Professional Documents

Culture Documents

Power Supply Design Guidelines v0.4 PDF

Uploaded by

dimitaringOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Supply Design Guidelines v0.4 PDF

Uploaded by

dimitaringCopyright:

Available Formats

Power Supply

Design Guidelines

Author

Name

David Tash

Date

August 3 2005

Version 0.4

21/09/2011

Company

Dgtronix

September 21, 2011

Power Supply Design Guidelines

Revision

0.1

0.2

0.3

0.4

Page 2 of 27

Description

Initial DRAFT

Correction equations 9 and 11

Changed document template

Fixed menu text

Date

31/07/05

15/09/05

13/09/11

21/09/11

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

Table of Contents

1.

1.1.

OVERVIEW ...................................................................................................................................... 5

GENERAL ............................................................................................................................................ 5

2.

2.1.

2.1.1.

2.1.2.

2.2.

2.2.1.

2.2.2.

2.2.3.

STEP DOWN TOPOLOGIES.......................................................................................................... 6

LINEAR REGULATORS, (LDO LOW DROP REGULATOR).................................................................... 6

Advantages .................................................................................................................................... 6

Disadvantages ............................................................................................................................... 7

SWITCHED POWER SUPPLIES - INTRO .................................................................................................. 7

Forward ......................................................................................................................................... 7

Common Topologies ...................................................................................................................... 7

Switching Frequency and Size ....................................................................................................... 8

3.

3.1.

3.1.1.

3.1.2.

SWITCHING IN AC/DC POWER SUPPLIES .............................................................................. 9

AC/DC POWER SUPPLIES .................................................................................................................... 9

Legacy AC/DC Power Supplies ..................................................................................................... 9

Switched AC/DC Power Supplies ................................................................................................ 10

4.

4.1.

4.2.

4.3.

4.3.1.

4.3.2.

4.3.3.

4.3.4.

PWM, (PULSE WIDTH MODULATION), BUCK TOPOLOGY ............................................. 12

FORWARD ......................................................................................................................................... 12

BUCK CONVERTER - BASIC SCHEMATICS .......................................................................................... 12

BUCK CONVERTER EQUATIONS......................................................................................................... 13

Developing Buck Converter Equations........................................................................................ 13

Conclusions on Buck Converter Equations ................................................................................. 14

Advantages .................................................................................................................................. 14

Disadvantages ............................................................................................................................. 14

5.

5.1.

5.2.

5.2.1.

5.2.2.

5.2.3.

SYNCHRONOUS BUCK TOPOLOGY ....................................................................................... 15

THE MOTIVATION TOWARDS THE SYNCHRONOUS BUCK TOPOLOGY ................................................. 15

SYNCHRONOUS BUCK CONVERTER BASIC SCHEMATICS ................................................................ 15

Further Improvements ................................................................................................................. 17

PWM Output Voltage Control Loop ............................................................................................ 17

Available PWM Controllers in the DC/DC converter Market ..................................................... 18

6.

6.1.

6.2.

6.2.1.

6.2.2.

6.2.3.

6.2.4.

6.2.5.

SYNCHRONOUS BUCK CONVERTER DESIGN FROM SCRATCH ................................... 19

FORWARD ......................................................................................................................................... 19

DESIGNING A SYNCHRONOUS BUCK CONVERTER ............................................................................. 19

Choosing the Switching Frequency ............................................................................................. 19

Define Ripple Current I .......................................................................................................... 20

Calculating the Minimum Inductance Value ............................................................................... 20

Output Voltage Ripple ................................................................................................................. 20

Output Capacitor Selection ......................................................................................................... 20

7.

7.1.

7.2.

7.3.

7.4.

7.5.

7.6.

LAYOUT GUIDELINES ................................................................................................................ 22

FORWARD ......................................................................................................................................... 22

SMALL CURRENT LOOPS ................................................................................................................... 22

CONTROL STAGE NOISE SENSITIVE ................................................................................................ 23

GROUND CONTROL ........................................................................................................................... 25

OUTPUT VOLTAGE PLANES ............................................................................................................... 25

LAYOUT EXAMPLE ............................................................................................................................ 26

Page 3 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

Table of Figures

Figure 1: Voltage Regulator ....................................................................................................... 6

Figure 2: Legacy AC/DC Power Supplies .................................................................................. 9

Figure 3: Current flow in the Bridge Rectifier for Positive Swing ............................................ 9

Figure 4: Current flow in the Bridge Rectifier for Negative Swing ........................................... 9

Figure 5: Switched AC/DC Power Supply Flyback Topology ............................................. 10

Figure 6: Switched AC/DC Power Supply Voltage on the Capacitor................................... 11

Figure 7: The Buck Converter .................................................................................................. 12

Figure 8: Current and voltage waveforms of the Buck Converter ........................................... 13

Figure 9: Synchronous Buck Converter with Parallel Schottky Diode .................................... 15

Figure 10: Dead Time and Schottky Diode Waveforms .......................................................... 16

Figure 11: Efficiency Improvement by employing Synchronous Rectification ....................... 16

Figure 12: Switching Loss of MOSFET during transition ....................................................... 17

Figure 13: PWM Output Voltage Control Loop ...................................................................... 18

Figure 14: Main source of EMI in a Buck Converter ............................................................... 22

Figure 15: Feedback Signal Routing ........................................................................................ 23

Figure 16: Feedback Traces (bold lines susceptible to noise) .................................................. 24

Figure 17: TPS40055 Evaluation Board Schematics by TI...................................................... 26

Figure 18: Top Side Component Assembly ............................................................................. 26

Figure 19: Top Layer Copper ................................................................................................... 27

Figure 20: Bottom Layer Copper.............................................................................................. 27

Page 4 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

1. Overview

1.1.

General

The purpose of this document is to introduce general design guidelines and knowledge on

power supply design methodologies and considerations. Most of the topologies shown in

this document relate to step-down power supplies, though step-up is shown also for

common knowledge.

The reader of this document will achieve the following:

Basic knowledge on AC/DC power supply units

Basic/Intermediate level of knowledge on DC/DC power supply units

Power supply topology design abilities for specific requirements of specific

systems

Understanding the trade-offs of the design topology

Selecting the required components and calculate their values

Controlling the output noise and ripple

A complete power supply design

These guidelines are based mostly on the following:

Page 5 of 27

Datasheets

Application Notes

Articles on Power Supplies

Power Supply Consultant instructions and guidelines

Previous Power Supply Designs

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

2. Step Down Topologies

A power supply is a buffer circuit that is placed between an incompatible power source and a

load in order to make them compatible.

Contemporary designs are usually generated of a single voltage power source, from which the

PCB is fed. The various voltages required by the components on the PCB are generated in

various methods, which are summarized as follows:

2.1.

Linear Regulators, (LDO Low Drop Regulator)

This is a linear solution. Figure 1 shows the Regulator Operation.

Figure 1: Voltage Regulator

The output voltage is sampled, (measured), through a resistor divider which is fed into the

inverting input of an error amplifier. The non-inverting input is tied to a reference voltage.

The error amplifier will always try to force the voltages at its input to be equal. To do this, it

sources current as required to provide sufficient load current to maintain the output voltage at

the regulated value, which is given by Vout = Vref (1+R1/R2).

The resistors R1 and R2 maybe external in adjustable LDO versions, or internal with fixed

output LDOs.

Typical Vref is about 1.25V depending on the component and technology.

2.1.1.

Page 6 of 27

Advantages

Low parts count and easy to design

Cheap

Excellent regulation characteristics

Low output noise

No generated EMI

Excellent transient response

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

2.1.2.

Disadvantages

Single Output

No Step-Up designs

Poor efficiency, especially in high V x I = (Vout-Vin) x I

Sometimes requires heat sinks as part of the PCB or external heat sinks.

2.2.

Switched Power Supplies - Intro

When higher efficiencies are required, one must apply a switched power supply topology.

2.2.1.

Forward

The concept of switching is based on transferring energy from the main power

supply source to the load during a time slot, (pulse width). In order to maintain

a DC voltage for the load, this energy is averaged, and the voltage ripple is

minimized.

The time slot, in which the energy is transferred, is increased on heavy loads

and decreased on lighter loads.

The switching frequency range is 50kHz to about 2MHz.

The switching circuitry is employed of a switching controller, a low series

resistant Transistor/FET, low ESR inductor/transformer, low ESR capacitor

and an output voltage correction loop. (Current limit and protection circuits are

also applied).

The efficiency ranges between 70% to 95%, depending on topology, Vin, Vout,

and the loss on the components.

2.2.2.

Common Topologies

The topologies are divided into three types:

Step down Relates to a power supply where Vout<Vin

o Flyback discussed shortly on Chapter 3.

o Buck discussed on Chapter 4

o Synchronous Buck discussed on Chapter 5

Step Up Relates to a power supply where Vout>Vin, (not in scope of this

document)

o Boost

Step Up/Down Relates to a power supply where Vout is greater or smaller

than Vin, (not in scope of this document)

o Buck-Boost

o SEPIC

Page 7 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

2.2.3.

Switching Frequency and Size

The physical size of power-switching and energy storage elements in switching DC/DC

converters is directly affected by the operating frequency. The power coupled by a magnetic

element is:

1

LI2 f

2

Equation 1: Power coupled by a magnetic element

P( L) =

As operating frequency rises, the inductance required to maintain a constant power decreases

proportionally. Since inductance is related to the area of magnetic material and number of

turns of wire, the physical size of an inductor can be decreased.

In other words, the higher the frequency the smaller the inductors physical dimensions.

Page 8 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

3. Switching in AC/DC power supplies

3.1.

AC/DC Power Supplies

This chapter shows the concept of switching related to an AC/DC power supply.

3.1.1.

Legacy AC/DC Power Supplies

Legacy, non-switched, power supplies were based on a 220V/110V input voltage, an input

stage transformer with a 1:X winding ratio, a bridge rectifier, and an output Low Pass Filter,

as shown in Figure 2. In order to comply with output voltage regulation smaller than 15%, an

additional linear regulator is required.

Figure 2: Legacy AC/DC Power Supplies

Figure 3: Current flow in the Bridge Rectifier for Positive Swing

Figure 4: Current flow in the Bridge Rectifier for Negative Swing

Page 9 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

For multiple output voltages, multiple output transformers are used, and output stage Low

Pass Filters are added for each stage.

3.1.1.1.

Advantages

Simple

50/60Hz transformers are robust and compliant with safety regulations

The output ripple is 50/60Hz, (and the related harmonics)

3.1.1.2.

Disadvantages

Large PCB Real Estate - Due to the use of 50/60Hz transformers

Heavy

Additional linear regulation is required due to the poor stability of the input 220/110V

voltage, (15%). For 5% stability requirements on contemporary circuits, this

regulator is a must.

Leading to switched Power Supplies.

3.1.2.

Switched AC/DC Power Supplies

In order to minimize the PCB Real Estate the following concepts are applied:

The transformer size increases as the operation frequency decreases and vice versa,

(Clause 2.2.3).

So, by increasing the switching frequency at the output, the transformer at the output

would be smaller.

In order to increase the output frequency, the input voltage should be rectified, and

should be DC as possible

Figure 5 shows the application of this concept:

AC/DC Based on Flyback Topology

AC

DC

Switching Frequency

50kHz - 1MHz

Vin

220/110V 50/60Hz

AC

Vout

DC with ~100V ripple

Bridge

Rectifier

Output

Stage

PWM

Switcher

C

400V

Load

Figure 5: Switched AC/DC Power Supply Flyback Topology

Page 10 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

The voltage on the High Voltage Capacitor is shown in Figure 5. One can see that

although its not a flat DC, its flat enough to operate with a PWM switcher

Figure 6: Switched AC/DC Power Supply Voltage on the Capacitor

The Capacitor C is physically small since it allows high ripple voltage. The operation

voltage is about 400V, (220V x 2 = ~312V).

Multiple outputs may be as well achieved with multiple output transformers.

Note that the Flyback topology is used not only in AC/DC power supplies but also in

DC/DC supplies. The Flyback section of the AC/DC described above converts a high

DC voltage to a lower DC voltage

3.1.2.1.

Advantages

Small output magnetic element, (due to high frequency switching)

Small Input capacitor C due to relatively high voltage ripple, about 100V

Total PCB Real Estate and weight

Isolation due to the Flyback topology, (is a must in AC/DC power supplies).

3.1.2.2.

Disadvantages

More complex design

Output ripple frequency depends on the switching frequency

EMI generation

Page 11 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

4. PWM, (Pulse Width Modulation), Buck Topology

4.1.

Forward

A Buck converter, also known as a Step-Down converter, is one of the common topologies for

DC/DC conversion.

Its based on a PWM controller, which controls the duration of the time in which a switch, a

Transistor/FET, will be ON and OFF. Hence, the amount of energy transferred from the

main power supply towards an energy storage component, Inductor, is controlled.

The control is operated by an output feedback circuitry that samples the variations in the

output voltage. These variations are both Vin and load dependent.

On high loads and/or lower Vin, the output voltage will drop, hence the ON time duration

will be increased. On light loads and/or higher Vin, the OFF time duration will be increased.

4.2.

Buck Converter - Basic Schematics

Figure 7 shows the basic schematics of a Buck Converter, and the ON/OFF states of the

switch Q1.

Figure 7: The Buck Converter

Page 12 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

When the switch Q1 is turned on, the input voltage is applied to the inductor, and power is

then delivered to the output, also energy is stored in the inductor and capacitor Co is charged.

When the switch is turned off, the voltage across the inductor reverses and the free-wheeling

diode D1 becomes forward biased. This allows the energy stored in the inductor to be

delivered to the output while the continuous current is then smoothed by the output capacitor.

Typical waveforms are shown below in Figure 8.

Figure 8: Current and voltage waveforms of the Buck Converter

4.3.

Buck Converter Equations

4.3.1.

Developing Buck Converter Equations

The voltage across the inductor equals to:

di

V L = Vin Vout = L

dt

Equation: 2

Solving for L di , well get the following:

L di = (Vin Vout )dt +

ON

OFF

(Vin Vout )dt

Equation: 3

Page 13 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

For steady state operation the current at the start and end of a period T will not change, hence,

di = 0 . To get a simple relation between voltages we assume no voltage drop across the

transistor Q1 or the diode D1 while ON, and a perfect switch change. Thus, during the

ON time Vin = Vout and in the OFF Vin = 0, hence the results will be as follows:

t"ON "

t"ON " + t"OFF "

t"ON "

L di = 0 =

(Vin Vout )dt +

(Vout )dt

Equation: 4

Resulting:

(Vin Vout )t "ON " Vout t"OFF " = 0

Equation: 5

Hence, solving for the duty cycle D will result in:

Vout t "ON "

=

=D

Vin

T

Equation: 6

4.3.2.

Conclusions on Buck Converter Equations

Equation 6 shows a very important relationship between the desired output voltage and

the input power supply voltage. One can see that the output voltage depends on the

input voltage and the duration of time in which the energy is delivered from the input

to the output during the ON time.

Note that the ON time will not be the same for different switching frequencies f, or

switching periods T.

This also shows that not every switching frequency can be used for every application.

This issue will be further discussed on the chapter 6, the Synchronous Buck Converter

Design.

4.3.3.

Advantages

Up to 85% efficiency, depending on Vin, Vout and switching frequency

4.3.4.

Disadvantages

PCB Real Estate

Complex design

Output ripple and noise greater than LDO outputs

Generated EMI

Page 14 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

5. Synchronous Buck Topology

5.1.

The motivation

Topology

towards

the

Synchronous

Buck

In order to increase the efficiency achieved in the Buck Topology, the transistor Q1 is

replace by a FET called as Main switching MOSFET and the free-wheeling diode

D1 is replaced by a Synchronous Rectifier FET. The PWM Controller, in this new

arrangement, must control the switching of both FETs.

Note that the FETs must be in ON state one at a time only. They must not be ON

simultaneously.

This topology is also known as Synchronous Rectifier.

In order to further minimize the power loss and increase the efficiency, during the dead

time when switching between one FET to the other, a Schottky free-wheeling diode is

added in parallel with the synchronous rectifier FET.

In addition to topology changes, the characteristics of the selected components have an

utmost importance regarding the efficiency. While defining the FETs, Inductor and

Filter Capacitor attention must be paid on the parasitic resistance.

o The FETs series resistance in ON state is called R DS"ON "

o The series resistance of the Inductor and Filter Capacitor is called ESR,

(Equivalent Series Resistance)

o Low forward drop Schottkys

5.2.

Synchronous Buck Converter Basic Schematics

Figure 9 shows the basic Schematics of the Synchronous Buck Converter.

Figure 9: Synchronous Buck Converter with Parallel Schottky Diode

When FET, (MOSFET), Q1 is switched off before Q2 turns on, the free-wheeling diode D1

will provide a continuous path for either the current and the energy stored in inductor L1 to

continue flowing through the diode. This waveform is shown below in Figure 10.

Page 15 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

Figure 10: Dead Time and Schottky Diode Waveforms

With the parallel Schottky diode D1 in place, the overall efficiency of the power supply is

slightly improved. The comparison of efficiency between Synchronous Rectifier with a

Parallel Schottky Diode and that of a Schottky Diode alone is shown in Figure 11.

Figure 11: Efficiency Improvement by employing Synchronous Rectification

Page 16 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

5.2.1.

Further Improvements

In order to improve the efficiency losses in the converter should be reduced by applying the

following:

Increase the turn-on and turn-off switching speed of the MOSFETs triggering

gate pulses to reduce the switching loss during transition

Reduce the switching frequency of the converter, which lead to the reduction of

the transitions during a single time unit.

As stated earlier, use low internal resistance components

The switching loss of the MOSFET is shown in Figure 12.

Figure 12: Switching Loss of MOSFET during transition

5.2.2.

PWM Output Voltage Control Loop

In order to control the output voltage which is influenced by the input voltage variations and

load variations, a Voltage Controlling Loop is used as part of the PWM controller circuitry.

Figure 13 shows how this is done:

Page 17 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

Vo

Vin

PWM

Switcher

RL

PWM Control

Error Amp

Comparator

delta

PWM Control

A2

A1

Clk

Vo

Vref

PWM Control

Desired Vo

D*Ts

Ts

2Ts

3Ts

Ts

2Ts

3Ts

Figure 13: PWM Output Voltage Control Loop

The Error Amplifiers operation resembles the error amplifier of the LDO shown in Figure 1.

The output of A1 is varied depending on the voltage difference between the (+) and the (-)

terminals. A2, is a comparator that outputs 1 and 0 depending on the time durations in

which the delta level compared to the Clk level. The pulse width will widen as long as the

output voltage is low and vice versa.

5.2.3.

Available PWM Controllers in the DC/DC converter Market

Many manufacturers such as TI, National, Linear, Onsemi, Maxim produce various PWM

controllers for various applications. The available Synchronous Buck Converter can be

divided into two groups.

5.2.3.1.

PWM Controllers with External FETs

Figure 9 shows that in order to design a Synchronous Buck PWM DC/DC Converter, there is

a need in two FETs. These controllers require the addition of these FETs externally, which of

course increase the PCB Real Estate demands for the application.

The advantage in this case is the ability to work with higher currents, assuming the proper

FETs are chosen.

In addition, multiple output PWM Controllers with external FETs are available.

5.2.3.2.

PWM Controllers with Internal FETs

As one can assume, these controllers have embedded FETs, hence it saves valuable PCB Real

Estate. The disadvantage of this controller is that it is aimed only for a restricted amount of

current and power. In addition, the series resistance of the internal FETs is relatively high.

Page 18 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

6. Synchronous Buck Converter design from SCRATCH

6.1.

Forward

This chapter is very technical and straightforward. All steps in Synchronous Buck DC/DC

Converter design are summarized from the first calculation to the last.

Naturally, common sense should be used on finalizing the design.

6.2.

Designing a Synchronous Buck Converter

6.2.1.

Choosing the Switching Frequency

The following parameters have an effect on the switching frequency definition:

6.2.1.1.

PCB Real Estate:

As mentioned in Clause 2.2.3, as the frequency rises, the inductor size decreases.

6.2.1.2.

Efficiency:

The higher the frequency, the greater are the switching losses. Clause 5.2.1

6.2.1.3.

Controller Switching Frequency Range

Depends on the chosen PWM Controller.

6.2.1.4.

Duty Cycle, (Vin vs. Vout)

The switching frequency is based on the minimum duty cycle ratio

Vout min t "ON "

=

= f t "ON " = Dmin

Vin max

T

Equation: 7

6.2.1.5.

Current Limit Propagation Delay to Output

In order to maintain current limit capability, the minimum ON time of the upper MOSFET,

must be greater than t "ON " , hence using Equation 7 and the latter inputs will lead to Equation

8.

V

( out min )

V

f max = in max

t "ON "

Equation: 8

A typical t "ON " is 300[ns].

Page 19 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

6.2.2.

Define Ripple Current I

Figure 8 shows the changes in the current flowing through the Inductor. A high ripple current

will lead to higher EMI but smaller size Inductor and vice versa.

A typical I will be 30% of the nominal current required by the load. For more conservative

designs I will be about 10% times the nominal current.

I is the peak-to-peak inductor current.

While selecting the output capacitor, in addition to the parameters defined in Clause 6.2.5, the

minimum ripple current of the output capacitor must be equal to or greater than I.

6.2.3.

Lmin =

Calculating the Minimum Inductance Value

Vout (Vin Vout )

Vin I f

Equation: 9

A typical 25% margin is acceptable, hence the inductance L to be selected will be:

L = 1.25 Lmin

Equation: 10

6.2.4.

Output Voltage Ripple

The Output Voltage ripple is affected by the output capacitance. A typical output ripple Vout

is about 20[mV] to 50[mV]. Conservative designs require about 10[mV] output ripple.

6.2.5.

Output Capacitor Selection

6.2.5.1.

C out =

Calculating the Minimum Output Capacitance

Vout (1 D)

8 L f 2 V

Equation: 11

Page 20 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

6.2.5.2.

Calculating ESR of the Output Capacitance

The output capacitor ESR will be calculated by equation 11, and usually in between

30[mOhm] to a few hundreds of mili ohms, depending on the design constraints.

V

I

Equation: 12

ESRCout =

6.2.5.3.

Minimum Ripple Current of the Output Capacitor

Note that the ripple current defined on Clause 6.2.2 flow through the output capacitor; hence

the capacitors minimum ripple current must be equal or greater than I.

6.2.5.4.

Capacitor Voltage Rating

Its very important to choose an output capacitor with appropriate voltage rating. The voltage

rating should be at least 20% higher than the operation voltage Vout.

Page 21 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

7. Layout Guidelines

7.1.

Forward

Power generating portions of the layout should be considered first. Second, sensitive nodes in

the layout that are susceptible to interference.

An efficient power-supply layout limits EMI and RFI by having small high-current loops,

proper grounding of the control stage, and strategically sized traces to handle peak currents

7.2.

Small Current Loops

Controlling current flow is of the utmost importance. Small current loops achieve two things:

1. They generate less radiation

2. They produce less magnetic coupling between adjacent circuitry

Figure 14 shows the main source of EMI in a Buck Converter power supply.

Figure 14: Main source of EMI in a Buck Converter

In other words, the placement of the input capacitor should be close as possible to the upper

FET and the controller. The lower FET, inductor free-wheeling diode and the output capacitor

should be as close as possible to each other and the controller as well.

Page 22 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

7.3.

Control Stage Noise Sensitive

The feedback signal of the power supplys controller is very sensitive to noise pickup.

One end of the trace connects to a low impedance node, which is the output rail or a resistive

divider at the output. The other end connects to the feedback pin, which is the high impedance

input of the error amplifier. If this trace picks up noise, (capacitively or inductively), as it

passes between these two nodes, it can lead to erroneous output voltages, and in extreme cases

even instability or device failure. Figure 15 relates to the feedback issue.

Figure 15: Feedback Signal Routing

There seem to be two options for this:

1. Keep the feedback trace short if possible so as to minimize noise pickup AND/OR

2. Keep it away from noise sources (e.g. switching diode, inductor)

Keeping the trace short may not be feasible. In fact the feedback trace may be deliberately

kept slightly longer so as to route it away from potential noise sources. It should not pass

under the inductor or diode in particular.

Page 23 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

If a double-sided SMT board is being used, a good strategy is as follows:

Use a via at the output resistive divider to bring the trace to the other side.

Run the trace to cut through the surrounding ground plane areas, taking care not to

pass it under the inductor/diode and not parallel to any power trace on either side of

the board (though it can cross them perpendicularly)

And then very close to the IC, use another via to bring out the trace to the component

side where it connects to the feedback pin of the IC.

Refer to Figure 16, (a), which shows the situation for the Adjustable part. The trace, which

picks up noise, is bold. However, if we consider fixed voltage part, we learn an important

thing. This is in Figure 16 (b). Note that the feedback trace here is not marked in bold. The

reason is that a trace can pick up noise only if at least one end of it is a high impedance

node. In Figure 16 (b), the feedback pin goes to a resistive divider rather than directly to the

input of the error amplifier. So, it is relatively immune to noise pick up. The only section

where noise can be picked up is inside the IC, shown in bold, and this is a very short path.

Applying the same principle to an adjustable part provides another interesting way to route the

feedback trace. One way is shown in Figure 16 (c). Here the length of the feedback trace is

very short, so it is relatively noise-free. The feedback resistors are physically close to the IC

and the trace from the output to the upper resistor has low impedances on either side, and does

not pick up noise. However, the connection of the lower resistor to ground is not ideal as the

resistive drop across the section marked Io*R will affect the output voltage load regulation

slightly.

Another way is in Figure 16 (d), and this solves both issues. This is therefore

recommended. If a ground plane is used however, both figure 16 (c) and 16 (d) are actually

the same if vias are correctly placed to couple into this plane. For Figure 16 (d), if possible, it

is a good idea to run the top and bottom traces to the resistive divider parallel and close to

each other, so as o minimize any further chance of noise pickup.

Figure 16: Feedback Traces (bold lines susceptible to noise)

Page 24 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

7.4.

Ground Control

Much effort should go into not breaking or partitioning this plane. Further, in general, if too

much swinging power flow occurs through such a plane, it can create ground bounce and

cause controller upsets. Therefore in higher power applications, with the added luxury of

multi-layer PCBs, separate Signal Ground and Power Ground planes are used.

In addition there should be a Digital GND. The Power Ground should be connected to the

Digital Ground at one point of connection through vias or a wide trace, which operates as an

inductor that filters the switching noise harmonics. The Signal Ground should be connected to

the Power Ground at a single point of connection.

7.5.

Output Voltage Planes

The output of the PWM Switcher is usually fed into the components on the PCB via the VCC

planes. The common tendency is to increase the VCC plane as much as possible in order to

reduce the plane impedance and to strengthen the VCC and GND planes capacitive coupling.

But, keeping in mind the high power switching areas where the PWM Switcher is employed

on the PCB, the designers motivation should be to narrowing down the output VCC plane to

the minimum under this area. The VCC plane should start only at the output capacitor Co

stage and then spread along the PCB.

Its important to remember that increasing the VCC plane area might end with negative

consequences in this case.

Page 25 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

7.6.

Layout Example

Figure 17 shows the schematics of the TPS40055 Evaluation Board by TI, (document

SLUU190)

Figure 17: TPS40055 Evaluation Board Schematics by TI

Figure 18 Shows the Top Side Component Assembly of the Evaluation Board.

Figure 18: Top Side Component Assembly

Page 26 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

September 21, 2011

Power Supply Design Guidelines

Figure 19 shows the application of the layout guidelines discussed previously. The Signal

GND is connected to the GND, (Power GND since this is an Evaluation Board and there is

no other Digital GND), in a single point, which is pin 9.

The Intentional Cut is made in order to separate the high switching area on the Cout

capacitor from the output connector.

Vin

TP5

Vout

Signal

GND

Intentional

Cut

GND

Figure 19: Top Layer Copper

TP2

TP5

TP6

TP3

TP4

TP10

Figure 20: Bottom Layer Copper

Page 27 of 27

This Document contains confidential and proprietary information of Dgtronix Ltd.

You might also like

- Digital Control of Switching Mode Power Supply Simone Buso 2Document77 pagesDigital Control of Switching Mode Power Supply Simone Buso 2Ahmed58seribegawanNo ratings yet

- 600W PFC Power Supply For Audio AmplifierDocument37 pages600W PFC Power Supply For Audio Amplifierpgamez833No ratings yet

- Power Supply Design 1 PDFDocument12 pagesPower Supply Design 1 PDFsenkum812002No ratings yet

- Course 1Document8 pagesCourse 1Nikhil PuriNo ratings yet

- Circuito de Controle Do Display TV Samsung Ln-26A330J: (PLACA T-CON V260-B1-C04)Document2 pagesCircuito de Controle Do Display TV Samsung Ln-26A330J: (PLACA T-CON V260-B1-C04)Beto HtNo ratings yet

- Build A Class-A AmplifierDocument9 pagesBuild A Class-A AmplifierFe DnyNo ratings yet

- TDA1514ADocument10 pagesTDA1514AMuammar RiskiNo ratings yet

- DC-DC Part 6 DoubleDocument18 pagesDC-DC Part 6 DoubleDefne AktemizNo ratings yet

- AmplidyneDocument2 pagesAmplidynetetrix50% (2)

- LTspice ManualDocument206 pagesLTspice ManualGhiles Khelil100% (1)

- 5 Current Mode Control ModelingDocument12 pages5 Current Mode Control ModelingzmrbillNo ratings yet

- Jump, Loop and Call Instructions: University of Engineering and Technology TaxilaDocument93 pagesJump, Loop and Call Instructions: University of Engineering and Technology TaxilaPraneetha InumarthiNo ratings yet

- High Power Switching Audio Power Amplifier With Symmetrical Topology and Digital ControlDocument3 pagesHigh Power Switching Audio Power Amplifier With Symmetrical Topology and Digital ControlPéter PAPPNo ratings yet

- SMPSRM DDocument73 pagesSMPSRM DtemplpaNo ratings yet

- Capacitor ESR, Dissipation Factor, Loss Tangent and QDocument2 pagesCapacitor ESR, Dissipation Factor, Loss Tangent and QIrfan UllahNo ratings yet

- OrCAD Altium Migration Guide PDFDocument8 pagesOrCAD Altium Migration Guide PDFElafanNo ratings yet

- Programming DsPIC Digital Signal Controllers in CDocument289 pagesProgramming DsPIC Digital Signal Controllers in Cthienthuy232No ratings yet

- ESR Tester 096kDocument41 pagesESR Tester 096kFabrício AngieneNo ratings yet

- Schematic Diagram OverviewDocument12 pagesSchematic Diagram Overviewalfredo_izquierdo_12No ratings yet

- SMPS For AudioDocument16 pagesSMPS For AudioTudor Gabriel GavrilescuNo ratings yet

- Comparing-High Resolution-Oscilloscope-Design ApproachesDocument68 pagesComparing-High Resolution-Oscilloscope-Design Approachesmejoe mejoeNo ratings yet

- 5635.under The Hood of Flyback SMPS DesignsDocument41 pages5635.under The Hood of Flyback SMPS DesignsAntochi CiprianNo ratings yet

- Analog Circuit AnalysisDocument51 pagesAnalog Circuit AnalysisvpsampathNo ratings yet

- Alternistor Triacs (6-40 Amps)Document10 pagesAlternistor Triacs (6-40 Amps)David Lovato100% (1)

- Troubleshooting Linear Power Supply Was Quite EasyDocument2 pagesTroubleshooting Linear Power Supply Was Quite EasyNAYEEMNo ratings yet

- National LVDS Owners Manual 4th Edition 2008Document110 pagesNational LVDS Owners Manual 4th Edition 2008raja273No ratings yet

- EXAMPLE 4.27: 10R) 10 (10 K) 100 K (Satisfied) ) 3.16 VDocument1 pageEXAMPLE 4.27: 10R) 10 (10 K) 100 K (Satisfied) ) 3.16 Vkhrid3No ratings yet

- MonkeyBoard DAB DAB FM Digital Radio Development Board Pro Mit SlideShowDocument3 pagesMonkeyBoard DAB DAB FM Digital Radio Development Board Pro Mit SlideShowDawid MleczkoNo ratings yet

- IRS2092 Stereo AmplifierDocument10 pagesIRS2092 Stereo AmplifierĐoàn Minh CươngNo ratings yet

- cd63 ModsDocument3 pagescd63 ModsJosé FernandesNo ratings yet

- ESR Capacitor Meter ProjectDocument22 pagesESR Capacitor Meter ProjectTonyandAnthony100% (1)

- EE2203-Electronic Device and Circuits Question BankDocument11 pagesEE2203-Electronic Device and Circuits Question BankAnbarasan Annamalai100% (1)

- 70 Watt MOSFET Audio AmplifierDocument5 pages70 Watt MOSFET Audio AmplifierJuan Sánchez LópezNo ratings yet

- DC DC Book of KnowledgeDocument287 pagesDC DC Book of KnowledgeJose Simon Bolivar MoranNo ratings yet

- LVDS SignalsDocument37 pagesLVDS SignalsDariel Hernández CarmonaNo ratings yet

- High-Speed Design TechniquesDocument28 pagesHigh-Speed Design TechniquesHemantkumarNo ratings yet

- Low Voltage Power MOSFETsDocument75 pagesLow Voltage Power MOSFETssetyco93No ratings yet

- Massachusetts Institute of Technology Department of Electrical Engineering and Computer Science 6.776 High Speed Communications Circuits Spring 2005Document29 pagesMassachusetts Institute of Technology Department of Electrical Engineering and Computer Science 6.776 High Speed Communications Circuits Spring 2005adi3443No ratings yet

- Semiconductor Device and Physics ApplicationDocument336 pagesSemiconductor Device and Physics ApplicationNguyenPhucTruong100% (1)

- High Voltage Direct Current Transmission: Converters, Systems and DC GridsFrom EverandHigh Voltage Direct Current Transmission: Converters, Systems and DC GridsNo ratings yet

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Fundamentals of Electronics 2: Continuous-time Signals and SystemsFrom EverandFundamentals of Electronics 2: Continuous-time Signals and SystemsNo ratings yet

- Power Electronic System Design: Linking Differential Equations, Linear Algebra, and Implicit FunctionsFrom EverandPower Electronic System Design: Linking Differential Equations, Linear Algebra, and Implicit FunctionsNo ratings yet

- Electromagnetic Compatibility (EMC) Design and Test Case AnalysisFrom EverandElectromagnetic Compatibility (EMC) Design and Test Case AnalysisNo ratings yet

- Digital Design of Signal Processing Systems: A Practical ApproachFrom EverandDigital Design of Signal Processing Systems: A Practical ApproachRating: 5 out of 5 stars5/5 (1)

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Simulation of Power Electronic Systems Using PSpice PDFDocument82 pagesSimulation of Power Electronic Systems Using PSpice PDFdimitaringNo ratings yet

- X'merDocument13 pagesX'mervatsalNo ratings yet

- Design of a 2.5kW isolated DC/DC fullbridge converter for electric vehicle applicationDocument55 pagesDesign of a 2.5kW isolated DC/DC fullbridge converter for electric vehicle applicationmarconi-agNo ratings yet

- Vector Calculus - Corral PDFDocument222 pagesVector Calculus - Corral PDFMartin Martin MartinNo ratings yet

- Frequency Analysis - FFT PDFDocument12 pagesFrequency Analysis - FFT PDFvenkatb70% (1)

- PVSYST User's Manual TutorialDocument102 pagesPVSYST User's Manual Tutorialcatalinopancho92% (12)

- Busbar Scheme (Siemens)Document78 pagesBusbar Scheme (Siemens)Hanis Halim100% (1)

- CD00003900 PDFDocument10 pagesCD00003900 PDFCactuSound CactusRecordsNo ratings yet

- Wave Energy Utilization PDFDocument20 pagesWave Energy Utilization PDFdimitaringNo ratings yet

- 20 Induction Motor Voltage Amplitude Control Technique Based On The Motor Efficiency ObservationDocument4 pages20 Induction Motor Voltage Amplitude Control Technique Based On The Motor Efficiency ObservationdimitaringNo ratings yet

- 6 Solid State Motor Control Induction Motor Speed Control PDFDocument22 pages6 Solid State Motor Control Induction Motor Speed Control PDFdimitaringNo ratings yet

- Power Management Control of Electrical Propulsion SystemDocument26 pagesPower Management Control of Electrical Propulsion Systemdimitaring100% (1)

- Advanced Control Engineer Roles Develop Advanced SolutionsDocument4 pagesAdvanced Control Engineer Roles Develop Advanced SolutionsdimitaringNo ratings yet

- DSP Based Simulator For Field Oriented Control of The Surface Permanent Magnet Synchronous Motor Drive PDFDocument9 pagesDSP Based Simulator For Field Oriented Control of The Surface Permanent Magnet Synchronous Motor Drive PDFdimitaringNo ratings yet

- 34 Cuzner EMTS2012Document9 pages34 Cuzner EMTS2012dimitaringNo ratings yet

- Aikido NJKS PDFDocument105 pagesAikido NJKS PDFdimitaring100% (5)

- InTech-New Trends in Efficiency Optimization of Induction Motor DrivesDocument19 pagesInTech-New Trends in Efficiency Optimization of Induction Motor DrivesdimitaringNo ratings yet

- IEC ShipsDocument6 pagesIEC ShipsdimitaringNo ratings yet

- Power Management Control of Electrical Propulsion SystemDocument26 pagesPower Management Control of Electrical Propulsion Systemdimitaring100% (1)

- Marine Brochure Revb - LowresDocument16 pagesMarine Brochure Revb - Lowresjohn9999_502754No ratings yet

- Busbar Scheme (Siemens)Document78 pagesBusbar Scheme (Siemens)Hanis Halim100% (1)

- Adjustable Speed Drives TutorialDocument13 pagesAdjustable Speed Drives Tutorialapi-3765150100% (2)

- Adjustable Speed Drives TutorialDocument13 pagesAdjustable Speed Drives Tutorialapi-3765150100% (2)

- Discoverer Case Study Prop SysDocument14 pagesDiscoverer Case Study Prop Syssk970No ratings yet

- dSPACE Magazin 2014 01 Gesamt PDF Final E WebDocument72 pagesdSPACE Magazin 2014 01 Gesamt PDF Final E WebdimitaringNo ratings yet

- Productinfo PFC SmallDocument6 pagesProductinfo PFC SmalldimitaringNo ratings yet

- State of The Art Electric Propulsion Vehicles and Energy SupplyDocument81 pagesState of The Art Electric Propulsion Vehicles and Energy SupplydimitaringNo ratings yet

- State of The Art Electric Propulsion Vehicles and Energy SupplyDocument81 pagesState of The Art Electric Propulsion Vehicles and Energy SupplydimitaringNo ratings yet

- Att Acquisition by Bloom BergDocument32 pagesAtt Acquisition by Bloom BergcrosleyjNo ratings yet

- Is 12554 1 1988Document10 pagesIs 12554 1 1988rajpd28No ratings yet

- Ferroresonance Explained - Incident Prevention Article - 100212Document2 pagesFerroresonance Explained - Incident Prevention Article - 100212Anonymous 980dmQfwmiNo ratings yet

- TB MTS 8000V2 User Manual English PDFDocument208 pagesTB MTS 8000V2 User Manual English PDFEduard IsturizNo ratings yet

- AMT200P: HF Drivers - 6.5 InchesDocument2 pagesAMT200P: HF Drivers - 6.5 InchesValdei JuniorNo ratings yet

- ElectronicspectraI Revised2010Document46 pagesElectronicspectraI Revised2010guruNo ratings yet

- Samsung UE37C5100Document203 pagesSamsung UE37C5100makasoNo ratings yet

- Actel Ide User Guide PDFDocument636 pagesActel Ide User Guide PDFEswaran SamyNo ratings yet

- Vibration Isolation and TransmissibilityDocument7 pagesVibration Isolation and TransmissibilitysaiyankiranNo ratings yet

- Hl1himam SCHDocument56 pagesHl1himam SCHjdfontalvo080No ratings yet

- Forcipol: Grinding & PolishingDocument4 pagesForcipol: Grinding & PolishingArifDarmawanNo ratings yet

- EBE Electronic EngineeringDocument51 pagesEBE Electronic EngineeringImisebe TelecomsNo ratings yet

- 7.3. Analog Input: Embedded System DesignDocument23 pages7.3. Analog Input: Embedded System DesignGia HuyNo ratings yet

- Arduino Portenta H7: FeaturesDocument22 pagesArduino Portenta H7: Featuresssprakoso_gmailNo ratings yet

- ISO1500 3-kV Basic Isolated RS-485/RS-422 Transceiver in Ultra-Small PackageDocument36 pagesISO1500 3-kV Basic Isolated RS-485/RS-422 Transceiver in Ultra-Small PackageSravan CholeteNo ratings yet

- FILM CHARACTERISTICS EXPLAINEDDocument148 pagesFILM CHARACTERISTICS EXPLAINEDgrkvani10100% (1)

- 3 Phase Imbalance Detection Using CR7310 SensorDocument1 page3 Phase Imbalance Detection Using CR7310 Sensorr.veenaaNo ratings yet

- 198 Form pg5Document3 pages198 Form pg5iosefatu63No ratings yet

- Ultra High Gain CMOS Op Amp Design Using Self Cascoding and Positive FeedbackDocument12 pagesUltra High Gain CMOS Op Amp Design Using Self Cascoding and Positive FeedbackVARSHALI SHARMANo ratings yet

- Dytran Documentation TheoryDocument35 pagesDytran Documentation TheoryGeorges KouroussisNo ratings yet

- Electrical Load Calculations For Residential Panel - Online Load CalculatorDocument8 pagesElectrical Load Calculations For Residential Panel - Online Load CalculatorTabrez AlamNo ratings yet

- Ph501 Electrodynamics Problem Set 2: Princeton UniversityDocument30 pagesPh501 Electrodynamics Problem Set 2: Princeton UniversityDavidSuarezNo ratings yet

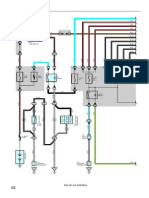

- Engine Control Celica 2000Document12 pagesEngine Control Celica 2000Giovanni Morales100% (2)

- Manual de Información Técnica Promass 83A PDFDocument36 pagesManual de Información Técnica Promass 83A PDFFredy BarretoNo ratings yet

- GME Land Communication CatalogueDocument16 pagesGME Land Communication CatalogueRadio PartsNo ratings yet

- Data SheetDocument5 pagesData SheetAndrey FelipeNo ratings yet

- EEP1 Topic 1Document36 pagesEEP1 Topic 1Saiful IslamNo ratings yet

- CNC MACHINE CONTROLLER SOLUTION FOR MACHINE TOOLSDocument12 pagesCNC MACHINE CONTROLLER SOLUTION FOR MACHINE TOOLSsh.machining industries100% (1)

- Basic PLC VDEE 2Document70 pagesBasic PLC VDEE 2Lawrence DataNo ratings yet

- VTU Seminar Report on Plastic MemoryDocument31 pagesVTU Seminar Report on Plastic MemoryKasetti BharathiNo ratings yet