Professional Documents

Culture Documents

Fabrication of Nano Object Imaging Probe Using Simple & Fast Hydro - Mechanical Etching Technique

0 ratings0% found this document useful (0 votes)

17 views5 pagesFaster improvement of near-field optical microscope (SNOM) technique make optical fibre nanoprobe an inevitable tools and has been applied to many fields extensively. Buffer Hydro Fluric Acid(BHF) etching method is very popular to produce optical fibre nanoprobe with low cost but this process is very slow. A method is developed to produce chemically etched optical fiber tips for small and nano objective imaging with valuable properties such as large transmission and no lateral light leaks by simple Hydro-mechanical etching technique which offer faster etching rate and very simple laboratory set up. Probing optical properties of materials and optical characterization of molecular defects at the nanometer scale have been inaccessible until recently due to the diffraction limit of light. With the invention of nanometric fiber optic tip by the help of Hydro-mechanical etching and tappering technique, resolution at the 50±100 nm level using visible or near infrared light is now practical. The unique capability of fiber optic probe to simultaneously measure surface topography and local optoelectronic properties, thereby eliminating the need to perform cross correlation analysis on results obtained using different techniques, is particularly useful in this area. The noticeable improvement of chemical etching through Hydro-mechanical technique was observed here.

Original Title

Fabrication Of Nano Object Imaging Probe Using Simple & Fast Hydro -Mechanical Etching Technique

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFaster improvement of near-field optical microscope (SNOM) technique make optical fibre nanoprobe an inevitable tools and has been applied to many fields extensively. Buffer Hydro Fluric Acid(BHF) etching method is very popular to produce optical fibre nanoprobe with low cost but this process is very slow. A method is developed to produce chemically etched optical fiber tips for small and nano objective imaging with valuable properties such as large transmission and no lateral light leaks by simple Hydro-mechanical etching technique which offer faster etching rate and very simple laboratory set up. Probing optical properties of materials and optical characterization of molecular defects at the nanometer scale have been inaccessible until recently due to the diffraction limit of light. With the invention of nanometric fiber optic tip by the help of Hydro-mechanical etching and tappering technique, resolution at the 50±100 nm level using visible or near infrared light is now practical. The unique capability of fiber optic probe to simultaneously measure surface topography and local optoelectronic properties, thereby eliminating the need to perform cross correlation analysis on results obtained using different techniques, is particularly useful in this area. The noticeable improvement of chemical etching through Hydro-mechanical technique was observed here.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views5 pagesFabrication of Nano Object Imaging Probe Using Simple & Fast Hydro - Mechanical Etching Technique

Faster improvement of near-field optical microscope (SNOM) technique make optical fibre nanoprobe an inevitable tools and has been applied to many fields extensively. Buffer Hydro Fluric Acid(BHF) etching method is very popular to produce optical fibre nanoprobe with low cost but this process is very slow. A method is developed to produce chemically etched optical fiber tips for small and nano objective imaging with valuable properties such as large transmission and no lateral light leaks by simple Hydro-mechanical etching technique which offer faster etching rate and very simple laboratory set up. Probing optical properties of materials and optical characterization of molecular defects at the nanometer scale have been inaccessible until recently due to the diffraction limit of light. With the invention of nanometric fiber optic tip by the help of Hydro-mechanical etching and tappering technique, resolution at the 50±100 nm level using visible or near infrared light is now practical. The unique capability of fiber optic probe to simultaneously measure surface topography and local optoelectronic properties, thereby eliminating the need to perform cross correlation analysis on results obtained using different techniques, is particularly useful in this area. The noticeable improvement of chemical etching through Hydro-mechanical technique was observed here.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

International Journal of Scientific Research and Engineering Studies (IJSRES)

Volume 1 Issue 4, October 2014

ISSN: 2349-8862

Fabrication Of Nano Object Imaging Probe Using Simple & Fast

Hydro -Mechanical Etching Technique

Fazle Kibria

Research Scholar,University of Calcutta,92 A.P.C.Road,

Kolkata, West Bengal ,India

Abstract: Faster improvement of near-field optical

microscope (SNOM) technique make optical fibre nanoprobe

an inevitable tools and has been applied to many fields

extensively. Buffer Hydro Fluric Acid(BHF) etching method

is very popular to produce optical fibre nanoprobe with low

cost but this process is very slow. A method is developed to

produce chemically etched optical fiber tips for small and

nano objective imaging with valuable properties such as

large transmission and no lateral light leaks by simple

Hydro-mechanical etching technique which offer faster

etching rate and very simple laboratory set up. Probing

optical properties of materials and optical characterization of

molecular defects at the nanometer scale have been

inaccessible until recently due to the diffraction limit of

light. With the invention of nanometric fiber optic tip by the

help of Hydro-mechanical etching and tappering technique,

resolution at the 50100 nm level using visible or near

infrared light is now practical. The unique capability of fiber

optic probe to simultaneously measure surface topography

and local optoelectronic properties, thereby eliminating the

need to perform cross correlation analysis on results

obtained using different techniques, is particularly useful in

this area. The noticeable improvement of chemical etching

through Hydro-mechanical technique was observed here.

Keywords: Hydromechanical etching, Simple chemical

etching, Faster etching technique, Nano imaging probe,HF

etching, Pencil tip fiber by Hydromechanical etching,

Etching by only HF, Hydromechanical nano probe

quality of measurements.The size and the shape of a nano

probe have to be optimized according to the application[2,3].

On the other hand, optical fibre nanoprobe has been applied to

collect spectra. Recently, optical fibre nanoprobe has also

been used to develop a new type coupling, for example,

between two sections fibre or the fibre and photonic crystal

micro-waveguide . Since fiber probes of good quality are still

expensive and restricted to a few standard types, versatile tip

fabrication remains of great interest to scientists working in

the area of fiber optics[4,5,6] . However, its cost is rather high

and the probability to create optical fibre nanoprobe in great

quantity has not been realized, which is a disadvantage to

commercial applications of the nanoprobe[5,7]. Two main

techniques have been used for the fabrication of tapered fibers:

pulling under laser heating and chemical etching. The pulling

technique has been quite well characterized and generally

offers tips with small cone angles which yield low optical

throughput. Fiber probes produced by chemical etching

usually provide higher optical throughput due to larger cone

angles and conservation of the fiber core up to the tip

apex[2,8]. In this paper, our target is to produced fine optical

fibre nanoprobes in large quantities which potentially able to

offer optical resolution in the sub-100 nm range under simple

experimental conditions with low cost. To maintain theoritical

size of the aperture, the tip is covered with an adjustable layer

of metal coating which shows refractive index close to that of

SiO2 so that can avoids an undesirable optical gap with the

substrate fiber.

II.

I.

TAPPERING OF FIBER BY CHEMICAL ETCHING

INTRODUCTION

With the development of SNOM, optical fibre nanoprobe

has made great progress in some novel application fields[1].

Nano optical fiber probe is a powerful tool for small and

nanometric object imaging. The high spatial resolution of nano

probe is defined largely by the aperture diameter of the optical

fiber probe as well as the tip-sample distance. This technique

allows us to probe optical phenomena into the sub-100nm

regime. The probe tip is a key element that determines the

www.ijsres.com

The most conventional technique to taper the fiber by

chemical etching is to use of BHF(Buffer Hydro Fluric

Acid)[2,9].We performed this technique to compare our new

technique.

Chemical Reaction[2,9]: Sio2 + 4HF = SiF4 + 2H2O,

SiO2 + HF = SiF4 + H2O

Page 17

International Journal of Scientific Research and Engineering Studies (IJSRES)

Volume 1 Issue 4, October 2014

ISSN: 2349-8862

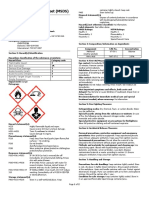

Concentration of

40%

35%

30%

25%

20%

acid

TimeforTapering:

28

35

35

47

55

Sample-1

mins

mins

mins

mins

mins

TimeforTapering:

25

29

40

40

58

Sample-2

mins

mins

mins

mins

mins

TimeforTapering:

27

39

42

49

52

Sample-3

mins

mins

mins

mins

mins

TimeforTapering:

29

32

38

50

65

Sample-4

mins

mins

mins

mins

mins

TimeforTapering:

30

30

42

45

63

Sample-5

mins

mins

mins

mins

mins

Table 1: represent etching rate in BHF solution with time for

sample fiber(100 micro meter single mode fiber) to get nano

pencil tips

In this method etching process is very slow and also

maintaining buffer state of the acid is very difficult task .So

we used here a new technique of direct use of HF(Hydro

Fluric Acid) known as Hydromechanical etching technique to

taper the fiber with faster rate.

Required chemicals:

i.HF acid(40% dilute)& ii.Oil

(Silicone oil)

Chemical Reaction: Sio2 + 4HF = SiF4 + 2H2O, SiO2 +

HF = SiF4 + H2O

Concentration of 40%

35%

30%

25%

20%

acid

TimeforTapering: 18

22

23

30

30

Sample-1

mins

mins

mins

mins

mins

TimeforTapering: 15

22

25

32

40

Sample-2

mins

mins

mins

mins

mins

TimeforTapering: 12

24

20

35

38

Sample-3

mins

mins

mins

mins

mins

TimeforTapering: 15

19

19

28

39

Sample-4

mins

mins

mins

mins

mins

TimeforTapering: 17

20

25

27

43

Sample-5

mins

mins

mins

mins

mins

Table 2: represent etching rate in HF solution with time for

sample fiber(100 micro meter single mode fiber) to get nano

pencil tips

It is very difficult to hold the fiber manually so that the

end surface of the fiber is into HF solution. As it is the most

important step of etching so we used the technique of selective

chemical etching.

A. EXPERIMENTAL SETUP

Required equipments (i) Microscope without optics as a

fiber stand (ii) Glass beaker (iii) Teflon beaker (iv)Liqued

Acetone (v) HF acid (40% wt. dilute) (vi) Optical microscope

(vii) CCD (viii) Scanning Electron Microscope(SEM) (ix)

Aluminium foil

B. EXPERIMENTAL PROCEDURE

At first the fiber is dipped into Acetone consists in a glass

beaker for five minutes to remove the plastic jacket of the

fiber[2,10]. Thus we get bare fiber as shown in the adjacent

figure.

www.ijsres.com

Figure1: Fiber dipped into acetone solution

Figure 2: Total fiber

Figure 3: Bare fiber after dipped

Then we dipped the bare fiber into HF (40%wt. dilute)

consists in a teflon beaker. This step is very crucial to get a

sharp tip (pencil shaped) of the fiber. For this purpose we used

our own arrangement to get selective etching of the fiber.

Adjasent picture shown our experimental arrangement. In this

arrangement a microscope table is used to dipped the fiber

into HF solution. In this setup we can move the fiver up and

down into the HF solution by the help of microscope screw.

To get pencil tip we have etched the fiber in two ways:

Firstly it is moving downwards by the help of microscope

screw so that the tip of the fiber exist more time with HF (40%

wt) contact than the remaining part of the fiber.

In second method we dipped the fiber into HF (40% wt)

and after a certain interval of time we rotate the screw of the

microscope to move the fiber upward direction so that the tip

Page 18

International Journal of Scientific Research and Engineering Studies (IJSRES)

Volume 1 Issue 4, October 2014

ISSN: 2349-8862

of the fiber exist more time with HF contact than the

remaining part of the fiber.

The adjasent figure shown my experimental arrangement.

Here we have seen that the tip end of the fibers are very

sharp and in nano range.

Figure 4:Moving downwards into HF solution

Figure 8: Sharp pencil shaped nano fiber tips

Figure 5: Fiber moving upwards from HF solution

But the experiment given us more better result in second

method rather than first one ,so our entire experimental result

based on this method.

In this method fiber is dipped for tweenty five minutes

into the HF solution. To get sharp tip care should be taken

from eighteen minutes after dipped the fiber. From this instant

of time movement of the fiber made very slowly through the

microscope screw and observe carefully so that the sharp tip

end will not break due to excess etching, this step is very

crucial to get sharp pencil shaped tip of the fiber in nano

scale.We have given below some pictures of tapered fiber

taken by optical microscope with the help of ccd.

Figure 9: Exactly pencil shaped fiber tips

Snapshot shown above that the shape of the fiber is

exactly like a pencil but the tip is not in nano range due to the

mechanical damage of the tip.

After that the sub-wavelength apertures of the probe are

then defined by coating the sides of the tapered fiber with

metal. This is usually done with electron beam or thermal

evaporation. We have performed with aluminium foil

evaporation process[11]. Aluminum is the most commonly

used material because it has the smallest penetration depth in

the visible and it forms a smooth film. Typical thickness is

100 nm.Chromium/gold and silver have also been used, but

they tend to form islands. Having a smooth metal coating is

essential because light can leak out of the tapered fiber

between metal islands, i.e. pinholes.

The following figure shown the different layers of the

probe which we want to fabricate.

Figure 6: Fine structure of fiber nano tip

Figure 7: Fine structure of sharp nano tip

Figure 10: Different layers of the fiber

www.ijsres.com

Page 19

International Journal of Scientific Research and Engineering Studies (IJSRES)

Volume 1 Issue 4, October 2014

ISSN: 2349-8862

Figure 10: SEM image of fiber tip

The figure given below shown the SEM image of Al

coated fiber optic probe in diametric view.

Figure 14: SEM image of gold coated fiber

SEM image of Al coated sample.

Figure 11: SEM image of broken tip fiber

Figure 15: Projected SEM image of 200 nm tip

Figure 12: SEM image of fabricated fiber

SEM image of gold coated optical fiber.

Figure 16: Simulated SEM image of 300 nm tip

Selected tips are SEMed after Al deposition to examine

the smoothness of the Al coating and to measure actual

aperture diameter. A more applicable geometry

experiment in the microwave regime suggest a

of aperture. To yield high resolution images, the probe must

be held in the near-field of the sample. Light quickly diffracts

after leaving the aperture. Since the mode diameter of the

fiber tip is significantly larger than the final tip size,much of

the optical intensity is not confined in the fiber near the end of

the taper. The tapering process also introduces additional

scattering. Hence, a significant amount of the power is

absorbed by the Al coating and causes heating.

Figure 13: SEM imge of unprotected gold coated fiber

www.ijsres.com

Page 20

International Journal of Scientific Research and Engineering Studies (IJSRES)

Volume 1 Issue 4, October 2014

ISSN: 2349-8862

III.

CONCLUSIONS

In this experiment, the Hydromechanical etching method

is proposed, and the desirable tips are created. In this method,

fibre firstly is dipped into acetone to remove the jacket. Next,

the tip can be etched in HF solution through some mechanical

arrangement to create the nanoprobe. Based on the etching

mechanisms, the tip can be dipped into HF solution repeatedly

if a nanoprobe is not realized last etching. When the

nanoprobe is obtained, it is coated with aluminum by vapour

deposition echnique. Finally, data can be collected by the

nanoprobe sensitively, which possibly benefit the fluorescent

spectral detection of micro and nano-sample. The applicability

of Optical fiber probe as a real-time in-situ probe increasing

very fastly hence the implimentation of new and simple

tecnique is precisely a prolific step towards the improvement

of this technology we can proposed to make AFM tips in this

technique in future.

IV.

ACKNOWLEDGEMENT

I would like to express my heartiest gratitude to Dr. Rajib

Chakraborty, Associate Professor, Department of Applied

Optics & Photonics, University of Calcutta under whose

guidance I did this project. Developing new technique with the

help of H.O.D Dr. Kallol Bhattacharya was indeed an

extremely enjoyable experience and I would like to thank him

for his entire support. I am very greatful to Dr. Anima Sen,

Ex.H.O.D USIC, CU for her encouragement and endeavour

support. Finally I would like to thank technical stuffs of

CRNN, CU Tridip Das and special thanks to research scholar

Ranjit Da at Department of Applied Optics &Photonics as a

whole which gave me an opportunity to undertake this project.

REFERENCES

[1] Fabrication of optical fiber probes for scanning near-field

optical microscopy ,Department of Physics, McGill

University, 3600 University, Montreal, Canada, H3A 2T8

,Si Yue Guo, Jeffrey M. LeDue, Peter Grutte

[2] M. Ohtsu , Progress of high-resolution photon scanning

tunnelingmicroscopy due to a nanometric fiber probe,

J.Lightwave Technol. Vol. 13, pp. 1200-1221,1995.

www.ijsres.com

[3] H.D. Hallen, A.H. La Rosa, and C.L. Jahncke,Physics

Department, North Carolina State University,Raleigh,

North Carolina 27695-8202

[4] Julia W.P. Hsu,Bell Labs, Lucent Technologies, 1-D-368,

600-700 Mountain Avenue, Murray Hill, NJ 07974,

USA,Accepted 15 December 2000

[5] The preparation of optical fibre nanoprobe and its

application in spectral detection Hongliang Rena, Chun

Jianga, Weisheng Hua, Mingyi Gaoa, Jingyuan Wanga,

Hui Wangb, Jintian Hec, Erjun Liangc a State Key

Laboratory of Advanced Optical Communication Systems

and Networks, Shanghai Jiao Tong University, Shanghai

200240, China ,bInstitute of Science, Zhanjiang Ocean

University, Zhanjiang 524025, China ,cInstitute of

Physical Engineering, Zhengzhou University, Zhengzhou

450052, China ,Received 28 November 2005; received in

revised form 21 April 2006; accepted 21 April 2006

[6] The preparation of optical bre nanoprobe and its

application in spectral detection Hongliang Rena, Chun

Jianga, Weisheng Hua, Mingyi Gaoa, Jingyuan Wanga,

Hui Wangb, Jintian Hec, Erjun Liangc a State Key

Laboratory of Advanced Optical Communication Systems

and Networks, Shanghai Jiao Tong University, Shanghai

200240, China ,bInstitute of Science, Zhanjiang Ocean

University, Zhanjiang 524025, China ,cInstitute of

Physical Engineering, Zhengzhou University, Zhengzhou

450052, China ,Received 28 November 2005; received in

revised form 21 April 2006; accepted 21 April 2006

[7] Mekis A, Joannopoulous JD. Tapered couplers for efficient

interfacing between dielectric and photonic crystal waveguides. IEEE J Lightwave Technol 2001;19:861.

[8] Lambelet P, Sayah A, Pfeffer M. Chemically etched fiber

tips for near-field optical microscopy: a process for

smoother tips. Appl Opt 1998;37:7289

[9] N. Chevalier, Y. Sonnefraud, J. F. Motte, and S. Huanta

Laboratoire de Spectromtrie Physique, CNRS, and

Universit Joseph Fourier, Grenoble BP 87, 38402

SaintMartin dHres, France,K. Karrai Center for

NanoScience, Department fr Physik, LudwigMaximilians-Universitt, Geschwister-Scholl-Platz 1,

80539 Mnchen, Germany,Received 9 March 2006;

accepted 7 May 2006; published online 16 June 2006

[10] Taylor, R.S. Bent Fiber Near-Field Optical Microscopy

Probes for Use With Commercial Atomic-Force Microscopes, Proc. SPIE, vol. 3009, 1997, p.119-129.

[11] E. Cefal`, S. Patane, PG. Gucciardi, M. Labardi, M.

Allegrini J Of Microscopy 210, 262 (2003)

Page 21

You might also like

- Experimental Investigation of Forced Circulation Solar Air Heater Along With Integrated Solar Collector and Phase Change Material (Paraffin Wax)Document11 pagesExperimental Investigation of Forced Circulation Solar Air Heater Along With Integrated Solar Collector and Phase Change Material (Paraffin Wax)International Journal of Scientific Research and Engineering StudiesNo ratings yet

- Combinatorial Interpretation of Some Rogers-Ramanujan Type IdentitiesDocument4 pagesCombinatorial Interpretation of Some Rogers-Ramanujan Type IdentitiesInternational Journal of Scientific Research and Engineering Studies100% (1)

- Components of Supply Chain Management in The Manufacturing SectorDocument4 pagesComponents of Supply Chain Management in The Manufacturing SectorInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Effective Awareness Creation and Sensitization As A Support To Waste Management Practices in EnuguDocument4 pagesEffective Awareness Creation and Sensitization As A Support To Waste Management Practices in EnuguInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Online Travel Agency Using Robust Module Based Data ManagementDocument4 pagesOnline Travel Agency Using Robust Module Based Data ManagementInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- MX/G (A, B) /1 With Different Thershold Policies For Vacations and Optional Re-ServiceDocument7 pagesMX/G (A, B) /1 With Different Thershold Policies For Vacations and Optional Re-ServiceInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Study of Performance of Single Cylinder Diesel Engine With Mullite As Thermal Barrier CoatingDocument3 pagesStudy of Performance of Single Cylinder Diesel Engine With Mullite As Thermal Barrier CoatingInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- High Reliability and Efficiency Single-Phase Transformerless Inverter For Grid-Connected Photovoltaic SystemsDocument6 pagesHigh Reliability and Efficiency Single-Phase Transformerless Inverter For Grid-Connected Photovoltaic SystemsInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Pollutant Levels of The Lake Water in Lake "TADIE"Document6 pagesPollutant Levels of The Lake Water in Lake "TADIE"International Journal of Scientific Research and Engineering StudiesNo ratings yet

- E-Commerce in India Future and Its Perspective: A StudyDocument7 pagesE-Commerce in India Future and Its Perspective: A StudyInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Preliminary Chemical Analysis of Shea Butter Tree (Butyrospermum Parkii) LatexDocument9 pagesPreliminary Chemical Analysis of Shea Butter Tree (Butyrospermum Parkii) LatexInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Point Spread Functions of Aberrated Optical Systems With Annular AperturesDocument3 pagesPoint Spread Functions of Aberrated Optical Systems With Annular AperturesInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Design and Development of Embedded System Based Multimedia SteganographyDocument4 pagesDesign and Development of Embedded System Based Multimedia SteganographyInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Constant Log BCJR Turbo Decoder With Pipelined ArchitectureDocument5 pagesConstant Log BCJR Turbo Decoder With Pipelined ArchitectureInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Recognition of Proximity and Phantom Nodes in Mobile Ad Hoc NetworksDocument9 pagesRecognition of Proximity and Phantom Nodes in Mobile Ad Hoc NetworksInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- A Novel Loaded-Resonant Converter For The Application of Solar (DC) - TO-DC Energy ConversionsDocument9 pagesA Novel Loaded-Resonant Converter For The Application of Solar (DC) - TO-DC Energy ConversionsInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- The Burden of Nutritional Anaemia Among Adolescent Girls in Muzaffarpur District of BiharDocument3 pagesThe Burden of Nutritional Anaemia Among Adolescent Girls in Muzaffarpur District of BiharInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Voice Activated Traffic Management System Using Apr 9600 Based On Embedded SystemDocument7 pagesVoice Activated Traffic Management System Using Apr 9600 Based On Embedded SystemInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Relevance of Various Fungicides For The Control of Powdery Mildew Leaf Spot Disease of Niger (Guizotia Abyssinica Cass) Under South Gujarat RegionDocument3 pagesRelevance of Various Fungicides For The Control of Powdery Mildew Leaf Spot Disease of Niger (Guizotia Abyssinica Cass) Under South Gujarat RegionInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Optimization and Mapping of The Process of Tariff Determination by The Electricity Regulator's in Context of Indian Power SectorDocument10 pagesOptimization and Mapping of The Process of Tariff Determination by The Electricity Regulator's in Context of Indian Power SectorInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Optimization and Mapping of The Process of Tariff Determination by The Electricity Regulator's in Context of Indian Power SectorDocument10 pagesOptimization and Mapping of The Process of Tariff Determination by The Electricity Regulator's in Context of Indian Power SectorInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Increased Prevalence of Dermographism, Filariasis, Mosquito Borne Diseases and Rising Environmental Estrogen Equating With Aborted Blood, Contraceptive Menstrual Blood PollutionDocument6 pagesIncreased Prevalence of Dermographism, Filariasis, Mosquito Borne Diseases and Rising Environmental Estrogen Equating With Aborted Blood, Contraceptive Menstrual Blood PollutionInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Analysis of Unsatisfactory Category of 1601 Cases of Breast Cytology - An Institutional StudyDocument4 pagesAnalysis of Unsatisfactory Category of 1601 Cases of Breast Cytology - An Institutional StudyInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pixl Knowit!: Gcse BiologyDocument66 pagesPixl Knowit!: Gcse BiologyEsther SparksNo ratings yet

- Special Safety Practices For CSL2Document1 pageSpecial Safety Practices For CSL2ipliprensNo ratings yet

- DistillationDocument12 pagesDistillationAbhishek SardaNo ratings yet

- Chemical EOR S2 1Document199 pagesChemical EOR S2 1Amry Sitompul100% (1)

- Lied Mann 2017Document8 pagesLied Mann 2017Chandra SekarNo ratings yet

- Pinch TechnologyDocument7 pagesPinch TechnologyAakanksha MahajanNo ratings yet

- Nital EtchDocument2 pagesNital EtchJohn GeddesNo ratings yet

- FTIR Determination of Unsaturation Grade & Isomers FatDocument6 pagesFTIR Determination of Unsaturation Grade & Isomers FatrajdewaanNo ratings yet

- Algal Oil Production: Modeling and Evaluation Using Superpro DesignerDocument26 pagesAlgal Oil Production: Modeling and Evaluation Using Superpro DesignerMira FazziraNo ratings yet

- Profile Sections and Molded Parts Made From Elastomers (EPDM) in The Body AreaDocument13 pagesProfile Sections and Molded Parts Made From Elastomers (EPDM) in The Body AreaNagarajan DS100% (1)

- Adapaleno - Clindamicina Gel HPLCDocument5 pagesAdapaleno - Clindamicina Gel HPLCDavid SanabriaNo ratings yet

- Bft60a Bfw60a Eu WebDocument618 pagesBft60a Bfw60a Eu WebvixentdNo ratings yet

- TP7 TP8manualDocument10 pagesTP7 TP8manualJuanita Ariza BernalNo ratings yet

- Lamb Meat NutritionDocument3 pagesLamb Meat NutritionMuhammad MuhsininNo ratings yet

- Cambridge International AS & A Level: Chemistry 9701/12Document16 pagesCambridge International AS & A Level: Chemistry 9701/12O and A Level TutorNo ratings yet

- Module 2 - Drug AbuseDocument35 pagesModule 2 - Drug AbuseMark Johnuel DuavisNo ratings yet

- MSC Thesis Updated Today PDFDocument89 pagesMSC Thesis Updated Today PDFDaguale Melaku AyeleNo ratings yet

- SK HazraDocument18 pagesSK HazraDr Sunipa RoyNo ratings yet

- Sanitary Engineering Lec.: November 2015Document110 pagesSanitary Engineering Lec.: November 2015Dynamo DSNo ratings yet

- Oasis Pro 20Document5 pagesOasis Pro 20Prosenjit76No ratings yet

- Sizing Up The Valve Guide: by Dave MonyhanDocument4 pagesSizing Up The Valve Guide: by Dave MonyhanRidwanUsmanNo ratings yet

- Castrol The Oil FactorDocument19 pagesCastrol The Oil FactorPrabhu LohakareNo ratings yet

- DroperidolDocument1 pageDroperidolIvanne HisolerNo ratings yet

- TB400 Painting and Corrosion ProtectionDocument21 pagesTB400 Painting and Corrosion ProtectionAliZenatiNo ratings yet

- FibreGlast 2023-2024 CatalogDocument56 pagesFibreGlast 2023-2024 Catalogcesar martinezNo ratings yet

- Barbicide MsdsDocument3 pagesBarbicide MsdstudorcerneaNo ratings yet

- Elements Compounds and Mixtures Revision 1Document6 pagesElements Compounds and Mixtures Revision 1api-310569693No ratings yet

- Concentration Term Jee Main Selected 2Document3 pagesConcentration Term Jee Main Selected 2aebafbigiNo ratings yet

- Axis TurbineDocument7 pagesAxis TurbineBhertrand GomesNo ratings yet

- CBLM SampleDocument26 pagesCBLM SampleMaryjane Binag Gumiran100% (1)