Professional Documents

Culture Documents

Batt Charge

Uploaded by

raotalhaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Batt Charge

Uploaded by

raotalhaCopyright:

Available Formats

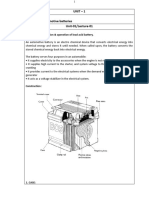

Technical notes of interest to Marine

Engineers

What is the difference between single-rate

battery chargers and two-rate chargers? Is

there a benefit to one over the other?

Generator set battery systems are very important for

many reasons. Their reliability is of much importance

when critical loads are a factor. While the battery and

charger work together to insure uninterrupted power,

the battery is ultimately responsible for reliable engine

starts. If the battery fails your generator might not

start resulting in lack of power to equipment and

facilities.

It is the battery charger's duty to maintain fully

charged batteries at all times to assure positive

engine starts under routine or emergency conditions.

The battery charger is designed to provide the

batteries with a charging current anytime the charge

level falls below acceptable limits. There are many

designs of battery chargers, but most operate under

one of the following two concepts:

1. Single-Rate Charger - Also known as "trickle

charger", this unit will produce its maximum

current for only a very short time, then begins

to taper off as the batteries' state of charge

increases. The only way to maintain a higher

current output into the battery would be to

increase the charger's output voltage. This,

however, would cause serious overcharging

problems as the battery becomes fully

charged. Thus, the voltage chosen for any

single-rate charger is a compromise between

fast charging and optimum battery

maintenance voltage. The most common

problem with the single-rate charger is the loss

of electrolyte in batteries caused by a "boiling"

effect as they are overcharged. This leads to

extensive labor hours replacing or servicing

batteries. It should also be noted that due to

their nature, most single-rate chargers sold as

"5 amp" never reach full current output and

therefore may offer the performance of a 2 amp

charger!

2. Two-Rate Charger - Also known as "float

chargers", the two-rate charger automatically

operates at a "boost" charging voltage that

allows the battery to draw the charger's

maximum output until is almost fully charged.

When the battery reaches a high rate of

charge, the charger shifts to the optimum float

voltage to minimize battery electrolyte

consumption. Since the charger monitors the

battery 100% of the time, the optimum charge

is provided without adjustments. The correct

two-rate battery charger will offer faster

charging performance and will reduce the

requirement for maintenance. No compromise

is made.

The benefits of the two-rate battery charger make for

a much more reliable battery system. However,

attention must be given to the various designs out in

the marketplace. The minimum requirements should

include: (a) temperature compensation which insures

correct charging in most conditions, (b) output voltage

regulation to maintain rated output regardless of input

volts and frequency variations, (c) current limiting and

(d) overload protection.

Calculation of battery charger size with automatic

two-rate charger - Engine Starting Application

The following formula can be used to determine the

required charger ampere rating to recharge a battery

used in an engine-starting application. This formula

assumes that there is little or no continuous current

drain on the charger and it is useful only in calulating

ampere rating of two-rate chargers. It is also assumed

that the charger will replenish only the ampere-hours

withdrawn by the engine-cranking event. The voltage

of the battery system is immaterial to this calculation.

Calculation Steps

Determine the current that the starter draws for the

entire starting cycle. Assume, for example, that:

The starter draws 900 amps rolling current,

worst case

The maximum cranking time per start attempt

is 15 seconds, which equals 0.0042 of an hour

The maximum number of start attempts will be

5

Ampere-hours (AH) drawn by the starter for this

example is (900) (0.0042) (5), or 18.9 AH

Decide how quickly you wish the battery to be

recharged. Assume, for example, that you wish to

recharge this battery in 5 hours

Plug variables into this formula to find the charger

ampere rating (use 1.4 for lead acid and 1.8 for

nickel-cadmium when asked for inefficiency constan):

Total AH drawn by starter X recharge inefficiency

constant / desired recharge hours

Answer (for above example): 18.9 x 1.4 / 5 = 5.29

amp charger

You might also like

- Battery User Manu: CautionDocument24 pagesBattery User Manu: Cautionbenbekreti amineNo ratings yet

- Teja.P Group5 EPT 02 FMGTPDocument3 pagesTeja.P Group5 EPT 02 FMGTPTeja pNo ratings yet

- Generator, Starter, Battery and Spark Plug Repair InstructionsDocument10 pagesGenerator, Starter, Battery and Spark Plug Repair InstructionsSoporte Tecnico AutoMotrixNo ratings yet

- Diagnostic Information and Procedure for Ignition and Charging SystemsDocument8 pagesDiagnostic Information and Procedure for Ignition and Charging SystemsRafael OlaveNo ratings yet

- NiMH Charger Application ManualDocument4 pagesNiMH Charger Application ManualFred BohnNo ratings yet

- Pequeño Libro Rojo de Las BateríasDocument11 pagesPequeño Libro Rojo de Las Bateríasrzetec1No ratings yet

- Automotive Electrical & ElectronicsDocument83 pagesAutomotive Electrical & ElectronicsSathya NarayananNo ratings yet

- AT2302 Automotive Electrical and ElectronicsDocument83 pagesAT2302 Automotive Electrical and ElectronicsShubham DawleNo ratings yet

- Nergie-: Diesel Engine Starting Batteries Guide and WorksheetDocument7 pagesNergie-: Diesel Engine Starting Batteries Guide and WorksheetAlexander OngNo ratings yet

- Testing and Commissioning of Substation DC SystemDocument4 pagesTesting and Commissioning of Substation DC Systemjob_pNo ratings yet

- Electrical Systems: Charging CircuitDocument11 pagesElectrical Systems: Charging CircuitBinoy BennyNo ratings yet

- Hyperion g5 50c 3s 1100mah Lipo Battery User Guide PDFDocument9 pagesHyperion g5 50c 3s 1100mah Lipo Battery User Guide PDFRaouf ChrisNo ratings yet

- Ex 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleDocument23 pagesEx 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleKunal TanwarNo ratings yet

- Quadrotor Power System DocumentationDocument18 pagesQuadrotor Power System DocumentationAhnassifNo ratings yet

- Applied Wh3-Manual PDFDocument24 pagesApplied Wh3-Manual PDFsaul rosalesNo ratings yet

- Tsbus2008 984Document47 pagesTsbus2008 984karlosc17No ratings yet

- Engine Electric Devices: GeneralDocument8 pagesEngine Electric Devices: GeneralBernd EikersNo ratings yet

- The Frequently Asked Questions About: Battery FaqsDocument2 pagesThe Frequently Asked Questions About: Battery FaqsJon FunNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Lucas Fault Diagnosis Service ManualDocument48 pagesLucas Fault Diagnosis Service ManualStephen RöhmNo ratings yet

- User Manual RV1 6.30.23Document10 pagesUser Manual RV1 6.30.23jurkusukneNo ratings yet

- A Map Battery WebDocument2 pagesA Map Battery WebCornel BicaNo ratings yet

- Tsbus2008 984 PDFDocument43 pagesTsbus2008 984 PDFkarlosc17No ratings yet

- Battery Charge - Discharge BattconDocument5 pagesBattery Charge - Discharge BattconmatarakiNo ratings yet

- Battery: Theory and PracticeDocument23 pagesBattery: Theory and PracticeAsmawi Mohd KhailaniNo ratings yet

- A Guide To Battery ChargingDocument7 pagesA Guide To Battery ChargingRohit BhogleNo ratings yet

- 11 - Electrical System PDFDocument31 pages11 - Electrical System PDFTanaji ShindeNo ratings yet

- Pump ED 101: Centrifugal Pump Motor Selection, Installation & Start UpDocument5 pagesPump ED 101: Centrifugal Pump Motor Selection, Installation & Start Upabdulyunus_amirNo ratings yet

- Battery ChargerDocument43 pagesBattery ChargerAhmed SheirNo ratings yet

- Batteries: Working of A BatteryDocument5 pagesBatteries: Working of A BatterykajalNo ratings yet

- 1Document10 pages1Jiji LakshmyNo ratings yet

- A Complete Guide To Battery ChargingDocument4 pagesA Complete Guide To Battery ChargingAman SinghNo ratings yet

- Bat Charging TipsDocument2 pagesBat Charging TipsFato NiNo ratings yet

- Battery Charging Guide - 6 VoltDocument5 pagesBattery Charging Guide - 6 VoltKidus DawitNo ratings yet

- Batteries For UPS PDFDocument4 pagesBatteries For UPS PDFrajpre1213No ratings yet

- Best of The Budget Chargers - EneloopDocument19 pagesBest of The Budget Chargers - EneloopreadalotbutnowisdomyetNo ratings yet

- Testing and Commissioning of Substation DC SystemsDocument3 pagesTesting and Commissioning of Substation DC Systemsagusraposobusto100% (1)

- UNIT 1 Moodle Lecture 1Document9 pagesUNIT 1 Moodle Lecture 1aryanNo ratings yet

- Battery TypesDocument19 pagesBattery Typessasa hhNo ratings yet

- BATTERY CHARGING GUIDEDocument3 pagesBATTERY CHARGING GUIDEPaul Cortes OlivosNo ratings yet

- Switchgear Battery Sizing by Hand - EC&MDocument11 pagesSwitchgear Battery Sizing by Hand - EC&MLowell Estrella-SchneiderNo ratings yet

- Switchgear Battery Sizing by HandDocument4 pagesSwitchgear Battery Sizing by HandNia KurniawatiNo ratings yet

- A Guide To LiPo BatteriesDocument10 pagesA Guide To LiPo BatteriesTonyBonjorniNo ratings yet

- Battery HandbookDocument7 pagesBattery Handbookcheguevara2010100% (1)

- A Primer On ATV Charging SystemsDocument8 pagesA Primer On ATV Charging SystemsMyBriggsNo ratings yet

- 08a Motor StartingDocument36 pages08a Motor StartingAhmed Abd El WahabNo ratings yet

- Lead Acid BatteryDocument13 pagesLead Acid BatteryThota MaheshNo ratings yet

- Hoppecke Fnceh PDFDocument7 pagesHoppecke Fnceh PDFkamal_khan85No ratings yet

- Electric Car ChargingDocument6 pagesElectric Car ChargingSaleh Al-SugairNo ratings yet

- SIS-Preventive Maintenance For BatteriesDocument2 pagesSIS-Preventive Maintenance For BatteriesmkNo ratings yet

- AGN 002 - Customer TrainingDocument7 pagesAGN 002 - Customer TrainingariwibowoNo ratings yet

- IntroductionDocument8 pagesIntroductionmanuNo ratings yet

- BU-603 Calibrate Smart BatteryDocument4 pagesBU-603 Calibrate Smart BatteryHugh Ell - auNo ratings yet

- SINGLE-PHASE INDUCTION MOTORS (Electric Motor) PDFDocument13 pagesSINGLE-PHASE INDUCTION MOTORS (Electric Motor) PDFMomanddad la Lng100% (2)

- Open-phase Protection for MotorsDocument5 pagesOpen-phase Protection for MotorsAnamarialuzNo ratings yet

- Engineering Installation Bulletin: Electrical SystemDocument7 pagesEngineering Installation Bulletin: Electrical Systemmxnoxn100% (1)

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.From EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Rating: 3 out of 5 stars3/5 (4)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- The Ins and Outs of The HeartDocument4 pagesThe Ins and Outs of The HeartAbdul AnisNo ratings yet

- MK-660 Tile Saw: Owner'S Manual Parts List & Operating InstructionsDocument44 pagesMK-660 Tile Saw: Owner'S Manual Parts List & Operating InstructionsAbdul AnisNo ratings yet

- 12 Proven Principles For Overcoming The Storms of LifeDocument41 pages12 Proven Principles For Overcoming The Storms of LifeRajib DasNo ratings yet

- Analysis of In-Port Vessel Operational Lubricant Discharges and LeakagesDocument25 pagesAnalysis of In-Port Vessel Operational Lubricant Discharges and LeakagesAbdul AnisNo ratings yet

- GNC Mega Men SportDocument4 pagesGNC Mega Men SportAbdul AnisNo ratings yet

- Jofra Ametek Temp Calibrator RTC, PTC User ManualDocument82 pagesJofra Ametek Temp Calibrator RTC, PTC User ManualAbdul AnisNo ratings yet

- WBL400 ManualDocument43 pagesWBL400 ManualAbdul AnisNo ratings yet

- Islam by CountryDocument27 pagesIslam by CountryAbdul AnisNo ratings yet

- Cryogenics Handbook PDFDocument227 pagesCryogenics Handbook PDFmangyanNo ratings yet

- Violence in The Workplace PowerpointDocument37 pagesViolence in The Workplace PowerpointAbdul AnisNo ratings yet

- Sewage RegsDocument4 pagesSewage RegsAbdul AnisNo ratings yet

- Glossary: Appendix A Glossary A 1Document56 pagesGlossary: Appendix A Glossary A 1houseboiNo ratings yet

- Fundamentals of Process Instrumentation: Course Number 205Document1 pageFundamentals of Process Instrumentation: Course Number 205Abdul AnisNo ratings yet

- Rule Finder 913 Jan 2010Document55 pagesRule Finder 913 Jan 2010Rick ZhuNo ratings yet

- The Happiness Bible 2Document43 pagesThe Happiness Bible 2Solomon Cosmin Ionut100% (1)

- Marine Engineer Officer Exam Reference PublicationsDocument2 pagesMarine Engineer Officer Exam Reference PublicationsAbdul AnisNo ratings yet

- ABB Turbocharging - Operating Turbochargers PDFDocument35 pagesABB Turbocharging - Operating Turbochargers PDFrajishrrrNo ratings yet

- Wartsila20 Project GuideDocument140 pagesWartsila20 Project GuideAbdul Anis100% (1)

- Manual Motor MANDocument393 pagesManual Motor MANAlejandro Bust88% (8)

- CA Ship Act DetailsDocument5 pagesCA Ship Act DetailsAbdul AnisNo ratings yet

- User GuideDocument214 pagesUser GuideAbdul AnisNo ratings yet

- ABB Turbo Systems Flyer Eng Low Res 01Document4 pagesABB Turbo Systems Flyer Eng Low Res 01Abdul AnisNo ratings yet

- The FUEL OIL Calculation ProgramDocument2 pagesThe FUEL OIL Calculation ProgramAbdul AnisNo ratings yet

- 3516b Marine EngineDocument12 pages3516b Marine EnginepipenandoNo ratings yet

- The Limitless Wealth and Success ManualDocument0 pagesThe Limitless Wealth and Success ManualJimmie L Simpson100% (1)

- Blue Water Bridge HistoryDocument9 pagesBlue Water Bridge HistoryAbdul AnisNo ratings yet

- Printer GuideDocument287 pagesPrinter GuideAbdul AnisNo ratings yet

- Hwy GuideDocument167 pagesHwy GuideAbdul AnisNo ratings yet

- IMPA Marine Stores GuideDocument10 pagesIMPA Marine Stores GuideAbdul Anis50% (2)

- SanderDocument26 pagesSanderAbdul AnisNo ratings yet