Professional Documents

Culture Documents

High Output Hydraulic - Mechanical Drilling Jar - (HO-HMJ) - Downhole Drilling Tools

Uploaded by

Hany AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Output Hydraulic - Mechanical Drilling Jar - (HO-HMJ) - Downhole Drilling Tools

Uploaded by

Hany AhmedCopyright:

Available Formats

3/8/2015

HighOutputHydraulic/MechanicalDrillingJar(HOHMJ)|DownholeDrillingTools

Calgary 403.235.2364

Edmonton 780.435.5455

HOME

ABOUT US

PRODUCTS

CONTACT

Home Products High Output Hydraulic / Mechanical Drilling Jar (HO-HMJ)

High Output Hydraulic / Mechanical Drilling Jar - (HO-HMJ)

Description

In todays Drilling applications longer reach Horizontal sections are becoming more popular.

With that in mind it has also become more difficult to determine just how much pull the drilling

jars are being subjected to. We are seeing more Drilling jars with damages due to being over

pulled and no longer able to fire.

Challenger Downhole Tools has worked to help alleviate this situation by creating High Output

Drilling Jar. The HO-HMJ (High Output-Hydraulic / Mechanical Drilling Jar) is capable of

withstanding up to 50% greater pull during delay; this will help eliminate the damage to jars

being over pulled and rendering them useless.

The HO-HMJ has 50% greater pulling power during delay than any other Drilling Jar of

comparable size. This ability to pull harder during delay also will increase the impact of the jar

once it does fire providing a significantly greater hitting force.

With longer reach horizontals being drilled and greater amounts of hole drag being created, the

Challenger HO HMJ, (High Output-Hydraulic / Mechanical Drilling Jar) has been designed to

function in these environments. The HO-HMJ is very effective in Horizontal applications

providing Weight or Pull can be applied to the Drilling Jars.

http://challengerdownhole.com/downholetoolproducts/highoutputhydraulicmechanicaldrillingjarhohmj/

1/4

3/8/2015

HighOutputHydraulic/MechanicalDrillingJar(HOHMJ)|DownholeDrillingTools

Features & Benefits

The Jar is normally operated in the latched position to reduce unexpected jarring while

drilling, and eliminate movement between jar components to increase service life.

The Jar operates with a simple up and down motion and is not affected by torque.

Standard seals in the tool are effective to 250F (120C). The jar can be dressed with seals

effective to 400F (200C) for hot hole environments. External sealing surfaces are tungsten

carbide-coated to enhance wear and corrosion resistance.

The Jar can be run in tension or in compression within the preset latch settings.

Operation

Jarring Up

Jarring up is achieved by applying sufficient over pull to overcome the latch setting, which

initiates the hydraulic time delay. During the time delay, the over pull at surface can be

adjusted to vary the impact force.

After impact, apply a down force sufficient to close jar and re-engage latch, then repeat the

jarring cycle as required.

Jarring Down

Jarring down is achieved by applying sufficient downward force to overcome the latch setting

and pump open force. At that point, the Jar will release and jar downward.

After impact, pick up the work string to re-engage the mechanical latch then repeat the jarring

cycle as required.

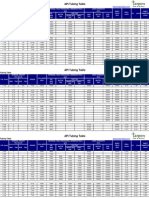

Imperial

http://challengerdownhole.com/downholetoolproducts/highoutputhydraulicmechanicaldrillingjarhohmj/

2/4

3/8/2015

HighOutputHydraulic/MechanicalDrillingJar(HOHMJ)|DownholeDrillingTools

Nominal

OD (inch)

Length

(ft)

Thru

Bore

(inch)

Approx.

Weight

(lbs)

Pump

Open Area

(in2)

Torsional

Limit (ft lbs)

Nominal Up

Latch Setting

(lbs)

Nominal

Down Latch

Setting (lbs)

Max Pull

During Delay

(lbs)

Tensile Yeild

(lbs)

4.75

19.6

2.25

765

11.8

20,000

55,000

30,000

132,000

391,000

5.25

19.6

2.25

890

11.8

31,500

55,000

30,000

132,000

391,000

6.25

20.5

2.25

1,570

19.6

48,500

90,000

40,000

250,000

777,000

6.50

20.5

2.25

1,630

19.6

52,400

90,000

40,000

250,000

777,000

6.62

20.6

2.75

1,600

21.7

53,800

90,000

40,000

250,000

722,500

6.75

20.5

2.75

1,760

23.8

48,800

95,000

42,000

270,000

907,500

8.00

20.7

2.81

2,600

30.7

98,000

100,000

45,000

400,000

949,000

Nominal

OD (inch)

Length

(m)

Thru

Bore

Approx.

Weight

(kgs)

Pump Open

Area (mm2)

Torsional

Limit (Nm)

Nominal Up

Latch Setting

(daN)

Nominal

Down Latch

Setting (daN)

Max Pull

During

Delay (daN)

Tensile Yeild

(daN)

121

6.0

57.2

350

7 606

27 120

24 460

13 340

58 710

173 900

133

6.0

57.2

400

7 606

42 710

24 460

13 340

58 710

173 900

159

6.2

57.2

710

12 664

65 760

40 030

17 790

111 200

345 600

Metric

http://challengerdownhole.com/downholetoolproducts/highoutputhydraulicmechanicaldrillingjarhohmj/

3/4

3/8/2015

HighOutputHydraulic/MechanicalDrillingJar(HOHMJ)|DownholeDrillingTools

165

6.2

57.2

740

12 664

71 040

40 030

17 790

111 200

345 600

168

6.3

69.9

730

13 968

72 940

40 030

17 790

111 200

321 400

171

6.2

69.9

800

15 323

66 160

42 260

18 680

120 100

403 700

203

6.3

71.4

1 180

19 806

132870

44 480

20 020

177 920

422 100

Copyright 2011 - 2015. All Rights Reserved. Challenger Downhole Tools.

http://challengerdownhole.com/downholetoolproducts/highoutputhydraulicmechanicaldrillingjarhohmj/

More

Website By: Impact Graphics

4/4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GrantPrideco Drill Pipe Data TablesDocument24 pagesGrantPrideco Drill Pipe Data TablesMaximo Biarrieta RodriguezNo ratings yet

- Year 2 - Push and Pull FPDDocument18 pagesYear 2 - Push and Pull FPDRebecca LNo ratings yet

- VV016042 Service Manual OS4 PDFDocument141 pagesVV016042 Service Manual OS4 PDFCamilo Andres Uribe Lopez100% (1)

- Critical Area Drawings: Document Number 50000805-MAN-001 Revision A 64 of 66Document2 pagesCritical Area Drawings: Document Number 50000805-MAN-001 Revision A 64 of 66Hany AhmedNo ratings yet

- Jereh ElevatorDocument4 pagesJereh ElevatorHany AhmedNo ratings yet

- Safety Alert: Stabbing Board Related IncidentsDocument1 pageSafety Alert: Stabbing Board Related IncidentsHany AhmedNo ratings yet

- S WeatherfDocument3 pagesS WeatherfHany AhmedNo ratings yet

- Jet Lube Jet Lok IIDocument2 pagesJet Lube Jet Lok IIHany Ahmed0% (1)

- Bushings Master BushingDocument2 pagesBushings Master BushingHany AhmedNo ratings yet

- Guidance For RcaDocument12 pagesGuidance For RcaHany AhmedNo ratings yet

- Critical AreaDocument2 pagesCritical AreaHany AhmedNo ratings yet

- Stabbing Board Accident Panel Report 2006-002Document48 pagesStabbing Board Accident Panel Report 2006-002Hany AhmedNo ratings yet

- Oilfield JetlubeDocument24 pagesOilfield JetlubeHany AhmedNo ratings yet

- Spider Varco 375Document1 pageSpider Varco 375Hany AhmedNo ratings yet

- Fishbone RevisedDocument3 pagesFishbone RevisedHany AhmedNo ratings yet

- API Tubing Table SpecificationsDocument6 pagesAPI Tubing Table SpecificationsDavid KusumaNo ratings yet

- Радиус-Сервис - Products - Shock ToolsDocument2 pagesРадиус-Сервис - Products - Shock ToolsHany AhmedNo ratings yet

- Радиус-Сервис - Products - JarsDocument4 pagesРадиус-Сервис - Products - JarsHany AhmedNo ratings yet

- Hydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsDocument4 pagesHydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsHany AhmedNo ratings yet

- 758 42000e Testork Revd LoresDocument4 pages758 42000e Testork Revd LoresHany AhmedNo ratings yet

- Hydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsDocument4 pagesHydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsHany AhmedNo ratings yet

- Challenger Bumper Jar - Downhole Drilling ToolsDocument3 pagesChallenger Bumper Jar - Downhole Drilling ToolsHany AhmedNo ratings yet

- Stabbing BoardsDocument2 pagesStabbing BoardsHany AhmedNo ratings yet

- Shock Tool - Downhole Drilling ToolsDocument4 pagesShock Tool - Downhole Drilling ToolsHany AhmedNo ratings yet

- Tianhe Oil Group Huifeng Petroleum Equipment Co - pdf1Document3 pagesTianhe Oil Group Huifeng Petroleum Equipment Co - pdf1Hany AhmedNo ratings yet

- Tianhe Oil Group Huifeng Petroleum Equipment Co - pdf2Document3 pagesTianhe Oil Group Huifeng Petroleum Equipment Co - pdf2Hany AhmedNo ratings yet

- Tianhe Oil Group Huifeng Petroleum Equipment Co - pdf4Document3 pagesTianhe Oil Group Huifeng Petroleum Equipment Co - pdf4Hany AhmedNo ratings yet

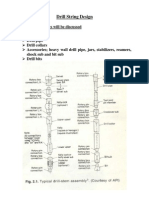

- Drill String DesignDocument12 pagesDrill String DesignAsaadgz100% (1)

- Tianhe Oil Group Huifeng Petroleum Equipment CoDocument3 pagesTianhe Oil Group Huifeng Petroleum Equipment CoHany AhmedNo ratings yet

- Pumps Motors AssDocument57 pagesPumps Motors AssHany AhmedNo ratings yet

- Jar Pro Drillstring Jarring Analysis SoftwareDocument5 pagesJar Pro Drillstring Jarring Analysis SoftwareHany AhmedNo ratings yet

- Pure Quality Pure Natural: Calcium Carbonate Filler / MasterbatchDocument27 pagesPure Quality Pure Natural: Calcium Carbonate Filler / MasterbatchhelenNo ratings yet

- Diwali - An Overview of The Festival of LightsDocument3 pagesDiwali - An Overview of The Festival of LightsSumeetNo ratings yet

- Gizmotchy 3 Element Complete Assembly InstructionsDocument5 pagesGizmotchy 3 Element Complete Assembly InstructionsEuropaNo ratings yet

- EMA Guideline on Calculating Cleaning LimitsDocument4 pagesEMA Guideline on Calculating Cleaning LimitsshivanagiriNo ratings yet

- Tiger Tales: From Colonial MalayaDocument16 pagesTiger Tales: From Colonial MalayamatarsNo ratings yet

- Wilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetDocument2 pagesWilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetTrung Trần MinhNo ratings yet

- Limit Switch 1LX7001-J AZBILDocument8 pagesLimit Switch 1LX7001-J AZBILHoàng Sơn PhạmNo ratings yet

- RRC Igc1Document6 pagesRRC Igc1kabirNo ratings yet

- A Comparison of Fuel Cell Testing Protocols PDFDocument7 pagesA Comparison of Fuel Cell Testing Protocols PDFDimitrios TsiplakidesNo ratings yet

- Equivalent Record Form: Department of Education MIMAROPA RegionDocument1 pageEquivalent Record Form: Department of Education MIMAROPA RegionEnerita AllegoNo ratings yet

- Beuys Begleitheft en ScreenDocument18 pagesBeuys Begleitheft en Screensofijawt0% (1)

- Unit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsDocument6 pagesUnit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsCristina Garcia50% (2)

- Lect 1.2 Principles of Food Process DesignDocument43 pagesLect 1.2 Principles of Food Process Designmahmoud hassanNo ratings yet

- Volume 4-6Document757 pagesVolume 4-6AKNo ratings yet

- Macbeth Introduction0Document40 pagesMacbeth Introduction0MohammedelamineNo ratings yet

- Untitled DocumentDocument2 pagesUntitled DocumentChristopher BellardNo ratings yet

- Advanced Financial Accounting Chapter 2 LECTURE - NOTESDocument14 pagesAdvanced Financial Accounting Chapter 2 LECTURE - NOTESAshenafi ZelekeNo ratings yet

- French Revolution ChoiceDocument3 pagesFrench Revolution Choiceapi-483679267No ratings yet

- Latihan Soal Recount Text HotsDocument3 pagesLatihan Soal Recount Text HotsDevinta ArdyNo ratings yet

- Day 2 TaskDocument4 pagesDay 2 TaskYaathriganNo ratings yet

- Linked ListDocument83 pagesLinked Listshahida18No ratings yet

- Oracle Time and Labor - Data SheetDocument5 pagesOracle Time and Labor - Data Sheetbilaltanoli@gmail.comNo ratings yet

- ALT Company Introduction 20170524.1Document51 pagesALT Company Introduction 20170524.1Terence WoonNo ratings yet

- Deconstructing Product Design Exploring The Form, Function, Usability, Sustainability, and Commercial Success of 100 Amazing Products PDFDocument100 pagesDeconstructing Product Design Exploring The Form, Function, Usability, Sustainability, and Commercial Success of 100 Amazing Products PDFMontserrat CifuentesNo ratings yet

- Salt Analysis-Ferric ChlorideDocument3 pagesSalt Analysis-Ferric ChlorideVandana0% (1)

- Understanding Urbanization & Urban Community DevelopmentDocument44 pagesUnderstanding Urbanization & Urban Community DevelopmentS.Rengasamy89% (28)

- Biology 11th Edition Mader Test BankDocument25 pagesBiology 11th Edition Mader Test BankAnthonyWeaveracey100% (44)

- Application of Carbon-Polymer Based Composite Electrodes For Microbial Fuel CellsDocument26 pagesApplication of Carbon-Polymer Based Composite Electrodes For Microbial Fuel Cellsavinash jNo ratings yet