Professional Documents

Culture Documents

Analytical Solutions For Square Shape Pressure

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analytical Solutions For Square Shape Pressure

Copyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

ANALYTICAL SOLUTIONS FOR SQUARE SHAPE PRESSURE

MICROSENSORS

Sumit Kumar Jindal1, Sanjeev Kumar Raghuwanshi2

1

2

Department of Electronics Engineering, Indian School of Mines, Dhanbad, 826004, India

Department of Electronics Engineering, Indian School of Mines, Dhanbad, 826004, India

Abstract

Most commonly for MEMS Systems the shapes used for diaphragm are square, circular or rectangular. Here square shape is

under consideration. Pressure microsensor designed is operated in linear range. All the analytical solutions are presented along

with set of simple equations to calculate and predict the sensitivity of pressure micro sensors. By the use of COMSOL and

simulation it can be found that analytical solutions hold good.

Keywords: Microsensors, sensitivity, Burst pressure, piezoresisive

-------------------------------------------------------------------***------------------------------------------------------------------1. INTRODUCTION

Miniaturisation and integration of electronic devices have

made far reaching technological revolutions. Integration of

micromechanics on the same chip has resulted in MicroElectro-Mechanical System(MEMS) that have added newer

dimensions to conventional ICs. With the advent of

micromachining technology, which is compatible with the

conventional IC industry, MEMS has become dominant in

many areas of applications. MEMS have main applications

in sensors, actuators and smart structures. [1]

One of the most common MEMS device is Pressure

microsensors. Due to demand for lower cost and smaller

dimensions transition from mechanical to silicon type has

occurred.[2] Sensor sensitivity and burst pressure

determines the diaphragm dimensions. By burst pressure we

mean maximum non destructive pressure. In a piezoresistive

device, when a silicon microdiaphragm is subjected to

uniform pressure, its internal strain changes and deflection

occurs. Silicon being a piezoresistive material due to change

in internal strain its resistance changes..Now pressure can be

measured by continuous check of resistance change by the

help of pressure sensing resistors. This change is then

converted to its equivalent electrical output signal. Thin

plate problem can be used to simulate the diaphragm.[3]

In this study, the stress is related to diaphragm size, burst

pressure, pressure sensitivity and piezoresistor length and

these corresponding factors are the main design parameters.

The present work offer simple and valid expressions for

designers and researchers to predict the piezoresistive

microsensors.

b) Plate is flat in nature,

c) Deflection is very small compared to the thickness of the

plate; therefore slope is small and hence square of slope is

negligible .

d) the strain line remain straight and normal to the middle

surface during the deformation

e) In the stress strain relation stress normal to the middle

plane is small compared with the other stress components

and for this reason it is neglected

f) Plate displacement is small and it is also assumed that

after bending middle surface remains unstrained

The deflection of the flat diaphragm under uniform pressure

load can be found by solving the differential equation

4w

4w

4w P

x 4

x 2y 2 y 4 D

(1)

Eh3

Where D is the flexural rigidity given by

. By

12(1 2 )

solving (1) with boundary conditions we get:

w 0,

w

0

n

(2)

3. RESULTS AND DISCUSSIONS

3.1 Diaphragm Size

The maximum deflection is found to be at the centre of the

diaphragm.[5-7]

2. NUMERICAL ANALYSIS

A resistor bridge is all that a piezoresistive sensor having

square shape contains. The basic assumptions for kirchoffs

plate theory are[4]

a) The plate material is elastic, isotropic and homogenous,

_______________________________________________________________________________________

Volume: 03 Special Issue: 15 | Dec-2014 | IWCPS-2014, Available @ http://www.ijret.org

48

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

At the middle of the edges the maximum stress occurs

3.3 Pressure Sensitivity

Parallel and perpendicular to the direction of the electrical

current, piezoresistivity of silicon can be studied. Gauge

factor can be represented as Fpar and Fper. Piezoresistive

constant is used to represent them as[1],[8]

Fpar

Fper

E l t

(1 2 )

(3)

E t l

(1 2 )

(4)

And the change in resistance is written as:

R

Fpar r Fper t

R

(5)

Which can further be written a

R

1

Fpar

R

1

1 2

r Fper

t

1

(6)

3.4. Optimization of Resistor Length

Fig-1: Lateral and front plane view of displacement for the

square diaphragm in agreement to the theory

The maximum deflection of diaphragm is linear to pressure

applied. The diaphragm thickness is about some ten

micrometres and the deflection is less than half of the

diaphragm thickness.

3.2 Burst Pressure

Important positions for sensing resistors are analyzed after

the calculation of sensitivity distribution. Then we calculate

the design of the resistors which includes shape and length

for the effective calculation of optimized sensitivity. Line

shape resistors are designed for change in strain to calculate

the maximum piezoresistive effect. In order to gain

maximum sensitivity the line shape resistors are placed at

the edges of the square diaphragm. The non-effective

portion used is 2m outside the diaphragm. This is taken

into consideration because misalignment cannot be avoided

during the process of fabrication. During pressure

measurement the sensor parts which are effective will stay

inside diaphragm.

Fig-2: Lateral view of stress for the square diaphragm in

agreement to the theory stated

_______________________________________________________________________________________

Volume: 03 Special Issue: 15 | Dec-2014 | IWCPS-2014, Available @ http://www.ijret.org

49

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

3.4.1. Configuration of the Piezoresistive Pressure

Where R is the change in resistance of R.

Sensor

So the output voltage can be expressed as

Vout

Reff

2 2 Rnon Reff Reff

Vin

(8)

Where Reff is the change effective resistance. In order to

get maximum voltage it is important to maximize Reff

and Rnon is the value assigned to non-effective resistance.

Reff is effective resistance.

It can be derived as:

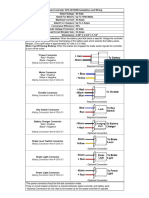

Figure-3:a) The physical configuration of the pressure

sensor and circuit fabricated on a membrane suspended on a

Si substrate. Rsensor is a piezoresistor that changes

resistance with the strain of the membrane, across which a

pressure differential is applied. b):The wheatstone quarter

bridge circuit used to sense the change in resistance of

Rsensor.

Figure (3a) and (3b) shows the circuit design for the square

shaped diaphragm pressure sensor. It also shows the

wheatstone bridge circuit used for signal conditioning of

pressure sensor. Here a quarter sensor bridge is employed. It

is enough to demonstrate the strain effect on the sensor. R1

is the piezoresistor on which membrane is embedded and

pressure difference is applied. To nullify the output voltage

Vout VA VB ,a variable resistor R2 is used. This is the

case when no pressure is applied across the membrane. For

balancing of bridge R3 is used. R4 is the reference resistor.

Since wheatstone bridge has maximum sensitivity for the

output voltage when variable resistance is used hence it is

used in this configuration. A constant voltage (RMS or dc),

Vin , is used as input voltage source.

Reff

Reff

1

l

L l

R

dx

R

(9)

Where l effective resistors length

Fig-4: Optimization result of effective resistor length for

square shaped diaphragm under consideration

Applied)

Effective resistors optimized length is calculated by the

help eqn (7) & (9). Fig.(4) shows the simulation result for

the circular diaphragm with above mentioned dimensions. It

is observed that diaphragm has an optimized output when

the effective resistor length is about 10m. It decreases

whether we increase or decrease the length.

For quarter bridge circuit the output is written as below

provided no pressure is [9]

4. CONCLUSION

3.4.2 Sensor Output Analysis (When a Voltage is

Vout

R1 R3 R2 R4

V

R1 R2 R3 R4 in

(7)

If all resistance is assumed to be R initially and then after we

apply pressure Vout is written as:

R

Vin

2 2 R R

In this paper we have provided all the analytical steps for the

calculation of the freely supported case for square shaped

pressure sensor. The results have been matched with the

existing literature. Design and modelling of pressure sensor

have been successfully established . We derived the relation

among maximum diaphragm deflection, diaphragm

configuration and applied pressure. The sensitivity has been

expressed in terms of piezoresistive constants. The effect of

piezoresistor has also been included in the model for more

precise calculation. The orientation, length and position of

the sensing resistors has completely been studied. For

square shape diaphragms, at the centre lies the most sensing

_______________________________________________________________________________________

Volume: 03 Special Issue: 15 | Dec-2014 | IWCPS-2014, Available @ http://www.ijret.org

50

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

portions i.e at 10m.When the shape or dimension or

orientation is changed for the diaphragm or resistor these

solutions provide researchers with important design outlines.

Moreover the literature has also been supported with

simulation result of COMSOL.

REFERENCES

[1]. Liwei Lin, Weijie Yun,1998.MEMS pressure sensors

for Aerospace Applications.IEEE 0-7803-4311-5/98, 429436

[2]. Smith,C.S.,1954.Piezoresistive Effect in Germanium

and Silicon. phys. Rev. 94, 42-49

[3]. Timoshenko,S.P., Woinowsky-Kreiger,S.,1959. Theory

of Plates and Shells, Second ed. McGraw Hill, New York

[4]. Carl T.F Ross, 1999. Strength of Mateial and Structure,

fourth ed. Arnold,London.

[5]. William P. Eaton et al.,1999. A new analytical

solution for Diaphragm Deflection and its application to a

surface- micromachined Pressure Sensor. International

Conference on Modelling and Simulation of Microsystems

[6]. DING Hao-jiang et al.,2005. Analytical solutions for a

uniformly loaded circular plate with clamped edges. Journal

of Zhejiang university Science A(10), 1163-1168

[7]. Khakpour,R.,et al.,2010. Analytical comparison for

square,Rectangular and Circular Diaphragms in MEMS

applications.

International Conference on Electronic

Devices. Systems and Applications, 297-99.

[8]. Lin L et al.,1999. A simulation program for the

sensitivity and linearity of piezoresistive pressure sensors. J.

Micro-electromech. Syst. 8, 514-22.

[9]. Byunghoon Bae et al.,2004. Design optimization of a

piezoresistive pressure sensor considering the outputsignalto-noise ratio. J. Micromech. Microeng. 14, 1597-1607

_______________________________________________________________________________________

Volume: 03 Special Issue: 15 | Dec-2014 | IWCPS-2014, Available @ http://www.ijret.org

51

You might also like

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDocument11 pagesWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDocument8 pagesFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDocument8 pagesEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDocument5 pagesGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDocument6 pagesRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDocument5 pagesLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDocument5 pagesImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDocument9 pagesEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shear Strength of RC Deep Beam Panels - A ReviewDocument15 pagesShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Review Study On Performance of Seismically Tested Repaired Shear WallsDocument7 pagesReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDocument8 pagesHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDocument10 pagesWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDocument3 pagesMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDocument3 pagesLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cyclone Disaster On Housing and Coastal AreaDocument7 pagesCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Assessment of Seismic Susceptibility of RC BuildingsDocument4 pagesAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDocument5 pagesA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDocument9 pagesDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDocument4 pagesEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDocument10 pagesComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDocument6 pagesCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDocument4 pagesCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Disaster Recovery Sustainable HousingDocument4 pagesDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDocument4 pagesBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDocument6 pagesDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDocument4 pagesChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDocument5 pagesCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDocument5 pagesRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Spesifikasi Teknis Deutz 500kva SilentDocument7 pagesSpesifikasi Teknis Deutz 500kva Silenthafid CJSPNo ratings yet

- Computer Power System AnalysisDocument155 pagesComputer Power System AnalysisSamir ElabasiryNo ratings yet

- Intrinsic Safety: Basic PrinciplesDocument13 pagesIntrinsic Safety: Basic PrinciplesJessica SimonNo ratings yet

- A Sinusoidal Pulse Width Modulation (SPWM) Technique For Capacitor Voltage Balancing of Nested T-Type Four-Level InverterDocument5 pagesA Sinusoidal Pulse Width Modulation (SPWM) Technique For Capacitor Voltage Balancing of Nested T-Type Four-Level InverterMd NuruddinNo ratings yet

- Leica EG1150 H Technical Data enDocument1 pageLeica EG1150 H Technical Data enrazaNo ratings yet

- Transformer Tests GuideDocument10 pagesTransformer Tests GuideKaleem UllahNo ratings yet

- Automatic Power Supply Control From Four Different SourcesDocument21 pagesAutomatic Power Supply Control From Four Different SourcesJishnu Ps100% (1)

- Service Manual: Panel Assy (A64-3921-02) Metallic Cabinet (A01-4406-02)Document38 pagesService Manual: Panel Assy (A64-3921-02) Metallic Cabinet (A01-4406-02)TeriOsNo ratings yet

- 5730A Omeng0100Document248 pages5730A Omeng0100chapumaoNo ratings yet

- SPD-481000B Installation and WiringDocument2 pagesSPD-481000B Installation and WiringMNo ratings yet

- Electrical Data: (Basta)Document2 pagesElectrical Data: (Basta)Anonymous ZlPONG100% (2)

- EasyMethodforTestingTransformerDifferentialRel PDFDocument15 pagesEasyMethodforTestingTransformerDifferentialRel PDFAgam Rodhi AditiawarmanNo ratings yet

- A Simple Guide To Selection of Lightning and Surge ProtectionDocument5 pagesA Simple Guide To Selection of Lightning and Surge Protectionyxp2237No ratings yet

- Olution AnualDocument207 pagesOlution Anualmrgummy2013No ratings yet

- Issa Batarseh, Ahmad Harb - Power Electronics - Circuit Analysis and Design (2018, Springer) PDFDocument689 pagesIssa Batarseh, Ahmad Harb - Power Electronics - Circuit Analysis and Design (2018, Springer) PDFtaufiqishak09100% (4)

- EE353-Electrical Power Systems-Hasan Ul Banna PDFDocument4 pagesEE353-Electrical Power Systems-Hasan Ul Banna PDFAlex DiazNo ratings yet

- EC302Document27 pagesEC302api-3853441No ratings yet

- hw8 SolnsDocument9 pageshw8 SolnsJennyNo ratings yet

- Essential FormulaeDocument32 pagesEssential FormulaeVirgilio Jose Cambraia LopesNo ratings yet

- Durable Pressure Transmitter for Harsh EnvironmentsDocument2 pagesDurable Pressure Transmitter for Harsh Environmentssaid_rahmansyah4750No ratings yet

- Mastering Physics Chapter 19 Electric Charges and ForcesDocument19 pagesMastering Physics Chapter 19 Electric Charges and Forcesodoratum0% (4)

- L&T Electrical & Automation: (+VE) (-VE) (+VE) (-VE)Document1 pageL&T Electrical & Automation: (+VE) (-VE) (+VE) (-VE)Sivachandran RNo ratings yet

- ADS Tutorial On PCB Design To Layout: ECE 451 Automated Microwave Measurements LaboratoryDocument4 pagesADS Tutorial On PCB Design To Layout: ECE 451 Automated Microwave Measurements Laboratoryten nheNo ratings yet

- Common Mode ChokeDocument2 pagesCommon Mode ChokeLeonardo MarraffiniNo ratings yet

- SHAPING MACHINE SETUP GUIDEDocument10 pagesSHAPING MACHINE SETUP GUIDEsifuszNo ratings yet

- Meo Class 4 - Electricals: Section - 1Document85 pagesMeo Class 4 - Electricals: Section - 1Mrithesh KathirNo ratings yet

- ESD-Ch3 2019 P6Document27 pagesESD-Ch3 2019 P6lan20102002No ratings yet

- NÜVE - NB Baño MariaDocument14 pagesNÜVE - NB Baño MariaDavid EguezNo ratings yet

- Room Air Conditioner Owner's Manual GuideDocument19 pagesRoom Air Conditioner Owner's Manual GuideMunteanu LucianNo ratings yet

- AM Broadcasting Midterms Lecture 3 SummaryDocument19 pagesAM Broadcasting Midterms Lecture 3 SummaryArthur JamesNo ratings yet