Professional Documents

Culture Documents

Asphalt MSDS

Uploaded by

Junard M. Lu HapCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asphalt MSDS

Uploaded by

Junard M. Lu HapCopyright:

Available Formats

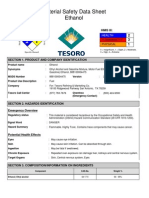

Material Safety Data Sheet

Asphalt

NFPA:

HMIS III:

HEALTH

Health

Reactivity

Flammability

FLAMMABILITY

PHYSICAL

2

1

0

0 = Insignificant, 1 = Slight, 2 = Moderate,

3 = High, 4 = Extreme

Specific Hazard

SECTION 1. PRODUCT AND COMPANY IDENTIFICATION

Product name

Asphalt

Synonyms

Pitch, Paving Asphalt, Performance Graded Asphalt, (PG) PG 52-28, PG 58-22,

PG 64-25, 888100004477

MSDS Number

888100004477

Product Use Description

Construction material

Company

For: Tesoro Refining & Marketing Co.

19100 Ridgewood Parkway, San Antonio, TX 78259

Tesoro Call Center

(877) 783-7676

Version

Chemtrec

:

(Emergency Contact)

1.12

(800) 424-9300

SECTION 2. HAZARDS IDENTIFICATION

Emergency Overview

Regulatory status

: This material is considered hazardous by the Occupational Safety and Health

Administration (OSHA) Hazard Communication Standard (29 CFR 1910.1200).

Signal Word

: WARNING

Hazard Summary

: Hot material can cause severe eye and skin burns on contact. Hydrogen sulfide

from heated material can accumulate in vapor space of tanks and containers.

Contact between heated material and water can cause a violent eruption. Fumes

from heated material can cause irritation to the eyes, skin, and respiratory system,

and can increase susceptibility to sunburn.

Potential Health Effects

Eyes

: Hot material can cause burns to the eyes. Mists, vapors or fumes from this

material can cause eye irritation with tearing, redness, or a stinging or burning

feeling.

Skin

: Hot material can cause burns to the skin. May cause skin irritation with redness,

an itching or burning feeling, and swelling of the skin. Exposure to sunlight and

to asphalt vapors may amplify tendency for sunburns. Skin contact may cause

harmful effects in other parts of the body.

Ingestion

: Contact with hot material may cause burns. If swallowed at ambient

temperatures, no significant adverse health effects are anticipated. If swallowed

in large quantities, this material can obstruct the intestine.

Inhalation

: No significant adverse health effects are expected to occur upon short-term

MATERIAL SAFETY DATA SHEET

Page 2 of 8

Asphalt

exposure to this product at ambient temperatures. Asphalt fumes have been

associated with irritation of eyes nose and throat. Also, lower respiratory effects

have been reported. Hydrogen sulfide (H2S) can evolve when this product is

stored or handled at elevated temperatures. H2S can cause respiratory irritation

and hypoxia. At low concentrations, H2S has an odor of rotten eggs. At higher

concentrations, H2S odor is not apparent. DO NOT use odor as an indicator of

exposure to H2S.

Target Organs

: Eyes, Skin, Respiratory system, Kidney, Liver

SECTION 3. COMPOSITION/INFORMATION ON INGREDIENTS

Component

CAS-No.

Weight %

Asphalt

8052-42-4

100%

Hydrogen Sulfide

7783-06-4

Trace

SECTION 4. FIRST AID MEASURES

General advice

Remove from exposure, lie down. Take off all contaminated clothing immediately.

When symptoms persist or in all cases of doubt seek medical advice. Never give

anything by mouth to an unconscious person.

Inhalation

Remove to fresh air. If breathing is irregular or stopped, administer artificial

respiration. Seek medical attention immediately.

Skin contact

Cool skin rapidly with cold water after contact with molten material. Take off all

contaminated clothing immediately. Wash off with soap and water but do not

attempt to remove asphalt that adheres to skin before obtaining medical

assistance. Wash contaminated clothing before re-use. If symptoms persist, seek

medical attention immediately.

Eye contact

Remove contact lenses. Rinse immediately with plenty of water, also under the

eyelids, for at least 15 minutes. If eye irritation persists, seek medical attention.

Ingestion

Do NOT induce vomiting. Seek medical attention immediately. Clean mouth with

water and drink afterwards plenty of water. If a person vomits when lying on his

back, place him in the recovery position.

SECTION 5. FIRE-FIGHTING MEASURES

Form

Solid form, viscous liquid when heated

Flash point

> 218 C (> 424 F)

Lower explosive limit

0.9 % (V)

Upper explosive limit

7 % (V)

Suitable extinguishing media

SMALL FIRES: Any extinguisher suitable for Class B fires, dry chemical, CO2,

water spray, fire fighting foam, or Halon.

LARGE FIRES: Water spray, fog or fire fighting foam. Water may be ineffective for

fighting the fire, but may be used to cool fire-exposed containers.

Specific hazards during fire

Isolate area around container involved in fire. Cool tanks, shells, and containers

2/8

MATERIAL SAFETY DATA SHEET

fighting

Asphalt

Page 3 of 8

exposed to fire and excessive heat with water. For massive fires the use of

unmanned hose holders or monitor nozzles may be advantageous to further

minimize personnel exposure. Major fires may require withdrawal, allowing the

tank to burn. Large storage tank fires typically require specially trained personnel

and equipment to extinguish the fire, often including the need for properly applied

fire fighting foam.

Special protective equipment

for fire-fighters

Use NIOSH/MSHA approved positive pressure self-contained breathing apparatus

and fully protective clothing such as bunker gear if needed to prevent exposure.

Withdraw immediately from the area if there is a rising sound from a venting safety

device or discoloration of vessels, tanks, or pipelines.

Further information

Vapors may form explosive mixture with air. Flammable vapor production at

ambient temperature in the open is expected to be minimal unless the oil is heated

above its flash point. When heated above flash point and mixed with air and

exposed to an ignition source, flammable vapors can burn in the open or explode

in confined spaces. Being heavier than air, vapors may travel long distances to an

ignition source and flash back.

SECTION 6. ACCIDENTAL RELEASE MEASURES

Personal precautions

ACTIVATE FACILITY'S SPILL CONTINGENCY OR EMERGENCY RESPONSE

PLAN. Evacuate nonessential personnel and remove or secure all ignition sources.

Consider wind direction; stay upwind and uphill, if possible. Evaluate the direction

of product travel, diking, sewers, etc. to confirm spill areas. Response and cleanup crews must be properly trained and must utilize proper protective equipment.

Environmental precautions

Carefully contain and stop the source of the spill, if safe to do so. Protect bodies of

water by diking, absorbents, or absorbent boom, if possible. Do not flush down

sewer or drainage systems, unless system is designed and permitted to handle

such material. Authorities should be notified if reportable quantity release occurs.

Methods for cleaning up

Soak up condensate with inert absorbent material and collect in ventilated waste

container for disposal.

SECTION 7. HANDLING AND STORAGE

Handling

Use only in well-ventilated areas.

Advice on protection against

fire and explosion

Do not smoke near areas where material is handled or stored. The product should

only be used in areas where electrical classification meets the product rating for

this product, i.e. intrinsically safe. Use only in area provided with appropriate

exhaust ventilation. Vapors may form explosive mixtures with air.

Dust explosion class

Not applicable

Requirements for storage

areas and containers

Product is generally transported and stored hot (typically at temperatures above

o

110 F and below 350F). Handle as a combustible liquid. Keep away from heat,

sparks, and open flame! Electrical equipment should be approved for classified

area. Bond and ground containers during product transfer to reduce the possibility

of static-initiated fire or explosion.

Consult API Recommended Practice 2023 for additional guidance. Store distant

from fire and ignition sources. No smoking near areas where material is stored or

used.

Advice on common storage

Keep away from flame, sparks, excessive temperatures and open flame. Use

approved vented containers. Keep containers closed and clearly labeled. Empty

3/8

MATERIAL SAFETY DATA SHEET

Page 4 of 8

Asphalt

product containers or vessels may contain explosive vapors. Do not pressurize,

cut, heat, weld or expose such containers to sources of ignition.

Store in a well-ventilated area. Avoid storage near incompatible materials. The

cleaning of tanks previously containing this product should follow API

Recommended Practice (RP) 2013 "Cleaning Mobile Tanks In Flammable and

Combustible Liquid Service" and API RP 2015 "Cleaning Petroleum Storage

Tanks.

Hydrogen sulfide may accumulate in tanks and bulk transport compartments.

Consider appropriate respiratory protection (see Section 8). Stand upwind. Avoid

vapors when opening hatches and dome covers. Confined spaces should be

ventilated prior to entry.

Other data

Stable under normal conditions.

SECTION 8. EXPOSURE CONTROLS / PERSONAL PROTECTION

Exposure Guidelines

List

Components

CAS-No.

Type:

Value

OSHA

Hydrogen Sulfide

7783-06-4

STEL

20 ppm

ACGIH

Asphalt

8052-42-4

TWA

0.5 mg/m3

Hydrogen Sulfide

7783-06-4

TWA

1 ppm

7783-06-4

STEL

5 ppm

Engineering measures

Engineering controls are normally required when handling hot materials. Use

process enclosures, local exhaust ventilation, or other controls to maintain airborne

levels below recommended exposure limits (see below). Engineering controls

should meet applicable requirements of the National Electrical Code (NEC)

Standards. Ensure that an emergency eye wash station and safety shower is

located near the work-station.

Eye protection

Use a full-face shield and chemical safety goggles if handling heated material. With

product at ambient temperatures, safety glasses equipped with side shields are

recommended as minimum protection in industrial settings. An eye wash station

immediately available to the work area.

Hand protection

When handling product at elevated temperatures, use long-cuffed leather or heatresistant gloves. When product is at ambient temperatures, use gloves constructed

of chemical resistant materials such as heavy nitrile rubber if frequent or prolonged

contact is expected.

Skin and body protection

Use insulated, heat-resistant clothing when handling heated material. Use a fullbody heat-resistant or internally cooled suit when work conditions dictate.

Respiratory protection

Contaminant air concentrations determine the level of respiratory protection

required. Use only NIOSH-approved respiratory equipment within the limits of the

protection factors for that equipment. Use supplied air respirators when H2S

concentrations are expected to exceed applicable workplace exposure levels. Do

not use air purifying respiratory equipment when considering elevated H2S

concentrations. Respiratory equipment must be selected on the basis of the

maximum expected air concentration.

4/8

MATERIAL SAFETY DATA SHEET

Hygiene measures

Asphalt

Page 5 of 8

Use good personal hygiene practices. Wash hands before eating, drinking,

smoking, or using toilet facilities. DO NOT use gasoline, kerosene, solvents, or

harsh abrasive skin cleaners to clean skin. Prevent skin contact when handling

heated material. Use insulated, heat-resistant clothing when handling heated

material. Use a full-body heat-resistant or internally cooled suit when work

conditions dictate.

SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

Form

: Solid form, viscous liquid when heated

Appearance

: Brown to black

Odor

: Characteristic sour, tar-like odor

Flash point

: > 218 C (> 424 F)

Thermal decomposition

: No decomposition if stored and applied as directed.

Lower explosive limit

: 0.9 % (V)

Upper explosive limit

: 7 % (V)

pH

: Not applicable

Freezing point

: No data available

Boiling point

: 343 C (649 F)

Vapor Pressure

: No data available

Density

: 0.9 1.05 g/mL

Viscosity, kinematic

: No data available

Percent Volatiles

: Negligible volatility

SECTION 10. STABILITY AND REACTIVITY

Conditions to avoid

Materials to avoid

: Strong acids and oxidizing agents

Hazardous decomposition

products

: In case of fire hazardous decomposition products may be produced such as:

Carbon oxides Hydrogen sulfide and other sulfur-containing gases can evolve

from this product particularly at elevated temperatures. No decomposition

products in case of appropriate storage / handling / transport.

Thermal decomposition

: No decomposition if stored and applied as directed.

Hazardous reactions

: Stable under normal conditions of use; however, incompatible with strong acids

and strong oxidizers. Keep away from oxidizing agents, and acidic or alkaline

products. Do not allow molten products to contact water or liquids as this can

cause violent eruptions. Hydrogen Sulfide from the product can react with iron in

asphalt storage tank to form iron sulfide, a pyrophoric (a material which ignites

spontaneously in air below 130F) material.

Heat, flames and sparks.

SECTION 11. TOXICOLOGICAL INFORMATION

Carcinogenicity

5/8

MATERIAL SAFETY DATA SHEET

Asphalt

Page 6 of 8

NTP

: This product, Asphalt (CAS-No.: 8052-42-4), may contain trace amounts of benzene

a chemical known to cause cancer.

IARC

: Asphalt

OSHA

: This product, Asphalt (CAS-No.: 8052-42-4), may contain trace amounts of benzene

a chemical known to cause cancer.

CA Prop 65

: WARNING! This product contains a chemical known to the State of California to

cause cancer.

Asphalt (CAS-No.: 8052-42-4)

Skin irritation

Result: Mild skin irritation

Prolonged skin contact may cause skin irritation and/or dermatitis.

Eye irritation

Result: Mild eye irritation

Contact with eyes may cause irritation.

Further information

Certain preparations of this material are classified as carcinogenic by OSHA, NTP,

or IARC. See section entitled: Carcinogenicity: of this MSDS for additional

information concerning the carcinogenic potential of this product.

(CAS-No.: 8052-42-4)

Component:

Asphalt

Acute oral toxicity: LD50 rat

Dose: 5,001 mg/kg

8052-42-4

Acute dermal toxicity: LD50 rat

Dose: 2,001 mg/kg

SECTION 12. ECOLOGICAL INFORMATION

Additional ecological

information

This product is estimated to have a slow rate of biodegradation. This product is not

expected to bioaccumulate through food chains in the environment. Analysis for

ecological effects has not been conducted on this product. Spills into water ways

may be harmful to organisms and bottom feeders.

SECTION 13. DISPOSAL CONSIDERATIONS

Disposal

Recover as much spilled material as possible for reuse or recycling.

Disposal of waste material must be conducted in accordance with RCRA regulations

(see 40CFR 260 through 40 CFR 271).

SECTION 14. TRANSPORT INFORMATION

CFR

Proper shipping name

UN-No.

Class

Packing group

Hazard inducer

:

:

:

:

:

Elevated temperature liquid, n.o.s.

3257

9

III

(Asphalt)

Proper shipping name

UN-No.

Class

: Elevated temperature liquid, n.o.s.

: UN3257

: 9

TDG

6/8

MATERIAL SAFETY DATA SHEET

Packing group

Hazard inducer

Page 7 of 8

Asphalt

: III

: (Asphalt)

IATA Cargo Transport

UN-No.

Class

: UN3257

: 9

Not permitted for transport

IATA Passenger Transport

UN-No.

Class

: UN3257

: 9

Not permitted for transport

UN-No.

Description of the goods

: UN 3257

: Elevated temperature liquid, n.o.s.

(Asphalt)

: 9

: III

: 9

: F-A S-P

: No

IMDG-Code

Class

Packaging group

IMDG-Labels

EmS Number

Marine pollutant

SECTION 15. REGULATORY INFORMATION

OSHA Hazards

: Moderate skin irritant

Moderate eye irritant

Toxic by inhalation.

Possible carcinogen.

CERCLA SECTION 103 and SARA SECTION 304 (RELEASE TO THE ENVIROMENT)

The CERCLA definition of hazardous substances contains a petroleum exclusion clause which exempts crude oil. Fractions of crude oil, and

products (both finished and intermediate) from the crude oil refining process and any indigenous components of such from the CERCLA Section

103 reporting requirements. However, other federal reporting requirements, including SARA Section 304, as well as the Clean Water Act may still

apply.

TSCA Status

: On TSCA Inventory

DSL Status

: All components of this product are on the Canadian DSL list.

SARA 311/312 Hazards

: Acute Health Hazard

PENN RTK

US. Pennsylvania Worker and Community Right-to-Know Law (34 Pa. Code Chap. 301-323)

Components

CAS-No.

Asphalt

8052-42-4

MASS RTK

US. Massachusetts Commonwealth's Right-to-Know Law (Appendix A to 105 Code of Massachusetts Regulations

Section 670.000)

Components

CAS-No.

Asphalt

8052-42-4

NJ RTK

US. New Jersey Worker and Community Right-to-Know Act (New Jersey Statute Annotated Section 34:5A-5)

7/8

MATERIAL SAFETY DATA SHEET

Page 8 of 8

Asphalt

Components

CAS-No.

Asphalt

8052-42-4

hydrogen sulfide

7783-06-4

California Prop. 65

: WARNING! This product contains a chemical known to the State of California to

cause cancer.

Asphalt

8052-42-4

SECTION 16. OTHER INFORMATION

Further information

The information provided in this Safety Data Sheet is correct to the best of our knowledge, information and belief at

the date of its publication. The information given is designed only as guidance for safe handling, use, processing,

storage, transportation, disposal and release and is not to be considered a warranty or quality specification. The

information relates only to the specific material designated and may not be valid for such material used in

combination with any other materials or in any process, unless specified in the text.

Template

Prepared by

GWU mbH

Birlenbacher Str. 18

D-57078 Siegen

Germany

Telephone: +49-(0)271-88072-0

Revision Date

11/29/2010

147, 148, 149, 150, 151, 156, 157, 158, 298, 299, 302, 313, 314, 324, 325, 515, 1596

8/8

You might also like

- A Short Guide To A Happy LifeDocument4 pagesA Short Guide To A Happy LifeHenry100% (1)

- Liquid Nitrogen SafetyDocument77 pagesLiquid Nitrogen Safetymech_sahilNo ratings yet

- KPI and Supplier Performance Scorecard ToolDocument7 pagesKPI and Supplier Performance Scorecard ToolJayant Kumar JhaNo ratings yet

- UWorld NCLEX Drug ListDocument16 pagesUWorld NCLEX Drug ListAngie Mandeoya91% (11)

- Job Hazard Analysis RiskassessmentDocument4 pagesJob Hazard Analysis RiskassessmentJunard M. Lu HapNo ratings yet

- Waterproofing Applications: Established in 1959Document16 pagesWaterproofing Applications: Established in 1959Chesca DacquelNo ratings yet

- MSDS HSDDocument3 pagesMSDS HSDharoonshaikh100% (2)

- Int Detection Sys For O&G Fire FigthingDocument65 pagesInt Detection Sys For O&G Fire FigthingRahmat IzaiziNo ratings yet

- Form16 (2021-2022)Document2 pagesForm16 (2021-2022)Anushka PoddarNo ratings yet

- Positive Isolation StandardDocument21 pagesPositive Isolation Standardmadhulika100% (2)

- Asphalt EmulsifierDocument5 pagesAsphalt EmulsifierGinanjar Surya RamadhanNo ratings yet

- DQ RMGDocument23 pagesDQ RMGDhaval ChaplaNo ratings yet

- NEBOSH International General Certificate Week 2 Element 6: Fire Hazards and ControlDocument37 pagesNEBOSH International General Certificate Week 2 Element 6: Fire Hazards and ControlJaballa AliNo ratings yet

- Chap-20 - Locomotion & MovementDocument52 pagesChap-20 - Locomotion & MovementMittal SavaniNo ratings yet

- Silo Clean Safe CleaningDocument7 pagesSilo Clean Safe CleaningSanjeev GuptaNo ratings yet

- Tanker Checklist Incoming EmptyDocument4 pagesTanker Checklist Incoming Emptybuddy-20087751No ratings yet

- 4 - Properties of AsphaltDocument8 pages4 - Properties of AsphalttunlajiNo ratings yet

- CGA Safety Checklist for Compressed Gas CylindersDocument4 pagesCGA Safety Checklist for Compressed Gas CylindersKhairul AmilinNo ratings yet

- Paints: Consists of 3 Components: Pigment:-Binder, Vehicle or Resin: - SolventDocument5 pagesPaints: Consists of 3 Components: Pigment:-Binder, Vehicle or Resin: - SolventAshitNo ratings yet

- H2S Safety Handbook SummaryDocument7 pagesH2S Safety Handbook Summarydurga273No ratings yet

- Bitumen SpecificationsDocument2 pagesBitumen SpecificationsAlexander IvanovNo ratings yet

- Dry ice blasting improves adhesive strength of aluminum jointsDocument11 pagesDry ice blasting improves adhesive strength of aluminum jointsliquidideasNo ratings yet

- Electric Vehicle BatteryDocument15 pagesElectric Vehicle BatteryTotal Acess100% (1)

- Engineering Manual Viscous and High Density: General Industry SegmentDocument52 pagesEngineering Manual Viscous and High Density: General Industry SegmentingrbarrosNo ratings yet

- Msds EthanolDocument11 pagesMsds EthanolAsih MiniartiNo ratings yet

- Astm d2872Document5 pagesAstm d2872KRamana ReddyNo ratings yet

- Bitumen Safety CodeDocument69 pagesBitumen Safety CodeVictor Eugen100% (2)

- Msds For KeroseneDocument6 pagesMsds For KeroseneMahadeva PrasadNo ratings yet

- Fuel Oil AdditivesDocument2 pagesFuel Oil AdditivesrajachemNo ratings yet

- SAFETY DATA SHEET FOR HYDRO-X BOILER TREATMENTDocument5 pagesSAFETY DATA SHEET FOR HYDRO-X BOILER TREATMENTZoran ObradovicNo ratings yet

- PPC Production PlantDocument106 pagesPPC Production PlantAljay Neeson Imperial100% (1)

- MSDS Asmaco 2500 Silicon SealantDocument6 pagesMSDS Asmaco 2500 Silicon SealantblackcapperNo ratings yet

- Kerosene PDFDocument9 pagesKerosene PDFishnafathonahNo ratings yet

- Safety of Oil Installations Standing Committee ReportDocument96 pagesSafety of Oil Installations Standing Committee ReportVaishnavi Jayakumar100% (1)

- Procedures Devices of LNG Operations TallinnDocument54 pagesProcedures Devices of LNG Operations TallinnbagasNo ratings yet

- Coca Cola Primary Activities: 1. Inbound Logistics Include Functions Like Receiving, Warehousing, and Managing InventoryDocument5 pagesCoca Cola Primary Activities: 1. Inbound Logistics Include Functions Like Receiving, Warehousing, and Managing InventoryJaene L.No ratings yet

- Polymer modified bitumen propertiesDocument5 pagesPolymer modified bitumen propertiesSushanta Kumar RoyNo ratings yet

- Lupranate® T80 Toluene DiisocyanateDocument3 pagesLupranate® T80 Toluene DiisocyanateEnio Miguel Cano LimaNo ratings yet

- Wiped Film Evaporators Engineered SystemsDocument5 pagesWiped Film Evaporators Engineered Systemsdj22500No ratings yet

- Bitumen Bound Materials GuideDocument131 pagesBitumen Bound Materials Guidelyes100% (1)

- 97.67% EFFICIENT PAINT MIXER MACHINEDocument9 pages97.67% EFFICIENT PAINT MIXER MACHINEArnold ManaigNo ratings yet

- Hot Mix Asphalt TestingDocument21 pagesHot Mix Asphalt TestingBhuiyan1No ratings yet

- Cold Mix Technology - BitChemDocument49 pagesCold Mix Technology - BitChemAnirudh SarkarNo ratings yet

- Bitumen: Construction Materials & TestingDocument12 pagesBitumen: Construction Materials & TestingChan OrsolinoNo ratings yet

- Asfier N-480L PDFDocument2 pagesAsfier N-480L PDFherry prasetyoNo ratings yet

- Safety Signs GuideDocument119 pagesSafety Signs GuideJoshua TroglioNo ratings yet

- Hazardous Material ClassificationDocument9 pagesHazardous Material Classificationahsen_hasanNo ratings yet

- Securea SCDocument2 pagesSecurea SCAutumn HernandezNo ratings yet

- Rubber Property-Vulcanization Using Rotorless Cure Meters: Standard Test Method ForDocument7 pagesRubber Property-Vulcanization Using Rotorless Cure Meters: Standard Test Method ForÇakıl ŞenolNo ratings yet

- 2017716154112bitumen 6070Document1 page2017716154112bitumen 6070lab copriNo ratings yet

- 60 Accredited Valid As On 15042018Document7 pages60 Accredited Valid As On 15042018Amit KumarNo ratings yet

- Stratco Selection Use and MaintenanceDocument6 pagesStratco Selection Use and MaintenanceAmjad PervazNo ratings yet

- Sulfur Extended Heavy Oil Fly Ash and Cement Waste Asphalt Mastic For Roofing and WaterproofingDocument12 pagesSulfur Extended Heavy Oil Fly Ash and Cement Waste Asphalt Mastic For Roofing and WaterproofingMohammad DalhatNo ratings yet

- شمع برافينDocument5 pagesشمع برافينhadjaidji abdhalimNo ratings yet

- Zinc Bromide Calcium Bromide Brine MSDSDocument7 pagesZinc Bromide Calcium Bromide Brine MSDSMohammed SafwanNo ratings yet

- Confined Vapor and Gas Fatalities in Upstream OperationsDocument16 pagesConfined Vapor and Gas Fatalities in Upstream Operationssmithyry2014No ratings yet

- Fireproof Duct Sealant Technical Data SheetDocument2 pagesFireproof Duct Sealant Technical Data SheetAMEENNo ratings yet

- Safety Shoes Specification PDFDocument1 pageSafety Shoes Specification PDFMohamed AliNo ratings yet

- Oxygen Cylinder MSDS General IndustrialDocument4 pagesOxygen Cylinder MSDS General IndustrialarvindsarkarNo ratings yet

- SDS - Bengalac Red Oxide Primer - English (Uk) - DubaiDocument5 pagesSDS - Bengalac Red Oxide Primer - English (Uk) - DubaiBalasubramanian Ananth100% (1)

- Fire Retardant Spray ComparisonDocument11 pagesFire Retardant Spray Comparisonsteve4goshel100% (1)

- Chemical Hazard Bulletin: Pow-R-Wash VZDocument1 pageChemical Hazard Bulletin: Pow-R-Wash VZHaleemUrRashidBangashNo ratings yet

- Review João SoaresDocument56 pagesReview João Soaresrodrib21No ratings yet

- Paint: Paint Is Any Liquid, Liquifiable, or Mastic Composition Which AfterDocument8 pagesPaint: Paint Is Any Liquid, Liquifiable, or Mastic Composition Which Aftersanthoshmarch9920No ratings yet

- OSHA Confined Space TrainingDocument187 pagesOSHA Confined Space TrainingPrimelift Safety Resources LimitedNo ratings yet

- Asphalt SDSDocument11 pagesAsphalt SDSAgustn LopzNo ratings yet

- Exxsol D60Document10 pagesExxsol D60Adi WiraNo ratings yet

- Material Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDocument11 pagesMaterial Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDeshanNo ratings yet

- ISOPAR HDocument11 pagesISOPAR Hwaxim26322No ratings yet

- Safety Data Sheet: Section 1 - Product and Company IdentificationDocument10 pagesSafety Data Sheet: Section 1 - Product and Company IdentificationAndhie OsloNo ratings yet

- GMC Cover Letter 2020Document1 pageGMC Cover Letter 2020Junard M. Lu HapNo ratings yet

- Unit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationDocument1 pageUnit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationJunard M. Lu HapNo ratings yet

- JUNARD Cover Letter 2020Document2 pagesJUNARD Cover Letter 2020Junard M. Lu HapNo ratings yet

- Hussain Mustafa Al-Shakhori: QA/QC InspectorDocument3 pagesHussain Mustafa Al-Shakhori: QA/QC InspectorJunard M. Lu HapNo ratings yet

- Health and Safety Practical Report TemplateDocument1 pageHealth and Safety Practical Report TemplateJunard M. Lu HapNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument1 pageNEBOSH International General Certificate in Occupational Health and SafetyJunard M. Lu HapNo ratings yet

- Junard M. Lu Hap, RNDocument6 pagesJunard M. Lu Hap, RNJunard M. Lu HapNo ratings yet

- Experienced Baker and Pastry Chef with International Work ExperienceDocument3 pagesExperienced Baker and Pastry Chef with International Work ExperienceJunard M. Lu HapNo ratings yet

- GC3 Executive SummaryDocument1 pageGC3 Executive SummaryJunard M. Lu HapNo ratings yet

- Basic Care and Comfort RationaleDocument2 pagesBasic Care and Comfort RationaleRae Krystylynne CodillaNo ratings yet

- Word Bank InvestigationDocument3 pagesWord Bank InvestigationJunard M. Lu HapNo ratings yet

- NYCDocument1 pageNYCJunard M. Lu HapNo ratings yet

- Top 5 HazardsDocument13 pagesTop 5 HazardsJunard M. Lu HapNo ratings yet

- Unit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationDocument1 pageUnit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationJunard M. Lu HapNo ratings yet

- GC3 Mark Sheet-Second PageDocument1 pageGC3 Mark Sheet-Second PageJunard M. Lu HapNo ratings yet

- Browse House LogoDocument11 pagesBrowse House LogoJunard M. Lu HapNo ratings yet

- Unit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationDocument1 pageUnit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationVinoth SudalaiNo ratings yet

- Nclex RN Q - A FB GroupDocument1 pageNclex RN Q - A FB GroupJunard M. Lu HapNo ratings yet

- Print Out Banner LogoDocument1 pagePrint Out Banner LogoJunard M. Lu HapNo ratings yet

- Audit: English Word Arabic Translation English Meaning Arabic MeaningDocument2 pagesAudit: English Word Arabic Translation English Meaning Arabic MeaningJunard M. Lu HapNo ratings yet

- 2 Word Bank Intro To OshDocument3 pages2 Word Bank Intro To OshJunard M. Lu HapNo ratings yet

- Browse House LogoDocument11 pagesBrowse House LogoJunard M. Lu HapNo ratings yet

- RL 2018Document1 pageRL 2018Junard M. Lu HapNo ratings yet

- Job Summary TKDocument5 pagesJob Summary TKJunard M. Lu HapNo ratings yet

- 1601E August 2008 GuidelinesDocument1 page1601E August 2008 GuidelinesAce NelsonNo ratings yet

- Job Summary TKDocument1 pageJob Summary TKJunard M. Lu HapNo ratings yet

- Writing Introduction: The Graph Below ShowsDocument4 pagesWriting Introduction: The Graph Below ShowsJunard M. Lu HapNo ratings yet

- Al Naba Answer KeyDocument11 pagesAl Naba Answer KeyJunard M. Lu HapNo ratings yet

- Measles/ Rubella & VPD Surveillance:: Allotment of EPID Number and Outbreak IDDocument7 pagesMeasles/ Rubella & VPD Surveillance:: Allotment of EPID Number and Outbreak IDDevendra Singh TomarNo ratings yet

- Human Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamDocument23 pagesHuman Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamkamranNo ratings yet

- Frontier DL650 Maintenance Guide Ver 1.0Document25 pagesFrontier DL650 Maintenance Guide Ver 1.0philippe raynalNo ratings yet

- Weekly Home Learning Plan: Grade 8 - Quarter 2. Week 7Document3 pagesWeekly Home Learning Plan: Grade 8 - Quarter 2. Week 7Danmer Jude TorresNo ratings yet

- NCM 117 Rle NAME: Guerzo, Danniel Dave Y. DATE/TIME: March 9, 2023 Section/Year Level: BSN 3B Group No:10 CIDocument2 pagesNCM 117 Rle NAME: Guerzo, Danniel Dave Y. DATE/TIME: March 9, 2023 Section/Year Level: BSN 3B Group No:10 CISherlyn Miranda GarcesNo ratings yet

- Chemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsDocument5 pagesChemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsShalini KumariNo ratings yet

- Computed Tomography (CT) - BodyDocument7 pagesComputed Tomography (CT) - Bodyfery oktoraNo ratings yet

- Breading Guide To All FoodDocument1 pageBreading Guide To All FoodInno EspinaNo ratings yet

- 2018 Nutrition Month ReportDocument1 page2018 Nutrition Month ReportAnn RuizNo ratings yet

- Anexo A2 - Ficha Panel CSUN250-60PDocument2 pagesAnexo A2 - Ficha Panel CSUN250-60PRobin Andres Quezada SanhuezaNo ratings yet

- Colours of the RainbowDocument16 pagesColours of the RainbowMd A RAZZAKNo ratings yet

- MSDS - ENTEL BatteryDocument3 pagesMSDS - ENTEL BatteryChengNo ratings yet

- Science 6-Q1-M6Document14 pagesScience 6-Q1-M6John Philip LegaspiNo ratings yet

- Ra 9520 Chapter VDocument8 pagesRa 9520 Chapter VLorribelle OcenarNo ratings yet

- Year 8 Drama ScriptDocument8 pagesYear 8 Drama ScriptTISMSecondaryNo ratings yet

- Design AI Platform Using Fuzzy Logic Technique To Diagnose Kidney DiseasesDocument9 pagesDesign AI Platform Using Fuzzy Logic Technique To Diagnose Kidney DiseasesTELKOMNIKANo ratings yet

- Soa Group Health TrackDocument2 pagesSoa Group Health TrackwasabiwafflesNo ratings yet

- Two-day workshop budgetDocument2 pagesTwo-day workshop budgetVishwanath BaliNo ratings yet

- Exudate Detection For Diabetic Retinopathy With Circular HoughDocument7 pagesExudate Detection For Diabetic Retinopathy With Circular HoughAshif MahbubNo ratings yet

- Rendemen Dan Skrining Fitokimia Pada Ekstrak DaunDocument6 pagesRendemen Dan Skrining Fitokimia Pada Ekstrak DaunArdya YusidhaNo ratings yet

- ZV Class Links @Medliferesuscitation-CopyDocument31 pagesZV Class Links @Medliferesuscitation-CopyDebajyoti DasNo ratings yet

- Employment Law Lubs 3915Document4 pagesEmployment Law Lubs 3915ogunsatoNo ratings yet