Professional Documents

Culture Documents

FP 00406

Uploaded by

Passmore DubeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FP 00406

Uploaded by

Passmore DubeCopyright:

Available Formats

18th European Symposium on Computer Aided Process Engineering ESCAPE 18

Bertrand Braunschweig and Xavier Joulia (Editors)

2008 Elsevier B.V./Ltd. All rights reserved.

Validation of an Ice-cream factory operations

model

Peter M.M. Bongers, Bas H. Bakker

Unilever Food and Health Research Institute, O. van Noortlaan 120, 3133 AT

Vlaardingen, The Netherlands

Abstract

The process plant of one of Unilevers ice-cream factories, needed to increase the output

by 30%. Outsourcing the volume or working overtime are not possible to generate the

additional output. The immediate engineering response was to propose a capital

investment project for building additional capacity. The key question is then in which

area of the plant to invest, because the bottleneck might not be obvious and might

depend on the actual portfolio. As an alternative we have pursued a modelling and

simulation route to identify which bottleneck(s) need enlarging, taking into account the

costs and the time needed. The model has been designed to quantify the effect of

working procedures, minimum and maximum storage time of the mixes, equipment

extensions and modifications.

Using the model, various scenarios have been simulated and the outcome evaluated.

Apart of a number of bottlenecks which have been identified and improved, the main

one has been the fact that only the packing lines are scheduled.

By scheduling the factory as a whole, the available overall capacity of the factory can

be increased significantly. The above factory schedule generates 10-30% additional

capacity without significant capital expenditure.

In this paper, the main emphasis will be the validation of the model to confirm that the

predicted capacity is achievable.

1. Problem description

1.1. Process description

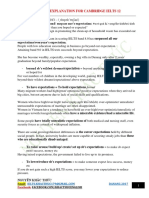

Figure 1 shows the ice-cream manufacturing process: All ingredients are stored in the

local warehouse, depending on quantities used, different ways of storage are used (bags,

silos, buckets, etc.). From here, the ingredients are transported to the mix department

where according to the recipe, all ingredients are mixed, pasteurised and stored in socalled ageing vessels. After a minimum required ageing time, the mixes are frozen in

continuous freezers. A number of freezers are needed to assemble the final products on

the packing lines. After the product assembly, the products are frozen in a hardening

tunnel.

P.M.M. Bongers and B.Bakker

Ingredient

storage

Mixing

4000kg

Processing

4000 kg

Process Line

8000lph

Buffering

4000 kg

4000 kg

F1

F2

8000 kg

8000 kg

F3

F4

8000 kg

F5

8000 kg

4000 kg

F6

F7

Line 4

Line 5

8000 kg

20000 kg

F9

F8

Freezing

Line 1

Line 13

Line 3

Line 23

Line 2

Line 8

Packing

Figure 1. Process flow diagram of ice cream manufacturing

1.2. Manufacturing complexity

The complexity of this manufacturing site (at the time of this study) includes:

8 packing lines

Buffer tanks per line vary in number and size

One process line to feed all packing lines

130 SKUs and 160 recipes

Fresh dairy ingredients (limited shelf life)

Stringent cleaning regime on process (Allergens & Kosher)

Minimum and maximum standing time in buffers

Mandatory CIP (24 hour cycle on process, 72 hour cycle on all other

equipment)

1.3. Problem description

The key question is how to increase the output of the factory by 30% within three

months. Outsourcing the volume or working overtime are not possible to generate the

additional output. The immediate engineering response is to propose a capital

investment project for building additional capacity. The key question is then in which

area of the plant to invest, because the bottleneck might not be obvious. In this paper we

will pursue a modelling and simulation route to identify which bottleneck(s) need

enlarging, taking into account the costs.

2. Factory modelling

In this section, the design of the multi-stage scheduling model of the ice cream plant

will be described, following Bongers and Bakker (2006,2007). The model should be the

lowest complexity description of the plant behaviour of the:

Validation of an Ice cream factory operations model

3

Manufacturing lines and their key equipment

Material flow through the plant;.

Operating procedures inside the plant.

The model will be built according to the schematics of Fig.2. It should be noted that the

softinformation bit provides valuable information about the plant operations, as there

is almost always a discrepancy between the written procedures and the actual ones.

Figure 2 Model building schematics.

The model has been implemented in the INFOR advanced scheduling software (INFOR

2003). Within the INFOR software, stages are being defined as processes coupled with

tanks. The behaviour of the stage is determined by the characteristics of both the

process as well as the tank. Products can be seen as the material flow from one stage to

another stage. A process step describes how a product is made (which stage, process,

tank and characteristics).

As an example, the 2 stages of the plant are depicted in Fig.3.

processing

Process line(s)

Vessel(s)

Mixes

Packing line(s)

packing

SKUs

Figure 3 two-stages as part of the scheduling model

3. Baseline operations

Before the benefits can be quantified, the baseline should be established. To this end,

the designed multi-stage scheduling model has been used to establish this baseline, i.e.

P.M.M. Bongers and B.Bakker

given the current portfolio, equipment and operating procedures is a 30% volume

increase possible? (see Fig. 4).

Figure 4 base-line

Fig.4 shows clearly that the requested 30% volume increase is not possible. The model

has been key to identify that the limitations are upstream in the process and not at the

packing lines. This is for the operational staff counter-intuitive as they observe a

bottleneck if the packing lines cannot run. The figure shows two main limitations: (i) no

space for CIP on the processing line, where there needs to be a mandatory cleaning

every 24 hrs. (ii) a tank overlap, showing insufficient capacity of the buffer vessels.

In utilising the model and analysing the results on a minute based scale, three

bottlenecks where idenfified:

1. The homogeniser was blocked for a long time by the pre-mix vessels in preparing a

water batch for cleaning between the different products;

2. CIP of the mixplant was longer than in other comparable plants;

3. Due to lack of transparancy in the operations, the mix plant operators are not aware

that any delay in changing between batches was causing reduction in volume. As

there is a large time delay between mix preparation and consumption, it is extremely

difficult to relate packing shortages can be caused the day before.

For both bottlenecks solutions have been identified:

1. Water batches for cleaning are now taken from mains water. This needed some

additional pipe work, valves and update of the control system;

2. CIP time reduction by learning from other plants;

3. Scheduling the upstream bottlenecks by multi-stage scheduling of the whole factory

and instructing the mix plant operators about the importance of their work.

The baseline mixplant output was retrieved from the factory data system prior to

implementing changes, it slightly depending on the product portfolio.

Validation of an Ice cream factory operations model

5

By implementing solutions (1) and (2) in the factory, and, adapting the multi-stage

scheduling model to the new situation, the improvements can be visualised figure 5. In

order to simulate the factory operations, the stragtegy that the operators are normally

using in the factory are used (i.e. filling the first tank that becomes available). An

improvement of appr. 8% in the capacity of the factory can be derived from figure 5.

Figure 5 effect of implementation of the technical changes

In the next step, the multi-stage scheduling (3) has been implemented in the factory, i.e.

the production schedule for the whole factory is made by the multi-stage scheduling

model. This weekly schedule is made by (i) importing the amount of SKUs to be

produced from the local ERP system; (ii) then the whole schedule from mixing to

packing is generated by the software; (iii) this schedule is exported to log-sheets for

each of the departments (including the start-time and end-time for each of the batches.

The actual production schedule for the whole plant, as generated by the model, for one

week is shown in figure 6. The amount of volume requested from the mixplant is an

increase by 30% with respect to the base-line.

Figure 6 Implementation of both the technical changes and the multi-stage scheduling

P.M.M. Bongers and B.Bakker

Based on the produced log-sheets

(generated the week before), the

operators in each of the departments

worked towards achieving the timings

in the provided log-sheets.

During this week, the actual produced

amount was 29% more than the

baseline (1% less than scheduled by

utilising the model), thereby validating

the model. This resulted in a

celebration in the plant, see the figure

on the left

Furthermore, the idle time due to lack of ingredients was reduced by 4% to virtually not

occurring anymore.

4. Conclusions and future work

The local ice-cream factory has achieved the required 30% volume increase.

A lot of attention was given to the operational implementation in its widest sense, as the

use of the model meant a complete new way of working for the people in the factory.

Furthermore, the model had to be embedded in the factory infrastructure. The key

changes that have been implemented where:

Implement the technical changes

Apply multi-stage scheduling for the whole factory, from material call-off to packing

lines, instead of scheduling the packing lines only.

Future work will include:

- The modelling and optimisation of a much more complex factory

- Optimisation of feasible schedules

References

Bongers, P.M.M., B.H. Bakker (2006). Application of multi-stage scheduling, ESCAPE

16 proceedings

Bongers, P.M.M., B.H. Bakker (2007). Modelling an Ice cream factory for debottlenecking, ESCAPE 17 proceedings

INFOR (2003), Advanced Scheduling: Users Course and Modelling course, Rijswijk,

The Netherlands

You might also like

- Deluge System Design GuideDocument14 pagesDeluge System Design GuidePassmore DubeNo ratings yet

- AGA Purging.2001 PDFDocument157 pagesAGA Purging.2001 PDFLeDzung100% (1)

- Code of Practice 5: The Design and Construction of Manifolds Using Acetylene Gas FROM 1.5 TO 25 Bar REVISION 3: 2016Document36 pagesCode of Practice 5: The Design and Construction of Manifolds Using Acetylene Gas FROM 1.5 TO 25 Bar REVISION 3: 2016Justin ChongNo ratings yet

- Worth ReadingDocument4 pagesWorth ReadingPassmore DubeNo ratings yet

- Trackless Mobile MachineryDocument21 pagesTrackless Mobile MachineryPassmore DubeNo ratings yet

- Deluge DesignDocument5 pagesDeluge DesignrendydunNo ratings yet

- Deluge Sprinkler SystemDocument8 pagesDeluge Sprinkler SystemPassmore DubeNo ratings yet

- Pricing Options Based On Trinomial Markov Tree PDFDocument8 pagesPricing Options Based On Trinomial Markov Tree PDFPassmore DubeNo ratings yet

- Hydrochloric AcidDocument11 pagesHydrochloric AcidPassmore DubeNo ratings yet

- Venting calculations for vertical cylinder tank per API 2000 7th editionDocument3 pagesVenting calculations for vertical cylinder tank per API 2000 7th editionKartik PatelNo ratings yet

- Multi Asset Math Finance PDFDocument46 pagesMulti Asset Math Finance PDFPassmore DubeNo ratings yet

- Company Name Most Recent Fiscal Year Date of Coverage AnalystDocument79 pagesCompany Name Most Recent Fiscal Year Date of Coverage AnalystPassmore DubeNo ratings yet

- Sect 4 Injection MoldingDocument3 pagesSect 4 Injection MoldingPassmore DubeNo ratings yet

- Linear EquationsDocument1 pageLinear EquationsPassmore DubeNo ratings yet

- This Book Is About Business Success Manual - Management & Leadership, It Is WonderfulDocument96 pagesThis Book Is About Business Success Manual - Management & Leadership, It Is Wonderfulraeissi100% (1)

- CH 06Document4 pagesCH 06Passmore DubeNo ratings yet

- Coal To Methanol To GasolineDocument113 pagesCoal To Methanol To GasolinePassmore DubeNo ratings yet

- Solving a system of 3 linear equations with 4 variablesDocument1 pageSolving a system of 3 linear equations with 4 variablesPassmore DubeNo ratings yet

- Chapter 6: Selected Uses of Fats and Oils in Food: PreviousDocument3 pagesChapter 6: Selected Uses of Fats and Oils in Food: PreviousPassmore DubeNo ratings yet

- Shopping Bag Quantity AssumptionsDocument6 pagesShopping Bag Quantity AssumptionsPassmore DubeNo ratings yet

- Plastics - Manufacturing MethodsDocument2 pagesPlastics - Manufacturing MethodsPassmore DubeNo ratings yet

- Fon Simult1Document14 pagesFon Simult1sharath1199No ratings yet

- Poly Lac TideDocument20 pagesPoly Lac TidechimikoxdNo ratings yet

- CH 07Document3 pagesCH 07Passmore DubeNo ratings yet

- Injection MoldingDocument2 pagesInjection MoldingPassmore DubeNo ratings yet

- FeasibilityDocument54 pagesFeasibilityPassmore DubeNo ratings yet

- Chapter 4: Global Trends in The Availability of Edible Fats and OilsDocument4 pagesChapter 4: Global Trends in The Availability of Edible Fats and OilsPassmore DubeNo ratings yet

- The Ethical Implications of Underfunding Development EvaluationsDocument8 pagesThe Ethical Implications of Underfunding Development EvaluationsPassmore DubeNo ratings yet

- Fats oils human nutrition report 1993Document1 pageFats oils human nutrition report 1993Passmore DubeNo ratings yet

- SheepDocument2 pagesSheepPassmore DubeNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 13 Fashion Studies Textbook XIDocument158 pages13 Fashion Studies Textbook XIMeeta GawriNo ratings yet

- Waves and Thermodynamics, PDFDocument464 pagesWaves and Thermodynamics, PDFamitNo ratings yet

- New Brunswick CDS - 2020-2021Document31 pagesNew Brunswick CDS - 2020-2021sonukakandhe007No ratings yet

- Micropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldDocument8 pagesMicropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldIJBSS,ISSN:2319-2968No ratings yet

- SEO Design ExamplesDocument10 pagesSEO Design ExamplesAnonymous YDwBCtsNo ratings yet

- Vehicle Registration Renewal Form DetailsDocument1 pageVehicle Registration Renewal Form Detailsabe lincolnNo ratings yet

- LON-Company-ENG 07 11 16Document28 pagesLON-Company-ENG 07 11 16Zarko DramicaninNo ratings yet

- Report Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIDocument26 pagesReport Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIHafizh ZuhdaNo ratings yet

- Module - No. 3 CGP G12. - Subong - BalucaDocument21 pagesModule - No. 3 CGP G12. - Subong - BalucaVoome Lurche100% (2)

- CL 5313 17021-1 Requirements Matrix-1458-5Document6 pagesCL 5313 17021-1 Requirements Matrix-1458-5Ana AnaNo ratings yet

- Key formulas for introductory statisticsDocument8 pagesKey formulas for introductory statisticsimam awaluddinNo ratings yet

- ExpDocument425 pagesExpVinay KamatNo ratings yet

- Postnatal Assessment: Name Date: Age: D.O.A: Sex: Hospital: Marital Status: IP .NoDocument11 pagesPostnatal Assessment: Name Date: Age: D.O.A: Sex: Hospital: Marital Status: IP .NoRadha SriNo ratings yet

- Digital Communication Quantization OverviewDocument5 pagesDigital Communication Quantization OverviewNiharika KorukondaNo ratings yet

- PharmacologyAnesthesiology RevalidaDocument166 pagesPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- Periodic ClassificationDocument4 pagesPeriodic ClassificationtusharNo ratings yet

- Practical Research 2: Self-Learning PackageDocument3 pagesPractical Research 2: Self-Learning PackagePrinces BaccayNo ratings yet

- WhatsoldDocument141 pagesWhatsoldLuciana KarajalloNo ratings yet

- Control SystemsDocument269 pagesControl SystemsAntonis SiderisNo ratings yet

- NGPDU For BS SelectDocument14 pagesNGPDU For BS SelectMario RamosNo ratings yet

- Transformer Oil Testing MethodsDocument10 pagesTransformer Oil Testing MethodsDEE TOTLVJANo ratings yet

- Easa Ad Us-2017-09-04 1Document7 pagesEasa Ad Us-2017-09-04 1Jose Miguel Atehortua ArenasNo ratings yet

- The Botanical AtlasDocument74 pagesThe Botanical Atlasjamey_mork1100% (3)

- Employee Engagement A Case Study at IVRCL-1Document7 pagesEmployee Engagement A Case Study at IVRCL-1Anonymous dozzql7znKNo ratings yet

- S2 Retake Practice Exam PDFDocument3 pagesS2 Retake Practice Exam PDFWinnie MeiNo ratings yet

- IELTS Vocabulary ExpectationDocument3 pagesIELTS Vocabulary ExpectationPham Ba DatNo ratings yet

- Environmental Technology Syllabus-2019Document2 pagesEnvironmental Technology Syllabus-2019Kxsns sjidNo ratings yet

- Afu 08504 - International Capital Bdgeting - Tutorial QuestionsDocument4 pagesAfu 08504 - International Capital Bdgeting - Tutorial QuestionsHashim SaidNo ratings yet

- Fong vs. DueñasDocument2 pagesFong vs. DueñasWinter Woods100% (3)

- Unit 1 - International Banking Meaning: Banking Transactions Crossing National Boundaries Are CalledDocument6 pagesUnit 1 - International Banking Meaning: Banking Transactions Crossing National Boundaries Are CalledGanesh medisettiNo ratings yet