Professional Documents

Culture Documents

Completing The LNG Value Chain

Uploaded by

librian_13Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Completing The LNG Value Chain

Uploaded by

librian_13Copyright:

Available Formats

[ ENERGY & MARINE / IN DETAIL ]

[ ENERGY & MARINE / IN DETAIL ]

Completing the LNG value chain

AUTHORS: Reidar Strande, Director, LNG, Wrtsil Oil & Gas Systems

Tord Johnsson, Area Business Development Manager, Oil and Gas Business, Wrtsil Power Plants

The use of natural gas is already strong

and will continue to increase. Wrtsil's

extensive expertise across the entire LNG

value chain enables it to bundle together

solutions that provide efficient energy

production from gas.

32

detail

Most experts predict that natural gas

demand will see strong growth in the future,

growing at a compound annual growth rate

(CAGR) somewhere in the region of 7-8 %.

According to the International Energy

Agency, we could be entering a golden age

for gas. In its World Energy Outlook 2012,

the agency projected gas demand to rise from

3.3 trillion cubic metres (tcm) in 2010 to 5.0

tcm in 2035, an increase of 50%. Its share of

the global energy mix rises from 22% in 2010

to 24% in 2035, all but catching up with coal.

Meanwhile, ExxonMobils Energy Outlook

2040 published in January 2013, forecasts

that natural gas will emerge as the number

one fuel for power generation within the

next 30 years, accounting for 30% of global

electricity generation.

The attraction of gas as an energy source

whether for heating, transport or power

generation is clear. Its price relative-to-

energy content is favourable when compared

with other fossil fuels, and it significantly

reduces SOx and CO2 emissions when

replacing coal and oil in power generation.

With global LNG (liquefied natural gas)

demand expected to show strong growth,

LNG production is forecasted to jump from

270 million t/year in 2011 to 350 million t/

year in 2016, according to the International

Gas Unions (IGU) World LNG Report 2011.

This growth in production will have to be

accompanied by a similar expansion in

LNG receiving terminal capacity, since gas

production is often not in the same

location as consumption.

Last year Wrtsil took a significant step

towards taking full advantage of this

booming LNG business. In January 2012, the

company gained expertise in small-scale LNG

liquefaction, regasification, and LNG fuel

systems through its acquisition of

WRTSIL TECHNICAL JOURNAL 01.2013

Hamworthy plc. It is a move that

strengthens its position as a total solutions

provider, with a complete range of products,

integrated solutions, and services to

the marine and offshore industries.

These new capabilities go hand-in-hand

with the companys existing expertise in ship

propulsion and power plant/land-based

design and construction. With capabilities

now extending across the point of

extraction, transport, regasification and

onshore delivery, to user off-take in the

form of power generation, Wrtsil is able to

integrate an LNG import terminal with a

power plant with an integrated EPC solution.

This can deliver a number of benefits to

potential customers.

LNG production

Wrtsil Oil & Gas has developed innovative

LNG production plant solutions based

on well-proven equipment and process

control principles, which are suitable for

small to medium size liquefaction capacities.

The LNG production facility in

Snurrevarden, Norway was the first freestanding small scale LNG plant in Northern

Europe. It is fully automated with remote

monitoring and control capabilities.

Since then Wrtsil Oil & Gas has

delivered a number of complete onshore

LNG production facilities, including the

introduction of an improved liquefaction

system with double expanders based on the

reverse Brayton cycle. The LNG production

plant for Gasum in Finland, delivered in

Fig. 1 Small scale liquefaction plant at Snurrevarden, Norway.

2010, uses surplus liquid nitrogen (LIN) for

the LNG generation and incorporates new

technology that reduces LIN consumption

by 50%.

Wrtsil Oil & Gas has also developed

the energy efficient NewMR liquefaction

technology for even lower capacities than its

usual small and mid-scale LNG plants. For

production capacities below 50 tonnes per

day, the NewMR technology uses a mixed

refrigerant in combination with standard

equipment to achieve low investment

costs and the rapid manufacture of the

liquefaction unit. In the growing liquid

biogas fuel market, this technology adds

to the value chain. Wrtsil Oil & Gas will

deliver a biogas liquefaction plant to the

Municipality of Oslo during spring 2013.

LNG transport

Most of the growth in the global LNG market

is expected to occur in large production

plants exceeding roughly 1 million t/

year in Australia, Asia, the US and parts

of Africa, mainly Mozambique. There

arealso a number of smaller scale plants that

will make the LNG business more local.

Typically, large LNG carriers transport

Fig. 2 Small scale liquefaction plant in Kollnes.

in detail 33

[ ENERGY & MARINE / IN DETAIL ]

[ ENERGY & MARINE / IN DETAIL ]

What is LNG?

Liquefied Natural Gas (LNG) is

Natural Gas that has been cooled

below the bubbling point, where

it is condensed to a liquid, which

occurs at a temperature dependent

of the gas composition, typically

close to 160 C at atmospheric

pressure

Consist mainly of methane

Methane (CH4)

Vol-%

Lean

Mean

Rich

Methane

96.2

91.7

84.8

Ethane

3.3

5.7

13.4

Propane

0.4

2.2

1.3

0.3

Buthane

0.1

0.3

Contains no sulphur or toxic elements

Pentane

0.0

0.0

Odourless

Nitrogen

0.0

0.1

0.2

MN

87

76

71

Fig. 3 LNG specifications.

What is LNG?

Solution to utilize natural gas where

pipeline gas is not available

Liquefaction reduces the volume

by approximately 600 times,

making it more economical

to transport over long distances

by specially designed semitrailers

and ships

1 m3 of LNG = 600 m3 of natural

gas

Density of LNG: 450 kg/m3

NATURAL

GAS

LNG

Fig. 5 The GdF Suez/HOEGH Neptune Shuttle Regasification Vessel (SRV).

detail

Wrtsil regasication for oshore and

onshore LNG storage

Regasification: The general idea of liquefying

natural gas is to reduce the volume to make

transport easier. LNG has a volume about

600 times less than natural gas. The LNG is

then regasified at the receiving terminal by

vaporising the LNG. The storage and

regasification terminal can be either an

onshore terminal, comprising a dedicated

jetty regas unit (JRU) that makes use of

a moored floating storage unit alongside to

hold the LNG buffer stock, or a floating

storage regasification unit on-board a ship.

Floating storage regasication units

Fig. 4 The relationship between natural gas and LNG in terms of volume.

34

LNG from the points of production

to consumption locations. Wrtsil s

strength in the ship power business has

seen it heavily involved in this sector.

Since their introduction in 2006, 65%of

all new LNG carriers have been fitted with

Wrtsil dual-fuel (DF) engines. Wrtsil

recently achieved the milestone of supplying

DF propulsion engines to 100 LNG carriers,

and has sold altogether some 720 DF engines

to both marine and land-based applications,

accumulating six million running hours

of experience with the technology.

In recent years there has been a growing

interest in ship and jetty-based LNG

regasification systems.

In a jetty regasification unit (JRU), the

regas unit is mounted on a dedicated jetty

while a floating storage unit (FSU) is moored

alongside to hold the LNG buffer stock.

Shuttles then bring the LNG to and from

the FSU before being fed to the JRU in

preparation for feeding to the gas grid or

power plant. This was a solution that

Wrtsil Oil & Gas provided for Malacca

in Malaysia (see box).

The ship-based option, more commonly

known as a floating storage and regasification

unit (FSRU), is essentially a LNG carrier

converted by the addition of on-board

storage and regas facilities. FSRUs present a

strong economic case when compared with

onshore import terminals. With no need to

go through onshore planning procedures,

they can typically be built in half the time

around two years and at half the cost in

some instances. FSRUs can also be built in

remote areas with an associated subsea

pipeline.

An increasing number of LNG importers

want to take advantage of the cost and

timing benefits offered by the jetty/regas

WRTSIL TECHNICAL JOURNAL 01.2013

vessels option, but they also want to be able

to keep the ships on station in uninterrupted

service for several years. They also want to

be able to process larger quantities of LNG

than converted FSRUs are capable of. This

joint requirement has led to a number of

orders for FSRU new builds.

New builds typically consist of a pair of

vessels that together fulfill the same role

as a FSRU. This configuration makes use

of a barge-mounted regasification plant

combined with an LNG carrier used as a

floating storage unit. This approach obviates

the need for a propulsion system on the

barge floating regas unit. At the same time,

a conventional LNG carrier can be easily

prepared for its floating storage role.

The market for FSRUs is a growing one

that Wrtsil has been taking advantage of.

So far, Wrtsil has delivered 10 floating

LNG terminals, representing a market share

of about 40%.

Reconverting the LNG at import terminals

requires a very large amount of energy

in the form of heat for LNG vaporisation.

Some FSRUs can actually provide the same

amount of heat that could be supplied

by a 1,000 MW nuclear power plant. To

3

vaporise 14 million m per day would

require in the region of 100 MW of heat.

Many companies use seawater only to

provide the heat for vaporisation but this

can have drawbacks. Over the last several

years, Wrtsil has been developing its

FSRU technology to increase the process

efficiency, reliability and economics.

A key Wrtsil LNG regasification

technology utilises propane and seawater

in cascade loops to warm the LNG.

Wrtsil built its first pilot to demonstrate

propane loop technology in 2005.

Propane is used in the first stage to heat

the LNG from -160C to -10C in a heat

exchanger. In the second stage, the LNG

can be heated further using seawater as

a heating medium. Propane is a suitable

heating medium as it does not freeze at the

-160C temperature of the LNG. Its use in

the first stage reduces the risk of freezing

the seawater in the heat exchanger.

Also, the latent heat from the propane

is used for the vaporisation, which is more

efficient and reduces the volume of

the heating medium compared to competing

technologies.

In the cascade systems first stage heat

exchanger, heat is exchanged against the

propane circulating in a closed loop. The

propane enters the heat exchanger at

Fig. 6 A gas barge power plant.

Fig. 7 An onshore gas power plant.

Fig. 8 A gas cube.

in detail 35

[ ENERGY & MARINE / IN DETAIL ]

[ ENERGY & MARINE / IN DETAIL ]

Wrtsil gas engine reference map

7,850 MW | in 44 countries | 275 power plants

Europe

DF engines

GD engines

SG engines

North & Central America

& Caribbean

1,390 MW

DF engines

GD engines

SG engines

360 MW

20 MW

1,010 MW

Middle East

DF engines

GD engines

SG engines

South America

585 MW

DF engines

GD engines

SG engines

110 MW

125 MW

350 MW

2,160 MW

300 MW

115 MW

1,745 MW

220 MW

95 MW

50 MW

75 MW

Africa

800 MW

DF engines

SG engines

520 MW

280 MW

Asia

2695 MW

DF engines

GD engines

SG engines

650 MW

650 MW

1,665 MW

Fig. 9 Wrtsil's worldwide installations of gas fuelled power plants.

approximately 0C and 4.7 bar as gas.

In the heat exchanging process, the propane

is condensed and leaves the exchanger in

a liquid state at about -5C.

The propane is then pumped by the

circulating pump and heated against

seawater in titanium, semi-welded-plate

heat exchangers. Here the propane is

evaporated and heated to 0C before returning

as gas to the printed circuit heat exchanger.

Wrtsil regas units use a type of printed

circuit heat exchanger that allows for a

compact unit capable of withstanding high

pressures. The simplicity of control of

the regas units using this technology has

been proven at a demonstration plant. The

robustness in terms of turndown capability,

ramping up and ramping down, has also

been demonstrated. Unlike other heat

exchangers, the units are not susceptible to

the fatigue caused by large changes in

temperature.

Wrtsil is also able to provide FSRUs for

situations where seawater cannot be used.

Here, steam from the ships boiler system and

cooling water from Wrtsils engines can be

36

detail

used for vaporisation.

The shipboard LNG regasification systems

have capacities in the 50-1,100 tonnes per

hour (tph) range, and send-out pressures

ranging from 46 to 130 bar. As an example,

a system based on the use of 630 tonnes/

hour trains can provide a regasification

capacity of 720 million standard cubic feet

3

of gas per day, and discharge a 145,000 m

LNG carrier in approximately four days.

However, the fuel cost when discharging

a LNG carrier provided with a propane/

seawater regas unit can be up to seven

times lower than for a similar size ship

fitted with a steam/water-glycol unit.

Onshore storage

Still, today most receiving terminals are built

with onshore storage, which has certain

advantages over FSRUs. Many of the smaller

and medium size terminals will be onshore

and for these Wrtsil can be a supplier.

Onshore storage can either be a flatbottom tank with a capacity ranging

3

from 4,000 m3 to 200,000 m , or a

horizontal or vertical, vacuum-jacketed,

pressure tank for smaller amounts of LNG

3

storage with less than 1,000 m /tank.

Integrated receiving terminal

and power plant

Wrtsil has a long history in building

power plants in the 1-500 MW range based

on modular 1-20 MW engine units capable

of running on fuel oil or gas, or on dual-fuel

engines that can use both without

modification. These power plants can be

used to generate electricity only, or combined

heat and power if there is also a requirement

for heat as such in industrial applications.

There are a number of synergies between

the power station and the regasification

plant. Obviously the power plant can

utilise the natural gas produced for power

generation, but there are other opportunities

for integration of the two systems.

When the LNG arrives at the country

of destination, it is received at a terminal

where it is stored and regasified before being

fed into the gas grid or piped to a power

plant for electricity generation.

The receiving terminal is designed

WRTSIL TECHNICAL JOURNAL 01.2013

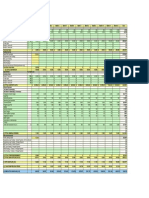

LNG conversions and engine consumptions

LNG volume

LNG mass

2.25 m3 LNG

LHV

1 ton

49.0 MJ/kg

Gas volume

1,370 Nm3 Gas

35.9 MJ/m

10.0 kWh/m3

HHV

54.4 MJ/kg

39.8 MJ/m3

11.1 kWh/m

1 ton LNG

13,700 kWh

Electrical energy

(Engine electrical efficiency 45%)

6,165 kWh

1 m3 LNG

6,090 kWh

Electrical enercy

(Engine electrical efficiency 45%)

2,740 kWh

50MW Electrical power

El eff. 45%

LNG mass flow

8.2 ton/h

LNG volume flow

3

18.4 m LNG/h

Gas volume flow

3

11,230 m LNG/h

3

10,000 m LNG

22.6 days

Fig. 10 Rule of thumb.

Fig. 11 Storage need versus power.

25,000

25,000

20,000

20,000

15,000

15,000

10,000

10,000

5,000

5,000

LNG mass

LNG volume

30,000

0

0

10

m3 (LNG)

15

20

m3 (tank volume)

25

30

ton

100 MW plant

100% utilization

0.14 Million Ton/year

(MTPA)

0.31 Millon m3/year

LNG storage

90,000

50,000

80,000

45,000

70,000

40,000

35,000

60,000

30,000

50,000

25,000

40,000

20,000

30,000

LNG mass

Storage: When the ship is safely moored

and ship-to-shore communications are

established, the vapour return arm and

the LNG unloading arms are connected.

The ships unloading pumps unload the LNG,

which is then piped to the onshore LNG

storage tank.

The LNG handling process creates a

boil-off gas (BOG) that can be burned as

part of the fuel for a power plant. There

are three sources of BOG. There is BOG

from the unloading ship, mainly due to

heat ingress and ship movement, where

the rate can range from 0.10% to 0.15%

of total tank mass per day. Since the ship

is stationary during the unloading, the

BOG rate is based on 0.10% per day.

There is also BOG from the onshore tank,

generated from heat ingress. This normally

ranges from 0.05% to 0.10% of total tank

mass per day. Finally, BOG from loading

the LNG into the onshore tank is released

due to large liquid movement and a high

tank temperature if the tank is not cooled

properly. The BOG rate can vary between

100% and 1,000% of the normal BOG rate.

Wrtsil s onshore tanks are well cooled

and designed to a 300% BOG rate. The rate of

BOG is determined by the amount of

LNG volume

according to ship size, LNG availability, and

the cost of constructing the LNG storage

facilities all depend on the required gas

send-out/consumption.

LNG storage

30,000

15,000

20,000

10,000

10,000

5,000

0

0

0

10

m3 (LNG)

15

20

m3 (tank volume)

25

30

ton

300 MW plant

100% utilization

0.41 Million Ton/year

(MTPA)

0.94 Millon m3/year

in detail 37

[ ENERGY & MARINE / IN DETAIL ]

[ ENERGY & MARINE / IN DETAIL ]

Fig. 12 A typical onshore power plant layout.

insulation in the tank. As the amount of

insulation has an impact on cost, it is

important to calculate the value of the BOG

before determining the investment in

insulation to limit BOG.

This requires two BOG systems; one that

handles the normal operation of the

terminal where the BOG comes solely from

the storage tank, and another that handles

the BOG produced during the loading and

unloading of the tank. The combined BOG

systems compress and handle the flow of BOG

fed to the power plant. A BOG re-liquefaction

system can be installed according to

the operating mode of the terminal.

Having a power plant at the LNG receiving

terminal can be a big advantage to customers.

A power plant can be the main off-taker of

the LNG, burning it along with the BOG to

supply electricity to the grid. An integrated

power plant can also provide the electricity

and heat requirements of the LNG terminal.

Wrtsil power plants can be easily integrated

with LNG receiving terminals with no

modifications needed to the engines.

These power plants can utilise LNG

directly without an external evaporation

system, as the fuel is heated before the

engine. They can also use the low-pressure

gas coming from the send-out system

without the need for any additional

compressors.

38

detail

Low (LP) pressure send-out system:

If the consumers needs are less than 10 bar,

then liquid is sent out from the LNG storage

tank, pumped by the LP LNG pumps and

sent to a LNG vaporiser. In this unit, the low

pressure LNG is vaporised and heated to

ambient condition before being sent as fuel

to the Wrtsil power plant. Vaporised LNG

is mixed with compressed BOG upstream

of the power plant.

High pressure (HP) send-out system:

The same equipment used for the regas unit

can also be used to increase the gas pressure

to the level needed for injection into a

natural gas pipeline. If a pressure higher than

10 bar is required, liquid is sent out from

the LNG storage tank. It is pumped by the

LP LNG pumps and sent to a regasifier.

The regasifier can be a module of the type

supplied by Wrtsil Oil & Gas, Norway,

comprising HP LNG pumps and a LNG

vaporiser. In this unit, the low pressure LNG

is vaporised and heated to ambient

temperature before it is fed to a standard

natural gas high-pressure pipeline system.

If fuel is needed for the Wrtsil power plant

it can be taken from the HP line via a

reduction valve. Vaporised LNG will be mixed

with compressed BOG upstream of

the power plant.

Whether the LNG comes from the lowpressure or high-pressure send-out system,

it has to be heated. This presents another

opportunity for power plant integration.

The ethylene glycol (glycol water) used

to provide engine cooling can be used to

help vaporise the LNG into natural gas.

This vaporisation takes place in a stainless

steel shell and tube heat exchangers.

The glycol water has a fixed flow rate,

where it enters the heat exchangers at

80C and returns at 30-65C, depending

on the LNG regasification capacity.

Project evaluation

Before offering an EPC contract for an

integrated plant, Wrtsil makes an in-depth

evaluation, looking at criteria such as

the size of the project and its location,

whether there is sufficient in-house

experience, and a network of local subsuppliers and sub-contractors.

One of the first tasks is to look at the LNG

import terminal in terms of sizing. Wrtsil

assesses the gas demand for both the power

plant and direct sales to either the pipeline

network, the LNG truck filling station, or

the ship bunkering service at the terminal.

This will give the total gas demand.

The next step is to look at the seasonal

variations to work out the peak demand

and average demand. It is also important to

investigate the supply of the LNG i.e. the

travel distance and time needed for a round

trip, together with the ship size and

WRTSIL TECHNICAL JOURNAL 01.2013

Fig. 13 A typical power barge layout.

availability, LNG consumption, and the

amount of required storage capacity.

All of this data is entered into a model to

determine the optimum for each of these

considerations, and for the receiving

terminal in terms of capital expenditure and

operational expenditure. It is important to

size items, such as storage, correctly as costs

increase with storage capacity and it may

not make economic sense to store

a commodity such as gas.

Wrtsil bases its project evaluation on

the price of LNG at the source, the shipping

costs, and the terminal import regasification

costs. This gives a total cost of gas output

from the terminal, which serves as an input

for the price of gas delivered to the power

plant or other consumers.

Project execution

The ability to deliver the equipment for both

the LNG terminal and power plant provides

customers with assurance as to the quality

and function of the equipment throughout

the installation.

Being able to execute these integrated

projects on an EPC basis can also bring added

benefits for customers. While there are cost

advantages, the main benefits result from

having just a single company with which to

interface. This makes the assignment of

responsibilities much easier and reduces the

risks relating to project execution and schedules.

Fig. 14 A moored power barge.

in detail 39

[ ENERGY & MARINE / IN DETAIL ]

[ ENERGY & MARINE / IN DETAIL ]

Fig. 15 The 'Viking Grace' the worlds largest LNG fuelled passenger ferry.

Strong market

The continued expansion of global gas

markets, along with steady growth in power

demand, will see the market for FSRUs

continue to be lucrative over the coming

3-5 years. In addition to those currently

being built, there are perhaps 30 FSRUs in

existence with prospects for another 30.

The use of FSRUs is increasingly becoming

the favoured option for bringing gas to

energy hungry countries with high demand

for energy, such as Indonesia, India and

China, as well as countries in Africa and

South America, which will continue to

drive demand. It is a trend that is likely

to continue, especially in those countries

that foresee a continued dependence on

fossil fuels for power generation but are

looking to cut emissions at the same time.

40

detail

Indeed the entire LNG chain is expanding.

Its attraction as a cleaner energy source

compared to coal and oil for power

generation, and its growing use for land

and sea transport continues to drive more

exploration.

From an energy-to-price point of view

compared to oil, gas is perhaps three to four

times cheaper. If it can be traded and

distributed more easily, it will become even

more attractive.

Wrtsil, through its activities right

across the LNG chain, from transport and

distribution, to processing and utilisation,

is in a good position to help customers take

advantage of this energy source by offering

complete systems with improved interfaces.

WRTSIL TECHNICAL JOURNAL 01.2013

MODULAR FABRICATION

To allow the modular fabrication of its regasification systems,

Wrtsil entered into a strategic partnership with a China-based

oil and gas engineering and construction company in September

2010. The first contract secured by the partnership was for the

supply of the seawater/propane-based regasification system for

the Khannur FSRU conversion.

3

The 125,000m spherical tank Khannur, built in Norway in

the mid-1970s, has operated reliably for several decades. The

transformation of the vessel into an FSRU was carried out at a

yard in Singapore.

Wrtsil handled the systems conceptual design, basic

specification, and the provision of key equipment for the regas

unit. The layout for all the equipment, structure and pipes was

carried out at a yard in China. Wrtsils joint venture partner was

also responsible for the procurement, construction, assembly and

final testing of the module.

The complete regasification unit, based on an assembly of

skid-mounted units, weighs around 700 tonnes and measures

21m x 27m x 15m.

The modular approach enabled Wrtsil to complete the unit on

a fast-track basis, and to have the regasification system almost

complete before lifting onboard the vessel. The limited number

of interfaces between the ship and the equipment were easily

connected, and delivery of the regas unit took place in November

2011.

The Khannur, with the SOE-built regas unit mounted on its bow, is

now on station in Jakarta Bay as the receiving facility for the West

Java LNG project. The vessel, renamed the FSRU Regas Satu, is

Indonesias first LNG regasification terminal and represents the

first FSRU project in Asia.

The vessel has the capacity to regasify up to 3 million tonnes per

annum (mta) of LNG, and the project operator plans to increase

the facilitys throughput up to this maximum level in the coming

years.

The Khannur project marked SOEs first foray into the LNG market

and the good relationship with Wrtsil is continuing. The Nantong

yard completed the JRU for Petronas and delivered it to the new

Malacca LNG receiving terminal on the east coast of the Malaysian

peninsular last year. Weighing 945 tonnes, the jetty-mounted

regas unit has three trains, each with a capacity of 220 tonnes per

hour, and is built to accommodate a 70 bar send-out pressure.

Following completion of the JRU for Malacca, regas units are

3

also being fabricated for the three 170,000 m FSRU new builds

under construction for Hegh LNG. Each of these units, which

are also based on Wrtsils propane/seawater LNG regasification

technology, will weigh about 600 tonnes.

Fig. 16 The PETRONAS Melaka Jetty regasification unit.

in detail 41

You might also like

- Understanding Natural Gas and LNG OptionsDocument248 pagesUnderstanding Natural Gas and LNG OptionsTivani MphiniNo ratings yet

- Fire Protection Inspection Checklist enDocument4 pagesFire Protection Inspection Checklist engalihasyhariNo ratings yet

- Brunei MCHE Replacement 2005 IPTC-10676-MS-P PDFDocument3 pagesBrunei MCHE Replacement 2005 IPTC-10676-MS-P PDFGeoff HunterNo ratings yet

- Completing The LNG Value ChainDocument8 pagesCompleting The LNG Value ChainManoj Gupta100% (1)

- Underground Gas Storage Facilities: Design and ImplementationFrom EverandUnderground Gas Storage Facilities: Design and ImplementationNo ratings yet

- Green Entrepreneurship For Green Economy - An OverviewDocument4 pagesGreen Entrepreneurship For Green Economy - An OverviewarcherselevatorsNo ratings yet

- Copeland Scroll Compressors - The Industry BreakthroughDocument451 pagesCopeland Scroll Compressors - The Industry BreakthroughMariano Daniel Silva100% (1)

- MidaDocument16 pagesMidaSyed Zafirna W HNo ratings yet

- What Is A Shell CorporationDocument25 pagesWhat Is A Shell CorporationJames MondeloNo ratings yet

- LNG Fundamentals Presentation 2019Document26 pagesLNG Fundamentals Presentation 2019endosporaNo ratings yet

- Offshore Salt Caverns Enable A 'Mega' Sized LNG Receiving TerminalDocument11 pagesOffshore Salt Caverns Enable A 'Mega' Sized LNG Receiving TerminalRizka KholistianiNo ratings yet

- Oil and Gas IndustryDocument23 pagesOil and Gas IndustryJoshwin JacobNo ratings yet

- FLNG Compared To LNG CarriersDocument72 pagesFLNG Compared To LNG Carriersscorpen100% (1)

- Floating LNG FLNG Technical Challenges and Future TrendsDocument12 pagesFloating LNG FLNG Technical Challenges and Future TrendsIsioma1100% (1)

- Innovations in LNG TechnologyDocument15 pagesInnovations in LNG TechnologyCraigUnderwoodNo ratings yet

- LNG 3 3 e 11 150dpi NB19 15617Document24 pagesLNG 3 3 e 11 150dpi NB19 15617Pawan ChaturvediNo ratings yet

- Tecno Economics of LNG Regasification Terminal inDocument11 pagesTecno Economics of LNG Regasification Terminal inShiella Marie PacturanNo ratings yet

- New Investor Overview March 20011Document27 pagesNew Investor Overview March 20011Amrinder6No ratings yet

- Guide to MIG Welding FundamentalsDocument31 pagesGuide to MIG Welding FundamentalsAndrés Hurtado100% (1)

- 3.2. The LNG Storage Business and Associated Costs Ángel Rojo ENAGÁSDocument26 pages3.2. The LNG Storage Business and Associated Costs Ángel Rojo ENAGÁSFirzaNo ratings yet

- LNG Terminals in IndiaDocument20 pagesLNG Terminals in IndiaJyotishko BanerjeeNo ratings yet

- Site Location SelectionDocument12 pagesSite Location Selectionhos JohnsonNo ratings yet

- Nigerian Local Content Oil and GasDocument4 pagesNigerian Local Content Oil and GasBalogun Ruth Oluwatosin100% (1)

- RP 158 PDFDocument40 pagesRP 158 PDFDeependra SinghNo ratings yet

- Investor Presentation Island Offshore FebruaDocument42 pagesInvestor Presentation Island Offshore Februacacalot93100% (1)

- Gas FacilitiesDocument38 pagesGas Facilitiesriyan100% (1)

- LNG Receiving Terminals: BY CH - Satvika 16021A2545Document24 pagesLNG Receiving Terminals: BY CH - Satvika 16021A2545Ram Charan Konidela100% (1)

- Roquette Activity and Sustainable Development Report 2016Document52 pagesRoquette Activity and Sustainable Development Report 2016Khushi ChadhaNo ratings yet

- Lamu Port Offshore Energy Park FeasibilityDocument11 pagesLamu Port Offshore Energy Park FeasibilityEric Mwangi NjorogeNo ratings yet

- Feasibility Study of Liquefied Natural Gas ProjectDocument13 pagesFeasibility Study of Liquefied Natural Gas Projectkeshermech100% (1)

- Pelan Induk Dan Pelaksanaan ECER - En. Azmi YahyaDocument130 pagesPelan Induk Dan Pelaksanaan ECER - En. Azmi Yahyanurmee100% (1)

- Abbas - Bilgrami CNG Transportation Trans CanadaDocument48 pagesAbbas - Bilgrami CNG Transportation Trans CanadaMustafa100% (1)

- Business Expense Budget1Document7 pagesBusiness Expense Budget1Kehan KhalidNo ratings yet

- Small Scale Import LNG Terminal PDFDocument9 pagesSmall Scale Import LNG Terminal PDFamirlngNo ratings yet

- IPTC 14548 FLNG Development: Strategic Approaches To New Growth ChallengesDocument15 pagesIPTC 14548 FLNG Development: Strategic Approaches To New Growth ChallengesIzhamKhairiNo ratings yet

- LNG Production For MidscaleDocument15 pagesLNG Production For MidscaleJavid Talib100% (1)

- Natural Gas Explained - LNGDocument24 pagesNatural Gas Explained - LNGMELVIN MAGBANUANo ratings yet

- World LNG Market Summary in 2018Document33 pagesWorld LNG Market Summary in 2018Rahul Atodaria100% (1)

- Training Project 2012Document115 pagesTraining Project 2012Mohit MangalNo ratings yet

- Rfsu Vs OnshoreDocument11 pagesRfsu Vs OnshoreGolfkung PairojNo ratings yet

- Indonesia Status 2014 by Willy OlsenDocument10 pagesIndonesia Status 2014 by Willy Olsendhana_benzNo ratings yet

- Arun Daniel Purba PresentationDocument14 pagesArun Daniel Purba PresentationIlham HakimNo ratings yet

- NM bp4Document1 pageNM bp4api-289869621No ratings yet

- Qatargas Leads Major Environmental Project to Recover Flared GasDocument4 pagesQatargas Leads Major Environmental Project to Recover Flared Gasrvkumar61No ratings yet

- Proposed Acquisition of MerlonDocument8 pagesProposed Acquisition of MerlonboringestNo ratings yet

- Natural Gas Utilization in Malaysia: by Ir. Ahmad Fauzi Hasan Energy Commission, MalaysiaDocument47 pagesNatural Gas Utilization in Malaysia: by Ir. Ahmad Fauzi Hasan Energy Commission, Malaysiafaiz_oeNo ratings yet

- Development of LNG Regasification Terminals in ASEANDocument8 pagesDevelopment of LNG Regasification Terminals in ASEANtcandelarioNo ratings yet

- Floating Regasification: The Growing Role of FSRUs and the Case of the Aegean LNG TerminalDocument21 pagesFloating Regasification: The Growing Role of FSRUs and the Case of the Aegean LNG TerminalMehmet Ali100% (1)

- NW bp3Document1 pageNW bp3api-289869621No ratings yet

- Floating Liquefaction Projects: Technical, Operational, Commercial and Legal ChallengesDocument11 pagesFloating Liquefaction Projects: Technical, Operational, Commercial and Legal Challengessamriddh25No ratings yet

- PD ProjectDocument70 pagesPD ProjectUmer AizazNo ratings yet

- Site Selection Plant LayoutDocument16 pagesSite Selection Plant LayoutsfsmNo ratings yet

- AbtngDocument5 pagesAbtngSushant PaiNo ratings yet

- Health Care, Oil and Gas SectorDocument52 pagesHealth Care, Oil and Gas SectorDhruvil GorsawalaNo ratings yet

- H2-Company Profile ChinaDocument22 pagesH2-Company Profile ChinappglNo ratings yet

- ProposalDocument24 pagesProposalVivek SinghNo ratings yet

- Small Scale LNG Power Generation in The PhilippinesDocument18 pagesSmall Scale LNG Power Generation in The Philippinesmardirad100% (1)

- Presentation For Gas Naturally Complete and Final Klapeidos NaftaDocument30 pagesPresentation For Gas Naturally Complete and Final Klapeidos Naftamilham09100% (1)

- Factory Acceptance Test For PRVDocument4 pagesFactory Acceptance Test For PRVUmair AwanNo ratings yet

- China - Welding Productivity PDFDocument165 pagesChina - Welding Productivity PDFCebrac ItatibaNo ratings yet

- Small Scale LNGDocument79 pagesSmall Scale LNGana astuti100% (1)

- 101 FA SEZ BrochureDocument18 pages101 FA SEZ BrochureTiar Pandapotan PurbaNo ratings yet

- Risk Analysis and Modeling Construction and Operation of Gas Pipeline Projects in PakistanDocument24 pagesRisk Analysis and Modeling Construction and Operation of Gas Pipeline Projects in PakistanJuanCarlosVilchisDuránNo ratings yet

- Short History Og LNG VesselDocument32 pagesShort History Og LNG VesseljwsommermannNo ratings yet

- 5NRJHL Saipem FY2020 Results JMEEBODocument42 pages5NRJHL Saipem FY2020 Results JMEEBOsudhakarrrrrrNo ratings yet

- WesPac Tilbury Marine Jetty Project Brochure 2014-09-02Document4 pagesWesPac Tilbury Marine Jetty Project Brochure 2014-09-02Jeff NagelNo ratings yet

- XojomixedawokukuvisavaneDocument2 pagesXojomixedawokukuvisavanehamdi maidisonNo ratings yet

- Cat Dual FuelDocument9 pagesCat Dual FuelStefano GandolfiNo ratings yet

- SingaporeDocument9 pagesSingaporeHiddenDNo ratings yet

- Green City PlanDocument29 pagesGreen City Planyogi_patel90No ratings yet

- Natco Dox PsDocument2 pagesNatco Dox PsShesharam ChouhanNo ratings yet

- LM 2931Document18 pagesLM 2931Krista TranNo ratings yet

- Abb CMD 2016 Fact SheetsDocument16 pagesAbb CMD 2016 Fact SheetsLuz Stella Calixto GomezNo ratings yet

- Areas of Specialisation in GENCO and DISCO - PPDocument33 pagesAreas of Specialisation in GENCO and DISCO - PPchdiNo ratings yet

- Romanian Oil IndustryDocument7 pagesRomanian Oil IndustryEnot SoulaviereNo ratings yet

- Loan Application v.2Document2 pagesLoan Application v.2Jose Rico ColigadoNo ratings yet

- Performance Appraisal at IOCLDocument107 pagesPerformance Appraisal at IOCLPradeep SharmaNo ratings yet

- M02 Mechanical160419022804 PDFDocument2 pagesM02 Mechanical160419022804 PDFVishal MandloiNo ratings yet

- MPR January 2019Document23 pagesMPR January 2019Anonymous MKT2rZVkNNo ratings yet

- LG Ac Owner ManualDocument24 pagesLG Ac Owner ManualGood SheperdNo ratings yet

- CSIC Annual 2016-MediumDocument44 pagesCSIC Annual 2016-MediumMarco Della PelleNo ratings yet

- Custom Stack Silencers for Power GenerationDocument2 pagesCustom Stack Silencers for Power GenerationAhmad DaoodNo ratings yet

- Petsec Energy Research Report 13 June 2017 FinalDocument40 pagesPetsec Energy Research Report 13 June 2017 Finalrasnowmah2012No ratings yet

- Consumer Switchgear CatalogueDocument128 pagesConsumer Switchgear CatalogueYasir ArafatNo ratings yet

- Havells Fans Marketing ReportDocument21 pagesHavells Fans Marketing ReportKushagra GuptaNo ratings yet

- Project Report On: "New Product Development Process in Textile Industry"Document54 pagesProject Report On: "New Product Development Process in Textile Industry"lalit kumarNo ratings yet

- EHLV Installation - First HalfDocument40 pagesEHLV Installation - First HalfKHA120096 StudentNo ratings yet

- Week 34 09092019 PDFDocument5 pagesWeek 34 09092019 PDFDasmamotor VenturesNo ratings yet

- CSRDocument1 pageCSRDandyNo ratings yet

- Chapter 12 ITDocument22 pagesChapter 12 ITFarhanah MansorNo ratings yet