Professional Documents

Culture Documents

Work Instruction For Bending Rev. 01.01.2013

Uploaded by

aymanmalahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Instruction For Bending Rev. 01.01.2013

Uploaded by

aymanmalahCopyright:

Available Formats

PAGE 1 0F3

ARABIAN INTERNATIONAL COMPANY

TOWER DIVISION

REV.NO.03,01Jan13

INFORM

TO

TITAL:

BENDING

SCOPE/PURPOSE:

The document defines the procedure to be followed for the fabrication.

REFERENCES1/P:

RESPONSIBILITY:

o

o

.

o

Rout Cards & Drawings.

Tracking List by Planning.

Machine allocation with proper machine setup.

Material with specified qty & Bend operation.

A)

Verify the existing lots from production, for mark no. with the help

of approved Shop Drawing & Rout Card'

B)

Verify Profile (section), Operation BEND type (cold or hot), degree

or gauge size, Quantity, Batch, with the help of Tracking List. Read

carefully all instruction from drawing & reference table of Bend'

C) After verification,

affange the material on the machine for process to

E)

F)

Lcad man

Shi

Supervlsor

Check the first piece at each stage of operation with the help of

approved shop drawing marked with "MASS FABRICATION" and

QC

Inspector

Check first piece to offer QC Inspector and every 25n (frequency

depend on rout card qty.) piece from the lot. Ifany fault or variation

observed, inform immediately to shift Engineer / Supervisor.

Put the required Qty with mark no. & further operation code on

every bundle after finished lots. If lot is ready for galvanizing tagged

rout card on the lots with sign by QC inspector.

J)

If found any Non Conformance during the process inform to QC

inspector, take the NCR report & again re-offer to QC after

Supervisor

Lead man

K)

Keep daily proper cleaning of machine & House keeping around the

machine.

L)

Use proper Safety utilities on the shop floor while running the

machine viz. Safety goggle, ear muffs/ plugs, hand gloves etc.

After complete the lot as per rout card qty., transfer to Galvanizing with

documents.

al

APPROVE

Tape.l

Meas.

Tape.l

gauge

Lead man

QC

Inspector

completion of Rework.

proper

Meas.

gauge

list without error.

ISSUED BY:

Vernier

Caliper

Use proper fixtures, gauges, bending die's & measuring instruments

like Right angle, steel scale, gauge, meter, vernier caliper,

thermometer etc.

To follow bending parameter, heating indicator please refer TABLE

H) Fill the report in the daily performance report & update the tracking

OUTPUT:

Meas.

Tape I

Shift

gauge.

G)

MEAS

RD.BY

Supervlsor

Bending operation.

D)

ISSUE DT 20.10.08

Lead man

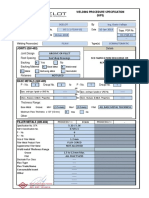

PAGE 2 0F 3

ARABIAN INTERNATIONAL COMPANY

ISSUE DT.20.10.08

TOWER DIVISION

REV.NO.03,01Jan13

REFERENCE TABLE

BENDING PROCESS PARNETER

r zER

Bendina Tolerance

Mr RE

+l-2.0mm

a. Bend Ref. Line -

b. Bend Angle -

MEASRD.BY

INSTRUMENT

+/-

TapeAvleter

1.0 Degree

tt

A::Mild steel(Ms materlal

Grade:A36 SS400/S275JR

Infrared

Thermometer

Follow the shop sketch instructions.Ifno instructiOns in shop sketch then foHOw as

below,

Inside Radius ofBend exceeding l.5tshaH Cold Bend

lnside Radius ofBend lesser than l.5t shall Hot Bend(TEDIP 750 C to 900 C)

(`t'=thiCkness ofmaterial bend)

All Hiah Tensile stee:fHT mater:al

Grade:GR60/GR50/SS540/S355JR

AH HT material must process Hot Bend(TEMP 750

C to 900 C)

For special steels fabricator should consult steel supplier

for bendin

and te

C CES

Gauge only

All Gauges shall

NE

be designated with Mark of Degree or

RttERFOR ttcBE

C-5 B2 6

MATE.THK

BEND DEGREE

UPT0 6

HEATING TIPIE

as

`Ob

BEND DEGREE

BEND DEGREE

ABOVE 6

ABOVE 6

EATING

roflle

10 MM THIcK MATE

MATE

12 MPITHIcK MATE

13

lTH

55 58

65 75

cK MATE

THIcK MATE

20 IDII THIcK MATE

rlle>L150)

Sec.

Sec.

110-120 Sec.

16 MIn4 THIcK MATE

18 Pl I

HEATING TIDIIE

52-55 Sec.

15 MPlTHIcK MATE

ISSUED BY:

TIPIE

L150)

9plEDII THICK MATE

1l M THIcK

with mark no.

100-104 Sec.

106-110 sec.

Sec.

155 Sec.

115-130 Sec.

140-150 Sec.

135 145

165 175

150

180-190 Sec.

Sec.

Infrared

Thermometer

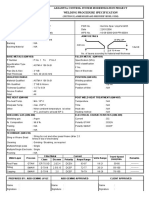

PAGE 3 0F3

ARABIAN INTERNATIONAL COMPANY

ISSUE DT.10.07.12

TOWER DIVISION

uV.NO.03,01Jan13

DEFINITION OF DIES AS FUNCTION OF ANGLE&MEOFBEND

SYMBOL

NAME OF BttND

OPEN BEND(0.B.)

CLOSE BEND(I.B.)

OPEN BEND ON THE CORNER(0.B.)

CLOSE BEND ON THE CORNER(1.B.)

HttEL UP BEND(0.B.DAVIATED)

FLANGE OPEN

FLANGE CLOSE

TWO FLANGE OP[N COMPLttTE

TWO FLANGE CLOSE COMPLETE

SPttCIAL

CC

ALL EX:STING DI

HEEL DOWN BEND(I.B.DAVIATED)

DRAWING

S WHlcH ARE NOT!NCLUDED ABOVE

NOTE:THE LABLES APPLIED TO THE DIESINDICATE THE NUMBERS OF DEGREE ORIGINALLY MEANT FOR THE

DIE CONSIDERING THE S IALL PLATES WELDED TO IT TEMPORARILY.

ISSUED BY:

APP

You might also like

- Method Statement For A Construction ProjectDocument114 pagesMethod Statement For A Construction ProjectCrazyBookWorm92% (87)

- Valid SOP: Standard Operating ProceduresDocument10 pagesValid SOP: Standard Operating ProceduresShahid Raza100% (2)

- Welding Procedure DatasheetDocument1 pageWelding Procedure Datasheetsajeev27No ratings yet

- SOP Gas Cutting and Heating .Document1 pageSOP Gas Cutting and Heating .aarunsnairNo ratings yet

- Welder, Welding Operator Qualification Test ReportDocument2 pagesWelder, Welding Operator Qualification Test Reportkarthik sundaramNo ratings yet

- Project Quality PlanDocument44 pagesProject Quality Planmd_rehan_2100% (1)

- Method Statement & Risk Assessment Installation of Structured Cabling SystemDocument16 pagesMethod Statement & Risk Assessment Installation of Structured Cabling SystemAbu Muhammed KhwajaNo ratings yet

- Commissioning Cooling TowersDocument3 pagesCommissioning Cooling TowerssdvitkoNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNo ratings yet

- Fabrication ProcedureDocument3 pagesFabrication ProcedureAndreMarcel100% (1)

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 pageTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarNo ratings yet

- Structure Fabrication ProcedureDocument10 pagesStructure Fabrication Procedureasmira rosliNo ratings yet

- Inspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadDocument1 pageInspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadilyasNo ratings yet

- Check List For Welding MachinesDocument1 pageCheck List For Welding MachinesSaravanan JambunathanNo ratings yet

- Powder Coating Procedure Guide for Oven Temperature Control, Degreasing, and Part PreparationDocument1 pagePowder Coating Procedure Guide for Oven Temperature Control, Degreasing, and Part Preparationnastyn-1No ratings yet

- 01fitting in FabricationDocument11 pages01fitting in Fabricationv.bhamidi100% (1)

- Welding Procedure and Safety ControlsDocument6 pagesWelding Procedure and Safety ControlsSIBINNo ratings yet

- CNC Vertical Milling Machine-JOB PROCEDUREDocument3 pagesCNC Vertical Milling Machine-JOB PROCEDUREpraveen_kumar_119No ratings yet

- Safe Use of Lifting Machines and Lifting TackleDocument59 pagesSafe Use of Lifting Machines and Lifting TackleJakesNo ratings yet

- PAHARPUR COOLING TOWERS MAGNETIC PARTICLE TEST REPORTDocument1 pagePAHARPUR COOLING TOWERS MAGNETIC PARTICLE TEST REPORTGoutam Kumar DebNo ratings yet

- Sop Hydraulic Punch and ShearDocument1 pageSop Hydraulic Punch and ShearBorislav VulićNo ratings yet

- RTC-161-MIR-A-ID-174 - R0 - B Off Site Material Inspection Request For Free Standing Bathtub 21095T-0 (Option 2) From KHALID CORPORATIONDocument7 pagesRTC-161-MIR-A-ID-174 - R0 - B Off Site Material Inspection Request For Free Standing Bathtub 21095T-0 (Option 2) From KHALID CORPORATIONeslam100% (2)

- ITP For Mild Steel Pipe WorksDocument4 pagesITP For Mild Steel Pipe WorksKumar AbhishekNo ratings yet

- Precautions for Semi-Automatic and Automatic WeldingDocument8 pagesPrecautions for Semi-Automatic and Automatic WeldingFaiz IshakNo ratings yet

- Procedure for Flame Straightening Structural SteelDocument3 pagesProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- How To Carry Out Tack WeldingDocument2 pagesHow To Carry Out Tack WeldingwentropremNo ratings yet

- Process Validation 1Document1 pageProcess Validation 1tayyabNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- The Welding Procedure QualificationDocument51 pagesThe Welding Procedure QualificationYousef Adel HassanenNo ratings yet

- Procedure For Heat Treatment Dated 29-09-06Document8 pagesProcedure For Heat Treatment Dated 29-09-06ravi00098100% (1)

- OC-1-1-FCAW-1 Rev 0 PDFDocument4 pagesOC-1-1-FCAW-1 Rev 0 PDFDario100% (1)

- Projects Assessments For Welding ProcessDocument8 pagesProjects Assessments For Welding ProcessKamarul NizamNo ratings yet

- Repair Procedure For Super Heater Coil TubesDocument2 pagesRepair Procedure For Super Heater Coil Tubesbehzad mohammadiNo ratings yet

- KGP-Flamme Cutting Proce For BEI PDFDocument4 pagesKGP-Flamme Cutting Proce For BEI PDFoomoomNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- MEI - Aluminium MIG WeldDocument56 pagesMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- 8 JSA Holyday TestDocument3 pages8 JSA Holyday TestYosua SitumorangNo ratings yet

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Patrol Inspection Report Check List UpdatedDocument2 pagesPatrol Inspection Report Check List Updatedanbusaravanan4No ratings yet

- Tasks and Responsibilities of RWCDocument1 pageTasks and Responsibilities of RWCKDT100% (1)

- Conveyor Check ListDocument2 pagesConveyor Check Listh1549697100% (1)

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- En Visual Testing ProcedureDocument7 pagesEn Visual Testing ProcedureAdham AhmedNo ratings yet

- Forging Machine Preventive MaintenanceDocument4 pagesForging Machine Preventive Maintenancemr. kNo ratings yet

- Radiation Safety Distance DiagramDocument3 pagesRadiation Safety Distance DiagramEswaranNo ratings yet

- Inspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsDocument1 pageInspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsmukeshayoorNo ratings yet

- Welding Consumable Baking Register PDFDocument1 pageWelding Consumable Baking Register PDFKandula Raju100% (1)

- Checklist For Fabrication & Erection of Structural Steel WorkDocument1 pageChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuNo ratings yet

- Gtaw WeldingDocument37 pagesGtaw WeldingSadhasivam VeluNo ratings yet

- Surface Preparation & Painting ProcedureDocument9 pagesSurface Preparation & Painting ProcedureRam ThevarNo ratings yet

- Work Instructions - Gas CuttingDocument2 pagesWork Instructions - Gas Cuttingvivek sureshNo ratings yet

- Welding Insection ReportDocument4 pagesWelding Insection ReportRanjeet MouryaNo ratings yet

- Procedure For WPSDocument7 pagesProcedure For WPSSatish KeskarNo ratings yet

- Daily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDocument1 pageDaily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDeniz AydinNo ratings yet

- EN ISO 9712 Level 2, UT PDFDocument1 pageEN ISO 9712 Level 2, UT PDFSantoshNo ratings yet

- Welding Repair Procedure for PT. Juhdi Sakti EngineeringDocument4 pagesWelding Repair Procedure for PT. Juhdi Sakti EngineeringRiky SumantriNo ratings yet

- Welding Safety ChecklistDocument2 pagesWelding Safety ChecklistSaid Elsamna100% (1)

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- SATR-J-6406 Rev 0 PDFDocument10 pagesSATR-J-6406 Rev 0 PDFAdel KlkNo ratings yet

- Calibration Procedure For Digital Multimter, Greenlee Model Dm-40 - Tb-9-6625-2403-24Document13 pagesCalibration Procedure For Digital Multimter, Greenlee Model Dm-40 - Tb-9-6625-2403-24luroguitaNo ratings yet

- Long Seam Inspection ProcedureDocument4 pagesLong Seam Inspection ProcedureDeepak100% (1)

- Itp For Main SteelaaaaaaDocument4 pagesItp For Main SteelaaaaaaaymanmalahNo ratings yet

- Work Instruction For Bending Rev. 01.01.2013Document3 pagesWork Instruction For Bending Rev. 01.01.2013aymanmalah100% (1)

- Itp For Casing, Ducting, StackaaaaaaaaaaaDocument4 pagesItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- Cswip 3.aaaaaaaaaaaaaaaaaaaaaaaaaDocument56 pagesCswip 3.aaaaaaaaaaaaaaaaaaaaaaaaaaymanmalah100% (2)

- Manual Dell Latitude E6410Document52 pagesManual Dell Latitude E6410Muhamad Agung W0% (1)

- Monthly Report JanDocument8 pagesMonthly Report JanaymanmalahNo ratings yet

- Aaaaaaaaaaaaa.... CSWIP Welding Inspection Notes and QuestionsDocument133 pagesAaaaaaaaaaaaa.... CSWIP Welding Inspection Notes and QuestionsaymanmalahNo ratings yet

- Jan2015 Accident AnalysisDocument9 pagesJan2015 Accident AnalysisaymanmalahNo ratings yet

- Coating Thickness ASTM 123 (1402) : T 1.6 MM 1.6 T 3.2 MM 3.2 T 4.8 4.8 T 6.4 T 6.4Document1 pageCoating Thickness ASTM 123 (1402) : T 1.6 MM 1.6 T 3.2 MM 3.2 T 4.8 4.8 T 6.4 T 6.4aymanmalahNo ratings yet

- Problems in DaLian (1309-CP7) AAAAAAAAAAAAAAAAAAAAAAAAAAAAAAADocument4 pagesProblems in DaLian (1309-CP7) AAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAaymanmalahNo ratings yet

- O S H A Checklist For General Industry SouathDocument26 pagesO S H A Checklist For General Industry Souathaymanmalah100% (1)

- Month Total No. of NCR Nov. 337 Oct. 523Document4 pagesMonth Total No. of NCR Nov. 337 Oct. 523aymanmalah100% (1)

- 200008-0-262413-0084-03 - Lyw1-A-E-55020 - Main Clean Earthing Schematic DiagramDocument1 page200008-0-262413-0084-03 - Lyw1-A-E-55020 - Main Clean Earthing Schematic DiagramKumarNo ratings yet

- Building Technology 4Document24 pagesBuilding Technology 4Melaine A. FranciscoNo ratings yet

- Advance Steel 2017 Getting Started Guide ImperialDocument55 pagesAdvance Steel 2017 Getting Started Guide ImperialRameshBathalaNo ratings yet

- TRISHUL Engineering PresentationDocument63 pagesTRISHUL Engineering PresentationaswarNo ratings yet

- 118 PlotDocument7 pages118 PlotMuhammad UsamaNo ratings yet

- Floor MatsDocument3 pagesFloor MatsphilipyapNo ratings yet

- Spec PavaDocument10 pagesSpec PavaDolyNo ratings yet

- 14 21 00 - Electric Traction ElevatorsDocument22 pages14 21 00 - Electric Traction ElevatorsMohamedNo ratings yet

- Method Statement For Miscellaneous Metal WorksDocument19 pagesMethod Statement For Miscellaneous Metal Worksmohsin.meizaNo ratings yet

- ITP Service PL 001 RWPDocument1 pageITP Service PL 001 RWPDedi KartiwaNo ratings yet

- No Exception Taken. Revise - No Resubmittal Required.: Clifford Dias P.E., P.C. Consulting EngineersDocument5 pagesNo Exception Taken. Revise - No Resubmittal Required.: Clifford Dias P.E., P.C. Consulting EngineersDarwin LeònNo ratings yet

- Method Statement For The Flushing of Firefighting Pipes.R7Document9 pagesMethod Statement For The Flushing of Firefighting Pipes.R7adel rihanaNo ratings yet

- Preparatory Works: 5.1 Approved Shop Drawing, Method Statement, Material and SampleDocument6 pagesPreparatory Works: 5.1 Approved Shop Drawing, Method Statement, Material and SampleJasonTeeNo ratings yet

- Method Statement For Installation of Diesel Generator SetDocument7 pagesMethod Statement For Installation of Diesel Generator SetAnonymous 8xHUWB100% (4)

- Building System Standards & Design GuideDocument289 pagesBuilding System Standards & Design GuideBoy Alfredo PangaribuanNo ratings yet

- MD Yusuf HvacDocument4 pagesMD Yusuf HvacMOHAMMED YUSUFNo ratings yet

- FS Hotel Jeddah Corniche - Background Music SystemsDocument37 pagesFS Hotel Jeddah Corniche - Background Music SystemsMahmoud MaghrpyNo ratings yet

- MS 29 Aggregate Base Course Road Works Rev00Document7 pagesMS 29 Aggregate Base Course Road Works Rev00Jojee Catap YabutNo ratings yet

- 6.5 Years Electrical Experience ResumeDocument3 pages6.5 Years Electrical Experience ResumepratikNo ratings yet

- 01 MS For Fcu - PSDocument11 pages01 MS For Fcu - PSASHWANINo ratings yet

- Pond & Res - LinersDocument9 pagesPond & Res - LinersAnonymous NR3qZ30No ratings yet

- Mos Plumbing Fixture InstallationDocument4 pagesMos Plumbing Fixture InstallationDon Roseller Dumaya100% (1)

- Structure Magazine-June 2017Document88 pagesStructure Magazine-June 2017rahuljoagNo ratings yet

- Tech Spec & Method of Measurement Batcoda With Table of ContDocument154 pagesTech Spec & Method of Measurement Batcoda With Table of Contmearig22293% (27)

- Standard Const Material SpecDocument320 pagesStandard Const Material SpecElin IrhamnaNo ratings yet

- Carbonel, Michael 2020Document4 pagesCarbonel, Michael 2020Kyla CarbonelNo ratings yet