Professional Documents

Culture Documents

The Vapour Compression Cycle: Low Pressure Liquid and Vapour

Uploaded by

ElOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Vapour Compression Cycle: Low Pressure Liquid and Vapour

Uploaded by

ElCopyright:

Available Formats

The Air Conditioning and Refrigeration Industry Board

THE VAPOUR

COMPRESSION CYCLE

LOW PRESSURE LIQUID AND VAPOUR

Many experienced and fully trained engineers will know much of this basic theory alreadybut the

guides can be used for training of col- leagues, apprentices or helping customers understand their

equipment.

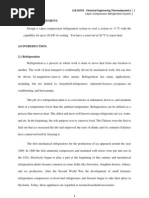

The basic vapour compression or mechanical

refrigeration cycle involves the circulation of

refrigerant, which in the process of boiling

(evaporating) absorbs large amounts of heat

and gives up heat when condensing. This heat

which must be gained or lost during the

change of state is called

latent heat of vaporisation. It is in general

more than the specific heat, that is the heat lost

or gained during a one de- gree change in

temperature.

There are in principal, only two pressures within

the refrig- eration system, which are relative to

the required evaporat- ing and condensing

temperatures but vary depending on the

refrigerant used, the temperature of the space

to be cooled and the type of application.

An example of a basic vapour compression

circuit for an air conditioning application is

shown above.

1. The refrigeration cycle start with high pressure

liquid (eg 9

BAR) in the liquid line passing through a

restrictor device, which typically could be a

capilliary line or an expansion valve. Here it is

allowed to expand and its flow is regulated.

2. Next it passes into the evaporator where

with its pres- sure greatly reduced eg 1.5 BAR, it

will be boiling at 5. But in order for it to

boil it must absort heat, which it gets from

the metal of the coils which in turn absorbs

the heat from

the room space which, in this example might

be around 5C.

3. Once the refrigerant has been vaporised it moves

from the evaporator into the suction line and on to

the compressor. The compressor compresses the

the vapour into a smaller volume and in doing so

raises its pressure (eg

9 BAR) and its condensing temperature (40C).

4. The high pressure refrigerant vapour now passes

into the condenser (also a matrix of finned pipes),

where it is condensed back into a liquid state, by

use of a fan drawing ambient air over it.

5. The high pressure refrigerant now moves to the

bottom of the condenser coil and sometimes into a

vessel called a liquid receiver, where the cycle

begins again!

The zone temperature can be controlled by simply

cycling

the compressor on and off according to the

desired set point of a thermostat or controller,

where it is monitored by a

bulb or sensor usually found in the return air to

the evaporator or a suitable place in the area.

Note: the refrigeration cycle does not create

cold it merely transfers heat from one place to

another. A heat pump system employs a valve

which basically reverses the cycle in order to

absorb heat from ambient air and transfer it to

where it is required.

Reproduced from MacTechnical bulletin no 28 by kind permission of MacWhirter Ltd

www.acrib.org.uk

You might also like

- Fundamentals 1 CycleDocument1 pageFundamentals 1 Cyclepali_peNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Chapter - 4-Simple Vapour Compression Refrigeration SystemDocument141 pagesChapter - 4-Simple Vapour Compression Refrigeration SystemMohamed Al-Odat0% (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Condenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToDocument37 pagesCondenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToAliceNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- RAC Lab ManualDocument27 pagesRAC Lab ManualKewal SinghNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Functioning of ChillersDocument22 pagesFunctioning of ChillersAnonymous b9fcR5No ratings yet

- Refrigeration and Air Conditioning (7.2.22)Document148 pagesRefrigeration and Air Conditioning (7.2.22)Edwin Abregú Leandro100% (1)

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Air Conditioning Systems Experiment: ProposalDocument16 pagesAir Conditioning Systems Experiment: ProposalShaktivell Letchumanan100% (1)

- Variation In Refrigeration Coefficient Of PerformanceDocument17 pagesVariation In Refrigeration Coefficient Of PerformanceSyahirzabidiNo ratings yet

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsFrom EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsNo ratings yet

- FridgeDocument6 pagesFridgeshashlearnNo ratings yet

- Refrigerator Revelations: A User's Guide to Operation and MaintenanceFrom EverandRefrigerator Revelations: A User's Guide to Operation and MaintenanceNo ratings yet

- Performance and Efficiency Test of Refrigeration Sysytem: (Mel Lab 3 Report)Document14 pagesPerformance and Efficiency Test of Refrigeration Sysytem: (Mel Lab 3 Report)Yhan SombilonNo ratings yet

- Chapter 4-Simple Vapour Compression Refrigeration SystemDocument40 pagesChapter 4-Simple Vapour Compression Refrigeration Systemm_alodat614450% (2)

- 1334337428180-Electr - QUESTION - BANK - TL - AC - AND - EM - Final PDFDocument116 pages1334337428180-Electr - QUESTION - BANK - TL - AC - AND - EM - Final PDFPankaj KumarNo ratings yet

- Vapor Compression Refrigeration Cycle ExplainedDocument16 pagesVapor Compression Refrigeration Cycle ExplainedDiether RigorNo ratings yet

- Chapter 4RACDocument32 pagesChapter 4RACSameer AhmadNo ratings yet

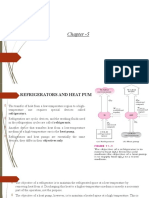

- Chapter - 5Document19 pagesChapter - 5Getasew TesfaNo ratings yet

- RAC Refrigeration System ExplainedDocument7 pagesRAC Refrigeration System ExplainedMuhammad AkhtarNo ratings yet

- Week 4-6 Vapour Comp. CycleDocument15 pagesWeek 4-6 Vapour Comp. CycleBorokinni ToluNo ratings yet

- Types of Refrigeration SystemsDocument16 pagesTypes of Refrigeration SystemsmeriiNo ratings yet

- Refrigeration CircuitDocument32 pagesRefrigeration CircuitHassan Iftekhar Ahmed100% (1)

- Chapter OneDocument135 pagesChapter OneTaytoNo ratings yet

- Performance and Efficiency Test of A Refrigeration Plant (Lecture)Document56 pagesPerformance and Efficiency Test of A Refrigeration Plant (Lecture)Anonymous xjV1llZS75% (4)

- Basic Design Vapor-Compression Refrigeration SystemDocument20 pagesBasic Design Vapor-Compression Refrigeration Systemscarmathor90No ratings yet

- Refregent and CryogenicsDocument7 pagesRefregent and CryogenicsViren ParwaniNo ratings yet

- Lab Manual: RGPV University (Bhopal)Document6 pagesLab Manual: RGPV University (Bhopal)Pushpendra KushwahaNo ratings yet

- Refrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFDocument13 pagesRefrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFMurillo MendesNo ratings yet

- Ec & Us Manual PDFDocument111 pagesEc & Us Manual PDFRamnarayan MeenaNo ratings yet

- R and AC Presentation - 2Document73 pagesR and AC Presentation - 2teddiyfentawNo ratings yet

- Performance and Efficiency Test of A Refrigeration PlantDocument17 pagesPerformance and Efficiency Test of A Refrigeration Plantjun75% (4)

- Performance and Efficiency Test of Refrigeration PlantDocument52 pagesPerformance and Efficiency Test of Refrigeration PlantIvy Joy UbinaNo ratings yet

- Refregeration, Psychrometry & Air ConditioningDocument47 pagesRefregeration, Psychrometry & Air ConditioningTamim Islam JoyNo ratings yet

- Introduction To Vapour Compression RefrigerationDocument9 pagesIntroduction To Vapour Compression RefrigerationmdmarufurNo ratings yet

- Condensing TDocument5 pagesCondensing TMIN GUINo ratings yet

- Performance and Efficiency Test of A Refrigeration PlantDocument17 pagesPerformance and Efficiency Test of A Refrigeration PlantAllen Espeleta0% (1)

- Troubeshooting Vapour ChillersDocument8 pagesTroubeshooting Vapour Chillersazher_memonNo ratings yet

- Vapor Compression Refrigeration SystemDocument6 pagesVapor Compression Refrigeration SystemGerson Paul BangoyNo ratings yet

- Refrigeration Cycle DiagramDocument7 pagesRefrigeration Cycle DiagramsrybsantosNo ratings yet

- Refrigeration and Air Conditioning 2Document33 pagesRefrigeration and Air Conditioning 2Christina OhNo ratings yet

- Hvac Lab Report: Name: Ali Raza Roll No: 18-MCE-18 Submitted To: Sir Murawat Abbas Semester 6Document11 pagesHvac Lab Report: Name: Ali Raza Roll No: 18-MCE-18 Submitted To: Sir Murawat Abbas Semester 6AliNo ratings yet

- Refrigeration With Hot and Cooled BoxDocument69 pagesRefrigeration With Hot and Cooled Boxkris_soneNo ratings yet

- RefrigerationDocument65 pagesRefrigerationyassinNo ratings yet

- HVAC and Refrigeration SystemDocument25 pagesHVAC and Refrigeration SystemZoya ShaikhNo ratings yet

- From Wikipedia, The Free Encyclopedia: Vapor-Compression CycleDocument5 pagesFrom Wikipedia, The Free Encyclopedia: Vapor-Compression CycleZerotheoryNo ratings yet

- 10air Con04Document7 pages10air Con04mister pogiNo ratings yet

- HVAC & Refrigeration SystemDocument22 pagesHVAC & Refrigeration SystemSivakumar NadarajaNo ratings yet

- 8141177810 Module 5 Est 120Document35 pages8141177810 Module 5 Est 120obeightroom1234No ratings yet

- Refrigeration Technology: Types of Refrigeration Systems AND Principles of OperationDocument3 pagesRefrigeration Technology: Types of Refrigeration Systems AND Principles of OperationJoseph Francis GalleraNo ratings yet

- Engineer Exam Refrigeration Systems GuideDocument20 pagesEngineer Exam Refrigeration Systems GuideDennis ErminoNo ratings yet

- Refrigeration and Air ConditioningDocument21 pagesRefrigeration and Air ConditioningShiva Kumar H MNo ratings yet

- Global Warming Effect:: Rise in Sea LevelsDocument4 pagesGlobal Warming Effect:: Rise in Sea LevelsElNo ratings yet

- Public SpeakingDocument1 pagePublic SpeakingElNo ratings yet

- Kreisberg-Zakarin Et Al IPNS Antonie Van Leeuwenhoek 1999Document8 pagesKreisberg-Zakarin Et Al IPNS Antonie Van Leeuwenhoek 1999ElNo ratings yet

- Som TutosDocument3 pagesSom TutosElNo ratings yet

- HuhDocument17 pagesHuhadityachakrabor6398No ratings yet

- What Is A Heat Pump? A Heat Pump Is A Tool Which Is Used To Pump Heat. Normally, Pumps Increases The Pressure of The Heat in Doing SoDocument1 pageWhat Is A Heat Pump? A Heat Pump Is A Tool Which Is Used To Pump Heat. Normally, Pumps Increases The Pressure of The Heat in Doing SoElNo ratings yet

- L'Hopital’s RuleDocument3 pagesL'Hopital’s RuleNélson MendonçaNo ratings yet

- Double IntegralDocument9 pagesDouble IntegralElNo ratings yet

- Cops Meaning and Role in SocietyDocument1 pageCops Meaning and Role in SocietyElNo ratings yet

- Heat Pump 1Document1 pageHeat Pump 1ElNo ratings yet

- Matlab Coding For Secant Method: 'Enter Function:' 'S' 'Enter First Guess: ' 'Enter Second Guess: ' 'Enter Tolerance: 'Document1 pageMatlab Coding For Secant Method: 'Enter Function:' 'S' 'Enter First Guess: ' 'Enter Second Guess: ' 'Enter Tolerance: 'ElNo ratings yet

- Heat Pump 1Document1 pageHeat Pump 1ElNo ratings yet

- Home Insert Page Layout References Mailings Review View Add-Ins These Are The Basic Buttons You Will Find in An Microsoft Word DocumentDocument1 pageHome Insert Page Layout References Mailings Review View Add-Ins These Are The Basic Buttons You Will Find in An Microsoft Word DocumentElNo ratings yet

- Problem SolvingDocument1 pageProblem SolvingElNo ratings yet

- PracticalsDocument1 pagePracticalsElNo ratings yet

- NomenclatureDocument1 pageNomenclatureToMemNo ratings yet

- Partes Compresor Gar 5Document6 pagesPartes Compresor Gar 5rolando mora zapataNo ratings yet

- Compressors Repair KitsDocument10 pagesCompressors Repair KitsfrigoremontNo ratings yet

- Pressure Reducing ValveDocument4 pagesPressure Reducing ValvemanhngoducNo ratings yet

- Lec 12Document15 pagesLec 12Muhammad SulemanNo ratings yet

- Normas Siemens VaiDocument668 pagesNormas Siemens VaiLeonardo CarvalhoNo ratings yet

- Commenly Used Materials: Rolta Training Center, Mumbai - IndiaDocument1 pageCommenly Used Materials: Rolta Training Center, Mumbai - IndiaTAMIZHKARTHIKNo ratings yet

- Valve CoatingDocument5 pagesValve CoatingSasi Head OfficeNo ratings yet

- CPL25-Stainless Steel Self-Sealing CouplingsDocument2 pagesCPL25-Stainless Steel Self-Sealing CouplingsSyed ImranNo ratings yet

- Il200 en PDFDocument1 pageIl200 en PDFFirshatul UlaNo ratings yet

- Experiment No 04 Francis TurbineDocument5 pagesExperiment No 04 Francis TurbineTapas Kumar80% (5)

- MSD Axially Split Multistage Pump E00577Document6 pagesMSD Axially Split Multistage Pump E00577Patrick Mxolisi NkomoNo ratings yet

- Flow CorrelationsDocument24 pagesFlow CorrelationsAliNo ratings yet

- MaK M20 - Инстр. по экспл.ГТН R4-3Document104 pagesMaK M20 - Инстр. по экспл.ГТН R4-3Serhii100% (1)

- Pump Head Calculation Sheet: S U P P L Y P U M PDocument6 pagesPump Head Calculation Sheet: S U P P L Y P U M PGokul GopalakrishnanNo ratings yet

- SNO-I-DS-006 - C Datasheet For Pressure Regulator ValveDocument44 pagesSNO-I-DS-006 - C Datasheet For Pressure Regulator Valveono_czeNo ratings yet

- 15-Fuel Oil SystemDocument37 pages15-Fuel Oil SystemMohammad Jahangir AlamNo ratings yet

- CFD Use in Venturi MeterDocument22 pagesCFD Use in Venturi MeterAditya Karan100% (1)

- Data Sheet No. 13.07 - 480 - 485 - 490 Safety Valve PDFDocument1 pageData Sheet No. 13.07 - 480 - 485 - 490 Safety Valve PDFGiftObionochieNo ratings yet

- Iii Viscous ResistanceDocument33 pagesIii Viscous Resistancesiddarth amaravathiNo ratings yet

- Materials Wet Stand PipeDocument1 pageMaterials Wet Stand PipeApril Grace BautistaNo ratings yet

- Some Technical and Practical Recommendations About Pulsation Dampeners in Circuits With Dosing or Volumetric PumpsDocument10 pagesSome Technical and Practical Recommendations About Pulsation Dampeners in Circuits With Dosing or Volumetric PumpsRoberto Leon MendezNo ratings yet

- Two Phase Separation Process OverviewDocument25 pagesTwo Phase Separation Process OverviewSafwan NasirNo ratings yet

- TSB Development Project PresentationDocument24 pagesTSB Development Project PresentationMarlon Moncada100% (2)

- UL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ADocument1 pageUL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ASiles LimberdsNo ratings yet

- Relief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsDocument1 pageRelief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- Experiment No. 4 HP145 Compact Reciprocating Pump Test SetDocument9 pagesExperiment No. 4 HP145 Compact Reciprocating Pump Test SetPietro Ian AbdonNo ratings yet

- PTC Cacls Asme b31.3Document1 pagePTC Cacls Asme b31.3MamacintNo ratings yet

- Tristar & SPS Product Presentation General - by CSIDocument68 pagesTristar & SPS Product Presentation General - by CSILaksanarote FongonNo ratings yet

- 15-Daf Recycle PumpDocument1 page15-Daf Recycle Pumpbalaji krishnanNo ratings yet

- Annex I-2.1 Technical Specification of Mechanical and Hydraulic Equipment-Rev01Document60 pagesAnnex I-2.1 Technical Specification of Mechanical and Hydraulic Equipment-Rev01jackhuguesNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet