Professional Documents

Culture Documents

Electrical Exam

Uploaded by

Sheraz Tariq0 ratings0% found this document useful (0 votes)

185 views3 pagesaramco electrical inspector questions for qc interview

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentaramco electrical inspector questions for qc interview

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

185 views3 pagesElectrical Exam

Uploaded by

Sheraz Tariqaramco electrical inspector questions for qc interview

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

Name: _____________________________ BI No.

/Contractor: __________________ Date:

___________

1. For Hazardous Locations, what is Class I Division I?

2. For Hazardous Locations, what is Class I Division 2?

3. For Hazardous Locations, what is Class II Division I?

4. For Hazardous Locations, what is Class II Division 2?

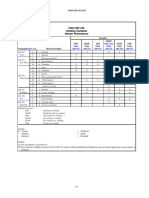

5. Percent of Cross Section of Conduit & Tubing for Conductors: (NEC Chapter 9

Table I)

No. of Conductors

1

2

Over 2

Filling Percentage (All Conductor Type)

____%

____%

____%

6. Severe corrosive environments include: (SAES-P-104 para. 4.2)

a.

b.

c.

d.

7. Conductors of multi-conductor control cables shall be numbered or colorcoded by colors other than___________, ________________, &

____________________. (SAES-P-104 para. 5.7)

8. Cables for security lighting (perimeter and area lighting)

shall_________________, installed underground and rising inside the lighting

poles. (SAES-P-104 para.5.9)

9. Identification of cables shall include the ____________ & _____________. (SAES-P104 para. 6.10.1)

10.Neutral (grounded) conductors shall be identified by colors ____________, and

insulated grounding conductors by _____________________________. (SAES-P-104

para.6.10.3)

11.In outdoor plant and other industrial areas located in severe corrosive

environments, equipment and terminal enclosures shall be: (SAES-P-104

para.7.3)

a.

b.

c.

12.Enclosures and junction boxes having an internal volume exceeding _______

cm shall be provided with Type 300 Series stainless steel __________and

___________, or a combination of breather and drain fitting. (SAES-P-104 para.

7.8.1)

13.The minimum conduit size shall be ____ inch or equivalent in metric size,

except for prefabricated skids. (SAES-P-104 para.8.6)

14.Conduit fittings for direct buried PVC coated rigid steel conduit shall be

_______________. (SAES-P-104 para.8.9.3)

15.The minimum crossing or parallel clearance between direct buried cables or

conduits and underground piping, including hydrocarbon pipelines shall be

_______. (SAES-P-104 para.10.13)

16.Low voltage (600, 450/750, or 600/1000 V rated) cables, including splices to

existing cables, shall be _________ megger tested after installation and prior

to placing in service (during commissioning). (SAES-P-104 para.13.1)

17.The integrity of the overall jacket of direct buried low voltage armored or

metal clad cables shall be tested by conducting a ______ megger test. (SAESP-104 para.13.5)

18.The minimum separation requirements between power and/or control

conductors for DC or AC circuit voltages less than 1000 V, provided the

insulation is rated at least 600 V or 450/750 V. ___________ (SAES-P-104

para.14.2)

19.When cables entering enclosures are required to be sealed by the NEC, they

shall be sealed by means of__________________, utilizing sealing compound,

(EEx d) or MI cable. (SAES-P-104 para.15.3)

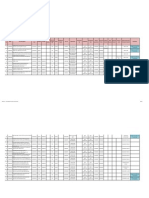

20.The minimum depth of burial requirements for underground installations shall

be: (SAES-P-104 para.10.1)

Millimeters from Grade Level to the Top Surface of

Cable, Conduit or Duct Bank

System

Direct

Direct

Duct Bank and

Voltage

Buried

Buried

Direct Buried

Cables

PVC

Rigid Steel

600 V and

below

Over 600 V to

35 kV

Over 35 kV

460

920

460

460

760

You might also like

- Grove Manlift Amz66 Parts PDFDocument294 pagesGrove Manlift Amz66 Parts PDFvankarp75% (12)

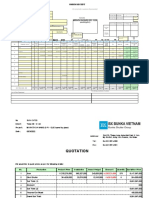

- Procurement PlanDocument27 pagesProcurement PlanSheraz Tariq67% (18)

- Basic Electrical QuestionsDocument14 pagesBasic Electrical QuestionsRajeev ValunjkarNo ratings yet

- CRMS ItpDocument2 pagesCRMS Itparockiyathass100% (1)

- IEEE 525-2007 Design and Installation of Cable Systems in SubstationDocument47 pagesIEEE 525-2007 Design and Installation of Cable Systems in SubstationSeahlkNo ratings yet

- QCP 040 QCP CrmsDocument7 pagesQCP 040 QCP Crmsarockiyathass100% (1)

- Weld Mech. QuestionsDocument4 pagesWeld Mech. QuestionservkslmNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- Submerged Arc Welding (Saw)Document5 pagesSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNo ratings yet

- Resume Sample PDFDocument4 pagesResume Sample PDFamitrdttecNo ratings yet

- Shaik Yousufuddin (Welding Inspector)Document3 pagesShaik Yousufuddin (Welding Inspector)Mohamed AdelNo ratings yet

- Petrofac Piping Inspection Handbook PDFPDFDocument25 pagesPetrofac Piping Inspection Handbook PDFPDFpediNo ratings yet

- Job Description NDTDocument4 pagesJob Description NDTNDTInstructorNo ratings yet

- API RP 577 Welding InspectionDocument7 pagesAPI RP 577 Welding InspectionLuthfi ArdiansyahNo ratings yet

- Duct Bank InformationDocument19 pagesDuct Bank InformationGaneshNo ratings yet

- Conduits PDFDocument12 pagesConduits PDFAnonymous PYEzEEVzNo ratings yet

- Stage 1 Welding Inspection Prior to WeldingDocument7 pagesStage 1 Welding Inspection Prior to WeldingIrvansyah RazadinNo ratings yet

- Curriculum Vitae: David GrahamDocument7 pagesCurriculum Vitae: David GrahamMohamad ShafeyNo ratings yet

- ASME B31.1 Pipe Code SectionsDocument2 pagesASME B31.1 Pipe Code SectionsDivakar PanigrahiNo ratings yet

- Cswip QuestionDocument3 pagesCswip Questionfasith9534No ratings yet

- Pipeline Welding Qualification TestsDocument2 pagesPipeline Welding Qualification TestsKali AbdennourNo ratings yet

- QC Inspector (Offshore Pipeline Installation) Jobs in Propel Consult in UAE - United Arab Emirates - NaukrigulfDocument7 pagesQC Inspector (Offshore Pipeline Installation) Jobs in Propel Consult in UAE - United Arab Emirates - NaukrigulfAshif IqubalNo ratings yet

- Dokumen - Tips Cswip TipsDocument16 pagesDokumen - Tips Cswip TipszuhebNo ratings yet

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- CSWIP 3.1U RevisionDocument12 pagesCSWIP 3.1U Revisionayman coreNo ratings yet

- Cswip 3 1 Wis5 Handout 2009 PDFDocument196 pagesCswip 3 1 Wis5 Handout 2009 PDFravi00098No ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- VT Acceptance Criteria Vs ASMEDocument1 pageVT Acceptance Criteria Vs ASMEAnonymous EkfqSPNo ratings yet

- FabricatorDocument4 pagesFabricatorhitanshuNo ratings yet

- 2018 Sea Cswip Course Exam FeeDocument4 pages2018 Sea Cswip Course Exam FeeAmar MohammedNo ratings yet

- Fired Heater Data Sheet and Fabrication Procedure IndexDocument2 pagesFired Heater Data Sheet and Fabrication Procedure Indexsajadsadeghi123100% (1)

- Saudi Aramco welding inspection planDocument12 pagesSaudi Aramco welding inspection planspravin231No ratings yet

- LV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientDocument1 pageLV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientsameershahzanNo ratings yet

- Lesson 14 WelderQuals - New2Document80 pagesLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Name: ANEEZ Wri 3 Batch: PDO Interview QuestiansDocument9 pagesName: ANEEZ Wri 3 Batch: PDO Interview QuestiansMohammed Raje100% (1)

- QC Questions InterviewsDocument23 pagesQC Questions InterviewsMohamed ElsayedNo ratings yet

- Template CV Sat Diver Ver 2Document5 pagesTemplate CV Sat Diver Ver 2subsea7divingcvNo ratings yet

- UAE-CSWIP Visual Welding Inspector Level 1 (3.0)Document2 pagesUAE-CSWIP Visual Welding Inspector Level 1 (3.0)adeoye_okunoyeNo ratings yet

- NDT As Per B31.3Document2 pagesNDT As Per B31.3invilink87No ratings yet

- Hands On Training For WPS, PQR - WQT Program May 2014, Chennai PDFDocument9 pagesHands On Training For WPS, PQR - WQT Program May 2014, Chennai PDFganeshjsiva100% (1)

- 2018 Uk Cswip Exam FeeDocument7 pages2018 Uk Cswip Exam FeeMostafaRockNo ratings yet

- Fosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionDocument4 pagesFosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionVincent JavateNo ratings yet

- Manoj Kumar QC (C.V)Document4 pagesManoj Kumar QC (C.V)HeartyscorpionNo ratings yet

- FE Ele CBT Specs With RangesDocument3 pagesFE Ele CBT Specs With RangesmedjacNo ratings yet

- PID ResponsibilityDocument2 pagesPID Responsibilityimurugan06No ratings yet

- Table - Qw-416 Welding Variables For Welder PerformanceDocument1 pageTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- API 570 Piping Code AssessmentDocument12 pagesAPI 570 Piping Code AssessmentMohamed ZainNo ratings yet

- Preview Report of A Visit To The Steel Structure WorkshopDocument2 pagesPreview Report of A Visit To The Steel Structure WorkshopMohamed BadraNo ratings yet

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocument50 pagesASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNo ratings yet

- Qa QC SyllabusDocument2 pagesQa QC SyllabusSTANDARD EDUCATION ACADEMY M.E.P CENTERNo ratings yet

- Radiography Test Procedure Part - 1Document21 pagesRadiography Test Procedure Part - 1Ahmed Lepda100% (1)

- British Standard 5289: 1976: Visual InspectionDocument10 pagesBritish Standard 5289: 1976: Visual InspectionMarcelo Rodriguez FujimotoNo ratings yet

- Portacabin Inspection ChecklistDocument2 pagesPortacabin Inspection ChecklistApm FoumilNo ratings yet

- Experienced QC Inspector CVDocument7 pagesExperienced QC Inspector CVBaraneedharanNo ratings yet

- AI Inspector Course Reference MaterialsDocument1 pageAI Inspector Course Reference MaterialsCepi Sindang KamulanNo ratings yet

- SAIC-P-3701 Rev 0Document3 pagesSAIC-P-3701 Rev 0mkalidas2006No ratings yet

- Asme Sec 9 - ADocument144 pagesAsme Sec 9 - Aروشان فاطمة روشانNo ratings yet

- Top 6 Hydrogen Cracking - Cswip 3.1 Course Questions and AnswersDocument3 pagesTop 6 Hydrogen Cracking - Cswip 3.1 Course Questions and AnswersJlkKumarNo ratings yet

- Inspection In Manufacturing A Complete Guide - 2020 EditionFrom EverandInspection In Manufacturing A Complete Guide - 2020 EditionNo ratings yet

- Tech - Spec. LA For WBSEDCL Sept.07, ArresterDocument6 pagesTech - Spec. LA For WBSEDCL Sept.07, ArresterThanh NguyenNo ratings yet

- Transformers 10 KVADocument39 pagesTransformers 10 KVARajuNo ratings yet

- Sandwich Bus Duct Specs for Power SystemDocument15 pagesSandwich Bus Duct Specs for Power SystemONILEDA1970No ratings yet

- Cable Tray QuestionsDocument17 pagesCable Tray QuestionsSheraz Tariq100% (1)

- WCDocument6 pagesWCSheraz TariqNo ratings yet

- IELTS Course InfromationDocument2 pagesIELTS Course InfromationSheraz TariqNo ratings yet

- Yes Items Instrument Oil and GasDocument3 pagesYes Items Instrument Oil and GasSheraz TariqNo ratings yet

- Arif Qazi ApplictaionDocument1 pageArif Qazi ApplictaionSheraz TariqNo ratings yet

- Ielts Test Dates 2015 One PageDocument1 pageIelts Test Dates 2015 One PageSheraz TariqNo ratings yet

- Telecom: T-001 RFI Top Page Has No Sign of PID: Richard FairbanksDocument1 pageTelecom: T-001 RFI Top Page Has No Sign of PID: Richard FairbanksSheraz Tariq100% (1)

- 28" Marafic Water Pipeline-Wasit Gas Plant ActivityDocument1 page28" Marafic Water Pipeline-Wasit Gas Plant ActivitySheraz TariqNo ratings yet

- A9k KABA RepeaterDocument8 pagesA9k KABA RepeaterSheraz TariqNo ratings yet

- AWG To MM2 ConverterDocument1 pageAWG To MM2 ConverterZiad Al MahmoudNo ratings yet

- A9k KABA RepeaterDocument8 pagesA9k KABA RepeaterSheraz TariqNo ratings yet

- SheraZ HSE CVDocument3 pagesSheraZ HSE CVSheraz Tariq100% (1)

- Networking Professional Seeking New OpportunitiesDocument4 pagesNetworking Professional Seeking New OpportunitiesSheraz TariqNo ratings yet

- Muhammad WDocument3 pagesMuhammad WSheraz TariqNo ratings yet

- VSWR MeasurementDocument5 pagesVSWR MeasurementSheraz TariqNo ratings yet

- Microprocessor 8086 by Nirvaan MahajanDocument14 pagesMicroprocessor 8086 by Nirvaan MahajanHallucinatory100% (1)

- User Manual: 3.6KW/5.6KW Solar Inverter / ChargerDocument82 pagesUser Manual: 3.6KW/5.6KW Solar Inverter / ChargerStLisNo ratings yet

- Title: Model Ut50A/B/C: Operating ManualDocument33 pagesTitle: Model Ut50A/B/C: Operating ManualEibar016No ratings yet

- FH e - FL eDocument2 pagesFH e - FL eKiet Pham TanNo ratings yet

- Plextor UltraPlex 40max UltraPlex Wide ManualDocument94 pagesPlextor UltraPlex 40max UltraPlex Wide ManualvegaskinkNo ratings yet

- 2022.03.03 - Toda - Murata (OP1 - SLD3 Glass) - Xoa FixDocument14 pages2022.03.03 - Toda - Murata (OP1 - SLD3 Glass) - Xoa FixHiếu NguyễnNo ratings yet

- Smart TrolleyDocument24 pagesSmart TrolleyAbdul Razzak100% (1)

- Circuit breaker test meterDocument5 pagesCircuit breaker test meterpawan deepNo ratings yet

- Wiring Diagram of Universal MotorDocument10 pagesWiring Diagram of Universal MotorYunus SiregarNo ratings yet

- Aerial Bunch CableDocument2 pagesAerial Bunch CablePrashant Jha100% (1)

- Gas Material and ServicesDocument6 pagesGas Material and ServicesSachin SinghNo ratings yet

- ARM ProcessorsDocument20 pagesARM Processorsrajkumar_jain4855No ratings yet

- OM C5613 1 Turismo Veloce 800 Lusso RC SCS 18-20 USA SMLDocument472 pagesOM C5613 1 Turismo Veloce 800 Lusso RC SCS 18-20 USA SMLJulio VizueteNo ratings yet

- 70 Series line monitoring relaysDocument10 pages70 Series line monitoring relaysovidiuNo ratings yet

- CX2020, CX2030, CX2040: ManualDocument46 pagesCX2020, CX2030, CX2040: Manualjoshikiran1234No ratings yet

- 316 HO Version Coding IC 98-99Document2 pages316 HO Version Coding IC 98-99arkhom1No ratings yet

- Chapter 4 Energy ConversionDocument3 pagesChapter 4 Energy ConversionLuelsonCordovaDeclaradorNo ratings yet

- Fosmon 4-In-1 Charging Dock For Nintendo Switch Joy-Con Controller With LED IndicatorDocument2 pagesFosmon 4-In-1 Charging Dock For Nintendo Switch Joy-Con Controller With LED Indicatorhenry sarmientoNo ratings yet

- Lathe Default MMDocument5 pagesLathe Default MMMaqsood WarNo ratings yet

- T Cross Online BrochureDocument21 pagesT Cross Online BrochureTettsNo ratings yet

- Health & Safety and Installation Guide for DishwashersDocument8 pagesHealth & Safety and Installation Guide for DishwashersRuben TavaresNo ratings yet

- Hardlock Set Screw: AdvantagesDocument4 pagesHardlock Set Screw: AdvantagesJayden BarnesNo ratings yet

- Advanced Power Electronics Corp.: AP0803GMT-HFDocument5 pagesAdvanced Power Electronics Corp.: AP0803GMT-HFAlexander TkachenkoNo ratings yet

- Fits and Clearances - Contents: Propeller Maintenance Manual 132ADocument8 pagesFits and Clearances - Contents: Propeller Maintenance Manual 132AAlexis KidemaNo ratings yet

- Smartclass-Fiber-Olp-88-88p-Truepon-Data-Sheets-En 2020 PDFDocument8 pagesSmartclass-Fiber-Olp-88-88p-Truepon-Data-Sheets-En 2020 PDFLuis Alberto Bermudez ArteagaNo ratings yet

- Rockwell JointerDocument18 pagesRockwell Jointernotjustsomeone100% (2)

- MZ Xpress PsDocument2 pagesMZ Xpress PsaznilNo ratings yet

- 4ABB Leaflet Terra 94 - 124 - 184 - v7Document12 pages4ABB Leaflet Terra 94 - 124 - 184 - v7michael esoNo ratings yet