Professional Documents

Culture Documents

Job Safety Analysis

Uploaded by

Senthooran SrikandarajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis

Uploaded by

Senthooran SrikandarajCopyright:

Available Formats

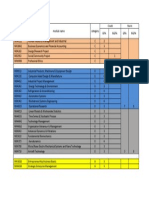

Job Safety Analysis Dynamic Technologies

Issuer

Name

Positi

on

Place

Date

&

Time

Company/

Project/Site

Type of Risk

Description

Comments

Height Works

Type

Risk

Applic

ability

Severity

Risk Management

Workers Detail

Falling from very high

points

Failure of safety

equipment

Using safety harness, using scaffoldings to climb, removing any

sharp objects from the working area.

Falling from mid

height points

Fork lift operation

Falling objects from

the fork lift

Folk lift accidents with

employees

Unbalanced operation

of fork lift

Using safety shoes in the work shop, using undamaged pallets

and lifting only the permitted tonnage for the fork lift. A speed

limit also should be maintained according to the load.

Accidents due

damaged pallets

Safety Equipment

Provided

Hot Works

Burn accidents in gas

cuttings

Back fire and cylinder

explosion

Gas cutting splatters

Burn accidents in arc

welding

Using protective gloves and eyeware.The nozzles of the gas cutter

should be cleaned frequently, the correct procedure of starting

the gas cutting should be implemented and always the acetylene

cylinder should be closed when not being used. Fire extinguishers

should be used in case of fire and employee should well aware of

it.

Electrical works

Manual Handling

Explosion during test

run of motors

Gloves

Safety shoes

Arc welding electrical

shocks

Eye damage due to

electric arc

Eye ware

Overall

Protective shields should be used when arc welding/tig welding

is carried out. Earth connections should be well established and

proper insulation material should be used in electric shock hazard

areas such as near panel boards. Safety/emergency switches

should be used when test running motors and the employees

should well aware of it.

Safety harness

Ear plugs

Short circuits in

machine and electric

shocks

Safety Helmet

Ergonomic hazards of

lifting heavy weights

Fire extinguishers

Cut wounds due to

improper handling of

sharp objects

Falling of heavy

objects

Trolleys should be used to handle heavy objects and protective

wear such as gloves and safety shoes should be used. The use of

fork lifts is highly recommended in these job activities. The

objects are to be well balanced when moving from one point to

another.

Trolleys

Others(mention)

Any specific Warnings

Machinery

Eye damage and

wounds due to flying

chips

Entanglement into

rotating /reciprocating

machines

Overhead crane operation

Slipping of workpeice

from the machine

Protective eye wares should be used always and overhanging

clothing/gloves are prohibited when using machinery. Damaged

tools are to be repaired to prevent any human involved accidents.

Floors around machines should be cleaned from any slippery

substance. All machines should be balanced and anchored to the

floor.

Risk

Accidents due to

damaged tools

High Risk

Falling object due to

unbalanced

weight/over load

Medium Risk

Low Risk

Very low

Crane belt failure

Accidents due to crane

hook/obects knocking

employees

The objects that are lifted using the crane should be well

balanced and the crane should be operated by a certified person.

The speed of operation should be under a controlled threshold.

The tonnage carried should match the capacity of the crane and

the no employees are to stand under any lifted objects by the

crane.

Impact

Slipping and falling

Hearing problems due

to heavy noise

High

Problems due to heavy

dust

Medium

Low

Very low

Others

Damages due to chips

from grinders

Improper lighting

Chemical exposure

Ear plugs, dust masks should be always used. The grinders should

be used in a manner so that it does not obstruct the other

workers. Air compressor should be checked for safe operation

frequently. Any slippery substance on the floor should be cleaned

properly. All chemical should be handled carefully and any sharp

off cut metal pieces should be stored or disposed in a proper

manner.

Severity = Risk X

Impact

Obstruction to other

employees

Explosion of air

compressors

Wounds due sharp

metal pieces/off cuts

Permits issued

Hot work

Height work

Others

Name

Engineers in charge

Workers Employed

Signature

You might also like

- List of Safety Forms: S. No. Title Rev. No. Rev. DateDocument1 pageList of Safety Forms: S. No. Title Rev. No. Rev. Dateadil khanNo ratings yet

- First Aid Kit Inspection Check List FormDocument1 pageFirst Aid Kit Inspection Check List Formmuhammad imtiazNo ratings yet

- JOB SAFETY ANALYSIS - 013 - Chemical HandlingDocument5 pagesJOB SAFETY ANALYSIS - 013 - Chemical Handlingvaibhav kuteNo ratings yet

- Safety and EHS Performance ReportDocument16 pagesSafety and EHS Performance Reportimam santosoNo ratings yet

- What Is HSE AccountabilityDocument4 pagesWhat Is HSE AccountabilityNisith SahooNo ratings yet

- HSE Alert - LTI Fall From Heights TBTDocument12 pagesHSE Alert - LTI Fall From Heights TBTrodman823No ratings yet

- 1.1. Hse Key Management StandardDocument26 pages1.1. Hse Key Management StandardagumsyahNo ratings yet

- Internal OHS Audit Methodology PDFDocument8 pagesInternal OHS Audit Methodology PDFPaul MaposaNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- JHA 001 Welding OperationsDocument3 pagesJHA 001 Welding OperationsAhmad alwaelyNo ratings yet

- July SMR RevDocument2 pagesJuly SMR RevShyam SadanandanNo ratings yet

- Heat stress cases by location, designation and dateDocument4 pagesHeat stress cases by location, designation and dateImam Hasan IdrisiNo ratings yet

- ISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFDocument5 pagesISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFpurva02No ratings yet

- Health and Safety Risks on School Farm VisitsDocument46 pagesHealth and Safety Risks on School Farm Visitsshan123455555555No ratings yet

- HSE Professionals - Fall Protection and PreventionDocument8 pagesHSE Professionals - Fall Protection and Preventionchinne046No ratings yet

- Work Procedure For The Construction of CO2 Cylinder HouseDocument9 pagesWork Procedure For The Construction of CO2 Cylinder HouseJoyce GordonioNo ratings yet

- Eye WashDocument21 pagesEye Washapi-273019508100% (1)

- Grinder AlertDocument1 pageGrinder Alertbsr8267% (3)

- Safety Officer Inspection ChecklistDocument3 pagesSafety Officer Inspection ChecklistSomesh Ingale100% (1)

- HSE Monthly MeetingDocument16 pagesHSE Monthly MeetingsajidNo ratings yet

- HSE Objective & Plan DatabasedDocument4 pagesHSE Objective & Plan DatabasedPrayogo ImamNo ratings yet

- Role of Safety OfficerDocument12 pagesRole of Safety OfficerChristian MeanaNo ratings yet

- Jsa Lifitng Gantry FabricationDocument3 pagesJsa Lifitng Gantry FabricationOsiobe EwomazinoNo ratings yet

- Machine Guarding Safety ChecklistDocument2 pagesMachine Guarding Safety ChecklistSirley Sanmartín RestrepoNo ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- Effective Safety Management Systems: by George RobothamDocument33 pagesEffective Safety Management Systems: by George RobothamLoganathan DharmarNo ratings yet

- Job Safety Analysis: JSA Basic DataDocument5 pagesJob Safety Analysis: JSA Basic DataPrabhu DivakaranNo ratings yet

- PT BUMI MOROWALI UTAMA HSE Monthly ReportDocument9 pagesPT BUMI MOROWALI UTAMA HSE Monthly ReportHifni GhazaliNo ratings yet

- Integr Ted Business Re S: at SourceDocument14 pagesIntegr Ted Business Re S: at SourcecyclopsoctopusNo ratings yet

- SWP Working Safely at Height Version 2.01Document7 pagesSWP Working Safely at Height Version 2.01marvinNo ratings yet

- External Communication RegisterDocument1 pageExternal Communication RegisterRanganayaki Tirumale Srinivasa Rangachar100% (1)

- 4.4.3.3 Data and Trend AnalysisDocument6 pages4.4.3.3 Data and Trend AnalysisIndermohan MehtaNo ratings yet

- SH-F43 - PTW Format - R02Document2 pagesSH-F43 - PTW Format - R02vini100% (1)

- Safety Incident ProcedureDocument15 pagesSafety Incident Proceduresivaguruaks100% (1)

- Ineco Hse Manual-SignedDocument27 pagesIneco Hse Manual-SignedTantely RazafimahatratraNo ratings yet

- 101 SafetyTalk Topics ZetekyDocument21 pages101 SafetyTalk Topics ZetekyMu'az ObadakiNo ratings yet

- Lockout Tagout TRNG GuideDocument7 pagesLockout Tagout TRNG GuideSyed Mujtaba Ali Bukhari100% (1)

- Safety Meeting TopicsDocument55 pagesSafety Meeting TopicsJayamal Induruwa100% (1)

- Preventing Heat-Related IllnessesDocument16 pagesPreventing Heat-Related Illnessesroland magoNo ratings yet

- Everythingohs Workplace Inspection ChecklistDocument4 pagesEverythingohs Workplace Inspection ChecklistsandyskadamNo ratings yet

- Training Program Peogram Pelatihan: NO. Training Training Type Location Month Realization Date (In-House / OJT)Document4 pagesTraining Program Peogram Pelatihan: NO. Training Training Type Location Month Realization Date (In-House / OJT)MillaNChakrabortyNo ratings yet

- Office EHS Audit ChecksheetDocument3 pagesOffice EHS Audit ChecksheetPanbarasan GanapathyNo ratings yet

- OHSE Project HIRA - Fencing Work - R 00Document3 pagesOHSE Project HIRA - Fencing Work - R 00Pankaj SinghNo ratings yet

- Job Hazard AssessmentDocument2 pagesJob Hazard AssessmentSreekumarNo ratings yet

- FR - HSE - 061 - en Permit To Work Audit ChecklistDocument2 pagesFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNo ratings yet

- Risk Assessment Form (RA1) : (Action by Whom and Completion Date - Use Separate Action Plan If Necessary)Document6 pagesRisk Assessment Form (RA1) : (Action by Whom and Completion Date - Use Separate Action Plan If Necessary)michael wakuthii100% (1)

- EGA SETP TT-CSM 13 Prequal Questionnaire v2.00Document6 pagesEGA SETP TT-CSM 13 Prequal Questionnaire v2.00shijadNo ratings yet

- HSE InductionDocument20 pagesHSE InductionShailendraNo ratings yet

- Milling MachineDocument1 pageMilling MachineJeannie TimothyNo ratings yet

- Ehs Plan - JSSLDocument61 pagesEhs Plan - JSSLneerajgulabNo ratings yet

- Employee Information: Area Scope of Orientation Orientation Date BYDocument2 pagesEmployee Information: Area Scope of Orientation Orientation Date BYAriani WidiawatiNo ratings yet

- EHS October 2019 Calendar Safety Training AuditsDocument1 pageEHS October 2019 Calendar Safety Training AuditsSiddharth RanaNo ratings yet

- Bloodborn Pathogen ProgramDocument22 pagesBloodborn Pathogen Programsitimaezyaroh100% (1)

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- JSA FormDocument6 pagesJSA FormAjeesh CochinNo ratings yet

- M7 Safety PrecautionsDocument10 pagesM7 Safety Precautionsketan SNo ratings yet

- OME553 Industrial Safety Engineering: (Open Elective)Document47 pagesOME553 Industrial Safety Engineering: (Open Elective)Jana garan.s100% (1)

- Safe Work ProceduresDocument193 pagesSafe Work ProceduresJoao Miguel Silva100% (7)

- Foldia Roll CageDocument4 pagesFoldia Roll CageSenthooran SrikandarajNo ratings yet

- FiER ThielenDocument41 pagesFiER ThielenSenthooran SrikandarajNo ratings yet

- Pspice InstructionDocument4 pagesPspice InstructionVIJAYPUTRANo ratings yet

- ReferenceDocument1 pageReferenceSenthooran SrikandarajNo ratings yet

- Group Assignment MN 3042 Financial Accounting Group AssignmentDocument3 pagesGroup Assignment MN 3042 Financial Accounting Group AssignmentSenthooran SrikandarajNo ratings yet

- C Port 3600 Data SheetDocument2 pagesC Port 3600 Data SheetSenthooran SrikandarajNo ratings yet

- MKMKMDocument98 pagesMKMKMSenthooran SrikandarajNo ratings yet

- Cover PageDocument50 pagesCover PageSenthooran SrikandarajNo ratings yet

- Sem 7 CurriculumDocument1 pageSem 7 CurriculumSenthooran SrikandarajNo ratings yet

- Silo Vent 2Document1 pageSilo Vent 2Senthooran SrikandarajNo ratings yet

- Cover PageDocument50 pagesCover PageSenthooran SrikandarajNo ratings yet

- WS45 Wind Speed SensorDocument2 pagesWS45 Wind Speed SensorSenthooran SrikandarajNo ratings yet

- Silo Vent Filter: SCALE 1: 22Document1 pageSilo Vent Filter: SCALE 1: 22Senthooran SrikandarajNo ratings yet

- B.Sc. Engineering & B.Sc. (T & LM) Calendar 2015Document1 pageB.Sc. Engineering & B.Sc. (T & LM) Calendar 2015Senthooran SrikandarajNo ratings yet

- Manual Air Flow Meter Pce 007Document15 pagesManual Air Flow Meter Pce 007Senthooran SrikandarajNo ratings yet

- Silo Vent FilterDocument1 pageSilo Vent FilterSenthooran SrikandarajNo ratings yet

- ReducerDocument1 pageReducerSenthooran SrikandarajNo ratings yet

- D-D Scale 1: 14: Revision Do Not Scale DrawingDocument1 pageD-D Scale 1: 14: Revision Do Not Scale DrawingSenthooran SrikandarajNo ratings yet

- AISC Errata ListDocument8 pagesAISC Errata ListLuis Gonzales Salazar67% (3)

- Silo Vent 2Document1 pageSilo Vent 2Senthooran SrikandarajNo ratings yet

- Silo Vent Filter: SCALE 1: 22Document1 pageSilo Vent Filter: SCALE 1: 22Senthooran SrikandarajNo ratings yet

- Linux Journal 2011 09Document143 pagesLinux Journal 2011 09Senthooran SrikandarajNo ratings yet

- Axis VM Step by StepDocument147 pagesAxis VM Step by StepBelak1100% (1)

- Motor WindingDocument3 pagesMotor WindingSenthooran Srikandaraj50% (2)

- Liugong Forklifts 2t Upto 5tDocument2 pagesLiugong Forklifts 2t Upto 5tHanin BouzianeNo ratings yet

- PTW Series Power Drive Lift Truck ManualDocument105 pagesPTW Series Power Drive Lift Truck ManualMarioNo ratings yet

- CALORIE FOOD COMPANY Case StudyDocument5 pagesCALORIE FOOD COMPANY Case StudyCoreen AndradeNo ratings yet

- Catalog Ia 2013Document72 pagesCatalog Ia 2013ioanNo ratings yet

- Nissan lx35Document2 pagesNissan lx35Ionut GrozaNo ratings yet

- Application of Lean Six Sigma Approach To Reduce Worker Fatigue in Racking AreasUsing DMAIC, VSM, FMEA and ProModelSimulation Methods in Sub Logistic Companies: A Case Study of IndonesiaDocument11 pagesApplication of Lean Six Sigma Approach To Reduce Worker Fatigue in Racking AreasUsing DMAIC, VSM, FMEA and ProModelSimulation Methods in Sub Logistic Companies: A Case Study of Indonesiaeditor ijeratNo ratings yet

- Cat ForkliftsDocument12 pagesCat ForkliftsJonathan Schauder100% (1)

- Kuriyama Hydraulic Hose Fittings BrochureDocument8 pagesKuriyama Hydraulic Hose Fittings BrochureWawanALKhatiryNo ratings yet

- Model Whp-200 BrochureDocument8 pagesModel Whp-200 Brochurekimberlyrobles79No ratings yet

- JCB Rough Terrain Forklift 930 940 950 Brochure PDFDocument16 pagesJCB Rough Terrain Forklift 930 940 950 Brochure PDFDmitry100% (2)

- Nilkamal Presentation 2011 FinalDocument33 pagesNilkamal Presentation 2011 Finalbhushii_jagsNo ratings yet

- Brosura Accesorii ManitouDocument148 pagesBrosura Accesorii ManitoudobasNo ratings yet

- IGC 2 Element 2 New Syllabus PDFDocument10 pagesIGC 2 Element 2 New Syllabus PDFnaveed awanNo ratings yet

- Linde H40 45 50Document6 pagesLinde H40 45 50Lucas IbañezNo ratings yet

- ForkliftsDocument16 pagesForkliftsabdulrahman hishamNo ratings yet

- Brochure Complete Pedestrian Pallet Truck RangeDocument32 pagesBrochure Complete Pedestrian Pallet Truck RangeGo WolowitzNo ratings yet

- 141 Operator Manual (1418042541) T20AP 0499-US (BR141 - T20AP - 0499 - GB)Document65 pages141 Operator Manual (1418042541) T20AP 0499-US (BR141 - T20AP - 0499 - GB)Luis MironNo ratings yet

- RX 60 Technical Data Electric Forklift TruckDocument10 pagesRX 60 Technical Data Electric Forklift Trucktoufik100% (1)

- Forklift Operator Evaluation FormDocument31 pagesForklift Operator Evaluation Formgomezgamf0% (1)

- Cat Forklift r50 r60 r70 r80 Service Operation Maintenance ManualDocument23 pagesCat Forklift r50 r60 r70 r80 Service Operation Maintenance Manualangelahorton220692gom99% (82)

- PR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and CertificationDocument112 pagesPR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and CertificationmishikhanNo ratings yet

- R 20-25T Parts ListDocument347 pagesR 20-25T Parts ListRafał HubczakNo ratings yet

- Cat Forklift Tc60d Schematic Service ManualDocument27 pagesCat Forklift Tc60d Schematic Service Manualchristineferguson190889rtw100% (119)

- ITSDF B56-5-2012-Rev-03-07-14 PDFDocument31 pagesITSDF B56-5-2012-Rev-03-07-14 PDFManoj KumarNo ratings yet

- BT CargoDocument4 pagesBT CargoAlmacen HuskyNo ratings yet

- Event Codes When A Malfunction OccursDocument52 pagesEvent Codes When A Malfunction OccursMiguel Angel Rodriguez CatroNo ratings yet

- BSBWHS521 CTI2XXXXX - Ass1 - Sub1-V4. CompletodocxDocument60 pagesBSBWHS521 CTI2XXXXX - Ass1 - Sub1-V4. CompletodocxJulijuliREYnu3nutsOOF Juanbox012100% (2)

- Risk assessment form for forklift operationsDocument5 pagesRisk assessment form for forklift operationsFachri HidayatNo ratings yet

- Delivering More: EP14-20A (C) N (T), EP25-35 (C) N, EP40-50 (C) (S) 2Document16 pagesDelivering More: EP14-20A (C) N (T), EP25-35 (C) N, EP40-50 (C) (S) 2Mushfique NowrozNo ratings yet

- BLP SolutionsDocument4 pagesBLP SolutionsMohamed FathyNo ratings yet