Professional Documents

Culture Documents

Prelubrication System Test

Uploaded by

Manolo AntonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prelubrication System Test

Uploaded by

Manolo AntonCopyright:

Available Formats

D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 En...

Pgina 1 de 9

Cerrar SIS

Pantalla anterior

Producto: TRACK-TYPE TRACTOR

Modelo: D8T TRACK-TYPE TRACTOR J8B

Configuracin: D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 Engine

Localizacin y Solucin de Problemas

C15 and C18 Engines for D8T and D9T Track-Type Tractors and for 583T and 587T Pipelayers

Nmero de medio -SENR9748-04

Fecha de publicacin -01/09/2008

Fecha de actualizacin -23/09/2008

i02500720

Prelubrication System - Test

SMCS - 1319-038

System Operation Description:

Use this procedure to troubleshoot any suspect problems with the prelube system.

This procedure covers the following diagnostic codes:

338-05 Pre-Lube Relay open circuit

338-06 Pre-Lube Relay short to ground

The Electronic Control Module (ECM) has the ability to automatically lubricate the engine before cranking.

This feature is enabled in the system configuration parameters. This may increase the life of certain engine

parts by lubricating the parts before the starting motor is engaged.

The prelubrication system is activated when the keyswitch is turned to the START position and the ECM

has received a request from the power train ECM in order to activate the prelube system. The prelube motor

will run until either the oil pressure is 15 kPa (2 psi) or the prelube motor has run for 45 seconds. The

prelube motor will continue to run during the crank cycle. The keyswitch must remain in the START

position for the duration of the prelube cycle.

The prelubrication system will not activate if the engine coolant temperature is above 49 C (120 F).

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 12/04/2011

D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 En...

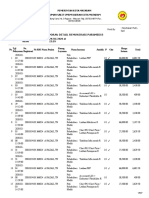

Illustration 1

Pgina 2 de 9

g01250692

Schematic for the engine prelube system

Test Step 1. Inspect the Electrical Connectors and the Wiring

A. Turn the keyswitch to the OFF position.

B. Turn the battery disconnect switch to the OFF position.

Illustration 2

g01250707

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 12/04/2011

D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 En...

Pgina 3 de 9

Locations of the components for the engine prelube system (typical left side engine view)

(1) Engine prelube relay

(2) Connector for the engine prelube system

(3) J1/P1 ECM connectors

C. Thoroughly inspect the terminal connections at relay (1). Also, thoroughly inspect connectors (2) and

(3). Inspect all of the other connectors for the circuit. Refer to Troubleshooting, "Electrical Connectors

- Inspect" for details.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 12/04/2011

D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 En...

Illustration 3

Pgina 4 de 9

g01250714

Terminal locations at the P1 ECM connector for the engine prelube system

(P1-13) Prelube relay

(P1-18) Digital return

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 12/04/2011

D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 En...

Illustration 4

Pgina 5 de 9

g01155187

Terminal locations at the connector for the engine prelube relay

(Terminal 1) Prelube relay

(Terminal 2) Digital return

D. Perform a 45 N (10 lb) pull test on each of the wires in the ECM connector that are associated with the

circuit.

E. Check the allen head screw for each of the ECM connectors and the machine connectors for the proper

torque. Refer to Troubleshooting, "Electrical Connectors - Inspect" for the correct torque values.

F. Check the harness and wiring for abrasion and for pinch points from the sensors back to the ECM.

Expected Result:

All connectors, pins, and sockets are completely coupled and/or inserted. The harness and wiring are free of

corrosion, of abrasion, and of pinch points.

Results:

OK - The harness and connectors appear to be OK. Proceed to Test Step 2.

Not OK - There is a problem in the connectors and/or wiring.

Repair: Repair the connectors or wiring and/or replace the connectors or wiring. Ensure that all of the

seals are properly in place and ensure that the connectors are completely coupled.Verify that the repair

eliminates the problem.

STOP

Test Step 2. Check for Active Diagnostic Codes

A. Connect Caterpillar Electronic Technician (ET) to the service tool connector.

B. Turn the battery disconnect switch to the ON position.

C. Turn the keyswitch to the ON position.

D. Proceed to the "Diagnostic Overrides" screen on Cat ET.

E. Activate the override for the engine prelube system.

F. Monitor the active diagnostic code screen on Cat ET. Check and record any active diagnostic codes.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 12/04/2011

D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 En...

Pgina 6 de 9

Note: Wait at least 30 seconds in order for the diagnostic codes to become active.

G. Turn the keyswitch to the OFF position.

H. Determine if the problem is related to an open circuit diagnostic code 05 or a short circuit diagnostic

code 06.

Expected Result:

No diagnostic codes are active.

Results:

OK - No diagnostic codes are active.

Repair: The problem may have been related to a faulty connection in the harness. Carefully reinspect

the connectors and wiring. If an intermittent electrical problem is suspected, refer to Troubleshooting,

"Electrical Connectors - Inspect".

STOP

Active 06 Code - A short circuit diagnostic code (06) is active at this time. Proceed to Test Step 3.

Active 05 Code - An open circuit diagnostic code (05) is active at this time. Proceed to Test Step 4.

Test Step 3. Create an Open at the Prelube Relay

A. Disconnect the wires from terminals G and S at the prelube relay.

B. Turn the keyswitch to the ON position.

C. Proceed to the "Diagnostic Overrides" screen on Cat ET.

D. Activate the prelube override.

E. Monitor the active diagnostic code screen on Cat ET. Check for an active open circuit diagnostic code

(05) for the prelube relay.

Note: Wait at least 30 seconds in order for the diagnostic codes to become active.

F. Turn the keyswitch to the OFF position.

Expected Result:

An open circuit diagnostic code 05 is now active for the prelube relay.

Results:

OK - A short circuit diagnostic code (06) was active before disconnecting the wiring. An open circuit

diagnostic code (05) became active after disconnecting the wiring.

Repair: There is a problem with the prelube relay. Temporarily connect a new prelube relay to the

harness, but do not install the new relay. Verify that there are no active diagnostic codes for the new

relay. If there are no active diagnostic codes for the relay, permanently install the new prelube relay.

Clear any logged diagnostic codes.

STOP

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 12/04/2011

D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 En...

Pgina 7 de 9

Not OK - An short circuit diagnostic code 06 remains active for the prelube relay. The problem is in

the harness between the ECM and the prelube relay. There may be a problem with the ECM. Restore

the wiring to the original configuration. Proceed to Test Step 5.

Test Step 4. Create a Short at the Prelube Relay

A. Disconnect the wires from terminals G and S at the prelube relay.

B. Short circuit the two wires from the prelube relay.

C. Turn the keyswitch to the ON position.

Note: Monitor the "Active Diagnostic Codes" screen on Cat ET after the wires have been shorted.

D. Proceed to the "Diagnostic Overrides" screen on Cat ET.

E. Activate the prelube override.

F. Wait at least 30 seconds for activation of the short circuit diagnostic code 06.

G. Turn the keyswitch to the OFF position.

Expected Result:

A short circuit diagnostic code 06 is active when the wires are shorted. An open circuit diagnostic code 05 is

active when the wires are not shorted.

Results:

OK - A short circuit diagnostic code 06 is active when the wires are shorted. An open circuit

diagnostic code 05 is active when the wires are not shorted.

Repair: The engine harness and the ECM are OK. There is a problem with the prelube relay.

Temporarily connect a new prelube relay to the harness, but do not install the new relay. Verify that

there are no active diagnostic codes for the new relay. If there are no active diagnostic codes for the

relay, permanently install the new prelube relay. Clear any logged diagnostic codes.

STOP

Not OK - The open circuit diagnostic code 05 remains active when the wires are shorted. The problem

is in the harness between the ECM and the prelube relay. There may be a problem with the ECM.

Restore the wiring to the original configuration. Proceed to Test Step 5.

Test Step 5. Check the Operation of the ECM

A. Disconnect the J1/P1 ECM connectors.

B. Fabricate two jumper wires that are long enough to create a short circuit at the ECM connector. Crimp

connector sockets to one end of each of the jumper wires.

C. Remove the wires from terminal locations P1-13 and P1-18 at the ECM connector. Install the jumper

wires into these terminal locations.

D. Connect the J1/P1 ECM connectors.

E. Check the operation of the ECM by creating an open at the ECM.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 12/04/2011

D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 En...

Pgina 8 de 9

a. Hold the loose ends of the jumper wires away from any ground source.

b. Turn the keyswitch to the ON position.

c. Proceed to the "Diagnostic Overrides" screen on Cat ET.

d. Activate the prelube override.

Note: Monitor the "Active Diagnostic Codes" screen on Cat ET.

e. Wait at least 30 seconds for activation of the open circuit diagnostic code 05.

f. Turn the keyswitch to the OFF position.

F. Check the operation of the ECM by creating a short at the ECM.

a. Short circuit the loose ends of the jumper wires.

b. Turn the keyswitch to the ON position.

c. Proceed to the "Diagnostic Overrides" screen on Cat ET.

d. Activate the prelube override.

Note: Monitor the "Active Diagnostic Codes" screen on Cat ET.

e. Wait at least 30 seconds for activation of the short circuit diagnostic code 06.

G. Turn the keyswitch to the OFF position. Restore all wiring to the original configuration.

Expected Result:

An open circuit diagnostic code 05 is active when the jumper wires are open. A short circuit diagnostic code

06 is active when the jumper wires are shorted.

Results:

OK - An open circuit diagnostic code 05 is active when the jumper wires are open. A short circuit

diagnostic code 06 is active when the jumper wires are shorted.

Repair: The ECM is operating correctly. The problem is in the wiring harness between the ECM and

the prelube relay. Repair the connectors or wiring and/or replace the connectors or wiring. Verify that

the problem is resolved.

STOP

Not OK - One of the following conditions exists: The open circuit diagnostic code 05 is not active

when the wire for the prelube relay is disconnected. The short circuit diagnostic code 06 is not active

when the wire jumper is installed.

Repair: There is a problem with the ECM. Replace the ECM. Refer to Troubleshooting, "Replacing

the ECM" before you replace the ECM. Verify that the problem is resolved.

STOP

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 12/04/2011

D8T TRACK-TYPE TRACTOR J8B00001-UP (MACHINE) POWERED BY C15 En...

Copyright 1993 - 2011 Caterpillar Inc.

Pgina 9 de 9

Tue Apr 12 10:34:04 MST 2011

Todos los derechos reservados.

Red privada para licenciados del SIS.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 12/04/2011

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tables of Contents: ParveenDocument7 pagesTables of Contents: ParveensambhajiNo ratings yet

- High-Performance Butterfly Valve Specs and DetailsDocument6 pagesHigh-Performance Butterfly Valve Specs and DetailsSergio Gaete CovarrubiasNo ratings yet

- Lesson 4 Obstacle Avoidance CarDocument13 pagesLesson 4 Obstacle Avoidance CarAdrian ChelenNo ratings yet

- 3.1 Metal RemovalDocument40 pages3.1 Metal RemovalMichael Kearney50% (2)

- 25KV Current TransformerDocument4 pages25KV Current TransformerKamlesh MhatreNo ratings yet

- Wilcox RAPTAR S Operator ManualDocument114 pagesWilcox RAPTAR S Operator ManuallazersteveNo ratings yet

- Poli Rehabilitasi Medik PDFDocument607 pagesPoli Rehabilitasi Medik PDFzakaria ezisNo ratings yet

- Understanding Polaroid SX-70 Manipulation Techniques (40Document18 pagesUnderstanding Polaroid SX-70 Manipulation Techniques (40epicenter75100% (1)

- EURODIMA Catalogue - 3-3Document1 pageEURODIMA Catalogue - 3-3Music NetNo ratings yet

- SB2X 22 06Document7 pagesSB2X 22 06Michael BuntonNo ratings yet

- Commissioning: Commissioning P63X/Uk Cm/A54 Micom P631, P632, P633, P634Document31 pagesCommissioning: Commissioning P63X/Uk Cm/A54 Micom P631, P632, P633, P634anon_143821310No ratings yet

- Restraints - 07 CX7Document98 pagesRestraints - 07 CX7sled novaNo ratings yet

- Wiring9001 1Document6 pagesWiring9001 1Marck JunoNo ratings yet

- NTS, Ntu eDocument29 pagesNTS, Ntu eKuroba KojiNo ratings yet

- Hardened Full Length Moldboard Rails Are Available For Parts Service (6151)Document7 pagesHardened Full Length Moldboard Rails Are Available For Parts Service (6151)wemersonsrNo ratings yet

- CONTRACT MANUAL FOR PULSE-JET FABRIC FILTERDocument5 pagesCONTRACT MANUAL FOR PULSE-JET FABRIC FILTERAmit SinghNo ratings yet

- F25-CP-01-X-1 - FCPG-E05B - Iraq - 1Document2 pagesF25-CP-01-X-1 - FCPG-E05B - Iraq - 1ahmedNo ratings yet

- MB27 PDFDocument2 pagesMB27 PDFumarNo ratings yet

- MRJ4 Servo Manual PDFDocument580 pagesMRJ4 Servo Manual PDFĐỗ Tuấn BằngNo ratings yet

- 5R55N Seminar InfoDocument18 pages5R55N Seminar InfocarlosNo ratings yet

- 20 Medical Equipment FunctionsDocument8 pages20 Medical Equipment FunctionsYunita HarahapNo ratings yet

- Cherry KeyboardDocument2 pagesCherry KeyboardKheshav JhundooNo ratings yet

- DBC1 AVR SINCRO MANUAL - Rev02Document12 pagesDBC1 AVR SINCRO MANUAL - Rev02jean sanchezNo ratings yet

- Fiber Optic Cable Types - Single Mode Vs Multimode Fiber Cable - FS Community - HTMLDocument9 pagesFiber Optic Cable Types - Single Mode Vs Multimode Fiber Cable - FS Community - HTMLwaqas_a_shaikh4348No ratings yet

- Application Note #120: Schneider ElectricDocument7 pagesApplication Note #120: Schneider ElectricraviNo ratings yet

- Kenr1689 PDFDocument2 pagesKenr1689 PDFslawny77No ratings yet

- 1 Sensor 12v Connection DiagramDocument1 page1 Sensor 12v Connection DiagramHenri KleineNo ratings yet

- Federal Electric - Short Catalogue 2016 PDFDocument28 pagesFederal Electric - Short Catalogue 2016 PDFzohaib khalidNo ratings yet

- January 17, 2020 appliance quotationDocument5 pagesJanuary 17, 2020 appliance quotationJordan Beleciña BlancoNo ratings yet

- Ed sq2 3ph 200 60 s2 15 enDocument2 pagesEd sq2 3ph 200 60 s2 15 ensáng nguyễnNo ratings yet