Professional Documents

Culture Documents

Generator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling System

Uploaded by

arkan1976Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling System

Uploaded by

arkan1976Copyright:

Available Formats

Applications Requirements Liquid Cooled Generator Sets

Cooling System

Generator set pre-start-up checklist

Coolant type.

Open & enclosed generator sets

Mix ratio..or factory installed

This checklist should be used to validate the completion of

generator set pre-commissioning. A check-list should be

completed for each generator set of a multiple installation.

Radiator clean, free from obstruction

Project Details

Overflow clear and routed to avoid pollution

Project Name ...

Radiator filled with correct coolant & cap replaced

....

Radiator, engine & pipework checked for leaks

Customer (End User)......

Belts checked for alignment, tension and damage

Guards in place & secure

....

Energise coolant heater supplies & check function

Address.....

Radiator clean, free from obstruction

....

Overflow clear and routed to avoid pollution

Customer representative.

Header tank filled with coolant & cap replaced

Tel. No ..

System & auxiliary tank (if fitted) filled

Email..

Radiator, engine & pipework checked for leaks

Air bled from system

Generator set details

Energise coolant heater supplies

Generator set model

Auxiliary supply to fans, pumps correctly installed

Generator set serial number.Set no.

Auxiliary supplies phase rotation / voltage check

Control type...

Heat exchanger & cooling tower systems

Control serial number..

Header tank filled with coolant & cap replaced

System control type (if applicable)

Auxiliary tank (if fitted) commissioned

System, engine & pipework checked for leaks

Generator set environment and services

Surroundings clean & clear from obstruction

Services to generator set complete

Remote mounted radiator systems

Installation work & checklist complete

Set mounted radiator

Air bled from system

Energise coolant heater supplies

Secondary cooling system is complete & filled

Secondary cooling systems pumps commissioned

Observations....

Cooling tower make up supply commissioned

Auxiliary supply to fans, pumps correctly installed

Auxiliary supply to fans etc., phase / voltage check

Safety Checks

Record coolant concentration used.......................

Set clean and fully assembled

No loose materials near generator set

Air ducts clear and clean

Access & egress routes unobstructed & labelled

Control & maintenance positions unobstructed

Room secure no unauthorised access

Generator set is level holding down bolts secure

Pipework and cables are secure with no trip hazards

Overhead obstructions clearly marked and labelled

Electrical bonding complete

Warn personnel of impending equipment start-up

Ensure starting is inhibited

Document Number: PGK FCD 04-0183

Fuel System

Bulk storage facility

Isolating valves correctly positioned

Tank contents gauge and alarm contacts checked

Transfer pump & controls tested

Electrical bonding complete

Pipeline/tank heating system tested & commissioned

Fill point installed & alarm tested & commissioned

Bulk system checked for leaks

Vent and overflow pipes open

Storage facility secure

Bulk storage tank filled

Pre-start-up checklist V1.0

2004 Cummins Power Generation Ltd

Applications Requirements Liquid Cooled Generator Sets

Day tank

Isolating and solenoid valves checked for operation

Engine fuel return open

Day tank filled

Air purged from system

Tank contents gauge and alarm contacts checked

Spillage containment alarms checked

Transfer pump functions checked

Fire valves & contacts installed & wired

Louver mechanisms checked and supply energised

Commission forced ventilation system if applicable

Electrical system

Control systems

Energise set control and check functionality

Energise system controls and check functionality

Check software versions and upload as required

Select set parameters on set/system control

Check remote control signals to set control

Check set control signals to remote control

Check signals to system control and switchgear

Check emergency stop controls

Enter / verify engine & alternator protection settings

Visual check completed

Gas fuel System

Visual check completed & test certificates present

Gas present at shut off valves

Fire alarm / suppression system

Fire alarm / suppression system commissioned

Fire wire & solenoid quick release commissioned

Suppression system lock off commissioned

Set / Switchgear / Changeover / Transfer

Visual check completed

Check cables installed correctly & torque marked

Verify cable flexibility at generator set

Lubrication system

Engine oil pan filled to correct level

Level alarms checked

Pre-lubrication system commissioned

Oil make up system filled & commissioned

Energise auxiliary supplies and check functionality

Enter switchgear protection settings and record

Utility sensing commissioned

Check auxiliary supply protection settings

Check auxiliary electrical supplies voltage & phase

Commission auxiliary supplies

Check utility supply protection settings

Check utility supply for voltage & phase

Commission utility supplies

Small power & lighting circuits test & commissioned

Test certificates available for all cables

Battery starting

Battery charger commissioned

Boost / float controls & instruments checked

Compressed air / hydraulic starting

Isolating valves correctly positioned & labelled

Pressure regulator & LP safety valve checked

Compressor commissioned

HP & LP air / hydraulic pressures checked

Condensate drained

Comments on any item that may affect commissioning

Exhaust system

Check security of bellows, pipework & muffler

Check all flanges, joints & welds

Check stack/tail pipe and rain cap are clear

Drain water from system

Pre-lubricate turbo charger if required

Checklist completed by .

Date...

Print Name

Ventilation & attenuation

Check louvers are clear and free to operate

Document Number: PGK FCD 04-0183

Electrical general

Starting system

Batteries filled, installed and connected

Company..

Note: Completion of this checklist does not relieve the installer of contract obligations.

Pre-start-up checklist V1.0

2004 Cummins Power Generation Ltd

You might also like

- PowerKit 6M26 Series Diesel Engine SpecsDocument2 pagesPowerKit 6M26 Series Diesel Engine SpecsDuc Thao VuNo ratings yet

- CAT 3616 Fuel Timing DimensionDocument1 pageCAT 3616 Fuel Timing DimensionAlfred MaspaitellaNo ratings yet

- X1.3 Final Part Book 261009 - PRINT PDFDocument72 pagesX1.3 Final Part Book 261009 - PRINT PDFNAVANEETH100% (1)

- QSD2 QSD28 QSD42 Bosch Bosch Marine 4082012Document2 pagesQSD2 QSD28 QSD42 Bosch Bosch Marine 4082012aleman100% (1)

- Operating Manual: HGM6200K Series Automatic Generator ModuleDocument35 pagesOperating Manual: HGM6200K Series Automatic Generator Modulejorgehrdz269No ratings yet

- Every Ton.: For Mining ApplicationsDocument4 pagesEvery Ton.: For Mining ApplicationsRichard Sequeiros AlvarezNo ratings yet

- 5d - Ignition System2Document9 pages5d - Ignition System2agvassNo ratings yet

- Generator Checklist TemplateDocument1 pageGenerator Checklist Templatesmart channelNo ratings yet

- Training AvrDocument64 pagesTraining AvrCamilo Andres Cardozo FajardoNo ratings yet

- 908-0200 Cummins QSK78 Engine Parts Manual (7-2014)Document68 pages908-0200 Cummins QSK78 Engine Parts Manual (7-2014)Zahid Jamil100% (1)

- Diesel Powered Generating Sets 690 KW - 925 KW 60 HZ QST30 Series EnginesDocument4 pagesDiesel Powered Generating Sets 690 KW - 925 KW 60 HZ QST30 Series EnginesDaniel GraterolNo ratings yet

- Technical Data: @perkinsDocument8 pagesTechnical Data: @perkinsHoang Minh HungNo ratings yet

- Service Tool ReadMe 11.0.8 PDFDocument88 pagesService Tool ReadMe 11.0.8 PDFUsman ShahNo ratings yet

- LEA DcDesk Configuration-Software eDocument4 pagesLEA DcDesk Configuration-Software eLuis JesusNo ratings yet

- B U L K H E A D: Green Data LinksDocument2 pagesB U L K H E A D: Green Data LinksedI_restrepo_1No ratings yet

- S 1250AJP JLG Service EnglishDocument788 pagesS 1250AJP JLG Service EnglishmilandilovNo ratings yet

- AML 210x297 Brochure Intl-Spec-Series 403Document24 pagesAML 210x297 Brochure Intl-Spec-Series 403Daniel BarronNo ratings yet

- Speed Gov Wiring AdjustDocument1 pageSpeed Gov Wiring Adjustagus sumantriNo ratings yet

- QSK60 Starting SystemDocument4 pagesQSK60 Starting SystemagvassNo ratings yet

- Commom RailDocument21 pagesCommom Railprueba1100% (1)

- Navitek Electronics: Utomatic Oltage EgulaterDocument1 pageNavitek Electronics: Utomatic Oltage EgulaterGiang DoNo ratings yet

- Cummins QSL9-G5 engine data sheetDocument4 pagesCummins QSL9-G5 engine data sheetHéctor VilaNo ratings yet

- 125 and 160kva Material Cost For 3 YearDocument1 page125 and 160kva Material Cost For 3 Yearnirav patelNo ratings yet

- QSK 45Document107 pagesQSK 45VinhNo ratings yet

- Oly Changeover SystemsDocument5 pagesOly Changeover SystemsCandiano PopescuNo ratings yet

- 5 Engine Specification SheetDocument6 pages5 Engine Specification SheetpyrodidoNo ratings yet

- Instruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Document3 pagesInstruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Quang Pham100% (1)

- PERKÿNS SABRE 6TG2AM AYRDIMCI MOTORDocument2 pagesPERKÿNS SABRE 6TG2AM AYRDIMCI MOTORRiki Akbar100% (1)

- Kohler 800rozmc SpecDocument4 pagesKohler 800rozmc Speclilama45-1No ratings yet

- Professional Automotive Air Conditioning Maintenance ProgramDocument88 pagesProfessional Automotive Air Conditioning Maintenance ProgramIgnasiNo ratings yet

- Lebh0023 01Document64 pagesLebh0023 01Sergio Ramos Rivera100% (1)

- GLPT 5590 en PDFDocument6 pagesGLPT 5590 en PDFmohsen_cumminsNo ratings yet

- 2 X1.3TAA G7 - 20kVA - Rev 2Document4 pages2 X1.3TAA G7 - 20kVA - Rev 2P.p. Arul IlancheeranNo ratings yet

- Specification Sheet (Template) CUMMINS QSL9 G5Document3 pagesSpecification Sheet (Template) CUMMINS QSL9 G5Ricardo La CruzNo ratings yet

- QST30 Upgrade PDFDocument1 pageQST30 Upgrade PDFabid hussainNo ratings yet

- Flywheel PM3516 3516B Power Module NBR00001-UPDocument2 pagesFlywheel PM3516 3516B Power Module NBR00001-UPFaresNo ratings yet

- Air Equipment Compressors Compressor 900 CFM DC750 125S C900 125S C650 170S C750 125S Operation ManualDocument67 pagesAir Equipment Compressors Compressor 900 CFM DC750 125S C900 125S C650 170S C750 125S Operation ManualAtaa AssaadNo ratings yet

- EMCP II+ Diagnostic ManualDocument12 pagesEMCP II+ Diagnostic ManualMoctar Sangho100% (1)

- Parallel Basics ASTCDocument14 pagesParallel Basics ASTCLuis Del Prado SalazarNo ratings yet

- 2946 1308 00 Leroy Somer LSA47.2 Installation & MaintenanceDocument20 pages2946 1308 00 Leroy Somer LSA47.2 Installation & MaintenanceJORGE ARMANDO CARRASCO TICLLENo ratings yet

- Module 8 - ToolsDocument17 pagesModule 8 - ToolsWilliam RuizNo ratings yet

- Electric Power Ratings Guide: Generator SetsDocument44 pagesElectric Power Ratings Guide: Generator SetsRick HunterNo ratings yet

- Control AFR CAT Gas Engine Management eDocument68 pagesControl AFR CAT Gas Engine Management eJaime CalmetNo ratings yet

- Battery ChargerDocument16 pagesBattery Chargerdimasrimantikto100% (2)

- DG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsDocument11 pagesDG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsMugeshNo ratings yet

- KTA38GC Gas Compression ApplicationsDocument4 pagesKTA38GC Gas Compression ApplicationsKriangkasem100% (1)

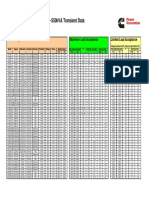

- 50Hz 11-550kVA Transient Data ChartDocument2 pages50Hz 11-550kVA Transient Data ChartQuang PhamNo ratings yet

- Alternator Aksa AK4200Document8 pagesAlternator Aksa AK4200Cris_eu09No ratings yet

- Application Engineering Bulletin: Installation RequirementsDocument24 pagesApplication Engineering Bulletin: Installation RequirementsDiego Castañeda SantaNo ratings yet

- DG Set Control MonitorDocument20 pagesDG Set Control Monitorkiro100% (1)

- Railway Engine Training-CUMMINS EngineDocument50 pagesRailway Engine Training-CUMMINS EnginemajjisatNo ratings yet

- Cummins c1675 d5 Spec Sheet With Kta50 Specs Appended Ado PDFDocument3 pagesCummins c1675 d5 Spec Sheet With Kta50 Specs Appended Ado PDFAdil Elyousfaoui100% (1)

- ATS OkDocument20 pagesATS Okducabc123No ratings yet

- Leroy Somer LSA 50.2 From Macfarlane Generators PDFDocument12 pagesLeroy Somer LSA 50.2 From Macfarlane Generators PDFAnonymous 3RS6JNcNo ratings yet

- 2806a-E18tag2 Electropak Pn1871Document2 pages2806a-E18tag2 Electropak Pn1871Charles CallahanNo ratings yet

- QSK50-G4: EPA Tier 2 and TA Luft CompliantDocument3 pagesQSK50-G4: EPA Tier 2 and TA Luft CompliantmualiminNo ratings yet

- 105 UserDocument8 pages105 Userint4400No ratings yet

- Liquid-Cooled Generator ChecklistDocument2 pagesLiquid-Cooled Generator Checklist4685752No ratings yet

- Generator Start Up Checklist 1 0Document2 pagesGenerator Start Up Checklist 1 0quynh_nguyen017724No ratings yet

- Aksa Startup ChecklistDocument2 pagesAksa Startup ChecklistUmar RajputNo ratings yet

- 8 Things You May Not Know About Hammurabi's Code - History ListsDocument10 pages8 Things You May Not Know About Hammurabi's Code - History Listsarkan1976No ratings yet

- Inrease in Water Pressur..Document3 pagesInrease in Water Pressur..arkan1976No ratings yet

- Model 818/918 Liter Gauges Specification SheetDocument2 pagesModel 818/918 Liter Gauges Specification Sheetarkan1976No ratings yet

- Generator ChecklistDocument2 pagesGenerator Checklistsidney_viegas67% (3)

- Energy Content in Common Energy SourcesDocument4 pagesEnergy Content in Common Energy Sourcesarkan1976No ratings yet

- Appendix D - DHWLRMPDocument23 pagesAppendix D - DHWLRMParkan1976No ratings yet

- Working Pressure Ratings 081114Document1 pageWorking Pressure Ratings 081114arkan1976No ratings yet

- Generator ChecklistDocument2 pagesGenerator Checklistsidney_viegas67% (3)

- Carbon Steel Pipe Pressure RatingsDocument4 pagesCarbon Steel Pipe Pressure RatingsthomasoburNo ratings yet

- Generator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling SystemDocument2 pagesGenerator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling Systemarkan1976No ratings yet

- Radiation Detection Devices - Radiation Emergency Medical ManagementDocument7 pagesRadiation Detection Devices - Radiation Emergency Medical Managementarkan1976No ratings yet

- Toolco GH1600 Heavy Duty Precision LatheDocument1 pageToolco GH1600 Heavy Duty Precision Lathearkan1976No ratings yet

- Valve Leakage: Home Glossary ResourcesDocument3 pagesValve Leakage: Home Glossary Resourcesarkan1976No ratings yet

- IELTS Band Scores and Marking CriteriaDocument3 pagesIELTS Band Scores and Marking Criteriaarkan1976No ratings yet

- Valve Actuators Information On GlobalSpecDocument5 pagesValve Actuators Information On GlobalSpecarkan1976No ratings yet

- Pipesim TutDocument1 pagePipesim Tutarkan1976No ratings yet

- Pressure Test of Piping SystemDocument9 pagesPressure Test of Piping Systemarkan1976No ratings yet

- Hydro Electric Power Plant: V P H H Y HDocument10 pagesHydro Electric Power Plant: V P H H Y Harkan1976No ratings yet

- Fracture Control - Offshore Pipelines JIP Use of Abaqus - Explicit To Simulate Ductile Tearing in Pipes With Defects Loaded Beyond Yielding - OnePetroDocument2 pagesFracture Control - Offshore Pipelines JIP Use of Abaqus - Explicit To Simulate Ductile Tearing in Pipes With Defects Loaded Beyond Yielding - OnePetroarkan1976No ratings yet

- Valve Leakage Rates Test STDDocument5 pagesValve Leakage Rates Test STD윤병택No ratings yet

- Demo Weld Cost Calc XLDocument10 pagesDemo Weld Cost Calc XLarkan1976No ratings yet

- ASTM Pipe Schedule DimensionsDocument5 pagesASTM Pipe Schedule DimensionshemnNo ratings yet

- DAAD - Country-Specific Information On The DAAD Scholarship Programmes 2014 - 2015 - DAAD - Deutscher Akademischer Austausch DienstDocument2 pagesDAAD - Country-Specific Information On The DAAD Scholarship Programmes 2014 - 2015 - DAAD - Deutscher Akademischer Austausch Dienstarkan1976No ratings yet

- Pipesim TutDocument1 pagePipesim Tutarkan1976No ratings yet

- Carburizing, Nitriding, and Boronizing in Vacuum Furnaces - IpsenDocument9 pagesCarburizing, Nitriding, and Boronizing in Vacuum Furnaces - Ipsenarkan1976No ratings yet

- Mechanical Text 2007 FinalDocument4 pagesMechanical Text 2007 Finalarkan1976No ratings yet

- 18 Gulbraar BPT - Tekna-ProcessSafety Rev01F - ConfPaperDocument14 pages18 Gulbraar BPT - Tekna-ProcessSafety Rev01F - ConfPaperbhen08No ratings yet

- E 6013Document1 pageE 6013Weld Bro SandeepNo ratings yet

- BHGGDocument15 pagesBHGGMohammed Abu SufianNo ratings yet

- Internal Combustion Engines OverviewDocument21 pagesInternal Combustion Engines OverviewRex SabersonNo ratings yet

- DIAGRAM Engine Management SystemDocument1 pageDIAGRAM Engine Management Systemjulio montenegroNo ratings yet

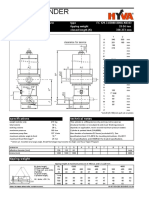

- HyvaDocument2 pagesHyvaRudi SyamNo ratings yet

- Modul I Uji SumurDocument61 pagesModul I Uji SumurDimas RahmadiNo ratings yet

- Vacuum Unit Pressure Control PTQ Revamps 2006Document5 pagesVacuum Unit Pressure Control PTQ Revamps 2006majope1966No ratings yet

- Generator AuxiliariesDocument4 pagesGenerator AuxiliariesNilesh KumarNo ratings yet

- P200h2-P220he2 (1) 001Document4 pagesP200h2-P220he2 (1) 001Carlos José Barrios InfanteNo ratings yet

- SubseaBoosting 022113Document1 pageSubseaBoosting 022113Myoung ChoiNo ratings yet

- VII B.tech (Vimla)Document3 pagesVII B.tech (Vimla)Priyanka PanigrahiNo ratings yet

- Cambridge November 2012 Answer KeyDocument6 pagesCambridge November 2012 Answer KeyGideonCavidaNo ratings yet

- Design of Engine Cooling SystemsDocument18 pagesDesign of Engine Cooling SystemsashokkumarNo ratings yet

- LHV of FuelDocument33 pagesLHV of FuelSeptian HardiNo ratings yet

- 03 Chapter 02 Internal Combustion Engines FundamentalsDocument8 pages03 Chapter 02 Internal Combustion Engines FundamentalsafiqzalhasmiNo ratings yet

- Konkan Gyanpeeth College of Engineering, Karjat.: CertificateDocument7 pagesKonkan Gyanpeeth College of Engineering, Karjat.: CertificateMadan ThewarNo ratings yet

- Product Information: Reference OnlyDocument4 pagesProduct Information: Reference Onlyjesus silvaNo ratings yet

- BRL K21011 02Document35 pagesBRL K21011 02bruno383No ratings yet

- A320 Lake FuelDocument9 pagesA320 Lake FuelCamilo MorenoNo ratings yet

- EME Unit 2 Turbines PPT by Kalyan ChakravarthyDocument64 pagesEME Unit 2 Turbines PPT by Kalyan ChakravarthyvenkatNo ratings yet

- How Does A Diesel Generator Create Electricity?Document3 pagesHow Does A Diesel Generator Create Electricity?ShreenivasNo ratings yet

- Suzuki g13 Engine AdjustmentDocument19 pagesSuzuki g13 Engine AdjustmentLuis Valerio100% (1)

- Crude Distillation UnitsDocument32 pagesCrude Distillation Unitsmoujahed100% (1)

- Report Electric Vehicles en Page 26Document86 pagesReport Electric Vehicles en Page 26Mohsin Hassan SyedNo ratings yet

- Faa S 8081 26Document26 pagesFaa S 8081 26flexomenoNo ratings yet

- What You Need To Know About Drilling Bit Balling Up and How To Troubleshooting ItDocument3 pagesWhat You Need To Know About Drilling Bit Balling Up and How To Troubleshooting ItShoaib KhalilNo ratings yet

- Lmv5 Qsgsection 04 2011Document70 pagesLmv5 Qsgsection 04 2011Adrian BudurNo ratings yet

- Thermodynamics Chapter 1 Key ConceptsDocument41 pagesThermodynamics Chapter 1 Key ConceptsJohn Raymart RaferNo ratings yet

- 546 E-1Document723 pages546 E-1Mihai Gherghisan100% (5)

- Parallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Document1 pageParallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Rubi AbionNo ratings yet

- Water and Oil Free Screw Compressor Evaluation ReportDocument4 pagesWater and Oil Free Screw Compressor Evaluation ReportdaritiNo ratings yet

- Meder Auto Brake Pedal Position SensorDocument4 pagesMeder Auto Brake Pedal Position Sensorpoojan kansaraNo ratings yet