Professional Documents

Culture Documents

4.hydrogen Generator System and Functions

Uploaded by

Anonymous ffje1rpaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.hydrogen Generator System and Functions

Uploaded by

Anonymous ffje1rpaCopyright:

Available Formats

Page 1 of 4

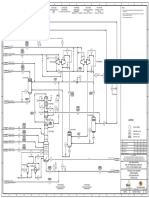

HYDROGEN GENERATOR SYSTEM AND FUNCTIONS

Pressurized water Electrolysis Hydrogen Plant

Description of control and operation logic as per

P & I D- ANE/P&I/01

Sheet No - 1

1

Electric AC Power from the Power distribution panel is Sent to

MCC panel ( refer Electrical and Control circuit Drawing also )

2

From MCC panel the power is sent to the Transformer where the

transformer reduces the voltage and increase the current

3

From Transformer the power goes to rectifier for Changing it to DC

Power

4

Rectifier is provided with Temperature alarm and control

5

Supply to Electrolyser is given from + ve of rectifier & - ve of

transformer.

6

Suitable electrolyte is used to generate sufficient quantity of

hydrogen & oxygen through electrolysis.

7

Temperature of oxygen thus generated is controlled.

Sheet No - 2

1 Hydrogen with KOH is fed to R 101 hydrogen separator & where

hydrogen is cooled in cooler E 103.

2 This hydrogen is routed through Moisture Separator R 103 to water

gas separator, R105, where water is separated from Hydrogen. This

hydrogen is taken further for processing.

3 Similarly oxygen with KOH from electrolyzer is fed to R102 oxygen

separator. Again oxygen is cooled in cooler E104 & routed through

Page 2 of 4

Moisture Separator R104 to gas separator R106.

4 Pressure in oxygen separator R102 is controlled.

5 P101, Hydrogen lye pump is used to feed Electrolyte

to electrolyzer through filter F102 & lye cooler E102.

6 Also oxygen lye is pumped to electrolyzer by pump P102 & routed

through filter

F102 & then cooled in oxygen lye cooler E102.

Cooling water is used to cool the lye in both cases.

Sheet No - 3

1 Oxygen thus separated from water is vented through pressure control

valve PCV102 located in H2 Transmitter in O2 (HTO).

2 Hydrogen from separator R105 is taken to oxygen analyzer for

measuring oxygen content & further processing in catalyst column,

R301 on Sheet # 6. Impure hydrogen is vented through flame arrester

R601 through PV101.

Sheet No - 4

1 This is Electrolyte preparation system where lye is prepared & fed to

electrolyzer. And feed water pump system.

Sheet No - 5

1 This covers various utilities like cooling water (filtered water) supply

& return system. Filtered water is used for various equipments, like

H2 lye cooler (E101), H2 compressor (C101), chilling plant and water

seal (R501). A pressure switch (PIS 501) is considered to generate an

alarm on low pressure of filter water.

2

Nitrogen gas is used in R101 hydrogen separator, R102 oxygen

separator & R301 catalyst column. Battery of Nitrogen cylinders is

used for this purpose. A pressure regulating valve (PRV) is set at 5

barg to regulate nitrogen pressure.

Page 3 of 4

3 Air is used for various instrument, valve actuators and solenoid

valves. A pressure switch (PIS 801) is considered to generate an alarm

on low pressure and to trip the plant on low low pressure. An air

pressure between 3 to 8 kg/cm2 is required to operate the valves. Air

is also used in Hydrogen purifying system.

4 DM water at a pressure of is required for lye making. This is fed to lye

making tank R202. DM water is also fed to hydrogen separator R101

from DM water storage tank (R201).

5

Chilled water unit E401 is considered for hydrogen purifier. Filtered

water is used in chilling plant.

Sheet No - 6

1 This sheet covers hydrogen purification and drying system

2 Hydrogen is fed to R 301 palladium catalyst column for purification

under certain temperature conditions.

3 This deoxidized hydrogen but wet is now fed to gas condenser E301

& cooled using cooling water is condenser.

4 Water content is separated from hydrogen in R303, water-gas

separator. After removal of water, hydrogen is fed to gas cooler &

dryer system R302 A / B.

5 There are 2 no. of dryers & gas coolers. This is a typical dryer plant

having 2 drying beds with change over valves. One set of dryer is

regenerated & kept ready for next switch over cycle while the other

one is in use. Waste water collected from gas separator is fed to water

Page 4 of 4

Seal R 501.Gases if any are vented through fire arrester R 601.Surface

heaters are used on catalyst column & dryer towers for adsorption &

regeneration.

Sheet No - 7

1 Dried hydrogen is analyzed for moisture and for traces of oxygen in

different analyzers.

Sheet No 8

1

Pure hydrogen is now collected in hydrogen buffer tank R401.

2

Pressure is monitored locally & also remotely by using PT403

transmitter.

3

Over pressure in tank is vented through safety valve PZV 401 &

fire arrester R602.

4

Hydrogen from buffer tank is taken to hydrogen compressor.

Compressed hydrogen is sent to hydrogen filling equipment

GF101. 8 high pressure cylinders are considered for simultaneous

filling of hydrogen per stream that means there will be 16 cylinders

for both the streams together.

5

A common vacuum pump has been considered to evacuate the

system before filling.

Note- Please refer P&ID (ANE/P&I/01, sheet 1 to 8)

You might also like

- Hydrogen DryerDocument2 pagesHydrogen DryerGandamana CitraksaNo ratings yet

- Enquiry: Bharat Heavy Electricals LimitedDocument21 pagesEnquiry: Bharat Heavy Electricals LimitedanjnaNo ratings yet

- Thermal Power Station Hydrogen Generation Using ElectrolysisDocument11 pagesThermal Power Station Hydrogen Generation Using ElectrolysisNageswar Makala100% (1)

- Hydrogen Generation PlantDocument3 pagesHydrogen Generation PlantKumaraswamy100% (1)

- Basics Water Treatment For Hydrogen Mini Leaflet EUROWATERDocument20 pagesBasics Water Treatment For Hydrogen Mini Leaflet EUROWATERhayamalhareeshaNo ratings yet

- bb1 DatasheetDocument14 pagesbb1 DatasheetMojtabaNo ratings yet

- 2.1 Integer Order Modeling and ControlDocument17 pages2.1 Integer Order Modeling and Controldebnathsuman49No ratings yet

- Valves SpecsDocument3 pagesValves SpecsTareq AlsadiNo ratings yet

- Regenerative Fuel Cells For Energy StorageDocument28 pagesRegenerative Fuel Cells For Energy StoragePavel BelovNo ratings yet

- Demineralization plant equipment and piping bill of quantitiesDocument3 pagesDemineralization plant equipment and piping bill of quantitiesdeyprasenNo ratings yet

- Supply, install and Commissioning of E tender for Majis Desalination PlantDocument26 pagesSupply, install and Commissioning of E tender for Majis Desalination PlantFeroz HakkimNo ratings yet

- Process Safety Overview - Dr. Wisdom Enang (FNSE)Document25 pagesProcess Safety Overview - Dr. Wisdom Enang (FNSE)Tony IsodjeNo ratings yet

- Motor Torque and Load Torque SelectionDocument22 pagesMotor Torque and Load Torque Selectionrobertovm2002No ratings yet

- RFQ Miscellaneous PumpDocument6 pagesRFQ Miscellaneous PumpGunturMudaAliAkbarNo ratings yet

- Compressor ChecklistDocument1 pageCompressor ChecklistRolando DaclanNo ratings yet

- TRU Waste Processing Center PBVS Design DescriptionDocument37 pagesTRU Waste Processing Center PBVS Design DescriptionShaimaa SaadNo ratings yet

- R134a Water Cooled Packaged Water Chillers - Cooling Only - : UWD Series (40HP 120HP)Document39 pagesR134a Water Cooled Packaged Water Chillers - Cooling Only - : UWD Series (40HP 120HP)MarceloRiosNo ratings yet

- Fire ExplosionDocument15 pagesFire ExplosionMutiaraNo ratings yet

- Achieving Zero Discharge Panipat Refinery and Petrochemical Complex-Indian OilDocument86 pagesAchieving Zero Discharge Panipat Refinery and Petrochemical Complex-Indian OilWalter GuttlerNo ratings yet

- Fire Case (Unwetted) PSVDocument2 pagesFire Case (Unwetted) PSVaw_aeNo ratings yet

- KUMAR ORGANIC PRODUCTS LIMITED SOLID FUEL BOILER DOSSIERDocument18 pagesKUMAR ORGANIC PRODUCTS LIMITED SOLID FUEL BOILER DOSSIERKiran DasNo ratings yet

- 0420 PV 201 Globe Valve Data SheetDocument12 pages0420 PV 201 Globe Valve Data SheetMohamed Farag MostafaNo ratings yet

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- Demi Water Storage and Distribution System description 除盐水储存和分配Document26 pagesDemi Water Storage and Distribution System description 除盐水储存和分配کالرو تحریک اتحادNo ratings yet

- Case Study 1. Developing HYSYS Material Stream: 1.1. Component and Fluid List SelectionDocument7 pagesCase Study 1. Developing HYSYS Material Stream: 1.1. Component and Fluid List SelectionChakravarthy BharathNo ratings yet

- Fractionation SystemsDocument8 pagesFractionation SystemsKha Damayantirika Tsf 'reall'No ratings yet

- Challenges in Steam Reforming PDFDocument28 pagesChallenges in Steam Reforming PDFSon Ngoc TranNo ratings yet

- Chlorsys: Electro-Chlorination PackageDocument8 pagesChlorsys: Electro-Chlorination Packagegkdora574No ratings yet

- Vent Tip Info Sheet SDocument1 pageVent Tip Info Sheet SabsahkahNo ratings yet

- Vacuum Breaker ValveDocument2 pagesVacuum Breaker ValveRaghunath YeturiNo ratings yet

- LNG Operations Manual Final Draft - 010515 - Web PDFDocument34 pagesLNG Operations Manual Final Draft - 010515 - Web PDFSushilNo ratings yet

- Is 3224 2002Document47 pagesIs 3224 2002suresh kumar100% (1)

- 110-Ee-420 110-VV-434 110-VV-420 110-VV-435 110-VV-430 110-Ep-425 110-CC-420Document1 page110-Ee-420 110-VV-434 110-VV-420 110-VV-435 110-VV-430 110-Ep-425 110-CC-420DIPANKAR LALANo ratings yet

- V Cone Flowmeter PDFDocument16 pagesV Cone Flowmeter PDFRajesh KrishnamoorthyNo ratings yet

- ENERGY ANALYSIS OF THERMAL DESALINATION PLANTDocument28 pagesENERGY ANALYSIS OF THERMAL DESALINATION PLANTJoel DaleNo ratings yet

- Feed Water Flow ControlDocument13 pagesFeed Water Flow ControlDwi Mulyanti Dwimulyantishop100% (1)

- Feedwater Deaerator: NIOEC-SP-47-05Document11 pagesFeedwater Deaerator: NIOEC-SP-47-05masoud132No ratings yet

- Excess Flow ValveDocument2 pagesExcess Flow ValveSyed Waqas HaiderNo ratings yet

- EntropyDocument10 pagesEntropyShyam DevNo ratings yet

- Simulation of Distillation For ACETONE-BENZENE-CHLOROFORMDocument8 pagesSimulation of Distillation For ACETONE-BENZENE-CHLOROFORMfjcgNo ratings yet

- Dr. CORRADO SOMMARIVA Desalination LectureDocument216 pagesDr. CORRADO SOMMARIVA Desalination LectureShubham BansalNo ratings yet

- Gestra Condensate ManualDocument172 pagesGestra Condensate ManualGeorge ClaessenNo ratings yet

- Desplazamiento Positivo PDFDocument20 pagesDesplazamiento Positivo PDFMelina SbhNo ratings yet

- U-Tube Heat ExchangerDocument9 pagesU-Tube Heat Exchangerhirenpatel_62No ratings yet

- Specification For Diesel Fuel Conditioning PackageDocument17 pagesSpecification For Diesel Fuel Conditioning PackagesudjonoNo ratings yet

- Miscellaneous Boiler Types, Economisers and Superheaters - International SitDocument4 pagesMiscellaneous Boiler Types, Economisers and Superheaters - International SitMohd ZaieriNo ratings yet

- On-Site Generation of Hypochlorite: First EditionDocument173 pagesOn-Site Generation of Hypochlorite: First EditiontestNo ratings yet

- Tank Venting Capacity-Fire CaseDocument1 pageTank Venting Capacity-Fire CaseAjay TiwariNo ratings yet

- 9013 Energy Requirements For Hydrogen Gas CompressionDocument6 pages9013 Energy Requirements For Hydrogen Gas CompressionPedro JuanNo ratings yet

- Simple ORC Model SQ110918Document9 pagesSimple ORC Model SQ110918radanpetricaNo ratings yet

- Hydrogen BroucherDocument16 pagesHydrogen BroucherIvo Padua100% (1)

- Diesel Fuel Storage Tank Vent Sizing CalculationDocument2 pagesDiesel Fuel Storage Tank Vent Sizing CalculationKrishnamoorthyNo ratings yet

- Acoustics Lesson 1 PDFDocument60 pagesAcoustics Lesson 1 PDFTejash SinghNo ratings yet

- Process Heat Transfer Hof MasterDocument327 pagesProcess Heat Transfer Hof MastersdrtfgNo ratings yet

- Cooling Water System ProceduresDocument8 pagesCooling Water System ProceduresBoiler Scrubber50% (2)

- DragonflyDocument22 pagesDragonflyjakkkkeNo ratings yet

- Allyl BDocument9 pagesAllyl BDemet AcargilNo ratings yet

- Hydrogen Plant Operation SOPDocument17 pagesHydrogen Plant Operation SOPSooraj Surendran Sugatha100% (1)

- Production of Ethylene GlycolDocument15 pagesProduction of Ethylene Glycoldrami9475% (4)

- Heat Recovery Presentation Rev 130213Document32 pagesHeat Recovery Presentation Rev 130213Budhi SaputraNo ratings yet

- VIBRATION ANALYSIS TITLEDocument153 pagesVIBRATION ANALYSIS TITLEAnonymous ffje1rpa100% (1)

- Numatics Valve TrainingDocument57 pagesNumatics Valve TrainingRaymond EsmeraldaNo ratings yet

- CircuitsDocument14 pagesCircuitsAnonymous ffje1rpaNo ratings yet

- AMRI ISORIA 10 Type Series Booklet Data PDFDocument20 pagesAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- C1 Compressor: Plant CharleroiDocument9 pagesC1 Compressor: Plant CharleroiAnonymous ffje1rpaNo ratings yet

- NPSHDocument7 pagesNPSHsateesh chandNo ratings yet

- Additel 918 ManualDocument2 pagesAdditel 918 ManualAnonymous ffje1rpaNo ratings yet

- GOSeDocument9 pagesGOSeAnonymous ffje1rpaNo ratings yet

- Parker Solenoid Valve Technical DataDocument2 pagesParker Solenoid Valve Technical DataAnonymous ffje1rpaNo ratings yet

- Fluke Pressure CalibratorDocument1 pageFluke Pressure CalibratorAnonymous ffje1rpaNo ratings yet

- THDRTDocument20 pagesTHDRTAnonymous ffje1rpaNo ratings yet

- Presentacion IlearnDocument38 pagesPresentacion IlearnAnonymous ffje1rpaNo ratings yet

- Air SeparatorsDocument28 pagesAir SeparatorsAnonymous ffje1rpaNo ratings yet

- Chapter 1 Ref CyclesDocument31 pagesChapter 1 Ref CyclesAnonymous ffje1rpaNo ratings yet

- Balancing: One Plane/two PlanesDocument19 pagesBalancing: One Plane/two PlanesAnonymous ffje1rpaNo ratings yet

- HR-4050 Emp. Recog. & Awards ProgramDocument2 pagesHR-4050 Emp. Recog. & Awards ProgramAnonymous ffje1rpaNo ratings yet

- Advanced NDT 2Document56 pagesAdvanced NDT 2Anonymous ffje1rpa83% (6)

- Acid Cleaner Life ExtensionDocument33 pagesAcid Cleaner Life ExtensionAnonymous ffje1rpaNo ratings yet

- Journal BearingsDocument23 pagesJournal BearingsAnonymous ffje1rpa100% (1)

- Equipment Specifications PDFDocument10 pagesEquipment Specifications PDFJ.SIVIRANo ratings yet

- Shaft Alignment: Nizwa College of TechnologyDocument15 pagesShaft Alignment: Nizwa College of TechnologyAnonymous ffje1rpaNo ratings yet

- Cooler Drain LocationDocument1 pageCooler Drain LocationAnonymous ffje1rpaNo ratings yet

- Sadat City Factories List 2009Document39 pagesSadat City Factories List 2009Anonymous ffje1rpaNo ratings yet

- Aps Loto Sample 2014Document4 pagesAps Loto Sample 2014Anonymous ffje1rpaNo ratings yet

- Oxygen Gas Feasibility StudyDocument36 pagesOxygen Gas Feasibility StudyGhulam Abbas100% (1)

- Detail WI Online TestingDocument9 pagesDetail WI Online TestingAnonymous ffje1rpaNo ratings yet

- Ed 021094Document19 pagesEd 021094Anonymous ffje1rpaNo ratings yet

- RELIEF VALVE TEST PROCEDUREDocument30 pagesRELIEF VALVE TEST PROCEDUREAnonymous ffje1rpa100% (1)

- Basic-Concepts MTBFDocument15 pagesBasic-Concepts MTBFAnonymous ffje1rpaNo ratings yet

- Aegi ClampsDocument12 pagesAegi ClampssssydorenkoNo ratings yet

- Logitech G27 C-Clamps ReplacementDocument20 pagesLogitech G27 C-Clamps Replacementfadli_nugraha6109No ratings yet

- AISC SectionsDocument3 pagesAISC SectionsraymondNo ratings yet

- Machining Report (Lathe)Document11 pagesMachining Report (Lathe)Syah KlAte67% (3)

- JENKA System Technical ManualDocument20 pagesJENKA System Technical ManuallutcusNo ratings yet

- Guide To DSEAR Risk AssessmentDocument25 pagesGuide To DSEAR Risk Assessmentkanakarao10% (1)

- Toshiba CodesDocument5 pagesToshiba Codesbruxo70No ratings yet

- BASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESDocument41 pagesBASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESKadiyam VijayNo ratings yet

- Thermal Expansion of Polytetrafluoroethylene (Teflon)Document4 pagesThermal Expansion of Polytetrafluoroethylene (Teflon)Josafat Cruz-PrietoNo ratings yet

- RV Valves Product Data SheetDocument16 pagesRV Valves Product Data SheetWaqar DarNo ratings yet

- International Journal of Plasticity: Luiz Carneiro, Qin Yu, Yanyao JiangDocument17 pagesInternational Journal of Plasticity: Luiz Carneiro, Qin Yu, Yanyao JiangBangjian YangNo ratings yet

- Evaluating Gas Turbine TestingDocument27 pagesEvaluating Gas Turbine TestingReshmi Vinu100% (2)

- Cast Iron: Cast Irons Are A Class of Ferrous Alloys WithDocument12 pagesCast Iron: Cast Irons Are A Class of Ferrous Alloys WithChandima K PriyamalNo ratings yet

- AC - MonthlyDocument1 pageAC - MonthlyManibalanNo ratings yet

- Frequently asked questions about hypochlorous acidDocument12 pagesFrequently asked questions about hypochlorous acidChoice OrganoNo ratings yet

- Review of Literature On Steam AccumulatorDocument10 pagesReview of Literature On Steam Accumulatortamil vaananNo ratings yet

- Hazardous Waste FlowchartDocument21 pagesHazardous Waste FlowchartRizki Mufidayanti100% (1)

- Approach Boundaries NFPA 70E Table 130 2 (C)Document8 pagesApproach Boundaries NFPA 70E Table 130 2 (C)kamal_khan85100% (1)

- Refrigeration Theory PDFDocument48 pagesRefrigeration Theory PDFValentin LupascuNo ratings yet

- Anhydrous Ammonia Unloading Station & Storage/Vaporizer SystemDocument2 pagesAnhydrous Ammonia Unloading Station & Storage/Vaporizer SystemWalter Rigamonti100% (1)

- QuestionnaireDocument5 pagesQuestionnairejc PH100% (1)

- Development of Nozzle Clogging IndexDocument13 pagesDevelopment of Nozzle Clogging Indexsdtd.ranchiNo ratings yet

- Chillers, AHU, RTU How They Work - The Engineering MindsetDocument8 pagesChillers, AHU, RTU How They Work - The Engineering Mindsetadk100% (1)

- Alpha Wire CatalogDocument418 pagesAlpha Wire CatalogmycopteraviationNo ratings yet

- Hitachi Shirokuma floor-mounted air conditioner features and benefitsDocument2 pagesHitachi Shirokuma floor-mounted air conditioner features and benefitsCristian TopalaNo ratings yet

- Handling Compressed Gas CylindersDocument103 pagesHandling Compressed Gas CylinderstorolsoNo ratings yet

- Service Manual SM1-10-33.0: Outrigger/Steer Pump, R & IDocument4 pagesService Manual SM1-10-33.0: Outrigger/Steer Pump, R & IMohamed RashedNo ratings yet

- FR700 Series Owner's ManualDocument60 pagesFR700 Series Owner's ManualmetasNo ratings yet

- Low Voltage Temperature Sensors / /: TMP35 TMP36 TMP37Document19 pagesLow Voltage Temperature Sensors / /: TMP35 TMP36 TMP37lord mace tyrellNo ratings yet

- Reactor Modeling and Simulations in Synthesis Gas ProductionDocument39 pagesReactor Modeling and Simulations in Synthesis Gas ProductionSteven Sandoval100% (1)