Professional Documents

Culture Documents

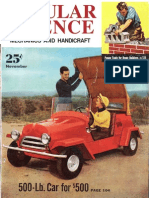

Maytag Roadster

Uploaded by

Jim100%(3)100% found this document useful (3 votes)

2K views5 pagesA half-horsepower washing machine engine is available in nearly all sections of the country. The engine enables the car to travel about 16 mph averaging 50 to 75 miles per gallon of gasoline. The hood, seat-back and dummy radiator are of galvanized iron cut as shown.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA half-horsepower washing machine engine is available in nearly all sections of the country. The engine enables the car to travel about 16 mph averaging 50 to 75 miles per gallon of gasoline. The hood, seat-back and dummy radiator are of galvanized iron cut as shown.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(3)100% found this document useful (3 votes)

2K views5 pagesMaytag Roadster

Uploaded by

JimA half-horsepower washing machine engine is available in nearly all sections of the country. The engine enables the car to travel about 16 mph averaging 50 to 75 miles per gallon of gasoline. The hood, seat-back and dummy radiator are of galvanized iron cut as shown.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Head on the "Weber

Roadster" has a strik-

ing appearance. In the

drawings below, the

construction details of

a simpler radiator and

hood are shown.

Above--when pushed forw-

ward, the hand lever causes

the idler pulley to tighten

the single drive belt, mov-

in the car. Pulling the lever

back applies the brakes.

THERE is one definite rule to follow in making a

sidewalk automobile--get your engine first and

build the car around it. This applies pretty much to

the wheels too.

A half-horsepower, two-cycle washing machine

engine is available in nearly all sections of the

country, and as these can be had second-hand at a

reasonable price and have sufficient power for

moderate speeds, they make satisfactory installa-

tions. Herewith are working drawings of the little

car owned by Richard Weber, of Sar. Marino, Cali-

fornia, which is driven by this type of

motor and has proved successful for a long

period. It is very easy to build.

In Figs, 1, 2 and 3 are given the general

over-all dimensions. Note that the front

wheels have a wider tread than the rear.

This permits a shorter turning radius, and

brings the back wheels in close to the

power unit, The engine is provided with

Modern Mechanix

Left--The trim little run-

about is powered by a

Maytag washing machine

motor of one-half horse-

power, which enables the

car to travel about 16 mph

averaging 50 to 75 miles

per gallon of gasoline.

Motor is connected to one

wheel by a drive belt.

by Hi Sibley

A kick starter, and clutch arrangement

consists of an idler pulley which tightens the

single drive-belt when the hand lever is

pushed forwardd. When pulled back, it

operates the brake. Drive is on one wheel,

brake on two.

Hood, seat-back and dummy radiator are

of galvanized iron cut as shown in Fig- 12.

These dimensions are approximate as a cer-

tain amount of fitting is always necessary for

curved members. If you have the facilities.

The start of a midget auto race

with the Weber car in

foreground of the lineup.

the edges of the metal should be beaded The

edge of the seat back is protected with a strip

of leather laced on with rawhide. It will be

best to leave the cutting of the hood, etc,

until the chassis is completed.

Several types of wheels are available for

small autos, being manufactured by toy

makers, tire companies, etc. The original car

in the photos has disk wheels with the brake

drum and pulley cast integral, and turned

Continued on page 118]

This Sidewalk Runabout

[Continued from page 75]

down on a lathe, as in Fig. 11. This of course

requires a pattern. Another very satisfactory

wheel used by the writer for several small power

vehicles Is a 3-inch by 12-inch disk with balloon

tire. It is assembled with six small bolts through

the hub, and by substituting longer ones for

these, a combination brake-drum and drive pulley

can be bolted securely to the wheel. A spacing

ring will be necessary to hold the drum away

from the tire, as- illustrated in Fig. 11.

The rear wheels turn on a stationary steel axle.

This is secured to the wooden cross - member at

rear of frame by means of J-bolts, simply a

1/4-inch carriage bolt with the head cut off and

the end bent as shown in Fig. G. Steering

knuckles and a built-up axle are used on. the

front end. Fig. 9. Construction of these parts

requires welding, bending and drilling only, and

the wheel spindle must be turned to accommodate

the standard wheel bearings.

Figs, 4 & 5 show the complete chassis as-

sembly. The sills or stringers are 1-1/2x2-inch

oak with 2x4-inch oak cross-members where

indicated. The chassis is 4 inches wider at back

than in front. After the front axle is bolted to

the sills, a pipe nipple socket for the bottom

end, of the steering post is installed. A plywood

floor is then carried as far as the back of the

seat. Upon this is erected a strap iron frame to

support the upper end of the steering post as

well as hood. The steering wheel may be either

a full she auto wheel, or a hardwood rim screwed

to a cut-down Model-T spider.

For the hand lever a pipe, bar or section of

seamless steel tubing is bent to a right angle and

carried in a pair at bearings screwed under the

sills, as shown in Fig. 4, An arm is welded onto

the lever for attaching the brake cables and a

yoke and link connect the lever with the idler

pulley assembly.

Fender bars protect the rear wheels, and the

engine bed is mounted on the rearmost cross-

member and one just behind the seat. The brakes

consist of brake-lining riveted to a shoe made in

the form shown in Fig. 7, which is welded to a

sliding bar, carried in a sheet steel guide screwed

to the chassis sill. A tension spring holds it

away from the brake drum when not applied.

A very satisfactory clutch consists of an idler

pulley mounted on a sliding bar as in Fig. S.

This tightens the belt on the drive pulley and

starts-the little car smoothly. As this type of

engine is not arranged for variable speed, no

controls are necessary, unless a shorting switch,

convenient to the hand while driving, is desired.

Various makes of engines can be used in this

car, the drive arrangement being identical, For

only one-half horsepower, have your wheel -

pulley at least 9 inches in diameter. This will

not give any startling speed, but enough power.

You might also like

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Building One Lung KartsDocument7 pagesBuilding One Lung KartsJim100% (5)

- Yard-Dozer MidgetDocument5 pagesYard-Dozer MidgetOlin Stej80% (5)

- Midget Tractor3 PlansDocument6 pagesMidget Tractor3 PlansDanilo RochaNo ratings yet

- King Midget ArticleDocument8 pagesKing Midget ArticleJim100% (10)

- Midgettractor PSMar 54Document7 pagesMidgettractor PSMar 54JimNo ratings yet

- Midget Sports CarDocument7 pagesMidget Sports CarJim100% (8)

- PowerCycle With SideCarDocument7 pagesPowerCycle With SideCarJim100% (2)

- Mite Cycle by Mechanix IllustratedDocument7 pagesMite Cycle by Mechanix IllustratedJim100% (3)

- Suitcase PowercycleV2Document13 pagesSuitcase PowercycleV2Jim67% (3)

- Pedalmatic 1951Document3 pagesPedalmatic 1951Jim100% (4)

- Brush Buggy, Build An ExcitingDocument5 pagesBrush Buggy, Build An ExcitingJim88% (8)

- YardHorse ScooterDocument9 pagesYardHorse ScooterJim100% (5)

- Wooden Scooter and PopcycleDocument6 pagesWooden Scooter and PopcycleJim75% (4)

- Plywood ScooterDocument7 pagesPlywood ScooterJim100% (4)

- Six Wheeled ATV by Mechanix IllustratedDocument7 pagesSix Wheeled ATV by Mechanix IllustratedJim100% (6)

- Relive the romance of early automobiles with a half-size 1901 Packard replicaDocument8 pagesRelive the romance of early automobiles with a half-size 1901 Packard replicaDillon Hartsyker100% (1)

- 1901 TruckDocument10 pages1901 TruckGary B. Watts100% (3)

- Build The Ison Race KartDocument8 pagesBuild The Ison Race KartJim100% (2)

- Vintage Power Tool Plans 1950sDocument180 pagesVintage Power Tool Plans 1950sPierre799es100% (5)

- Super Scooter by Mechanix IllustratedDocument12 pagesSuper Scooter by Mechanix IllustratedJim100% (3)

- Homebuilt Wood CarDocument26 pagesHomebuilt Wood Carsjdarkman1930100% (3)

- 3 Wheel Dune BuggyDocument5 pages3 Wheel Dune BuggyyukitadaNo ratings yet

- Beep Plans CompleteDocument9 pagesBeep Plans Completetaxmac80% (5)

- Suburba ContestDocument4 pagesSuburba ContestJim100% (3)

- Build Your Own Mini Bike PlansDocument8 pagesBuild Your Own Mini Bike Plansmawan_jogjaNo ratings yet

- Wren Minibike PlansDocument7 pagesWren Minibike PlansJim100% (5)

- Mini Dozer Info 1979Document6 pagesMini Dozer Info 1979Jim100% (3)

- Mini BeepDocument17 pagesMini Beeptaxmac67% (6)

- SMFeb 56 Roamabout Part 1Document17 pagesSMFeb 56 Roamabout Part 1Jim86% (7)

- Suburba Car, Chassis For ADocument7 pagesSuburba Car, Chassis For AJim100% (9)

- Mini-Skat 6-Wheel Plans AssemblyDocument40 pagesMini-Skat 6-Wheel Plans AssemblyВладимир Батманов100% (3)

- Fee Jee PMFM47Document7 pagesFee Jee PMFM47Jim100% (3)

- Offroad Kart PlanDocument24 pagesOffroad Kart PlanAnshul Kothari100% (1)

- Wartime ScooterDocument7 pagesWartime ScooterJim100% (5)

- Bull Frog Go KartDocument15 pagesBull Frog Go KartJim100% (3)

- Motorcycle Components - Wikipedia PDFDocument35 pagesMotorcycle Components - Wikipedia PDFJunior EdgerNo ratings yet

- Starting SysytemDocument12 pagesStarting SysytemMathews P RejiNo ratings yet

- Rear Wheel Drive Vs Front Wheel DriveDocument11 pagesRear Wheel Drive Vs Front Wheel DriveVineeth MaxxNo ratings yet

- Power BikeDocument4 pagesPower BikeGreg AnguishNo ratings yet

- Alfasud 8v EngineDocument6 pagesAlfasud 8v EngineAlexandru IonescuNo ratings yet

- Seminar Report On Fuel Cell Powered CarsDocument28 pagesSeminar Report On Fuel Cell Powered CarsANAND POZHATHNo ratings yet

- Unit-IV Steering System IntroductionDocument20 pagesUnit-IV Steering System IntroductionMark MubiruNo ratings yet

- Front Wheel Drive V/S Rear Wheel Drive: Vineeth CsDocument11 pagesFront Wheel Drive V/S Rear Wheel Drive: Vineeth CsSurajbhan BheemNo ratings yet

- Ninty Degree SteeringDocument48 pagesNinty Degree Steeringparas bhogulkarNo ratings yet

- Power Steering System PresentationDocument15 pagesPower Steering System PresentationDeepak Kango100% (1)

- Design and Fabrication of a Two-Wheel Drive BikeDocument37 pagesDesign and Fabrication of a Two-Wheel Drive BikeKARUNKO Covid ProductsNo ratings yet

- Muhoja AssignmentDocument9 pagesMuhoja AssignmentSire MkubwaNo ratings yet

- Auto Chassis NotesDocument90 pagesAuto Chassis Notesanishsukumar000gmailcomNo ratings yet

- MCT 311 Lesson 5Document16 pagesMCT 311 Lesson 5Moussa SaidNo ratings yet

- Sidewalk Play Car: by Elmer V. ClarkDocument5 pagesSidewalk Play Car: by Elmer V. ClarkJimNo ratings yet

- Bicycle MinibikeDocument6 pagesBicycle MinibikeJim100% (1)

- Gokart Project ReportDocument18 pagesGokart Project ReportSudhir RojeNo ratings yet

- CVTDocument40 pagesCVTziko23100% (1)

- Chapter 4 Answers To Review QuestionsDocument3 pagesChapter 4 Answers To Review QuestionspbendreNo ratings yet

- Bike Engine PartsDocument10 pagesBike Engine PartsKomarac DzemilNo ratings yet

- Good Morning .?: Presentation On Vehicle Steering Systems by Pari, D.J & K.CDocument29 pagesGood Morning .?: Presentation On Vehicle Steering Systems by Pari, D.J & K.CSrikar ChinmayaNo ratings yet

- Polliwog Sailboat PlansDocument6 pagesPolliwog Sailboat PlansJim100% (4)

- Listening LoopsDocument2 pagesListening LoopsJim75% (4)

- Bull Frog Go KartDocument15 pagesBull Frog Go KartJim100% (3)

- Homemade ATVDocument67 pagesHomemade ATVJim100% (7)

- Super Scooter by Mechanix IllustratedDocument12 pagesSuper Scooter by Mechanix IllustratedJim100% (3)

- Candle Powered EngineDocument2 pagesCandle Powered EngineJimNo ratings yet

- Free Electric Power WindmillDocument3 pagesFree Electric Power WindmillJim100% (4)

- Breeze Baby Sailboat PlansDocument5 pagesBreeze Baby Sailboat PlansJim100% (5)

- Star Lite SailboatDocument13 pagesStar Lite SailboatJim100% (8)

- Air Cooled Hot Air EngineDocument6 pagesAir Cooled Hot Air EngineJim50% (2)

- Electric Scooter PlansDocument6 pagesElectric Scooter PlansJim88% (8)

- Radio SimplifiedDocument94 pagesRadio SimplifiedJim100% (3)

- Dorothy 24 Foot Sailing CruiserDocument11 pagesDorothy 24 Foot Sailing CruiserJim92% (12)

- Model Hot Air EngineDocument4 pagesModel Hot Air EngineJim100% (4)

- Magnetic Current PamphletDocument9 pagesMagnetic Current PamphletJim100% (2)

- Mineral Vegetable and Animal LifeDocument4 pagesMineral Vegetable and Animal LifeJim86% (7)

- Vintage Transistor RadioDocument4 pagesVintage Transistor RadioJim100% (1)

- Magnetic BaseDocument3 pagesMagnetic BaseJim100% (2)

- Space Age Crystal SetDocument3 pagesSpace Age Crystal SetJim100% (3)

- The Boy's Book of Crystal SetsDocument36 pagesThe Boy's Book of Crystal SetsJim100% (9)

- War Toys For BoysDocument48 pagesWar Toys For BoysJim100% (2)

- Foxhole RadioDocument2 pagesFoxhole RadioJim89% (9)

- Flashlight RadioDocument5 pagesFlashlight RadioJim67% (3)

- Crystal Radio LampDocument4 pagesCrystal Radio LampJim100% (2)

- O Livro de Ouro Dos Experimentos Químicos (RARIDADE)Document114 pagesO Livro de Ouro Dos Experimentos Químicos (RARIDADE)Davidson De Oliveira Lima100% (1)

- A Crystal Set For The Boy BuilderDocument3 pagesA Crystal Set For The Boy BuilderJim100% (4)

- Vintage Transistor RadioDocument4 pagesVintage Transistor RadioJim100% (1)

- Receive Short W A V E Onyour HomeradioDocument5 pagesReceive Short W A V E Onyour HomeradioJim100% (9)

- Build A Scintillometer Uranium Detector For ProspectingDocument11 pagesBuild A Scintillometer Uranium Detector For ProspectingJim80% (5)

- Wren Minibike PlansDocument7 pagesWren Minibike PlansJim100% (5)

- MachineDocument15 pagesMachinemaria katherine pantojaNo ratings yet

- Issue01 - Mar2000extreme Rocketry MagazineDocument48 pagesIssue01 - Mar2000extreme Rocketry Magazineobx4everNo ratings yet

- Preambles To Method of MeasurementDocument20 pagesPreambles To Method of MeasurementMiguel EllaNo ratings yet

- Hardinge HLV H ManualDocument35 pagesHardinge HLV H ManualSergio CarvalhoNo ratings yet

- Yamaha FZ6-S 2004 (Europe) Service ManualDocument456 pagesYamaha FZ6-S 2004 (Europe) Service Manualm.kelleci724880% (5)

- ShopNotes Issue 12Document32 pagesShopNotes Issue 12benignoNo ratings yet

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- Specs PeDocument8 pagesSpecs PeKhairilMunawarNo ratings yet

- Welded Wire Mesh Fence & MEP InstallationDocument3 pagesWelded Wire Mesh Fence & MEP InstallationAbdul HakkimNo ratings yet

- EK 290 NK Air Ends: Repair ManualDocument38 pagesEK 290 NK Air Ends: Repair Manualfauzy syaeful100% (2)

- 53007-San FranciscoDocument32 pages53007-San Franciscomarcial rubioNo ratings yet

- Investigation and Repair of H (1) - E.R Flange LeakDocument19 pagesInvestigation and Repair of H (1) - E.R Flange LeakriysallNo ratings yet

- Service Manual: Powershift Transmission T16000Document138 pagesService Manual: Powershift Transmission T16000Marcos Aldana VillaldaNo ratings yet

- Critical Spare ListDocument38 pagesCritical Spare Listsiruslara6491No ratings yet

- Option ModuleDocument35 pagesOption ModuleAlcides Huacho OsorioNo ratings yet

- GKI Cutting Tool Catalog MKT-173-Rev 2-13Document28 pagesGKI Cutting Tool Catalog MKT-173-Rev 2-13RachmatRyfaldiPartINo ratings yet

- ELECTRONIC KILOWATT-HOUR METER SPECIFICATIONSDocument30 pagesELECTRONIC KILOWATT-HOUR METER SPECIFICATIONSnatsclimbersNo ratings yet

- Evo Design - Structural Design: Calculation SheetDocument4 pagesEvo Design - Structural Design: Calculation SheetVij Vaibhav VermaNo ratings yet

- Steering Wheel - Contact Spiral - Remove&InstallDocument1 pageSteering Wheel - Contact Spiral - Remove&InstallpekksNo ratings yet

- BMT 5011E - EnglishDocument28 pagesBMT 5011E - EnglishIng Tino TecorralNo ratings yet

- Door & Ironmongery ScheduleDocument1 pageDoor & Ironmongery ScheduleKamalGhazaliNo ratings yet

- Royal Enfield Crusader Engine RebuildDocument11 pagesRoyal Enfield Crusader Engine Rebuildbill_wattNo ratings yet

- Manual Fold Door 8920PLDocument40 pagesManual Fold Door 8920PLCristian Luis Mansilla SilvaNo ratings yet

- Locker Gripspan Technical ManualDocument16 pagesLocker Gripspan Technical ManualRobert SiraschNo ratings yet

- Anchor Bolt BiAxialDocument10 pagesAnchor Bolt BiAxialALPHYL BALASABASNo ratings yet

- BoltCalcs R5Document4 pagesBoltCalcs R5Homer SilvaNo ratings yet

- Experimenters Guide To The Joe CellDocument46 pagesExperimenters Guide To The Joe CellKseniya Smolyanova100% (1)

- Md-89 Offshore Windwills 1Document14 pagesMd-89 Offshore Windwills 1Roger Hazim100% (1)

- PC 30dmh 04Document60 pagesPC 30dmh 04argodumilahNo ratings yet

- Installation of Ductile-Iron Water Mains and Their AppurtenancesDocument6 pagesInstallation of Ductile-Iron Water Mains and Their Appurtenancesmailmaverick0% (1)