Professional Documents

Culture Documents

Glass Block: High Performance, Sustainable Design & Daylighting

Uploaded by

Hanley Wood UniversityOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glass Block: High Performance, Sustainable Design & Daylighting

Uploaded by

Hanley Wood UniversityCopyright:

Available Formats

CONTINUING EDUCATION

GLASS BLOCK

Presented by:

HIGH PERFORMANCE, SUSTAINABLE DESIGN & DAYLIGHTING

LEARNING OBJECTIVES

At the end of this program, participants will be able to:

1. List and describe the types of glass block products

that are available, including energy efficient

systems that optimize energy performance.

2. Explain how glass block systems contribute to

LEED points.

3. Discuss how innovative glass block systems

contribute to the health, safety and welfare of

building occupants.

4. Identify the green features of glass block that

combine to provide a building material that

plays a significant role in sustainable design and

daylighting strategies.

CONTINUING EDUCATION

CREDIT: 1 LU

COURSE NUMBER: ARjan2015

GBCI: 1 CE Hour

GBCI NUMBER: 0920001951

Use the learning objectives to focus your study as

you read this article. To earn credit and obtain a

certificate of completion, visit http://go.hw.net/

AR115Course1 and complete the quiz for free

as you read this article. If you are new to Hanley

Wood University, create a free learner account;

returning users log in as usual.

By Marissa Hovraluck

INTRODUCTION

As a proven natural building material, glass

block can add beauty and inspiration to a

project, while playing a significant role in

sustainable design. Glass block is 100%

recyclable, low- maintenance, and highly

durable, yet its dynamic relationship with

light provides architects the opportunity to

create both aesthetically pleasing and energy

efficient spaces.

With low construction waste, glass block is

considered an environmentally preferable

product, made largely from sand, an abundant

raw material, and limestone.

ENERGY EFFICIENCY

keep interiors warmer in the winter and

cooler in the summer. It filters out about 70%

of total solar energy while still allowing for

superior day lighting. And with an insulating

U-Value of 0.34, unframed, these panels can

keep HVAC costs in line too. Panels framed by

a 2-piece aluminum channel have a U-Value

of 0.38. The lower U-value associated with

unframed and framed panels indicate their

high levels of insulation.

Energy efficient glass block panels let in the

suns light, but also keep out the heat. The

blocks are aesthetically pleasing and functionally smart as they feature a low-emissivity

coated glass panel sandwiched inside to help

Glass block can provide more than double the

thermal resistance, or R-Value, of a single-glaze

1/8" thick plate glass. Glass block also provides

an R-value that is equivalent to a standard

thermal pane window. Also, the louvering

With a range of sizes, styles and patterns,

building with glass block offers tremendous

design versatility. Because of its versatility, it

can be used in a wide variety of projects, and

offers a universal appeal. Glass block walls,

partitions and windows combine the beauty

and light transmission of glass with

the strength of glass block.

CONTINUING EDUCATION

effect of glass blocks horizontal mortar joints

helps to reduce the light transmission from

the higher summer sun. The mortar used in

between the blocks helps to create a shade

from the high summer sun. However, during

the winter, the rays from the lower sun will

shine through the glass and help with solar

heating. It is important to note that the size

and orientation of the blocks can greatly affect

the amount of shading that can occur.

SAFETY

Glass block windows permit plenty of visible

light, but can also feature patterns and designs

that obscure the view of home occupants. Glass

block is inherently stronger than a conventional

glass window. This is because of the thickness

of the faces and the mortar that binds the

blocks together. As a result, the glass blocks

are more difficult to break and therefore

provide resistance and are a deterrent to forced

entry. If safety is a concern, the individual blocks

are more challenging to break through than

a typical window, offering a higher security

option. Even when vents are added to an

exterior window installation, the security of the

window is not compromised.

enduring material, lasting over 50 years,

which helps reduce the need to replace and

recycle building materials. However, when

damage has occurred, usually only one or two

glass blocks need to be replaced out of the

entire installation.

Some common patterns of glass block

include: clear, waves, diamond, iced, frosted,

and ribbed.

By selecting a solid glass block, it creates a

dense barrier to sounds, such as traffic, trains,

crowds and machinery. Also, it is scratch

resistant and graffiti resistant, and also very

easy to clean.

HEALTH AND SAFETY

Designing with glass block helps contribute

to the health and safety of the buildings

occupants. Glass block combines visibility

with security, providing solutions to meet

demanding security needs of the architectural

and design community. Available in the market

are glass block systems that provide resistance

to hurricane, blast, intruder or ballistic threats.

As well, certain glass block products may help

avoid glare, improving visual comfort.

nominal face thickness is .25 inches, and the

standard blocks offer a 45minute fire rating

as a window in mortar. When it is installed in

mortar, it has an R-value of 1.96, and when

it is installed in silicone, that R-value is 2.2.

Depending upon the block pattern, standard

block can have a visible light transmission

ranging from 55 percent to 91 percent.

As stated earlier, glass block can help create

a noise barrier. The Sound Transmission Class,

or STC, of standard block is 3539, depending

upon the block size. An STC rating roughly

reflects the decibel reduction in noise provided

by a partition and the higher the number, the

better the decibel reduction. In this range,

normal speech could not be heard, and louder

speech would be audible, but not intelligible.

Depending on the pattern of the standard

block, the Solar Heat Gain Coefficient is

between 0.66 and 0.68. Also, standard block

offers a compressive strength of 400 to 600 psi.

It should be installed using a mortar or channel/

spacer system, and the panel size should be

limited to 250 square feet for interior walls, and

up to 144 square feet for exterior walls.

Thick Face Block

Glass block provides exceptional visibility in

compliance with ADA guidelines for enclosed

areas. It has a dynamic relationship with light,

both natural and artificial, and transmits up to

80% of available light in both directions. As the

light changes, so does the materials appearance and in turn the surrounding environment

without any yellowing, clouding or weathering.

An important feature of glass block, critical to

safe building design, is the products inherent

fire resistance property. By varying the face

thickness of the product and conforming to

installation specifications, manufacturers are

able to offer a range of fire rated products

approved and rated according to Underwriters

Laboratories (UL) standards. For window

assemblies, glass block is available in 45, 60,

and 90minute ratings.

Depending on the type of thick face block

selected, they are available to meet 45, 60 or

90minute fire rated window assemblies in

mortared panels up to 100 square feet. The

nominal face thickness ranges from .375" to

.75". The Sound Transmission Class, or STC,

is 50 in mortar, and 48 in silicone. In this STC

range, loud speech would not be audible and

other loud noises, such as musical instruments,

would only be faintly heard.

ADDITIONAL FEATURES

INSTALLATION CONSIDERATIONS

Thick Face Block has an R-Value of 1.96 in

mortar, and 2.22 in silicone. Depending on

the pattern selected, the Visible Light

Transmission would range between 49 and

70 percent, while the Solar Heat Gain

Coefficient would range between 0.66 and

0.68. It offers a comprehensive strength of

2,500 psi, and is often used for hurricane

and blast resistant windows.

VISIBILITY/LIGHT TRANSMISSION

Glass block is non-load bearing; therefore,

adequate provisions must be made for the support of construction materials above the glass

blocks. Glass blocks are mortared at the sill with

jamb and head details designed with soft joints

to accommodate for building movement and

lintel deflection. Local building codes should

be considered for any limits on panel size or

installation details. Glass block is available in

a range of products including standard block,

thick face block, and solid block.

Glass blocks are available in a variety of patterns to fit the

projects requirements.

Glass block is made largely of sand and

limestone, and is 100 percent recyclable, low

maintenance, and highly durable. It is an

TYPES OF BLOCK

Standard Block

Standard block offers the largest selection of

patterns and sizes, ranging from 6 inch by

6 inch up to 12 inch by 12 inch blocks. The

Solid Glass Block

Solid Glass Block is also listed for use as 45,

60 or 90minute fire rated window assemblies

in mortared panels up to 100 square feet. The

actual face thickness is 3 inches, and it offers

an R-value of 1.15 in mortar. Depending on the

pattern, solid glass block offers a Visible Light

Transmission between 83 and 90 percent. The

Solar Heat Gain Coefficient ranges between

CONTINUING EDUCATION

0.750.78, depending upon pattern. The STC,

or Sound Transmission Class, is 53. At this

rating, very loud noises are almost inaudible,

and loud talking noises cannot be heard. These

solid glass blocks offer a compressive strength

of 80,000 psi and are able to resist penetration

from high-impact ballistics. They have a UL 1, 2

and 6 ballistics rating.

Specialty Block

section focuses on LEED 2009 and will break

down each credit category and credit that glass

block helps contribute to possible LEED points for

a project.

ENERGY AND ATMOSPHERE

Energy and atmosphere credits promote better

building energy performance through innovative

strategies. Reducing energy use in buildings

through improved energy performance and energy-saving strategies, like daylighting, helps reduce

the impact buildings have on our atmosphere.

Prerequisite 2: Minimum

Energy Performance

Glass blocks daylighting properties can help

achieve the required minimum energy performance for LEED certification.

Credit 1: Optimize Energy Performance

Glass block can be used as part of an overall strategy to earn points

in several LEED categories.

Shaped blocks are used to turn corners or create

curves. Finishing units are rounded on one or two

sides and are used to complete open edges and

corners. Be sure to note that shaped blocks and

finishing units are not fire rated.

Glass Block and LEED

The U.S. Green Building Council, USGBC,

is a non-prot organization composed of

leaders from every sector of the building industry

working to promote buildings and communities

that are environmentally responsible, protable

and healthy places to live and work. USGBC

developed the LEED, Leadership in Energy and

Environmental Design, green building certification

program, which is the nationally accepted

benchmark for the design, construction, and

operation of high performance green buildings.

LEED credit requirements cover the performance

of materials in aggregate, not the performance of

individual products or brands. Therefore, products

that meet the LEED performance criteria can

only contribute toward earning points needed

for LEED certification; they cannot earn points

individually toward LEED certication.

For detailed information about the council,

their principles and programs, please visit

www.usgbc.org.

Glass block can be part of an overall strategy to

earn points in several LEED categories. This next

Glass block can support various strategies,

including passive solar designs, to reduce a

buildings energy consumption. Furthermore,

because this credit includes interior lighting

energy demands, glass block can improve energy

performance even more. Developments in

glass block have significantly improved thermal

performance. As a result, energy efficient glass

block or glass block panels with Low-E glass,

demonstrate up to a 43 percent improvement in

U-value and up to a 52 percent improvement in

Solar Heat Gain Coefficient when compared to

the baseline performance ratings for glass block

specified in ASHRAE/IESNA 90.12007.

MATERIALS AND RESOURCES

Materials and Resources credits encourage

the use of sustainable building materials and

reducing waste. The production and transport of

building materials can impact our environment

in many ways. Conserving resources, using

local materials and reducing construction waste

reduces that impact.

Credits 2.1 and 2.2: Construction

Waste Management

Both glass block scrap and its packaging can be

recycled, nearly eliminating waste.

Credits 3.1 and 3.2: Resource Reuse

Salvaged glass block can be reused in some

jurisdictions, with careful consideration.

Credits 5.1 and 5.2: Regional Materials

Glass block manufactured in a facility within 500

miles of a project site can include that percent

(by weight) of the raw materials that are also

within 500 miles of the project site toward the

calculation of the total regionally located content

in all building materials.

INDOOR ENVIRONMENTAL QUALITY

Indoor environmental quality credits promote

better indoor air quality and access to

daylight and views. The U.S. EPA (Environmental

Protection Agency) estimates that the average

American spends over 80% of his/her time

indoors. Therefore, it is important that our indoor

spaces are healthy and comfortable.

Credit 4: Low Emitting Materials

Glass block meets the intent of eliminating VOCs

from the indoor environment when used as

interior walls or floors.

Credit 8: Daylight and Views

Glass block provides daylight and views without

sacrificing sound control, security and privacy. For

example, glass block wall tubes offer a unique

and creative way to maximize natural light

entering the building.

INNOVATION

Innovation credits address sustainable building

expertise as well as design measures not covered

under the five LEED credit categories.

Credit 1: Up to Three Points

Glass block can help earn points for good

acoustics, use of durable materials, and good

indoor environmental quality, meaning no VOC

and no mold.

Regional Priority Credits

Regional priority credits address regional

environmental priorities for buildings in different

geographic regions. Most manufacturers

will assist architects/designers with glass block

solutions that can be used to help fulfill specific

regional credits, for example, hurricane-resistant

windows that meet the high wind- and

large missile-impact requirements of Dade

County, Florida.

GLASS BLOCK WINDOWS WITH

LOW-E GLASS

Energy efficient glass block windows are

aesthetically pleasing and functionally smart.

Every block works like a traditional energy

efficient window, and thats because each block

features a low-emissivity coated glass panel

sandwiched inside the block that filters out about

70% of total solar energy, while still allowing for

superior daylighting.

CONTINUING EDUCATION

With an insulating R-value of 2.63, these

windows can keep HVAC costs in line. Not only

are glass block windows with Low-E glass useful

for daylighting strategies, but as the last section

shows, they can contribute to LEED points.

Other features of glass block windows with

Low-E glass:

R-Value: all patterns 2.63

Visible Light Transmission: 33%76%

depending upon pattern

Solar Heat Gain Coefficient: 0.27

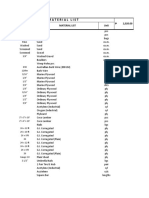

U-Factor

SHGC

Glass Block default from

ASHRAE 90.1

0.60

0.56

Typical Glass Block

in Mortar

0.51

0.67

QUIZ

1. True or False: Glass block is inherently stronger than a conventional glass window.

a. True

b. False

2. Which of the following is not a type of block?

a. Standard Block

b. Thin Front Block

c. Thick Face Block

d. Solid Block

3. Which of the following LEED category can glass block earn points in?

a. Energy and Atmosphere

b. Materials and Resources

c. Innovation

d. All of the above

4. True or False: Glass block wall tubes are perfect for when you want to bring light into commercial buildings without

compromising the masonry design.

a. True

b. False

5. With a solid glass block, detention and security windows are ballistic-resistant for UL Levels: (Select all that apply)

a. 1

b. 2

c. 4

d. 6

6. Tornado-resistant glass block windows are composed of:

Low-E Glass Block

in Mortar

0.45

% Improvement

over ASHRAE 90.1

25%

43%

7. True or False: Glass block is load bearing; therefore, adequate provisions do not have to be made for the support of

construction materials above the glass blocks.

Low-E Glass

Block Window

0.38

0.27

8. True or False: Glass block can provide more than double the thermal resistance, or R-Value, of a single-glaze 1/8" thick

plate glass.

% Improvement over

ASHRAE 90.1

37%

0.32

b. Grid assembly and

c. Laminated glass blocks

d. All of the above

a. True

52%

Building with Low-E glass block can help optimize energy

performance, as illustrated in this table that compares U-factor and

SHGC of various window options.

Glass block windows with Low-E glass are

available in a range of patterns. To significantly

improve solar heat gain, thermal loss and UV

radiation values, glass block windows with Low-E

glass are installed in a variety of projects.

Daylighting is increasingly important in buildings

today. Not only does daylighting have a positive

effect on mood, atmosphere and productivity,

but the more daylight that enters a room, the less

energy is needed by electrical systems.

a. A steel frame and

This article continues on

http://go.hw.net/AR115Course1.

Go online to read the rest of the article and

complete the corresponding quiz for credit.

b. False

9. Glass block can help earn points in which of the following credits under the Materials and Resources category?

(Select all that apply)

a. Resource Reuse

b. Daylight

c. Construction Waste Management

d. Energy Performance

10. True or False: Not only does daylighting have a positive effect on mood, atmosphere and productivity, but the more

daylight that enters a room, the less energy is needed by electrical systems.

a. True

b. False

SPONSOR INFORMATION

Pittsburgh Corning manufactures premium glass block products and innovative architectural systems for commercial,

institutional, government and residential building applications.Pittsburgh Corning glass block products offer versatile

designs and provide daylighting without sacrificing sound control, security and privacy. High performance glass block

products can also provide ballistic, blast, hurricane and tornado resistance. pittsburghcorning.com

CONTINUING EDUCATION

GLASS BLOCK WALL TUBES

Glass block wall tubes are easy to install and are

self-supporting when installed in a running bond

wall. Unless a lintel is provided, do not install

glass block wall tubes in stack bond CMU walls.

As with single unit glass blocks, the installation

of glass block wall tubes include proper sealing

between the edges of the wall and the tube on

both the exterior and interior walls.

HURRICANE RESISTANT GLASS BLOCK

Hurricane-resistant glass block windows are

available in a variety of patterns to suit a range

of visibility and privacy options and are customizable to meet specific project needs. They

are guaranteed to meet your project needs and

performance requirements. Hurricane-resistant

glass blocks are often offered as pre-assembled

systems and can be delivered to the job site to

facilitate easy installation.

BLAST RESISTANT GLASS BLOCK WINDOWS

Glass block wall tubes provide a unique setting and are able to bring

natural daylight into any space.

Glass block wall tubes are perfect for when

you want to bring light into commercial

buildings without compromising the masonry

design. Glass block wall tubes more than

double the thermal insulation of single glass

block. The mirror-like finish of the reflective

stainless steel walls captures and reflects the

natural sunlight, while solving many design

issues related to single or double glass block

installations in multi-wythe wall construction.

Glass block wall tubes allow the architectural

look of single or double glass blocks on both

sides of a thick wall, while providing a visually

aesthetic look in the hollow area between the

glass blocks. The sturdiness of the metal tube

prevents any loading from above the opening

being transferred to the glass block when

installed to specification.

Glass block wall tubes are thermally broken and

thus provide improved thermal performance.

They are available in 8" and 16" modules in

various privacy levels and depths to meet wall

thickness requirements.

Type of Glass Block in

Wall Tube

U-value

R-Value

8" x 8" Low-E Hollow Block

0.26

3.85

8" x 16" Low-E Hollow Block 0.17

5.88

8" x 8" Hollow Block

0.27

3.70

8" x 8" Solid Block

0.33

3.03

8" x 16" Hollow Block

0.21

4.76

8" x 16" Solid Block

0.26

3.85

This table shows the U-values and R-values for both hollow and

solid blocks.

A glass block partition is used at the Miami airport because it is

hurricane resistant and aesthetically pleasing.

Anyone who has ever experienced a hurricane

knows that hurricane force winds are powerful,

but a real danger comes from flying debris.

If one is designing a building to withstand

hurricane-force winds, it needs to be able to

stand up to flying debris as well. Negating the

need for shutters, hurricane-resistant glass

block window systems are designed to meet

the large missile impact tests referenced in the

International Building Code, IBC, in accordance

with ASTM E-1886 and ASTM E-1966.

Additionally, they are tested to Dade County

Approval Protocols TAS 201, 202 and 203.

Window Size

Design Pressure

Wind Speed

4 ft. x 4 ft.

100 psf

198 mph

4 ft. x 8 ft.

80 psf

177 mph

6 ft. x 6 ft.

68 psf

163 mp

The window size and design pressure rating of hurricane-resistant

residential glass block windows is indicated in this table. The 4 foot

by 8 foot size at 80 psf is also rated for commercial applications.

It is important to compare the performance

of conventional laminated windows versus

hurricane-resistant glass block systems. When

laminated glass flexes under pressure, it will

crack and, if successful, the laminate will

contain the fragments. Conversely, thick face

glass block construction behaves differently.

When exposed to pressure, thick face glass

block windows do not crack at all. Hurricaneresistant glass block windows are also visually

stunning, while offering light transmission and

protection against the hurricane force winds.

With the increased threat and awareness

of explosive ballistic devices, responsible

government and commercial organizations

are responding with more stringent building

requirements, along with better products and

construction methods. In the past, the majority

of injuries to building occupants from a blast

force have been caused by airborne shattered

glass fragments. Unlike laminated flat glass,

which will often crack and release fragments

during a blast, blast resistant glass block

windows do not crack or lose glass fragments.

This section presents a discussion on blastresistant glass block windows, beginning with

a review of the key parameters used to define

blast magnitude.

With a nearly infinite range of explosive

devices and potential standoff distances,

standards have been developed to simplify

blast parameters for testing and application

purposes. To that end, a blast pulse is often

simplified to a triangular shape, where the

pressure rapidly rises from ambient pressure,

to a maximum pressure, and then declines

linearly back to ambient.

The key parameters used to define a blast in

standards and specifications for fenestration

are maximum pressure and impulse.

Maximum pressure is the highest level of

pressure above ambient that is typically reached

immediately after detonation. Measured in

pounds per square inch, or psi, it is often

referred to as peak pressure and applied

pressure. Overpressure is often used to describe

pressures above ambient.

Impulse is a function of the pressure and

duration and is the area under the pressure

curve from detonation to when the pressure

returns to ambient. Measured in psimsec , or

pounds per square inchmilliseconds, it is often

simplified as the area of the triangle.

Another important parameter for fenestration

is how well it resists a blast in order to protect

CONTINUING EDUCATION

the buildings occupants. The two commonly

used standards are ASTM Hazard Rating and

GSA Performance Condition. Both standards

refer to a test window located on the wall

nearest the blast in a 3-meter deep room.

DETENTION AND SECURITY WINDOWS

TORNADO-RESISTANT WINDOWS

With the increasing devastation caused by

weather-related disturbances, building requirements are becoming more stringent. Shelters

need to be designed to provide protection

from the elements. A tornado-resistant glass

block window provides effective protection

against air pressure and flying debris caused

by tornado-force winds. A tornado-resistant

window provides protection from these winds,

while letting daylight into a space so as to not

have to rely solely on artificial lighting.

The steel framed unit is bolted into the opening

of the shock tube. Aluminum diaphragms are

inserted in the tube, and pressure is built up

until the aluminum ruptures. Using aluminum

thickness and pressure control, blast levels can

be simulated accurately.

The agencies that reference the levels of

blast resistance protection related to glazing

systems include:

ASTM International Standard Test

Method for Glazing and Glazing

Systems Subject to Airblast Loadings

(F 164204).

General Services Administration (GSA)

is responsible for all government

buildings. The standard is U.S.

General Services Agency Test Method

for Glazing and Window Systems Subject

to Dynamic Overpressure Loadings

(GSA-TS01-2003).

Unified Facilities Criteria (UFC)

DoD Minimum Antiterrorism

Standards for New and Existing

Buildings (UFC 04-010-01).

Interagency Security Committee (ISC)

reports to the Office of Homeland

Security and utilizes the GSA criteria.

Blast-resistant glass block windows have been

designed and tested to meet and exceed

stringent government, military and international

building requirements. Applications include

high-risk buildings, such as military facilities,

airports, government offices, embassies,

courthouses, correctional facilities, arenas,

financial centers, and other high-profile spaces.

Blast-resistant glass block windows meet GSA

and UFC 04-010-01 blast glass standards with

no cracking or loss of glass during testing.

Blast-resistant glass block

windows have been designed

and tested to meet and

exceed stringent government,

military and international

building requirements.

To obtain pleasing aesthetics and increased

levels of privacy, one or two of the interior

faces of the glass can be sandblasted.

Glass block is used in detention centers to let natural light in, while

offering a ballistic resistant option.

Detention and security windows resist

escapes while allowing natural light and

views between rooms or to the outside.

Quality systems are composed of a steel frame

and grid that frame solid glass block with

pick-proof grout. Some typical applications

include jails, detention centers, holding cells,

correctional facilities, criminal justice facilities

and police departments.

With a solid glass block, detention and

security windows are ballistic-resistant for UL

Levels 1, 2 and 6. If needed, these systems

can be enhanced for higher levels of ballistic

resistance. New technologies have led to the

development of ballistic-resistant laminated

glass block for applications requiring higher

levels of security and ballistic resistance.

Ballistic-resistant systems are composed of a

steel frame and grid that house the laminated

glass block. These systems have passed UL

Levels 16 as a system. An additional benefit of

the new laminate technologies is UV resistance

over 99%. Applications of ballistic-resistant

laminated glass block include institutional

environments, commercial settings, schools,

transportation terminals, courthouses and

police stations.

Test labs use very accurate methods to test

ballistic-resistant products, including location of

the shot, weight and speed. Due to the spaces

between the blocks, as well as the glass face,

the testing lab will take two additional shots at

what they perceive to be the weakest points.

Tornado-resistant glass block windows are

composed of a steel frame and grid assembly

and laminated glass block and are extremely

versatile and available in a variety of sizes.

These systems have successfully passed the

highest standards of performance for FEMA361 Design and Construction Guidance for

Community Safe Rooms. Some tornadoresistant windows have passed several levels

of air pressure tests, including 309 positive psf

and negative 413 psf. The 413 psf equates to

a wind speed of over 400 miles per hour. It is

important to note that the highest recorded

wind speed on earth was 253 miles per hour,

meaning these tornado-resistant windows

will stand up to the toughest of tornados.

Applications for tornado-resistant windows

include safe rooms for schools, community

shelters, corporate campuses, government

facilities and hospitals.

SUMMARY

This article has highlighted the attributes

of glass block in architectural applications,

including how glass block supports LEED

building certification, how it contributes to

sustainable design, as well as its value in

daylighting strategies. It has also covered

the variety of glass block products that are

available today, including the range of solutions

where security and safety are priorities.

Extraordinarily versatile and offered in many

aesthetically pleasing sizes and patterns, glass

block offers tremendous design flexibility for

todays architects and designers.

In summary, building with glass block combines

sustainable design, function, and innovation.

To that end, this article concludes with two

case studies showcasing unique installations of

glass block systems.

CONTINUING EDUCATION

CASE STUDIES

The Miami International Airport, Miami, Florida

Located just a few short miles from the coastline, Miami

International Airport is a prime target for hurricanes.

And, since its construction in 1928, has seen its fair share

of close calls from Mother Nature. So when American

Airlines officials announced plans for their new

commuter terminal expansion, this project was a great

opportunity for hurricane resistant glass block windows.

keep the overall cost down as only three workers were

needed instead of the original estimate of many more.

Worth safe and retain its title of one of Americas Most

Livable Communities.

Altogether, the new American Airlines Commuter

Terminal at the Miami International Airport features 547

Hurricane Resistant Windows. Using a random pattern

of six different sizes of windows, the design offers

ample light while also providing an increased circulation of airflow. Unlike other windows that feature

traditional sheet glass or curtain walls, the windows

are a great addition to the airport and really combine

aesthetics, light transmission and high performance.

Part of what helps the FWPD keep their beautiful city

safe is the Crime Lab and Property Evidence Room

recently renovated using Ballistic Resistant Windows.

The project was originally designed with plans to use

hollow glass block, but that product didnt have the

ballistic resistant qualities that were required for this

type of structure.

The project architect and the general contractor

discussed how glass block might fit into the eventual

design. As it turned out, project goals not only required

a product durable enough to stand up to hurricane

season but one that would also easily allow an inflow of

light into the terminal.

Unlike the traditional method of laying block, which

will not comply with the hurricane codes, choosing the

glass block prefabricated systems would not only give

the design the desired look and feel but also the safety

and security needed for such a high-profile application.

After installing the first of several panels, the mason

contractors team immediately felt comfortable with

both the product and its installation method. Frames

were set in place, panels were shipped and in almost

no-time, windows were installed. This seamless process

not only helped the project stay on pace but also helped

Fort Worth Crime Lab, Fort Worth, Texas

The Fort Worth Police Department has a rich history

dating back to the days of the Wild West. Today,

the tumbleweeds have long since blown away and it

now patrols Fort Worth, one of the largest cities in

Texas with an estimated population of 741,206. Lead

by Police Chief Jeffrey Halstead, the 1,562 officers and

452 civilians who make up the FWPD help keep Fort

The project specifications called for ballistic resistance

and the windows met the UL 752 requirements while

also providing daylighting to the space. The steel

framed windows feature solid laminated glass blocks

which provide enhanced security as well as resistance

to forced entry. The architect realized the extra security

added from using these high performance products

would be vital for this project.

If youve ever seen TV shows like CSI, you can imagine

the kinds of tests run by forensic scientists in the lab

that might require the privacy and security offered by

ballistic resistant glass block systems. Additionally, these

kinds of rooms house sensitive information, evidence,

and valuablesall of which could be targeted during a

break-in. Ballistic Resistant Windows were perfect for

the Crime Lab and Property Evidence Room because

they are resistant to ballistics and forced entry, while

still allowing natural light into the room. With the

strength and durability of steel and glass, they offer

maximum security without locking up the budget,

which is why many police stations choose them for

renovations and new builds.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Renault Megane 2 Rastavljanje Središnje KonzoleDocument127 pagesRenault Megane 2 Rastavljanje Središnje Konzolehrc555No ratings yet

- Maps by SimonDocument8 pagesMaps by SimonThư NguyễnNo ratings yet

- BOQ of Proposed Bungalow For Providing Approximate CostDocument13 pagesBOQ of Proposed Bungalow For Providing Approximate CostA.k. Mishra100% (1)

- TEMA 2 ACT 2 PROBLEMARIO Balance de MomentumDocument1 pageTEMA 2 ACT 2 PROBLEMARIO Balance de MomentumMichelleNo ratings yet

- Material List: 4" 6" PortlandDocument32 pagesMaterial List: 4" 6" PortlandJoella MaderaNo ratings yet

- Construction Cost Break Up For A Typical Residential BuildingDocument5 pagesConstruction Cost Break Up For A Typical Residential Buildingmr.xinbombayNo ratings yet

- Main - Group 05Document131 pagesMain - Group 05lokezhengyan22No ratings yet

- Maco Okov Uputstvo Za PodesavanjeDocument21 pagesMaco Okov Uputstvo Za PodesavanjenamkvalNo ratings yet

- Free Energy - Passive Solar CoolingDocument21 pagesFree Energy - Passive Solar CoolingGiuseppe VaccinaNo ratings yet

- Vol2 - Room Data Sheet A To L PDFDocument425 pagesVol2 - Room Data Sheet A To L PDFAhmad Gamal Elden MAhanyNo ratings yet

- Roto Patio S: The Standard Hardware For Tilt&Slide Windows and Doors Up To 160 KGDocument104 pagesRoto Patio S: The Standard Hardware For Tilt&Slide Windows and Doors Up To 160 KGSakshi SharmaNo ratings yet

- Loxone - Real Smart Home Compendium ENDocument36 pagesLoxone - Real Smart Home Compendium ENmbyaray75 ByarayNo ratings yet

- CBLM Fabricate Install Door Window Jambs and PanelsDocument46 pagesCBLM Fabricate Install Door Window Jambs and PanelsYeng Lugtu100% (1)

- Toa & BT 1 PDFDocument13 pagesToa & BT 1 PDFFrancis Anne DoradoNo ratings yet

- NHouse SelfBuilder Brochure v2 Jan19 LowresDocument56 pagesNHouse SelfBuilder Brochure v2 Jan19 LowresAndrew Richard ThompsonNo ratings yet

- 2.1 Daylighting H3Document18 pages2.1 Daylighting H3RajendranbehappyNo ratings yet

- Lea 202 Group 2 Full TextDocument33 pagesLea 202 Group 2 Full TextTabaosares JeffreNo ratings yet

- Study ViewerDocument22 pagesStudy ViewerNAndreiNo ratings yet

- A2 40 SkylightsDocument16 pagesA2 40 SkylightsJacky TiongNo ratings yet

- CWCT Curtain Wall Installation HandbookDocument34 pagesCWCT Curtain Wall Installation HandbookmoudshahineNo ratings yet

- Ultimate Property Inspection Checklist GuidesDocument34 pagesUltimate Property Inspection Checklist Guidesharendra100% (1)

- VVIP Circuit House Achieves Green Building CertificationDocument3 pagesVVIP Circuit House Achieves Green Building CertificationRaj Agrawal100% (1)

- Maps by Simon Sample 1:: The Diagrams Illustrate Some Changes To A Small Island Which Has Been Developed For TourismDocument8 pagesMaps by Simon Sample 1:: The Diagrams Illustrate Some Changes To A Small Island Which Has Been Developed For TourismThư NguyễnNo ratings yet

- Undergraduate thesis explores green building awareness centreDocument24 pagesUndergraduate thesis explores green building awareness centreamlaNo ratings yet

- Glass PresentationDocument59 pagesGlass PresentationdialaNo ratings yet

- Civil Construction 2: Student:Mușet Andrei Group:3304 Year:2019-2020Document22 pagesCivil Construction 2: Student:Mușet Andrei Group:3304 Year:2019-2020Mihai ManoleNo ratings yet

- Lagon Vs Hooven Comalco Industries (2001)Document16 pagesLagon Vs Hooven Comalco Industries (2001)J.N.No ratings yet

- Aluminium Window QuotationDocument5 pagesAluminium Window QuotationUndefinedIndianNo ratings yet

- HAFELE BalamaleDocument54 pagesHAFELE BalamaleCrestin OrtodoxNo ratings yet

- IELTS Writing Task 1 Workbook Provides Detailed Lessons on Describing Graphs, Charts and Other Visual DataDocument263 pagesIELTS Writing Task 1 Workbook Provides Detailed Lessons on Describing Graphs, Charts and Other Visual DataHuongHaNguyenNo ratings yet