Professional Documents

Culture Documents

1 s2.0 S0892687506003219 Main PDF

Uploaded by

evelynOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S0892687506003219 Main PDF

Uploaded by

evelynCopyright:

Available Formats

Minerals Engineering 20 (2007) 496505

This article is also available online at:

www.elsevier.com/locate/mineng

Automated mineralogical analysis of coal and ash

products Challenges and requirements

C. van Alphen

Van Alphen Consultancy, P.O. Box 1648, Jukskei Park 2153, Johannesburg, South Africa

Received 25 September 2006; accepted 13 December 2006

Available online 15 February 2007

Abstract

To ensure accurate and reliable automated mineralogical analysis of a sample, it is a common practise to use chemically derived elemental proportions to validate the mineralogical proportions. Automated mineralogical analysis of coal and corresponding ash is a challenge as a signicant proportion of the phases/minerals are amorphous with variable elemental proportions. In coal, the organic macerals

are the amorphous phases and depending on the rank of the coal have varying carbon, hydrogen, nitrogen, oxygen and inorganic element

compositions. In ash, aluminosilicate glasses and partially transformed minerals are the major amorphous phases. The elemental composition of these glasses is controlled by the mineral deportment in the source coal, operating conditions and conguration of the boiler,

gasier or furnace.

To compound the problem, the traditional chemical analysis of coal (proximate, ultimate and XRF ash elemental analysis) is based on

heating the coal to dierent temperatures and recording mass losses or analysing the ash derived from the coal. These analyses each have

inherent limitations, sampling and analytical errors, which when combined can provide misleading interpretations.

If accurate and precise mineralogical data are to be provided to coal practitioners for optimising processing plant, predicting combustion/gasication performance and for resolving coal quality problems, it is necessary to develop a cost eective and reliable automated coal and ash analytical system.

With the advancement in X-ray detector and scanning electron microscope technology it is potentially feasible to provide a cost eective and quick mineralogical (minerals and macerals) and elemental analysis of raw coal and ash. The new automated systems have the

potential of combining the traditional proximate, ultimate, XRF ash elemental, XRD and petrographic analyses into one analysis, without heating or modifying the existing coal sample.

Detailed coal and ash particle characterisation is now feasible, enabling the development of coal processing, y ash formation, slagging prediction and combustion performance models. Coal and ash analysis is now entering a new and exciting era.

2007 Elsevier Ltd. All rights reserved.

Keywords: Automation; Coal; Fly ash; CCSEM; QEMSCAN; MLA

1. Introduction

Simplistically, coal consists of organic amorphous macerals and inorganic crystalline minerals in varying proportions, whereas ash consist of minerals, char and amorphous

aluminosilicate glasses.

Tel.: +27 117046657.

E-mail address: cncc@mweb.co.za

0892-6875/$ - see front matter 2007 Elsevier Ltd. All rights reserved.

doi:10.1016/j.mineng.2006.12.013

The element composition (carbon, hydrogen, oxygen,

nitrogen and organically bound inorganic elements) of the

macerals is inuenced by the rank of the coal, whereas

the elemental composition of the glasses is controlled by

the minerals deportment in the source coal and the operating conditions and conguration of the boiler or furnace.

With the high proportion of amorphous phases in coal

and ash, accurately characterising elemental distributions,

elemental proportions and mineralogical characteristics is

dicult for coal and ash, irrespective of the technique used.

C. van Alphen / Minerals Engineering 20 (2007) 496505

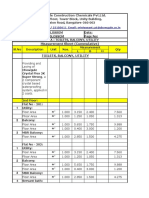

Proximate and ultimate and to lesser extent X-ray uorescence (XRF) ash elemental are some of the traditional

and routine analyses undertaken by coal suppliers, users

and buyers to characterise coal (Fig. 1).

Proximate analysis is the inherent moisture, volatile

matter, ash, xed carbon (by dierence) and ultimate analysis is the carbon, hydrogen, nitrogen, total sulphur and

oxygen (by dierence) content of the coal. Ash elemental

is the elemental composition of the ash derived from the

coal. For each analysis, the coal is heated and the mass%

loss, mass% of the reaction products and mass% of the residue (ash) are measured.

Inherent moisture is the mass loss after heating the coal

to 100110 C (SABS Method 925), volatile matter is mass

loss after heating the coal to 900 C (SABS Method 927,

ISO562M and ASTMD3175M) and ash is non-combustible residue after slowly heating the coal to 815 C (SABS

Method 926) or 900 C (ASTM D3174). The volatile matter is derived from organic fraction and from certain minerals, whereas the ash% can include volatile organic

sulphur, which has reacted with CaO and uncombusted

carbon. Ash% is not a direct measure of the total mineral

matter content of the coal. The sum of inherent moisture,

volatile matter and ash% subtracted from 100% is termed

xed carbon. Fixed carbon should represent the proportion

of non-volatile carbon and is the accumulation of any analytical errors.

The ultimate analysis reports the carbon, hydrogen,

nitrogen, total sulphur and oxygen content. Carbon

includes organic carbon and inorganic carbon from carbonates, hydrogen includes organic hydrogen and hydrogen in the water derived from minerals and nally total

COAL

Proximate Analysis

Inherent moisture

Ash-%

Volatile

matter

Fixed carbon (by difference)

XRF Ash elemental

SiO2, Al2O3, Fe2O3,

TiO2, CaO, MgO,

K2O, Na2O, P2O5,

MnO, SO3

LOI

Ultimate Analysis

Carbon

Hydrogen

Nitrogen

Oxygen (by difference)

Other

AFT

CO2 (carbonates)

Total sulphur

HGI

Calorific value (CV)

XRD

Petrography

CCSEM

MINERALS

Fig. 1. The variety of typical coal and ash analyses.

497

sulphur is organically bound sulphur and sulphur derived

from pyrite. Oxygen is a calculated value.

Determining the mineral matter in coal is either calculated using X-ray uorescence (XRF) ash elemental proportions (SEDNORM, Cohen and Ward, 1991) or

determined directly using X-ray diraction (XRD) and by

scanning electron microscope (SEM) based automated

mineralogical systems such as CCSEM, QEMSCAN and

MLA.

Normative programs such as SEDNORM assumes that

specic elements can be assigned to one mineral. Unfortunately, this is not always possible as certain elements occur

in more than one mineral. An example is Fe, which can

occur in pyrite, siderite Fe-chlorite and Fe-oxides, K in

mica/illite and feldspar and nally Si in quartz, clays,

mica/illite and feldspars. In lower rank coal, a proportion

of the elements are organically bound to carbon and not

associated with minerals. Extensive knowledge of the coal

prior to normative analysis is benecial.

An X-ray diraction pattern of raw coal and ash is characterised by high background continuum originating from

the amorphous macerals in coal and amorphous aluminosilicate glass in the ash. This broad background can mask

peaks of crystalline phases. Ashing the coal at low temperature (120150 C) in electronically excited oxygen plasma

can isolate minerals from the organic fraction (LTA).

Unfortunately, LTA can take 34 days and in lower

rank-coals secondary calcium and iron sulphates are

formed during the ashing process (Ward, 2002). A technique was developed to determine the proportion and elemental composition of glass in ash (Ward and French,

2003). The calculated elemental proportion of the glass

relies on the accuracy of XRF ash elemental analysis and

X-ray diraction derived mineral proportions in the ash.

X-ray diraction and normative calculation predicts the

mineral composition of the coal, but does not determine

the morphological features (size, association) of the minerals and particle characteristics.

Petrographic analysis describes the proportion of macerals in coal and to a limited extent the proportion of minerals in coal. Maceral discrimination is visual and based on

texture, morphology and light reectance observed under

a reected light microscope tted with an oil immersion

objective. Since maceral identication is visual and requires

human intervention, it can be subjective, especially for ne

particles. Micrinite, a maceral described by petrographers

was shown by Faraj and Mackinnon to be ne-grained

kaolinite (Faraj and Mackinnon, 1993) and not a carbon

bearing phase. The mineral proportions are reported as

the three main groups quartz/clays, pyrite and carbonates.

It is not possible to accurately distinguish between the different minerals, especially if they are ne grained and

included in coal matrix.

The US Steel Research Laboratories initiated the scanning electron microscope (SEM) based automated mineralogical analysis of coal in the early 1970s with the

development of the particle recognition and characterisation

498

C. van Alphen / Minerals Engineering 20 (2007) 496505

(PRC) software (Galbreath et al., 1996). PRC software

located the minerals dispersed in the coal matrix and positioned the electron beam at the centre of the included grain

(Lee et al., 1978; Huggins et al., 1982). Initially, CCSEM

analysis was time consuming and only the minerals were

quantied. It was only in the early 1990s that the organic

coal was analysed (Human et al., 1991; Straszheim and

Markuszewski, 1990, 1992). This was made possible by

mounting the coal sample in either carnauba wax (Straszheim et al., 1988) or iodoform doped epoxy resin (Gomez

et al., 1984) and by the introduction of light element detectors. Since CCSEM mineralogical identication is based

on the elemental proportions derived from X-rays, it can

accurately determine the mineral type and elemental proportions of the minerals in coal (Van Alphen and Falcon, 2000)

and amorphous glass phases (Van Alphen, 2005). In its current form, CCSEM is unable to accurately distinguish

between the dierent macerals and all the macerals are

grouped as coal. This is a limitation.

Each of the chemical and mineralogical analytical techniques described above have limitations and do not provide

the full particle and mineralogical characterisation required

for coal-processing optimisation, coal combustion performance assessment and the impact on boiler/furnace/gasier

performance. For ne (<0.5 mm) coal-processing optimisation it is important to quantify the density, ash deportment

and size distribution of particles. The surface characteristics of particles are important for otation. The liberation

characteristic of the inorganic and organic component in

coal is important for assessing the potential yields and

grade (ash%) of the product and can be used to evaluate

the eciency of separation technique (spirals, cyclones or

otation). The mineral deportment in coal and organically

bound inorganic element distribution inuences the slagging potential of the coal. The proportion of reactive macerals (vitrinite and liptinite) in the particle controls ignition

and combustion rate.

The development of faster X-ray detectors, stable scanning electron microscopes, and high-resolution backscattered electron detectors and good processing software

have improved the analytical capabilities of automated

scanning electron microscopes (CCSEM, QEMSCAN

and MLA). With further research, these systems have the

potential of providing the detailed mineralogical and elemental information required.

2. Coal and ash automated mineralogical systems

There are numerous CCSEMs around the world,

which have dierent congurations, analytical approaches

and data processing software. Each system is however

based on a scanning electron microscope, use X-rays to discriminate minerals and have suitable microanalysis and

image processing systems.

The numerous data processing software programs

include

1. Particle recognition (PRC) and coal mineral analysis

(CMA) developed by the US Steel Research Laboratories (Nissen and Greulich, 1987). The Combustion

Research Facility at Sandia National Laboratories (Nissen and Greulich, 1987; Yang and Baxter, 1991), University of Kentucky (Human et al., 1991) and the

Combustion Research Facility at Massachusetts Institute of Technology (Beer et al., 1991) employ CCSEM

with the basic PRC and CMA routines.

2. The Energy and Environment Research Centre (EERC)

at the University of North Dakota developed the SEM

point-count routine (SEMPC), windows based MINCLASS mineral classication program (Folkedahl

et al., 1993) and particle-by-particle scanning electron

microscope programme (Steadman et al., 1991).

3. Brigham Young University developed the Analysis of

Minerals and Coal Associations (AMCA) program

(Yu et al., 1993).

4. Anglo American Research Laboratory developed the

ASCAN software to initially analyse base metals, but

was modied by Van Alphen Consultancy to analyse

coal and ash (Van Alphen, 2005).

QEM*SEM or QEMSCAN is an integrated system originally designed by CSIRO (Skorupska and Couch, 1993)

for the base and precious metal mining industry, but has

been used to classify mineral matter in coal and y ash

(Creelman et al., 1993; Creelman and Ward, 1996; Gottlieb

et al., 1991).

University of Queenslands JK Centre recently

announced an ACARP funded project to integrate of the

Mineral Liberation Analyser (MLA) and the JenkinsKwan Technology MACE 300 system (MLA Today,

October 2005).

The multitude of possible CCSEM congurations, different analytical conditions and software approaches has

resulted in some concern regarding the reliability and accuracy of the CCSEM. To address this problem an international round robin test involving six laboratories was

undertaken in 1994 (Galbreath et al., 1996). The laboratories that participated were EERC (CCSEM), CSIRO

(QEMSCAN), the R.J. Lee Group (CCSEM), the University of Kentucky (CCSEM), the Sandia National Labs

(CCSEM) and the Netherlands Energy Research Foundation (CCSEM). Each laboratory determined the abundance

of calcite, kaolinite, pyrite and quartz for three North

American coals. The results indicated that QEMSCAN

reported the most precise results. Kaolinite showed the

poorest reproducibility for all three coals. Kaolinite had

the lowest backscattered electron intensity (BSI) of the

minerals and typically occurs as ne disseminated grains

included in a coal particle. These attributes make it dicult

to accurately detect kaolinite and to quantify its morphological and association properties.

X-ray acquisition speeds, electron beam positioning

and mineral characterisation procedures are the main

dierences in the automated systems described above.

C. van Alphen / Minerals Engineering 20 (2007) 496505

499

Further research is required and new techniques need to

be developed to improve quantitative elemental analysis,

maceral discrimination and mineral and particle characterisation.

Fortunately, coal and ash have certain mineralogical

and physical characteristics that can be exploited to achieve

the objectives listed above. These characteristics are outlined in the following sections.

3.1. Quantitative elemental proportions

Fig. 2. Electron beam positioning. Centroidal or raster of closely spaced

points.

QEMSCAN X-ray acquisition speed is 1015 ms, ASCAN

is 100 ms and remaining systems in excess of 400 ms25 s.

Either the electron beam is positioned at the centre of a

phase of similar backscatter electron intensity (centroidal

approach) or a closely spaced raster of points are positioned across the particle (Fig. 2). MLA and the traditional

CCSEM systems use the centroidal approach, whereas

ASCAN, QEMSCAN and EERC CCSEM use the raster

approach. QEMSCAN and the traditional CCSEM systems use a sequential mineral identication program,

ASCAN uses fuzzy logic and MLA compares standard

X-ray spectrum of the unknown to identify the minerals.

The two commercially available automated mineralogical systems, QEMSCAN and MLA have included the

signicant advances in X-ray detector technology, backscatter electron detectors and the modern digital scanning

electron microscopes. The introduction of the liquid nitrogen free silicon drifted detectors (SDD) with counts rates in

excess of 1,000 000 cps are 10 times faster than the traditional Si(Li) detectors.

Increase counting times will ensure better statistics and

rapid analytical times. The introduction of these new technologies will advance the analytical capabilities of these

two systems, especially for analysing coal and ash

products.

In coal, elements can be distributed between organic

(macerals) and the inorganic components (minerals). Low

rank lignites and sub-bituminous coals commonly have a

signicant proportion of organically bound inorganic elements (Fig. 4). The organically bound elements increase

the average backscatter electron intensity of organic coal

particles (Fig. 3).

The mineral free organic phase in a lignite sample had

signicant proportions of Ca, Mg, Fe and S (Fig. 4). It is

perceived that these inorganic elements are bound to the

carboxyl group (COOH). As the rank increases, the proportion of organically bound inorganic elements decrease

(Fig. 4).

The macerals of a South African high volatile bituminous (RoV% random = 0.64) coal, have distinct organically bound elements (Fig. 5). Generally, sulphur and

titanium were elevated in vitrinite and pseudovitrinite, aluminium, silicon, sulphur, and to a lesser extent calcium and

magnesium are elevated in reactive and inert semifusinite,

calcium and sulphur are elevated in sclerotinite and aluminium, silicon, sulphur in liptinite.

Electron microprobe analysis of telecollinite in Australian DM Bando coal with a Rmax varying from 0.68 to

2.20 identied organically bound Al, Si and Fe (Gurba

3. Automated mineralogical system requirements

In the authors opinion, to provide the necessary mineralogical information required by coal practitioners,

researches and users, the new generation automated mineralogical systems must:

1. accurately quantify the elemental proportions and elemental distribution between the organic (macerals) and

inorganic (minerals) fractions;

2. discriminate and quantify the proportion of macerals

and determine the maceralmineral association characteristics on a particle-by-particle basis;

3. accurately determine the mineral/coal proportions and

mineral/coal morphological features;

4. be cost-eective with a minimum turnaround time of

two days for a batch of six sections. The sample must

not be heated or chemically treated prior to the analysis.

Fig. 3. Backscatter electron intensity image of lignite mounted in normal

epoxy resin. The organic component (light grey) has a high BSE intensity

relative to epoxy resin (grey) and the included minerals white. Scale bar is

100 lm.

500

C. van Alphen / Minerals Engineering 20 (2007) 496505

0.5

0.45

Counts

0.4

0.35

0.3

0.25

O

Na

0.05

0

Ca

Mg

Fe

4

5

6

Peak Positions

10

Fig. 4. X-ray spectrum obtained from the organic phase in a lignite.

Normalised counts (cts/s)

0.006

Si

0.005

Reactive Semifusinite

Al

Inert Semifusinite

Liptinite

Vitrinite

0.004

S

0.003

ASCAN elemental proportion was within 15% of the standard XRF ash elemental analysis for the major elements.

This provided sucient information for trending and to

conrm the elemental variation between samples.

Increasing the number of counts from 1000 to 10,000

will obviously improve the accuracy, but will unfortunately

will increase the time and cost to analyse a sample using the

existing Si(Li) EDS detectors. However, with the introduction of new liquid nitrogen free SDD detectors this

becomes a feasible option, without signicantly compromising the time required to analyse a sample.

Organic hydrogen will be the only element, which cannot be directly quantied using the existing EDS detector

technology. This however, could be calculated by dierence, analogous to determining the proportion of oxygen

in an ultimate analysis and xed carbon in the proximate

analysis. Since the macerals and glasses are amorphous,

the elemental proportions are not consistent. If the elemental composition of macerals and glasses are to be accurately

quantied the automated mineralogical system should be

based on raster of analytical points across particles and

not on the centroidal positioning method (Fig. 2).

3.2. Maceral discrimination

Mg

0.002

Ca

Ti

0.001

0

0.8 1.3 1.8 2.3 2.8 3.3 3.8 4.3 4.8 5.3 5.8 6.3 6.8

KeV

Fig. 5. Organically bound elements associated with dierent macerals in

high volatile bituminous coal.

and Ward, 2000). Organically bound sulphur is widely

reported (Timmer and van der Burgh, 1984; Straszheim

et al., 1983) in bituminous coals.

Improvement in elemental quantication is important as

the automated mineralogical system must be able to quantify the proportion of organically bound inorganic elements, discriminate between organic and inorganic C, H

and N and the elements associated with minerals.

Elemental quantication using the rapidly acquired 1000

count X-ray spectrum was achieved on the ASCAN system

(Van Alphen, 2005). Two to three second count energy dispersive (EDS) X-ray spectra were acquired from mineral

standards. Using a random number generator, the standard X-ray spectrum was broken down into a 1000 count

spectrum a 100 times and the number of counts for each

element was computed. Good correlations were obtained

between the average elemental count and the known elemental proportion (Fig. 6) for the major elements. The correlation coecient varied from 0.98 to 0.99. The linear

equation was used to determine the oxide proportions of

coal and ash from the ASCAN 1000 count X-ray spectrum.

Compared to the standard XRF ash elemental analysis, the

Accurately discriminating and quantifying macerals in

coal is important as the proportion of reactive macerals

is used to predict combustion behaviour (Su et al., 2001).

Su maceral index is a function of vitrinite, liptinite and

inertinite. Magasiner used the reactive maceral proportions to predict the ratings of chain grate stockers combusting coal and biomass (Magasiner et al., 2001). This index

was based on the proportion of vitrinite, liptinite, reactive

inertodetrinite and reactive inertinite. Following this

research, the automated mineralogical system, should at

best be able to discriminate between reactive macerals (vitrinite and liptinite) and inert macerals (inertinite).

Under the light reectance optical microscope maceral

characterisation is based on texture, association and light

reectance intensity. It is reliant on the interaction of light

with the sample and the ability of the eye and human brain

to discriminate textures. Mineral discrimination in a scanning electron microscopes (SEM) is based on the interaction of a high-energy electron beam and the sample.

Typically, backscatter electron intensity (BSI), secondary

electrons intensity (SEI) and X-rays are produced and used

to acquire images and the elemental composition of the

mineral or phase. Since SEM discrimination is electron

based and the optical microscope is light based, the SEM

is unable to identify all the macerals.

JKTech at University of Queensland has initiated maceral discrimination by integrating the Mineral Liberation

Analyser (MLA) and the MACE 300 system. The MLA

using the centroidal approach will dene the mineral content and the MACE 300 system will dene the macerals.

A composite image of each eld of view will be developed

by combining the MACE 300 maceral image and the

C. van Alphen / Minerals Engineering 20 (2007) 496505

40

0.8

0.7

0.6

80

Ca%=-0.43 + 79.18cts

n=23

r=0.98

30

Fe%=2.78 + 94.93cts

n=36

r=0.98

70

% Elemental Fe

35

25

20

15

10

5

60

50

40

30

20

0.8

0.7

0.6

0.5

0.4

Fe X-Ray Count Fraction (Total Spectra)

0.07

0.06

0.04

0.03

0.02

Mg%=0.11+ 73.87cts

n=19

r=0.98

0.01

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Element % Mg

Ca X-Ray Count Fraction (Total Spectra)

0.3

0.2

0.5

0.45

0.4

0.3

0.35

0.25

0.2

0.15

0.1

0.05

10

Element % Ca

0.5

Si X-Ray Count Fraction (Total Spectra)

Al X-Ray Counts Fraction (Total Spectra)

0.4

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45

0.1

0.3

0.2

10

Si%=0.17 + 60.46cts

n=36

r=0.98

0.1

15

50

45

40

35

30

25

20

15

10

5

0

0.05

Element % Al

20

Element % Si

Alwt%=0.128 + 56.78cts

n=39

r=0.99

25

501

Mg X-Ray Count Fraction (Total Spectra)

Fig. 6. Correlation between element counts and known elemental proportions. Data acquired on the ASCAN system (Van Alphen, 2005).

MLA mineral image, from which the maceral and mineral proportions will be determined (Fandrich et al.,

2006). If liptinite proportions are required the images are

edited manually to separate liptinite from the dark minerals (OBrien et al., 2006). The combined MACE 300

and MLA system will quantify maceral and mineral proportions and will characterise each particle into specied

groups depending on the maceral and mineral associations.

As the electron beam is not positioned on the macerals, it

will not be able to automatically determine the elemental

proportions of the macerals. The expected turnaround time

of a single sample is one day (OBrien et al., 2006, personal

communication).

It is proposed that the macerals can be discriminated

using a combination of backscattered electron intensity

and elemental proportions. This could be the focus of the

new automated mineralogical systems.

The density of vitrinite varies from 1.27 g/ml in high volatile bituminous coals to 1.8 g/ml in anthracites (Falcon

and Snyman, 1986). Liptinite ranges in density from 1.18

to 1.25 g/ml with increasing rank. The density of the individual inertinite macerals vary from 1.35 to 1.7 g/ml, but

do not change signicantly with an increase in rank. Since

backscattered electron images are atomic weight contrast

images, the density variation of macerals will be reected

by a variation in grey levels in backscattered electron

images (Fig. 7). Any low-density phase (vitrinite/liptinite)

will be black and high-density phase will be grey

(inertinite).

For a given rank, liptinite has the highest hydrogen content, vitrinite the highest oxygen content and inertinite the

highest carbon content (Tang et al., 2005; Ward and

Gurba, 1999). Published data on mainly density-separated

fractions in general support the trend observed by Tang

502

C. van Alphen / Minerals Engineering 20 (2007) 496505

Fig. 7. Individual high volatile bituminous coal particles highlighting the textural relationship and variation in backscatter electron intensity (<1.5 g/ml

density fraction). Low-density coal is black, higher-density coal is light grey and minerals are white.

90

20

Exinite

Vitrinite

Inertinite

82

80

12

14

10

78

76

74

0.44

Mass-% hydrogen

oxygen

84

16

Mass-%

86

8

7.5

7

6.5

6

5.5

5

4.5

4

3.5

3

0.44

0.5

0.56

0.63

Rank (Romax)

Exinite

Vitrinite

Inertinite

18

0.82

4

0.44

0.91

0.5

0.56

0.63

Rank (Romax)

0.82

0.91

2.4

2.2

Mass-% nitrogen

Mass-% carbon

88

Exinite

Vitrinite

Inertinite

0.5

0.56

0.63

Rank (Romax)

0.82

0.91

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.44

Exinite

Vitrinite

Inertinite

0.5

0.56

0.63

Rank (Romax)

0.82

0.91

Fig. 8. Carbon, hydrogen, nitrogen and oxygen variation with rank (Burragato et al., 1997; White et al., 1987; Xie et al., 1994; Milligan et al., 1997).

and Ward (Fig. 8). Any variation is attributed to the density fraction not necessary containing 100% of the maceral

of interest.

It is conceivable that a new SEM based maceral classication scheme could be developed based on elemental

proportions and backscattered electron intensity. This

new classication scheme is not subjective and once set

up will not require an experience operator.

If backscatter electron intensity is the main discriminator, then the automated mineralogical system has to be

extremely stable as the BSE variations are a few atomic

mass units. It is imperative to monitor the beam current

C. van Alphen / Minerals Engineering 20 (2007) 496505

during the analysis and if necessary automatically adjust the

beam. The mineral identication software used by the automated mineral identication software must include BSE

intensity as a discriminating factor. Using the raster of analytical points instead of centroidal method is preferable as

the slight changes in BSE intensity and elemental compositions can be recorded and used to dene the maceral. This

ne detail will produce an image texture, which could

be used to classify macerals (Fig. 6). Maceral discrimination

in high rank coals, using BSE based automated mineralogical system will probably not be as successful as in lower

rank coals. From a practical point of view, this is not a

major issue as a signicant proportion of the coal utilised

is high to low volatile bituminous coal. Obviously, if the

rank of the coal is known prior to analysis, the maceral discrimination system can modied to suit this rank of coal.

In ash, the prominent carbon phase is char. Char identication is based on morphological features (Alvarez

et al., 1997). The automated mineralogical system must

rst identify carbon-rich phases in the ash samples and secondly have image analysis capabilities that measure wall

thickness and porosity of the char particles. It is important

to have the necessary o-line processing software, which

can classify the particles into dierent classes based on

the wall thickness and porosity.

3.3. Mineral quantication and particle characterisation

Quantifying and qualifying minerals in coal is routine

for any automated mineralogical system, but not necessary

as routine for ash. In coal, ne clay is nely disseminated in

coal. It is this reason why kaolinite is often over or under

reported (Galbreath et al., 1996). The automated mineralogical system must have the mechanism to quantify the

mineralogical variations of these nely disseminated grains.

A system using a raster of closely spaced analytical points

will provide the best opportunity to record the elemental

and subsequently mineral variations.

Simplistically, ash (y ash, slag and clinkers) consists of

crystalline phases (e.g. anorthite, mullite and spinels),

amorphous Ca- and Fe-bearing aluminosilicate glasses of

varying elemental compositions, amorphous Ca-oxide rich

ash particles, amorphous Fe-oxide rich particles and char.

Quantifying and identifying the crystalline phases

should not propose a problem as by denition these phases

have a dened elemental composition and structure. The

problem is classifying the amorphous phases. Grouping

the dierent amorphous phases based on the elemental

composition is the only feasible route.

In South African y ashes and slag deposits at least six

groups have being identied (Van Alphen, 2005). These

include

1. Aluminosilicate, with a Al/Si ratio similar to the original

kaolinite source and no uxing elements (Ca, Fe, Mg, K

and Na). This phase represents the intermediate to high

temperature transformation products of kaolinite.

503

2. CaFe-bearing aluminosilicate glass, typically occur as

spherical particles and is derived by the coalescence of

pyrite, carbonates and kaolinite. Invariably, these

phases initiate the development of slag deposits.

3. K-bearing aluminosilicate glass is derived from K-bearing illite/mica and feldspar.

4. Quartz and Si-rich glasses with minor proportions of Al,

Ca, Fe and Mg. Quartz is the nal transformation product of quartz and the Si-rich glasses represent the high

temperature coalescence of quartz with kaolinite, calcite/dolomite and pyrite.

5. Ca(Mg)-rich oxides (lime) with minor concentrations of

Al and Si. This y ash phase is transformation product

of extraneous calcite and dolomite.

6. Fe-rich oxides with minor concentrations of Al and Si.

This y ash phase is the transformation product of

extraneous pyrite.

Operating conditions and ash formation processes

within the boiler/furnace can be inferred from the mineralogy and elemental distribution of the ash. Comparing the

elemental distribution of the y ash phases to the elemental

distribution in the source coal provides valuable information, which can be used to trace mineral transformation

and reactions within the combusting coal particles and in

the combustion zone. In eect, the elements are used as

tracers.

Measuring the sulphur content in Fe-oxide rich y ash

particles, C-content in Ca-rich y ash particles and the

Al/Si ratio in aluminosilicate y ash particles are indicative

of the extent of pyrite, carbonate and kaolinite transformation. If the data from an automated mineralogical system

are to be used to model mineral transformation, y ash formation and slag development in any commercial boiler,

gasier or furnace, it is important to accurately characterise the y ash phases and to fully understand mineral and

elemental deportment in the source coal (Van Alphen,

2005). Without this detail, the model will not produce accurate and meaningful results.

Identifying these ash phases and measuring the variation

in elemental proportion is only possible if a raster of points

is used. Since there is a tenuous link between the backscattered electron intensity and elemental composition of

glasses, the centroidal approach is not feasible.

4. Conclusion

To satisfy the mineralogical requirements for coal utilisation, coal-processing optimisation, coal resource assessment and coal combustion performance it is important that

the automated mineralogical system should be able to

quantify and qualify elemental proportions (organic and

inorganic), major maceral groups, mineral deportment

and proportions in coal. This same system must identify

the numerous amorphous phases in glass and accurately

quantify the elemental proportion of these amorphous

glasses.

504

C. van Alphen / Minerals Engineering 20 (2007) 496505

Coal process engineers require the particle size distribution, density distribution and mineral(ash) distribution of

coal particles for optimising the circuit and improving the

quality of the product. The maceral composition and surface characteristics of ne particles are important for

otation.

Reducing the number of ame-outs, unplanned outages

and the proportion of char in the y ash are important for

combustion engineers. Flame-outs are partially a function

of the maceral composition and unplanned outages are

commonly attributed to extensive slagging and fouling.

To resolve these problems, the automated mineralogical

system must accurately determine mineral proportion and

deportment, proportion and deportment of reactive macerals, particle characteristics, size and angularity of abrasive

minerals, distribution of elements and nally the distribution of carbon, hydrogen and oxygen.

The introduction of liquid nitrogen free SDD detectors,

stable digital scanning electron microscopes and high-resolution backscatter electron detectors coupled with unique

mineralogical features will enable the automatic mineralogical analysis of coal and ash samples. In the authors opinion, the raster of closely spaced points is preferable to using

the centroidal method of position the electron beam. Further research is required to substantiate the trends and

observations mentioned in this paper. Coal and ash analysis is now entering a new and exciting era.

Acknowledgements

The original mineral matter transformation, y ash formation and slag development research and setting up the

ASCAN system was funded by Eskom Resources and

Strategy Division. This funding enabled the author to

develop the techniques and to comprehend the complexity

of analysing coal and ash. Eskoms support and funding is

gratefully acknowledged.

References

Alvarez, D., Borrego, A.G., Menendez, R., 1997. Unbiased methods for

the morphological description of char structures. Fuel 76 (13), 1241

1248.

Beer, J.M., Sarom, A.F., Barta, L.E., 1991. From coal mineral matter

properties to y ash deposition tendencies: a modelling route. In:

Benson, S.A. (Ed.), Inorganic Transformation and Ash Deposition

During combustion, pp. 7189.

Burragato, F., Caminiti, R., Ferraro, M., Gelli, J., Sadun, C., 1997.

EDXRD-RDF characterisation of maceral group concentrates for

assessing coal reactivity. Fuel 76 (9), 887892.

Cohen, D.R., Ward, C.R., 1991. SEDNORM a program to calculate a

normative mineralogy for sedimentary rocks based on chemical

analysis. Computers and Geoscience 17 (9), 12351253.

Creelman, R.A., Ward, C.R., 1996. A scanning electron microscope

method for automated, quantitative analysis of mineral matter in coal.

International Journal of Coal Geology 30, 249269.

Creelman, R.A., Holcombe, D., Gottlieb, P., Trenaman, K.J., Juniper,

L.A., 1993. FIy ash erosion measurements in utility boilers and a pilot

scale facility. In: Williamson, J., Wigley, F. (Eds.). The Impact of Ash

Deposition on Coal Fired Plants, pp. 747758.

Falcon, R.M.S., Snyman, C.P., 1986. An Introduction to Coal Petrography: Atlas of Petrographic Constituents in the Bituminous Coals of

Southern Africa. The Geological Society of South Africa (Review

Paper Number 2).

Fandrich, F., Gu. Y., Jenkins, B., OBrien. G., 2006. Integration of light and

electron microscope coal petrography methods. In: Proceedings of the

Automated Mineralogy 06, MEI Conference, 1718 July 2006, Brisbane.

Faraj, B.S.M., Mackinnon, I.D.R., 1993. Micrinite in Southern Hemisphere sub-bituminous and bituminous coal: redened as ne grained

kaolinite. Organic Geochemistry 20 (6), 823841.

Folkedahl, B.C., Steadman, E.N., Brekke, D.W., Zygarlicke, C.J., 1993.

Inorganic phase characterization of coal combustion products using

advanced SEM techniques. In: Williamson, J., Wigley, F. (Eds.), The

Impact of Ash Deposition on coal red plants, pp. 399407.

Galbreath, K., Zygarlicke, C., Casuccio, G., Moore, T., Gottlieb, P.,

Agron-Olshina, N., Human, G., Shah, A., Vang, N., Vleeskens, J.,

Hamburg, G., 1996. Collaborative study of quantitative coal mineral

analysis using computer-controlled scanning electron microscopy. Fuel

75 (4), 424430.

Gomez, C.O., Strickler, D.W., Austin, L.G., 1984. An iodinised mounting

medium for coal particles. Journal of Electron Microscopy 1, 285287.

Gottlieb, P., Argon-Olshina, N., Sutherland, D.N., 1991. The characterisation of mineral matter in coal and y ash. In: Benson, S.A. (Ed.),

Inorganic transformations and ash deposition during combustion

Proceedings of the Engineering Foundation Conference. The American Society of Mechanical Engineers, pp. 135145.

Gurba, L.W., Ward, C.R., 2000. Elemental composition of coal macerals

in relation to vitrinite reectance, Gunnedah Basin, Australia, as

determined by electron microprobe analysis. International Journal of

Coal Geology 44, 127147.

Huggins, F.E., Human, G., Lee, R.J., 1982. Scanning electron microscope-based automated image analysis (SEM-AIA) and Mossbauer

spectroscopy quantitative characterization of coal minerals. ACS

Symposium Series 205, 239258.

Human, G.P., Huggins, F.E., Shah, A., Casuccio, G., Mershon, W.J.,

1991. Development of computer-controlled scanning electron microscopy (CCSEM) techniques for determining mineralmaceral association. American Chemical Society 36 (3), 1151163.

Lee, R.J., Huggins, F.E., Human, G.P., 1978. Scanning Electron

Microscopy 1, 561571.

Magasiner, N., Van Alphen, C., Inkson, M.B., Misplon, B.J., 2001.

Characterisation of fuels for biomass coal red cogeneration. In:

Proceedings of the South African Sugar Technologists Association

Conference, July 2001.

Milligan, J.B., Thomas, K.M., Crelling, J.C., 1997. Temperature-programmed combustion studies of coal and maceral group concentrates.

Fuel 76 (13), 12491255.

Nissen, D.A., Greulich, F.A., 1987. Automated image analysis of coal

minerals. In: Proceedings of the Symposium on High temperatures

Materials Chemistry, pp. 494504.

OBrien, G., Jenkins, B., Ferguson, K., Ofori, P., 2006. Semi-automated

Petrographic Assessment of Coal by Coal Grain Analysis. In:

Proceedings of the Automated Mineralogy 06, Brisbane, Australia,

July 1718, 2006.

Skorupska, N.M., Couch, G. 1993. Coal characterisation for predicting

ash deposition: an international perspective. In: Williamson, J.,

Wigley, F. (Eds.), The Impact of Ash Deposition on Coal Fired

Plants, pp. 137150.

Steadman, E.N., Erickson, T.A., Folkedahl, B.C., Brekke, D.W. 1991.

Coal and ash characterisation: Digital image analysis applications. In:

Benson, S.A. (Ed.), Inorganic Transformation and Ash Deposition

During combustion, pp. 147163.

Straszheim, W.E., Markuszewski, R., 1990. Automated image analysis of

minerals and their association with organic components in bituminous

coals. Energy and Fuels 4, 748754.

Straszheim, W.E., Markuszewski, R., 1992. SEM-AIA measurement of

the association of mineral matter with the organic coal matrix for

predicting ne Coal cleanability. Coal Preparation 10, 5975.

C. van Alphen / Minerals Engineering 20 (2007) 496505

Straszheim, W.E., Greer, R.T., Markuszewski, R., 1983. Direct determination of organic sulphur in raw and chemically desulphurized coals.

Fuel 62, 10701075.

Straszheim, W.E., Jounkin, K.A., Greer, R.T., Markuszewski, R., 1988.

Mounting materials for automated image analysis of coal using

Backscattered Electron Imaging. Scanning Electron Microscopy 2 (3),

12571264.

Su, A., Pohl, J.J., Holcombe, D., Hart, J.A., 2001. A proposed maceral

index to predict combustion behaviour of coal. Fuel 80 (5), 699706.

Tang, L.G., Gupta, R.P., Sheng, C.D., Wall, T.F., OBrien, G., 2005. The

Heterogeneity of coal chemical properties derived from reectogram.

Energy and Fuel 19, 130137.

Timmer, J.M., van der Burgh, N., 1984. Automated determination of

organic sulphur in coal use of scanning electron microscope and energy

dispersive X-ray microanalysis. Fuel 63, 16451648.

Van Alphen, C., Falcon, L., 2000. Application of CCSEM to coal

processing. Coal the future. In: Proceedings of the 12th International

Conference on Coal Research, SAIMM.

Van Alphen, C. 2005. Factors inuencing y ash formation and slag

deposit formation (slagging) on combusting a South African pulverised fuel in a 200 MWe boiler. In: Proceedings of the Pittsburgh Coal

Conference, 1215th September, Pittsburgh and PhD thesis, University

of Witwatersrand.

505

Ward, C.R., 2002. Analysis and signicance of mineral matter in coal

seams. International Journal of Coal Geology 50, 135168.

Ward, C.R., French, D., 2003. Evaluation of glass content and estimation

of glass composition in y ash using quantitative X-ray diractometry.

In: Proceedings of the 12th International Conference on Coal Science,

Cairns, Australia.

Ward, C.R., Gurba, L.W., 1999. Chemical composition of macerals in

bituminous coals of the Gunnedah Basin, Australia, using electron

microprobe analysis techniques. International Journal of Coal Geology 39, 279300.

White, A., Davies, M.R., Jones, S.D., 1987. Reactivity and characterisation of coal maceral concentrates. Fuel 68 (4), 511519.

Yang, N.Y.C., Baxter, L.L., 1991. Instrument and sample preparation for

Computer Controlled Scanning Electron Microscopy (CCSEM). In:

Benson, S.A. (Ed.), Inorganic Transformation and Ash Deposition

During Combustion, pp. 191206.

Yu, H., Marchek, J.E., Adair, N.L., Harb, J.N., 1993. Characterization of

minerals and coal/mineral associations in pulverized coal. In: Williamson, J. Wigley, F. (Eds.), The Impact of Ash Deposition on Coal

Fired Plants, pp. 361371.

Xie, K.-C., Li, Wen-Ying, Zhu, Su-Yu, 1994. Pyrolysis studies on coal

macerals using DTA-GC, 13C-NMR and SEM techniques. Fuel

Science and Technology INTL 12 (9), 11591168.

You might also like

- Pea - Vol. 14, No 1 - 01. 2017Document4 pagesPea - Vol. 14, No 1 - 01. 2017Lily Camila GalárragaNo ratings yet

- Tillová (2011) - Structural Analysis of Heat Treated Automotive Cast AlloyDocument7 pagesTillová (2011) - Structural Analysis of Heat Treated Automotive Cast AlloyevelynNo ratings yet

- Tillová (2012) - Solution Treatment Effect On Microstructure and Mechanical Properties of Automotive Cast AlloyDocument8 pagesTillová (2012) - Solution Treatment Effect On Microstructure and Mechanical Properties of Automotive Cast AlloyevelynNo ratings yet

- 3-The Grain Refinement Mechanism of Cast Aluminium by ZirconiumDocument10 pages3-The Grain Refinement Mechanism of Cast Aluminium by ZirconiumevelynNo ratings yet

- Clustering and Formation of Nano-Precipitates in Dilute Aluminium and Magnesium AlloysDocument6 pagesClustering and Formation of Nano-Precipitates in Dilute Aluminium and Magnesium AlloysevelynNo ratings yet

- AluminumDocument5 pagesAluminumBlueOneGaussNo ratings yet

- Annealing Effects in Al-Sc AlloysDocument5 pagesAnnealing Effects in Al-Sc AlloysevelynNo ratings yet

- 5Document4 pages5evelynNo ratings yet

- Microstructure, Tensile Strength and Wear Behaviour of Al-Sc AlloyDocument7 pagesMicrostructure, Tensile Strength and Wear Behaviour of Al-Sc AlloyevelynNo ratings yet

- E3-11 Preparation of Metallographic Specimens PDFDocument12 pagesE3-11 Preparation of Metallographic Specimens PDFevelyn50% (2)

- Mar 12Document10 pagesMar 12evelynNo ratings yet

- Phases Examination in Cast Alsi5cu1mg and Alcu4ni2mg2 Aluminium Alloys in As Cast and t6 ConditionDocument23 pagesPhases Examination in Cast Alsi5cu1mg and Alcu4ni2mg2 Aluminium Alloys in As Cast and t6 ConditionevelynNo ratings yet

- 28 Pezda Effect of t6 1s 2013Document4 pages28 Pezda Effect of t6 1s 2013evelynNo ratings yet

- Heat Treatments Improve Corrosion Resistance of 319 Al AlloyDocument4 pagesHeat Treatments Improve Corrosion Resistance of 319 Al AlloyevelynNo ratings yet

- ANALYSIS OF INTERMETALLIC PHASES IN AGE-HARDENED RECYCLED AlSi9Cu3 CAST ALLOYDocument12 pagesANALYSIS OF INTERMETALLIC PHASES IN AGE-HARDENED RECYCLED AlSi9Cu3 CAST ALLOYevelynNo ratings yet

- Pen Rchive Oulouse Rchive Uverte : O A T A O OataoDocument5 pagesPen Rchive Oulouse Rchive Uverte : O A T A O OataoevelynNo ratings yet

- 2006 Osaka 593Document8 pages2006 Osaka 593evelynNo ratings yet

- FtirDocument13 pagesFtirevelynNo ratings yet

- Effect of Hardness Test On Precipitation Hardening Aluminium Alloy 6061-T6Document11 pagesEffect of Hardness Test On Precipitation Hardening Aluminium Alloy 6061-T6evelynNo ratings yet

- Aluminium in Innovative Light-Weight Car Design PDFDocument7 pagesAluminium in Innovative Light-Weight Car Design PDFΝΙΚΟΛΑΟΣ ΚΑΡΑΓΚΙΑΟΥΡΗΣNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MAE 207 - Microfluidics - Winter 2012 Lecture 17 - Notes Prepared by Sandeep KannanDocument8 pagesMAE 207 - Microfluidics - Winter 2012 Lecture 17 - Notes Prepared by Sandeep KannanSandeep KannanNo ratings yet

- Bullet-Proof Glass by KaDocument8 pagesBullet-Proof Glass by Kaapi-260953119No ratings yet

- CHEM 142 Experiment #4: Calibration Curves and An Application of Beer's LawDocument4 pagesCHEM 142 Experiment #4: Calibration Curves and An Application of Beer's Lawapi-532728017No ratings yet

- March Bill1Document38 pagesMarch Bill1ShakthivelNo ratings yet

- Seminar on Friction Stir Welding: FSW Process, Parameters, ApplicationsDocument26 pagesSeminar on Friction Stir Welding: FSW Process, Parameters, ApplicationsDeepak Kaushal0% (1)

- OLI Course IntroductionDocument7 pagesOLI Course Introductionahad_shiraziNo ratings yet

- Black Eagle Hose BE 4466-UKDocument44 pagesBlack Eagle Hose BE 4466-UKmhollowayNo ratings yet

- A History of Greek MathematicsDocument598 pagesA History of Greek MathematicssonicskaNo ratings yet

- Quan Et Al. - 2016 - Effect of Modification Degree of Nanohydroxyapatite On Biocompatibility and Mechanical Property of Injectable Poly (Document9 pagesQuan Et Al. - 2016 - Effect of Modification Degree of Nanohydroxyapatite On Biocompatibility and Mechanical Property of Injectable Poly (Morteza AtaeiNo ratings yet

- Assessment of Surface Water Chemistry of Ghan Dam and Kaam Dam Lakes, Northwest LibyaDocument7 pagesAssessment of Surface Water Chemistry of Ghan Dam and Kaam Dam Lakes, Northwest LibyaijsretNo ratings yet

- SterilizationDocument11 pagesSterilizationAndhika SetiawanNo ratings yet

- Progress in Energy and Combustion Science Volume 6 Issue 2 1980 (Doi 10.1016/0360-1285 (80) 90002-7) F. Briscoe P. Shaw - Spread and Evaporation of LiquidDocument14 pagesProgress in Energy and Combustion Science Volume 6 Issue 2 1980 (Doi 10.1016/0360-1285 (80) 90002-7) F. Briscoe P. Shaw - Spread and Evaporation of LiquidFarahatNo ratings yet

- Plug-Flow Tubular Reactor Modeling and SimulationDocument16 pagesPlug-Flow Tubular Reactor Modeling and SimulationKasun K RanasingheNo ratings yet

- PS Ball - TDSDocument2 pagesPS Ball - TDSMunawwar Mukhtar100% (1)

- ECS - Electrochemical Series arrangement of metals by electron donation tendencyDocument7 pagesECS - Electrochemical Series arrangement of metals by electron donation tendencyHui Min TehNo ratings yet

- Anjana Seminar SlideshareDocument38 pagesAnjana Seminar SlideshareAnjana kpNo ratings yet

- Indus University BS Textile Technology Course SyllabusDocument3 pagesIndus University BS Textile Technology Course SyllabusMujahid MehdiNo ratings yet

- D Firm InfoDocument4 pagesD Firm InfoSarfaraj KamalNo ratings yet

- BIOLOGY FOLIO Form 4 - Chapter 9 (Endangered Ecosystem)Document17 pagesBIOLOGY FOLIO Form 4 - Chapter 9 (Endangered Ecosystem)ilyaskhan00295% (22)

- Element List: Breeding ChartDocument33 pagesElement List: Breeding ChartJaye MananNo ratings yet

- Water Quality (4th Edition) - Principles and Practices of Water Supply Operations SeriesDocument226 pagesWater Quality (4th Edition) - Principles and Practices of Water Supply Operations SeriesLenin PatiñoNo ratings yet

- CE101 LEC5 Tape CorrectionDocument35 pagesCE101 LEC5 Tape CorrectionGerard Co100% (1)

- Welding of 5083 Aluminum AlloyDocument6 pagesWelding of 5083 Aluminum AlloyMario MirićNo ratings yet

- Module 4 Inspection Methods PDFDocument86 pagesModule 4 Inspection Methods PDFElias Jurado TeixeiraNo ratings yet

- Influence of Air Pockets in PipelinesDocument10 pagesInfluence of Air Pockets in PipelinesslawiNo ratings yet

- Modern Technology of Printing Inks: Price: Availability: in Stock Isbn Number: Writer: Publisher: Average RatingDocument4 pagesModern Technology of Printing Inks: Price: Availability: in Stock Isbn Number: Writer: Publisher: Average RatingeiribooksNo ratings yet

- 1,3 ButadieneDocument7 pages1,3 ButadieneAbdalmoedAlaiashyNo ratings yet

- Script v2Document3 pagesScript v2umidesuNo ratings yet

- 41.is25 - General Guidance On Shielding Requirements For Medical X-Ray Diagnostic RoomsDocument2 pages41.is25 - General Guidance On Shielding Requirements For Medical X-Ray Diagnostic RoomsMuzri MuhammoodNo ratings yet