Professional Documents

Culture Documents

Er 26

Uploaded by

michaelxiaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Er 26

Uploaded by

michaelxiaoCopyright:

Available Formats

ENGINEERING REFERENCE

The contents of this document are proprietary and confidential. They are the

property of Ariel Corporation and may not be disclosed, reproduced, or used for

manufacture in part or in whole without written permission from Ariel Corporation.

Hold-down Bolting to Resist Shaking Forces and

Couples in Reciprocating Compressors

Requirements

1. To use the torques in the tables, the ultimate strength (Su) of the stud material must equal or exceed

100,000 psi (690 MPa); higher strength stud material is preferred. In all cases, torque the nuts to

stress the stud to about 55% of the ultimate strength of the stud material; higher strength materials

require higher torques than shown in the tables. Material strength and torque are directly proportional. Example: for 120,000 psi (825 MPa) ultimate strength material: 120,000 100,000 = 1.2 x

min. torque from table = required torque for given nut size. To use a different stud diameter, consult

Ariel for feasibility and torque.

2. Compressor frame foot hold-down studs and crosshead guide to support bolting should be as long

as possible. Ariel recommends a minimum 12 to 1 length to diameter ratio.

NOTE: Bolting long enough to reach only through the compressor foot and a deck plate

or flange of an I-beam can loosen if not provided with engineered devices to maintain

bolt pre-load.

3. Tighten nuts as recommended above to maintain fastener pre-load during operation. Ariel also recommends rolled threads and hardened spherical washers for hold down bolting to help compensate

for fastener to frame bolt surface angular misalignment.

4. Use grade 8 or 9 bolting to hold crosshead guides to supports.

5. Re-preserve any fasteners subject to corrosion after installation.

6. Follow lubrication guidelines and recommended procedures for torque accuracy in ER-63.

For the most recent edition of this document, visit www.arielcorp.com.

15

Transferred document to Flare, Added links to referenced documents. Added "F" to

all references of JGC:D frames.

REV

Page 1 of 2

DESCRIPTION

REV 15

14

13

12

11

10

REV

018450

015759

016442

016770

015403

EC

9-21-12

8-11-10

7-8-10

6-9-10

9-29-08

DATE

15

REV

019144

EC

11-6-13

DATE

ER-26

ENGINEERING REFERENCE

The contents of this document are proprietary and confidential. They are the

property of Ariel Corporation and may not be disclosed, reproduced, or used for

manufacture in part or in whole without written permission from Ariel Corporation.

TABLE 1 Hold-down Bolting - Minimum Torquesa

Frame Foot

Compressor

Model

Crosshead Guide to Supportb

Hole Diameter

inch (mm)

Recommended

Stud Size

inch--TPI

Minimum Nut

Torquec

lb-ft (Nm)

Bolting Size

inch--TPI

Bolting Torque

lb-ft (Nm)

JGI

7/8 (22)

3/4--10

175 (235)

---

---

JGM:N:P:Q

3/4 (19)

5/8--11

100 (130)

5/8--11

90 (120)

JG:A

7/8 (22)

3/4--10

175 (235)

5/8--11

90 (120)

ACFd, JGR:J

1 (25)

7/8--9

280 (380)

3/4--10

160 (215)

JGW

1 (25)

7/8--9

280 (380)

5/8--11

90 (120)

JGH:E

1-1/4 (32)

1-1/8--7

600 (805)

7/8--9

255 (345)

JGK:Te

1-1/4 (32)

1-1/8--7

600 (805)

1--8

380 (515)

JGC:D:F

1-1/2 (48)

1-3/8--6

1100 (1500)

1-1/4--7

765 (1040)

JGZ:U

1-7/8 (48)

1-3/4--5

2300 (3100)

1-1/4--7

765 (1040)

KBZ:U

1-7/8 (48)

1-3/4--5

2300 (3100)

1-1/4--12

780 (1055)

JGB:V, KBB:V

1-7/8 (48)

1-3/4--5

2300 (3100)

1-1/2--6

1340 (1815)

a. See #1, "Requirements".

b. Not applicable to directly-opposed compressors.

c. When using a stud pitch other than those listed above in the same nominal diameter size, use this formula to determine required torque: Torque = (TABLE 1 fastener torque) x (target fastener root area TABLE 1 fastener root

area).

d. For directly-opposed compressors, use frame foot values.

e. For JGT compressors with ET crosshead guides, use the 7/89 TPI bolting size in TABLE 1 as a minimum torque to

bolt the crosshead guide to the support.

TABLE 2 Crosshead Guide Support Foot Hold-down Bolting - Minimum Torquesa

Compressor Model

Hole Diameter

inch (mm)

Recommended Stud

Size, inch--TPI

JGM:N:P:Q:I

Minimum Nut Torqueb lbft (Nm)

N/A

JG:A

3/4 (19)

5/8--11

100 (130)

JGR:J:W

1 (25)

7/8--9

280 (380)

JGH:EK:T

1-1/4 (32)

1-1/8--7

600 (805)

JGC:D:F:Z:U

1-1/2 (38)

1-3/8--6

1100 (1500)

JGB:V, KBB:V:Z:U

1-7/8 (48)

1-3/4--5

2300 (3100)

a. See #1, "Requirements".

b. When using a stud pitch other than those listed above in the same nominal diameter size, use this formula to determine required torque: Torque = (TABLE 2 fastener torque) x (target fastener root area TABLE 2 fastener root

area).

Page 2 of 2

REV 15

ER-26

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 6T40 DetayDocument52 pages6T40 Detaysuattosun100% (11)

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- Culata 3406E C15Document19 pagesCulata 3406E C15carlos moralesNo ratings yet

- Cyl Head ReusedDocument56 pagesCyl Head ReusedAnonymous V9fdC650% (2)

- Es 9-54 Fastener Installation and Torque ValuesDocument33 pagesEs 9-54 Fastener Installation and Torque ValuesCarlosFernandoMondragonDominguezNo ratings yet

- Basic Tools in 3D in AutoCAD - 12CADDocument7 pagesBasic Tools in 3D in AutoCAD - 12CADMuthu KumarNo ratings yet

- 773E Off-Highway Truck BDA00001-UP (MACHINE) POWERED BY 3412E Engine (SEBP3401 - 98) - Búsqueda BásicaDocument5 pages773E Off-Highway Truck BDA00001-UP (MACHINE) POWERED BY 3412E Engine (SEBP3401 - 98) - Búsqueda Básicatommy lanyonNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Grant Prideco Rotary Shoulder HandbookDocument112 pagesGrant Prideco Rotary Shoulder Handbookrlk2806No ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Ariel Performance Software DescriptionDocument8 pagesAriel Performance Software Descriptionmichaelxiao100% (2)

- Ariel Performance Software DescriptionDocument8 pagesAriel Performance Software Descriptionmichaelxiao100% (2)

- Ariel Performance Software DescriptionDocument8 pagesAriel Performance Software Descriptionmichaelxiao100% (2)

- Ariel Performance Software DescriptionDocument8 pagesAriel Performance Software Descriptionmichaelxiao100% (2)

- SEBF8043 Crankshaft Visual InspectionDocument49 pagesSEBF8043 Crankshaft Visual InspectionpramNo ratings yet

- CulatasDocument25 pagesCulatasWilbort Encomenderos RuizNo ratings yet

- Er 82Document2 pagesEr 82michaelxiaoNo ratings yet

- Reuse and Salvage Guidelines - Specifications For Crankshafts in 3000 To 3400 and D-Series EnginesDocument38 pagesReuse and Salvage Guidelines - Specifications For Crankshafts in 3000 To 3400 and D-Series EnginesJuan Pujol100% (2)

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- GRPTS TurbochargersDocument65 pagesGRPTS TurbochargersFaur RahmanNo ratings yet

- SureTork II - Electronic Manual Ver 1.0.unlockedDocument139 pagesSureTork II - Electronic Manual Ver 1.0.unlockedmetallica123No ratings yet

- Aplicación ARMDocument25 pagesAplicación ARMKjatunMayu GutierrezNo ratings yet

- Deflexión de CigueñalDocument21 pagesDeflexión de CigueñalCatalina HuenumanNo ratings yet

- SEBF 8164 гизьзы 3500Document19 pagesSEBF 8164 гизьзы 3500Aminadav100% (1)

- Sebf 8054 Обмеры и Правка КвDocument33 pagesSebf 8054 Обмеры и Правка КванджелаNo ratings yet

- Til 1214-3R3Document7 pagesTil 1214-3R3Hernan Giraut100% (2)

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Increase TorqueDocument7 pagesIncrease TorqueJohnSmithNo ratings yet

- LE501 Service ManualDocument73 pagesLE501 Service Manuallau_hy2158100% (1)

- Api RP 8BDocument6 pagesApi RP 8BAntonio França0% (1)

- Alignment Coupling Operation Manual Tyre-FlexDocument37 pagesAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatelNo ratings yet

- Understanding Nema MG1Document14 pagesUnderstanding Nema MG1Andavilli Srihari KumarNo ratings yet

- SEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series EnginesDocument19 pagesSEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series Enginesyahmanmahira4No ratings yet

- SEBF8054 - Procedure To Measure and Straighten Bent CrankshaftsDocument28 pagesSEBF8054 - Procedure To Measure and Straighten Bent Crankshaftsyahmanmahira4No ratings yet

- Product Specs GuideDocument2 pagesProduct Specs GuideUrsula JohnsonNo ratings yet

- Er 108 1 PDFDocument3 pagesEr 108 1 PDFDIEGO YECID MILLAN MENDOZANo ratings yet

- Er 108 1Document3 pagesEr 108 1DIEGO YECID MILLAN MENDOZANo ratings yet

- Pistons and Connecting Rods - AssembleDocument6 pagesPistons and Connecting Rods - AssemblealonsoNo ratings yet

- Acoplamiento Sure-Flex Couplings PDFDocument4 pagesAcoplamiento Sure-Flex Couplings PDFFederico Pérez de LeónNo ratings yet

- Ms27488 Rev NDocument9 pagesMs27488 Rev NTeck Kian ChiaNo ratings yet

- Aerospace T-Seals: ISO 9001 CertifiedDocument20 pagesAerospace T-Seals: ISO 9001 Certifiedchamaljs100% (1)

- 02X7815C0110 Rev03 09-11Document67 pages02X7815C0110 Rev03 09-11tinpenaNo ratings yet

- 8218 спецификация головки 3116 -с7Document19 pages8218 спецификация головки 3116 -с7Евгений АбрамовNo ratings yet

- Process Piping Systems: Scrubber Design and Installation RequirementsDocument6 pagesProcess Piping Systems: Scrubber Design and Installation RequirementsCamilo Andres Cardozo FajardoNo ratings yet

- Selection of Push-Pull SolenoidDocument5 pagesSelection of Push-Pull SolenoidPOOVENDHAN TNo ratings yet

- Serie FF PDFDocument3 pagesSerie FF PDFYanderier RiveraNo ratings yet

- Pistao e Biela - c9 - 01Document4 pagesPistao e Biela - c9 - 01Victor NoschangNo ratings yet

- Manual & Hydraulic Pullers: Operating Instructions For: "Power Team - Posilock Puller Sets"Document23 pagesManual & Hydraulic Pullers: Operating Instructions For: "Power Team - Posilock Puller Sets"DamianLopezNo ratings yet

- Manual Manual Manual Manual For Propeller Type For Propeller Type For Propeller Type For Propeller Type H50V H50V H50V H50VDocument12 pagesManual Manual Manual Manual For Propeller Type For Propeller Type For Propeller Type For Propeller Type H50V H50V H50V H50VDiego GomesNo ratings yet

- ER-26 en Hold-Down Bolting To Resist Shaking Forces and Couples in Reciprocating CompressorsDocument3 pagesER-26 en Hold-Down Bolting To Resist Shaking Forces and Couples in Reciprocating CompressorsCamilo Andres Cardozo FajardoNo ratings yet

- Er 26 PDFDocument3 pagesEr 26 PDFCamilo Andres Cardozo FajardoNo ratings yet

- Wire Rope Terminations 22Document33 pagesWire Rope Terminations 22Luffy11No ratings yet

- AirdromeDocument137 pagesAirdromejcNo ratings yet

- Advance Adapters Inc. P/N: 716138Document5 pagesAdvance Adapters Inc. P/N: 716138joseph lopezNo ratings yet

- SEBF 8380 перечень инструкции по ремонту головокDocument8 pagesSEBF 8380 перечень инструкции по ремонту головокЕвгений АбрамовNo ratings yet

- ASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005Document9 pagesASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005yu gangNo ratings yet

- M Technical ManualDocument36 pagesM Technical ManualJuan Martin RomeroNo ratings yet

- Hartzell Hc-A3, PHC, Ehc TcdsDocument7 pagesHartzell Hc-A3, PHC, Ehc TcdshurleyjonNo ratings yet

- Crankshaft Front Seal InstallSMCS - 1160 - 012Document4 pagesCrankshaft Front Seal InstallSMCS - 1160 - 012Tawanda Tradyboy MorgansNo ratings yet

- IPP STATEMENT SSP Duolok Swagelok Interchange Intermix Pages From ASTM F1387 GE 362A2915 Test PlanDocument5 pagesIPP STATEMENT SSP Duolok Swagelok Interchange Intermix Pages From ASTM F1387 GE 362A2915 Test PlanAnonymous otUd3TzINo ratings yet

- 804Document259 pages804juanNo ratings yet

- Testing For Excessive Cylinder Blowby in 3500 EnginesDocument9 pagesTesting For Excessive Cylinder Blowby in 3500 EnginesKusuma JayaNo ratings yet

- Ariel Compressor Performance Quote DataDocument1 pageAriel Compressor Performance Quote DataCarlos MantillaNo ratings yet

- F-35463 Ariel Unit RecordDocument1 pageF-35463 Ariel Unit RecordmichaelxiaoNo ratings yet

- Vendor Literature Selection For Reciprocating Compressor Customer ManualsDocument2 pagesVendor Literature Selection For Reciprocating Compressor Customer ManualsmichaelxiaoNo ratings yet

- Ariel Quality Control Plan W Optional TestsDocument2 pagesAriel Quality Control Plan W Optional TestsCarlos MantillaNo ratings yet

- CTBOODocument7 pagesCTBOOmichaelxiaoNo ratings yet

- Leveling Limits For Stationary Reciprocating Compressors: Engineering ReferenceDocument2 pagesLeveling Limits For Stationary Reciprocating Compressors: Engineering ReferencemichaelxiaoNo ratings yet

- Rotary Compressor Warranty Notification and Installation List DataDocument1 pageRotary Compressor Warranty Notification and Installation List DatamichaelxiaoNo ratings yet

- FVCPDocument14 pagesFVCPmichaelxiaoNo ratings yet

- Protection of Non-Lube Compressor Cylinders and Distance Pieces With VCI Powder For ShipmentDocument2 pagesProtection of Non-Lube Compressor Cylinders and Distance Pieces With VCI Powder For ShipmentmichaelxiaoNo ratings yet

- Ar166 208 260Document82 pagesAr166 208 260michaelxiaoNo ratings yet

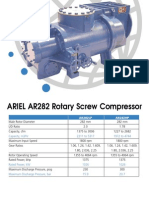

- ARIEL AR282 Rotary Screw Compressor: Capacity, m3/hr 2211 To 5317 1972 To 4744Document2 pagesARIEL AR282 Rotary Screw Compressor: Capacity, m3/hr 2211 To 5317 1972 To 4744michaelxiaoNo ratings yet

- Ariel Quality Control Plan W Optional TestsDocument2 pagesAriel Quality Control Plan W Optional TestsCarlos MantillaNo ratings yet

- Valve Theory DesignDocument345 pagesValve Theory Designmichaelxiao0% (1)

- Sharp Lc32bd6x LCD TV SMDocument212 pagesSharp Lc32bd6x LCD TV SMkothuraNo ratings yet

- Kristian Tlangau - November, 2016 PDFDocument52 pagesKristian Tlangau - November, 2016 PDFMizoram Presbyterian Church SynodNo ratings yet

- Class Ab Output BufferDocument4 pagesClass Ab Output BufferrivercamNo ratings yet

- WebLink 2.0 InstructionsDocument14 pagesWebLink 2.0 InstructionsSwami MeeraNo ratings yet

- Zynq Ultrascale+ LVDS in Native Mode or Component ... - Community ForumsDocument1 pageZynq Ultrascale+ LVDS in Native Mode or Component ... - Community ForumsgerNo ratings yet

- Qual Comm 2016Document15 pagesQual Comm 2016Manoj Kumar Gunturi100% (2)

- Cetpa Infotech Pvt. LTD: Department of Embedded SystemDocument49 pagesCetpa Infotech Pvt. LTD: Department of Embedded SystemsknagarNo ratings yet

- 1 AbstractDocument43 pages1 AbstractNagarjuna ReddyNo ratings yet

- Semi-Custom Design Flow for Leveraging Place and Route Tools in Custom Circuit DesignDocument20 pagesSemi-Custom Design Flow for Leveraging Place and Route Tools in Custom Circuit DesignCatherine OliverNo ratings yet

- Recloser NOJADocument28 pagesRecloser NOJAPhan TiếnNo ratings yet

- SIB List Rev 16Document11 pagesSIB List Rev 16Chris RobertsNo ratings yet

- Soliphant M With Electronic Insert FEM58: Functional Safety ManualDocument12 pagesSoliphant M With Electronic Insert FEM58: Functional Safety ManualTreeNo ratings yet

- The Home Tab in Microsoft Word PDFDocument14 pagesThe Home Tab in Microsoft Word PDFSunil baghelNo ratings yet

- mc166 Kompend e PDFDocument1,444 pagesmc166 Kompend e PDFsanjaycsawantNo ratings yet

- Ccna4 7.5.1Document5 pagesCcna4 7.5.1Mark ManingasNo ratings yet

- Finding A Route TutorialDocument17 pagesFinding A Route TutorialArda YoungNo ratings yet

- Router w330 TuyuDocument91 pagesRouter w330 TuyuMatias FerrariNo ratings yet

- CP SirDocument238 pagesCP SirKaran SharmaNo ratings yet

- Data Protection and Management Participant Guide 1 PDFDocument610 pagesData Protection and Management Participant Guide 1 PDFKevin YuNo ratings yet

- EchoAndReverberation PDFDocument19 pagesEchoAndReverberation PDFSlavita JarcovNo ratings yet

- SHS STEM Requirements Facilities Materials EquipmentDocument12 pagesSHS STEM Requirements Facilities Materials EquipmentBROWN SCHOOLNo ratings yet

- Robotics Lab Session Covers Drive Mechanisms, Payloads, Sensors (MECH 4002YDocument12 pagesRobotics Lab Session Covers Drive Mechanisms, Payloads, Sensors (MECH 4002Ysanjiv0909No ratings yet

- Infineon-Getting Started-Toolchain Installation Guide For MOTIX Embedded Power ICs (System-on-Chip) - DevelopmentTools-v01 00-ENDocument1 pageInfineon-Getting Started-Toolchain Installation Guide For MOTIX Embedded Power ICs (System-on-Chip) - DevelopmentTools-v01 00-ENNik NameNo ratings yet

- Computer Networking: A Top Down Approach ,: 5 Edition. Jim Kurose, Keith Ross Addison-Wesley, April 2009Document80 pagesComputer Networking: A Top Down Approach ,: 5 Edition. Jim Kurose, Keith Ross Addison-Wesley, April 2009Hoang NguyenNo ratings yet

- Manual Gasmonitor EnglezaDocument143 pagesManual Gasmonitor EnglezaccdumitraNo ratings yet

- Fundamentals of Microprocessor 8085: Multiple Choice QuestionsDocument21 pagesFundamentals of Microprocessor 8085: Multiple Choice Questionsraghavrocks89No ratings yet

- MSI Motherboard & Video Card PricelistDocument1 pageMSI Motherboard & Video Card PricelistMarvin Mark AbamongaNo ratings yet