1 360

Heavy plate for pressure

vessels (low temperature)

GB T 714

(2000)

Q420q-D; Steels for bridge conL14204 struction

toughness

1.1106

ASTM A 707-02

K12510 Forged flanges of alloyed

A 707 (L3) and unalloyed steel for use

1.1106

GB 6654

(1996)

16MnR; Heavy plate for

L20163 pressure vessels

in low temperatures

192

193

7.1 | Material data sheets

7.1 | Material data sheets

Material designations according to international specifications

Material designations according to international specifications

Material

no. to

DIN EN

1.4511

1.4512

1.4301

Standard

ASTM A 240-02

ASTM A 240-02

1.4306

ASTM A 240-02

1.4541

ASTM A 240-02

1.4571

ASTM A 240-02

1.4404

ASTM A 240-02

1.4435

ASTM A 240-02

1.4565

ASTM A 240-02

1.4539

ASTM A 240-02

1.4529

ASTM B 625-99

USA

UNS Semi-finished product

designation applications / title

(AISI)

S40900; Sheet and strip of

A 240 heatproof stainless

Cr and Cr-Ni steel for

(409)

S30400; pressure tanks

A 240

(304)

S30403;

A 240

(340L)

S32100

A 240

(321)

S31635

A240

(316Ti)

S31603

A240

(316L)

S31603

A240

(316L)

S34565

A240

N08904

A240

(904L)

N08925 Sheet and strip of lowcarbon Ni-Fe-Cr-Mo-Cu

B 625

Standard

JIS G 4305

(1999)

JAPAN

Designation Semi-finished product

applications

SUS 430LX Cold-rolled sheet, heavy

Material

no. to

DIN EN

1.4511

plate and strip

Standard

KOREA

Designation Semi-finished product

applications

KS D 3698

(1992)

STS 430LX

SUS 304 Cold-rolled sheet, heavy

JIS G 4305

(1999)

SUS 304L

JIS G 4305

(1999)

CHINA

Designation Semi-finished product

applications

Cold-rolled sheet, heavy

olled sheet, heavy plate

plate and strip

1.4512

JIS G 4305

(1999)

Standard

and strip

GB T 4238

(1992)

0Cr11Ti;

S11168

GB T 3280

(1992)

0Cr18Ni9;

S30408

KS D 3698

(1992)

STS 304

1.4306

KS D 3698

(1992)

STS 304L

GB T 3280

(1992)

00Cr19Ni10;

S30403

SUS 321

1.4541

KS D 3698

(1992)

STS 321

GB T 3280

(1992)

0Cr18Ni10Ti;

S32168

JIS G 4305

(1999)

SUS 316Ti

1.4571

KS D 3698

(1992)

STS 316Ti

GB T 3280

(1992)

0Cr18Ni12Mo2Cu2

S31688

JIS G 4305

(1999)

SUS 316L

1.4404

KS D 3698

(1992)

STS 316L

GB T 4239

(1991)

00Cr17Ni14Mo2;

S31603

JIS G 4305

(1999)

SUS 316L

1.4435

KS D 3698

(1992)

STS 316L

GB T 3280

(1992)

00Cr17Ni14Mo2;

S31603

KS D 3698

(1992)

STS 317J5L

1.4301

plate and strip

Cold-rolled sheet, heavy

plate and strip

Hot-rolled sheet of

heatproof steel, ferritic

Cold-rolled sheet, heavy

plate and strip

1.4565

1.4539

1.4529

Cold-rolled sheet, heavy

plate and strip

alloys

194

195

7.1 | Material data sheets

7.1 | Material data sheets

Material designations according to international specifications

Material designations according to international specifications

Material

no. to

DIN EN

1.4948

Standard

ASTM A 240-02

1.4919

ASTM A 240-02

1.4958

ASTM A 240-02

1.4828

ASTM A 167-99

1.4876

ASTM A 240-02

USA

UNS

Semi-finished product

designation applications / title

(AISI)

S30409 Sheet and strip of heatproof

A240 stainless Cr and Cr-Ni steel

(304H) for pressure tanks

S31609

A240

(316H)

N 08810

A 240

S30900 Sheet and strip of stainless

A 167 heatproof Cr-Ni steel

(309)

N 08800 Sheet and strip of stainless

heatproof Cr and Cr-Ni steel

A 240

Standard

JAPAN

Designation Semi-finished product

applications

Material

no. to

DIN EN

1.4948

Standard

KOREA

Designation Semi-finished product

applications

Standard

CHINA

Designation Semi-finished product

applications

GB T 1221

(1992)

1Cr20Ni14Si2; Heatproof steels,

austenitic

S38210

1.4919

1.4958

JIS G 4312

(1991)

SUH 309

JIS G 4902

(1991)

NCF 800

JIS G 4902

(1991)

NCF 825

Heatproof sheet and

1.4828

heavy plate

Special alloy in sheet form

KS D 3732

(1993)

STR 309 Heatproof sheet and

KS D 3532

(1992)

NCF 800 Special alloys in sheet and

KS D 3532

(1992)

NCF 825

heavy plate

GB T 15007

(1994)

NS 111; Stainless alloys

H01110

GB T 15007

(1994)

NS 142;

H01420

2.4816

GB T 15007

(1994)

NS 312;

H03120

2.4819

GB T 15007

(1994)

NS 333;

H03330

GB T 15007

(1994)

NS 336;

H03360

GB T 15007

(1994)

NS 335;

H03350

1.4876

heavy plate form

for pressure tanks

2.4858

ASTM B 424-98

N 08825 Sheet and strip of low-carbon

Ni-Fe-Cr-Mo-Cu alloys

B 424

2.4816

ASTM B 168-98

N 06600 Sheet and strip of low-carbon

Ni-Cr-Fe and Ni-Cr-Co-Mo

B 168

2.4819

ASTM B 575-99

N 10276 N06690)

Sheet and strip of low-carbon

B 575

2.4856

ASTM B 443-99

N 06625

Sheet and strip of Ni-Cr-Mo-Nb

B 443

2.4858

(UNS N08825 and N08221)

alloys (UNS N06600 and

Ni-Mo-Cr alloys

JIS G 4902

(1991)

NCF 625

Special alloy in sheet form

2.4856

KS D 3532

(1992)

NCF 625 Special alloys in sheet and

heavy plate form

alloy (UNS N06625)

2.4610

ASTM B 575-99

N 06455

Sheet and strip of low-carbon

B 575

2.4360

ASTM B 127-98

N 04400

Sheet and strip of Ni-Cu alloy

B 127

2.4610

Ni-Mo-Cr alloys

2.4360

(UNS N04400)

196

197

7.1 | Material data sheets

Permissible operating pressures and temperatures

for threaded fittings in malleable cast iron

Threaded fasteners of malleable cast iron are applicable up to the operating pressures

indicated in the table below, depending on type of fluid and operating temperature.

permissible operating pressure for the fluids

DN

d

inch

water and gas

up to max. 120 C

6-50

gases and steam

up to max. 150 C

gases and steam

up to 300 C

oils

up to 200 C

nipples, flat sealing threaded fasteners

1

- 2

65 bar

50 bar

40 bar

35 bar

conically sealing threaded fasteners

6-32

4 - 1 14

65 bar

50 bar

40 bar

35 bar

40

1 12

65 bar

50 bar

40 bar

30 bar

50

55 bar

40 bar

32 bar

24 bar

Sealing is to be carried out with special care. The sealing materials are to be selected

according to the operating conditions. Only approved sealing materials must be applied

for sealing of threaded fasteners in drinking water and gas insulations.

Only high-quality threads are appropriate for high operating requirements.

198

You might also like

- EN 10208-2 - Pipes Marial PDFDocument2 pagesEN 10208-2 - Pipes Marial PDFVictor MacoveiNo ratings yet

- Clasificare TeviDocument2 pagesClasificare TeviMocanu Stefan Artemon100% (1)

- Asme Ks Jis Din 재질 대조표Document25 pagesAsme Ks Jis Din 재질 대조표kanosriNo ratings yet

- Din MaterialDocument110 pagesDin Materialdnageshm4n244100% (1)

- BS en Iso 4017-2014Document22 pagesBS en Iso 4017-2014Pablo DM100% (1)

- Flange Din 2576Document1 pageFlange Din 2576Braz Pataro NetoNo ratings yet

- DIN Survey - Welding-Standards - 16-03-2010 PDFDocument1 pageDIN Survey - Welding-Standards - 16-03-2010 PDFVijayananda AnandaNo ratings yet

- DIN 908 (Rev - 0192)Document3 pagesDIN 908 (Rev - 0192)erka934881No ratings yet

- Fisa Tensionare Incercare de Receptie (280kn) - LISTAREDocument1 pageFisa Tensionare Incercare de Receptie (280kn) - LISTAREAlexeiviciNo ratings yet

- Flange Din 2573Document4 pagesFlange Din 2573Braz Pataro NetoNo ratings yet

- Din ADocument60 pagesDin AJoseNo ratings yet

- Remanierea Defectelor Din Subansamblele SudateDocument8 pagesRemanierea Defectelor Din Subansamblele SudateVasile TomsaNo ratings yet

- Standarde Din FlangeDocument45 pagesStandarde Din Flangeadri2No ratings yet

- Ghid Corespondenta OteluriDocument17 pagesGhid Corespondenta OteluriFulop DanielaNo ratings yet

- Otel Pentru Organe de AsamblareDocument2 pagesOtel Pentru Organe de AsamblareSara HeartNo ratings yet

- Aufst Ba-2Document2 pagesAufst Ba-2WormInchNo ratings yet

- Manual - of DIN Standard PDFDocument13 pagesManual - of DIN Standard PDFkhanz88_rulz1039No ratings yet

- DIN SpecsDocument2 pagesDIN SpecsSantosh Kumar50% (2)

- Materiale Actiuni EUROCODEDocument53 pagesMateriale Actiuni EUROCODEMagno Alexandru100% (5)

- Standarde Anulate InlocuiteDocument6 pagesStandarde Anulate InlocuiteAnton ValentinNo ratings yet

- Oteluri Diverse Pentru SudatDocument13 pagesOteluri Diverse Pentru SudatCristian GîdeaNo ratings yet

- Pregled Vazecih Standarda 04-06-2014 PDFDocument1 pagePregled Vazecih Standarda 04-06-2014 PDFVladan TimotijevicNo ratings yet

- Standardi Celika Uporedni JUS en DINDocument3 pagesStandardi Celika Uporedni JUS en DINAlen HusagićNo ratings yet

- FLANSEDocument5 pagesFLANSERadu RadNo ratings yet

- Vane Cu Sertar ServomotorizateDocument2 pagesVane Cu Sertar ServomotorizatectartzaNo ratings yet

- DIN FlangesDocument24 pagesDIN FlangesH6volleyNo ratings yet

- SAF-FRO Catalog Echipamente & Accesorii 2014Document146 pagesSAF-FRO Catalog Echipamente & Accesorii 2014muntelemarecluj100% (1)

- Cos Fum - Montaj, Utilizare, IntretinereDocument29 pagesCos Fum - Montaj, Utilizare, IntretinereIosif BabiasNo ratings yet

- EquivalentMaterial ASME KS JIS DINDocument25 pagesEquivalentMaterial ASME KS JIS DINahmadlieNo ratings yet

- Catalog Oteluri SpecialeDocument12 pagesCatalog Oteluri SpecialeAdelamaria87No ratings yet

- DIETZEL-tuburi MetaliceDocument22 pagesDIETZEL-tuburi MetaliceSara PotterNo ratings yet

- 1 3 2 1 Pipe Spec 20120531Document125 pages1 3 2 1 Pipe Spec 20120531saravootNo ratings yet

- Vana Fluture Cu Flansa DublaDocument2 pagesVana Fluture Cu Flansa DublaDorin CalugaruNo ratings yet

- Din 1681-GS 52 6Document1 pageDin 1681-GS 52 6Vishnu AgawaneNo ratings yet

- Din EN1Document1 pageDin EN1Alex NeculaNo ratings yet

- RostasDocument4 pagesRostasEveline EveNo ratings yet

- XtendDocument12 pagesXtendStanciu OanaNo ratings yet

- Catalog Produse Big Impex - Luminatoare Din Policarbonat Pentru Hale PDFDocument4 pagesCatalog Produse Big Impex - Luminatoare Din Policarbonat Pentru Hale PDFGubavu ConstantinNo ratings yet

- Irwin-Mipal Cenovnik 2016Document6 pagesIrwin-Mipal Cenovnik 2016Prointel MONTNo ratings yet

- Ansamblu AcumulatorDocument6 pagesAnsamblu AcumulatorToretoiuewrweewNo ratings yet

- Aseptic Flange Connection Din 11864 Din 11853Document7 pagesAseptic Flange Connection Din 11864 Din 11853César HermosoNo ratings yet

- 13 Mat - 2009 - 399 428 RDocument30 pages13 Mat - 2009 - 399 428 RRogo CatalinNo ratings yet

- Corespondente Stas Din NFDocument11 pagesCorespondente Stas Din NFJaroslav CîmpanNo ratings yet

- Echipamentetig 56018Document17 pagesEchipamentetig 56018Pierre LandryNo ratings yet

- 33222Document15 pages33222Zota Alexandru FlorinNo ratings yet

- Anulate Februarie 2017Document3 pagesAnulate Februarie 2017Lucica ZaineaNo ratings yet

- DIN 471-472 SeriesDocument8 pagesDIN 471-472 SeriesaydemirmagNo ratings yet

- GeralDocument4 pagesGeralOsmar GomesNo ratings yet

- Standarde Anulate InlocuiteDocument6 pagesStandarde Anulate InlocuiteRadu RadNo ratings yet

- Dibluri Sisteme AncorareDocument51 pagesDibluri Sisteme AncorarecmcerneaNo ratings yet

- Catalog Bile Ductil Fise TehniceDocument79 pagesCatalog Bile Ductil Fise Tehniceionicabeg7955No ratings yet

- Catalog RotundDocument58 pagesCatalog RotundStefanNo ratings yet

- Prirubnice DIN2633Document1 pagePrirubnice DIN2633sirovinhoNo ratings yet

- Standarde 1966-2009Document581 pagesStandarde 1966-2009Ignat ValentinNo ratings yet

- DIN Flange Data ChartsDocument3 pagesDIN Flange Data ChartsmarcalpiNo ratings yet