Professional Documents

Culture Documents

Programming Lathe Cycles Guide

Uploaded by

markoskitpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Programming Lathe Cycles Guide

Uploaded by

markoskitpCopyright:

Available Formats

Manual Guide-0i

Programming for Lathe

1st Edition

November 2007

DOOSAN Infracore eZ Guide i

TABLE OF CONTENTS

OVERVIEW

2-3

MAIN MENU

CYCLE SELECTION MENU LAYOUT

PROCESS MENU DESCRIPTION

HELP SCREEN DESCRIPTION

CONTOUR MENU DESCRIPTION

STARTING A NEW PROGRAM

CREATE A DRILLING CYCLE

9-11

CREATE A ROUGH FACING CYCLE

13-21

CREATE A ROUGH TURNING CYCLE

22-26

CREATE A GROOVING CYCLE

27-29

CREATE A THREADING CYCLE

30-32

DETAILS OF CYCLE MENU INPUT ITEMS

34-41

Page 1

Manual Guide 0i

OVERVIEW

Manual Guide 0i is a basic, conversational-type NC tool path generator for

shop-floor programming. Conversational simply means that when the

programmer starts a process (by pushing a selection button), the

system will request information pertaining only to that process, in the

form of a dialog box. When all required information is input, the system

will advance to the next logical step in the process until a tool path is

created.

The programming system is integrated into the standard NC edit screen, with

a soft key to activate the programming menus.

The output from Manual Guide 0i is similar to a standard NC program, but

with special 4-digit G-codes. This allows a traditional NC program

created offline to be combined with Manual Guide 0i code in the same

program, and edited or executed in the same screen.

Manual Guide 0i is only intended to automate the time consuming task of

calculating points along a tool path. Knowledge of NC programming is

still required, since the system will not output the incidental codes

required to safely move a lathe turret to and from the cutting area, and

perform tool changes, spindle start/stop, etc.

There is no special graphic simulation function provided with Manual Guide

0i. Instead, the standard Fanuc tool path graphics are used in

conjunction with Machine Lock (M17) mode.

This manual will cover, step-by-step, the method of creating a usable

program. Pages 34 thru 41 contain detailed descriptions of the menu

input items used in creating a program in Manual Guide 0i

Page 2

Manual Guide 0i

Programs are created through the standard NC interface

Preparatory commands and initial positioning moves are input through the

standard NC edit mode, then C.A.P. mode is entered for cutting cycle

creation.

NOTE: Manual Guide 0i will not create rapid points or tool change information

automatically, The programmer is responsible for all machine movement

between actual cutting cycles, including rapid to/from home position, tool

changes, spindle and tailstock commands, etc.

Press the C.A.P. soft key to access the

programming functions

Page 3

Manual Guide 0i

Main C.A.P. menu

Page 4

Manual Guide 0i

Cycle Selection Menus

Page 5

Manual Guide 0i

The PROCESS key does nothing more than paste F,S,M, and T codes

into the program. It is generally easier to add these commands

manually, so this function will be not be covered in this manual.

Page 6

Manual Guide 0i

The G CODE and M CODE buttons function as an online help feature.

M code help is similar to G code help shown here.

Page 7

Manual Guide 0i

The CONTUR key uses the exact same menu as the FIGURE menu (shown on

page 5) to create the tool path geometry, but the output is different in that

the CONTUR output is converted directly into standard NC code, while the

FIGURE output is in 4-digit G-code format.

CONTUR and FIGURE

intermediate format

MG0i uses this code

internally to calculate

the tool path, and

resulting G-codes

FIGURE program output

This code must be

preceded by a cycle

block

CONTUR program output

This is direct NC code and

cannot be applied to a

roughing cycle, for

example

Page 8

Manual Guide 0i

The first step in creating a new program is to input the startup commands that

will index the turret to the proper station, start the spindle, and move the turret

to the cutting start point.

Again, it is important to note that ONLY cutting motions are handled by the cycle

menus - all other machine motions must be programmed manually.

Check for available program numbers, and start a new program.

In this case, enterO0003, EOB, and press INSERT. This is done

on the standard NC edit screen

The first tool will drill a 1 dia. hole x 1 deep. Enter

the blocks shown here through the MDI keys

..then press the C.A.P. soft key to access the

cycle and part figure menus

Page 9

Manual Guide 0i

Select DRILL

There are (5) choices for drilling. Select

#2 G1101 DRILLING

Page 10

Manual Guide 0i

The Q value specifies

the peck depth. We will

use drilling type 1, so

this value can be

omitted.

If an unneeded value is

entered, the system will

ignore it. If a necessary

value is missing, an

alarm will be issued

when the OK button is

pressed later.

The W value

selects the

type of

drilling.

Fill in remaining values as

shown

When all values are entered, press OK. The

cycle will be added to the program at the last

cursor position

Page 11

Manual Guide 0i

The system will return to the main menu. The zero return motions

and tool change must be entered manually, so press the LEFT SHIFT

soft key to return to the NC edit screen

This is the code that was just

created by the G1101

DRILLING menu. Note the

highlighted EOB

Insert the blocks

after the G1101 line

as shown, then

press the C.A.P.

soft key to create

the next cycle

IMPORTANT : The rough facing

cycle (or any other cycle) will

consider these coordinates to be

the corner of the rough stock, and

will begin cutting from here

Page 12

Manual Guide 0i

Next, we will rough face the part. Facing cycles are in the TURN menu

Press TURN

Select 3 - END

FACE

ROUGHING

Page 13

Manual Guide 0i

Turning cycles are slightly different than drilling cycles. Once the cycle menu

has been filled out, a part figure must be created in order to describe the

cutting area

Cycle information is

described on 2

screens. The

screens advance

automatically when

the last value on

each screen is

entered, or the

PAGE hard key can

be used

As each item is

highlighted, the

diagram changes

After entering all cutting data, press FIGURE. The

cycle line will be automatically written to the program,

and the part figure menu will appear

Page 14

Manual Guide 0i

When the FIGURE or CONTUR soft key is pressed, a message may pop up

asking whether to edit the contour program or create a new one. Manual

Guide 0i uses a temporary program number, set by parameter, as a

working program area. This has no effect on the NC program currently

being created.

OR

Set this parameter to a

program number that you

will never use for regular

NC programs, since MG0i

will delete it the first time

you create a part figure

Page 15

Manual Guide 0i

Press 1

This is the only choice of

figures for turning

Enter values as

shown. The FEED

METHOD determines

how the tool will travel

to the beginning of the

cycle from where it is

currently located.

The optional FEED

RATE may be used to

vary the cutting feed at

different points along

the contour.

Press OK when finished

Page 16

Manual Guide 0i

This screen shows the

temporary output for the part

figure, and a line drawing of

the figure so far. This is an

intermediate step before the

G codes are written to the

program. Later, once we have

built a part figure, we will

go back and modify one of

the elements

The first element

of this figure will

be a straight line

to Z0, so press

LINE

In this case, the system

only needs to know the

end point Z for this line,

so enter 0

TOUCH STATE

defaults to nothing.

If the element you are

drawing is tangent to,

or blends with, the last

element, press LAST,

otherwise you can just

press OK to accept

the data

Page 17

Manual Guide 0i

The next element is

added to the list.

Press LINE

Enter end point as shown, and press OK

Page 18

Manual Guide 0i

This is all that is needed for a facing tool path. The process type determines the

cutting direction. The part figure points determine the area to be cut. After the

area specified by the part figure is machined, the tool will return automatically

to the coordinates immediately preceding the cutting cycle command.

Press the right shift key, then NC

CNV to add this part figure to the

program

Page 19

Manual Guide 0i

There are (3) options on this screen:

1) Enter an unused 4-digit program number, then press YES the part figure

codes are generated and saved as a subprogram that can be called with an

M98 command. This option is normally used when a rough and finis profile

are the same, to save the effort of drawing the figure twice

2) Press YES without entering a number the part figure codes are inserted

directly into the main program. Use this option if the figure will only be used

with one cycle / tool.

3) Press NO to return to the part figure creation menus (touchup / edit)

Press YES

In this case, we will simply insert the figure codes directly into the main

program since there are no other processes that will use this figure.

Page 20

Manual Guide 0i

Again, the main menu appears. Press the left shift key and check the output

from the facing cycle. Note the G1122 block from the rough facing cycle

menu, and the 4-digit G code format representing the part figure

Output from

FIGURE menu

Output from END

FACE ROUGHING

menu

All MG0i output will be in this format, with a cycle block (G1122 in this

case) followed by part figure blocks (G1400 through G1406). Each 4digit G code has a specific meaning to the system, such as G1400 for start

point, G1401 for a line element, etc.

The blocks above the G1122 shown here MUST BE MANUALLY INPUT by the

programmer (ref. page 12), since MG0i only deals with the cutting

portion of the program.

The next process will be rough turning the OD, using the same tool. After

rough face machining, the tool will return to X2.35, Z1. (see above)

ALL MG0i CYCLES ATTEMP TO START CUTTING FROM WHEREVER THE

TOOL HAPPENS TO BE WHEN THE CYCLE IS COMMANDED, AND WILL

RETURN THE TOOL TO THAT POINT AFTER THE CYCLE IS COMPLETED

Page 21

Manual Guide 0i

Since we are using the same tool as the rough facing cycle, no manual input is

required. Press the C.A.P. key, TURN key, then select 1 G1120 OUTER BAR

ROUGHING

Fill in menu items

with this data

Page 22

Manual Guide 0i

Press FIGURE, select 1, and enter X0.9, Z.050 as your start point, then press OK

Page 23

Manual Guide 0i

Insert lines, arcs, and chamfers as shown here, in order

Page 24

Manual Guide 0i

A graphic representation

of the contour is overlaid

on the program screen

Press the right shift key to

continue the menu selections

Then press NC CNV to generate the

codes for this part figure

This figure may be used again for another cycle, so we

will save the output as a sub program. Enter 1111, then

press YES.

Page 25

Manual Guide 0i

This is the output from the part figure creation. Note the 4-digit G-code format.

IMPORTANT: There are two methods of creating a profile, FIGURE and

CONTUR. If a profile is created using the FIGURE menu, the output must be

preceded by a cycle description, like the G1122 and G1120 blocks shown

above. If the profile is created using the CONTUR menu, the output will be in

standard G-code format, and the cycle command will be ignored, which will

most likely result in a broken tool.

In this case, we created an OUTER BAR ROUGHING block (G1120 shown

above), and created the matching profile using the FIGURE menu, saving

the result as subprogram 1111.

Page 26

Manual Guide 0i

The rough turning process is complete. Now we need to add commands to

bring the turret to a tool change position, then bring it back to the part, and

create a grooving cycle with its associated part figure

Enter these blocks manually, after the

M98 block shown above

Press C.A.P. key, then

select OUTER

GROOVE ROUGHING

Page 27

Manual Guide 0i

Enter these values ,

then press FIGURE

Select

NORMAL

GROOVE

Page 28

Manual Guide 0i

Enter these values,

then press OK

This is the output from the grooving cycle and part figure

creation

OUTER GROOVE

ROUGHING cycle

NORMAL

GROOVE figure

Page 29

Manual Guide 0i

To create a threading process, add the following to the program:

Manually insert the positioning and

tool change information

Press the C.A.P. soft key, select

OUTER THREADING, and enter the

values as shown here

Then press the FIGURE soft

key

Page 30

Manual Guide 0i

Enter the threading figure coordinates.

Select G1450

THREAD FIGURE

and enter the

values shown

here

Note: contour threading can be

programmed using this menu. For a

standard thread, as in this example,

simply fill in the A and B values,

and leave the rest blank

Page 31

Manual Guide 0i

This is the output from the threading cycle (G1140 and G1450 blocks) and the

program end sequence.

Page 32

Manual Guide 0i

The program is now complete. As an exercise, try placing the machine into

Machine Lock (M17) mode, and verifying the program using standard tool

path graphics.

The remainder of this manual contains excerpts from the Fanuc operators

manual, to be used as reference material.

Page 33

Manual Guide 0i

Page 34

Manual Guide 0i

Page 35

Manual Guide 0i

Page 36

Manual Guide 0i

Page 37

Manual Guide 0i

Page 38

Manual Guide 0i

Page 39

Manual Guide 0i

Page 40

Manual Guide 0i

Page 41

You might also like

- Repair and recut threads with Doosan eZ Guide iDocument11 pagesRepair and recut threads with Doosan eZ Guide iAnonymous 6d3EkEwlMNo ratings yet

- Doosan Infracore EZ Guide-I Programming For Lathe.Document108 pagesDoosan Infracore EZ Guide-I Programming For Lathe.JohnPaulSmith1100% (1)

- Ponz Controller Fanuc Oi PF ManualDocument89 pagesPonz Controller Fanuc Oi PF ManualRose Ann C. RofuliNo ratings yet

- Alpha S Ia e 07 PDFDocument42 pagesAlpha S Ia e 07 PDFNoemiaNo ratings yet

- CNC Pilot 640: User's ManualDocument619 pagesCNC Pilot 640: User's ManualcioparNo ratings yet

- 38M21C-1809EN Instruction ManualDocument396 pages38M21C-1809EN Instruction ManualCoptil NicolaeNo ratings yet

- OPERATION MANUAL SR-20R IV Type B cz.2Document300 pagesOPERATION MANUAL SR-20R IV Type B cz.2slawekudNo ratings yet

- M-codes explainedDocument19 pagesM-codes explaineddevinNo ratings yet

- M800-M80 Series PLC Programming Manual - IB1501271-C (ENG) PDFDocument780 pagesM800-M80 Series PLC Programming Manual - IB1501271-C (ENG) PDFXavier TorrasNo ratings yet

- V55 Maintenance 5Document5 pagesV55 Maintenance 5วรพงษ์ กอชัชวาลNo ratings yet

- Puma Work Ejector Tip ReplacementDocument3 pagesPuma Work Ejector Tip ReplacementpaulNo ratings yet

- Turm Mate ManualDocument292 pagesTurm Mate Manualanniyan009No ratings yet

- Mori Seiki GM CodeDocument10 pagesMori Seiki GM CodevusvusNo ratings yet

- Mori - ATC38 - 50 Installation - Maintenance Manual PDFDocument54 pagesMori - ATC38 - 50 Installation - Maintenance Manual PDFTheo SouzaNo ratings yet

- NC Guide ProDocument4 pagesNC Guide ProBhupesh Kumar100% (2)

- Manual Guide I CNC Milling Made Easy ManualDocument126 pagesManual Guide I CNC Milling Made Easy ManualJasminNo ratings yet

- CNC Lathe CrownDocument93 pagesCNC Lathe CrownReynaldo Antonio MarcosNo ratings yet

- Руководство пользователя V600Document119 pagesРуководство пользователя V600Marković AlexandarNo ratings yet

- 004 Basic Bop Lea312 AstDocument188 pages004 Basic Bop Lea312 AstKITTICHAI100% (1)

- Alignment of The Tool Turret MT-HT-E en V2xDocument10 pagesAlignment of The Tool Turret MT-HT-E en V2xAdnan MehmoodNo ratings yet

- Mori Seiki ZT 1000 y enDocument16 pagesMori Seiki ZT 1000 y enOswald muñoz100% (1)

- DD322148000C PDFDocument13 pagesDD322148000C PDFEdimilson RodriguesNo ratings yet

- Operator's ManualDocument405 pagesOperator's ManualParamasivam VeerappanNo ratings yet

- GSK980TDb Turning CNC System User ManualDocument41 pagesGSK980TDb Turning CNC System User ManualJean Carlos Fabián LeónNo ratings yet

- Easy Guide Programming Manual For Mc.Document55 pagesEasy Guide Programming Manual For Mc.JohnPaulSmith1No ratings yet

- 65264EN Servo Tuning Alfa - FanucDocument58 pages65264EN Servo Tuning Alfa - FanucpkrkaranNo ratings yet

- Makino STL Cam PDFDocument98 pagesMakino STL Cam PDFberri23No ratings yet

- Yasnac MX-1Document252 pagesYasnac MX-1DOBJANNo ratings yet

- 63003en1.PDF FanucDocument1,467 pages63003en1.PDF FanucAmauriGarciaNo ratings yet

- Lathe MachiningDocument207 pagesLathe MachiningClode23No ratings yet

- Tool Load For MC-APP2008-003Document16 pagesTool Load For MC-APP2008-003jon doughNo ratings yet

- The First Step of SERVO GUIDE PDFDocument58 pagesThe First Step of SERVO GUIDE PDFVladimirAgeevNo ratings yet

- Gv-2500 (Vtl-3200) Operation Manual 01verDocument195 pagesGv-2500 (Vtl-3200) Operation Manual 01versunhuynhNo ratings yet

- Doosan Puma MX Series PDFDocument68 pagesDoosan Puma MX Series PDFGuillermo RamirezNo ratings yet

- Turn Mate I Operator's ManualDocument322 pagesTurn Mate I Operator's ManualAnirban PalNo ratings yet

- Vt-1150 User ManualDocument22 pagesVt-1150 User ManualAnne RodriguesNo ratings yet

- FanucManuals1793 PDFDocument93 pagesFanucManuals1793 PDFkkcm100% (1)

- FANUC 30i/31i/32i SERIES BOOT SYSTEM APPENDIX C SCREEN AND OPERATION GUIDEDocument6 pagesFANUC 30i/31i/32i SERIES BOOT SYSTEM APPENDIX C SCREEN AND OPERATION GUIDERelu ChiruNo ratings yet

- Custom macro programmingDocument114 pagesCustom macro programmingTL PNo ratings yet

- CNC Tapping Center: TC-S2D TC-22B TC-20B TC-R2B TC-32B TC-31BDocument15 pagesCNC Tapping Center: TC-S2D TC-22B TC-20B TC-R2B TC-32B TC-31BFodor Attila BotondNo ratings yet

- B 64304en 3 - 01 - V2008 09 02Document68 pagesB 64304en 3 - 01 - V2008 09 02Ferenc UngváriNo ratings yet

- CNC Programming Workbook For Milling 1aDocument147 pagesCNC Programming Workbook For Milling 1aTruonglana100% (3)

- Sequence of Programming Steps For PartMaker SwissCAMDocument1 pageSequence of Programming Steps For PartMaker SwissCAMshawntsungNo ratings yet

- DNC Operation Management Package PDFDocument120 pagesDNC Operation Management Package PDFVìAi0% (1)

- Makino 3Document90 pagesMakino 3maneesh100% (1)

- MTconnect Installation Manual v2.2.5.0Document106 pagesMTconnect Installation Manual v2.2.5.0sunhuynhNo ratings yet

- ATC Arm Home Position AdjustmentDocument6 pagesATC Arm Home Position AdjustmentVinicius PerondiNo ratings yet

- CNC ProgramiranjeDocument333 pagesCNC ProgramiranjeSimon RisteskiNo ratings yet

- Cincom Evolution Line: Sliding Headstock Type Automatic CNC LatheDocument8 pagesCincom Evolution Line: Sliding Headstock Type Automatic CNC Lathecmgankl100% (1)

- Custom Macro Variable Peck Drilling Cycle MacroDocument2 pagesCustom Macro Variable Peck Drilling Cycle MacroRelu ChiruNo ratings yet

- Doosan HC II SeriesDocument20 pagesDoosan HC II SeriesBow LinNo ratings yet

- Manual Guide: Turning ExamplesDocument116 pagesManual Guide: Turning Examplessavoire et savoire faireNo ratings yet

- FANUC Series 0M-D Machining Center ManualDocument406 pagesFANUC Series 0M-D Machining Center Manualcesar_abdd100% (1)

- ROBOSHOT a-SiA-Series Data SheetsDocument22 pagesROBOSHOT a-SiA-Series Data SheetsHernan LopezNo ratings yet

- Technology of Machine Tools: Electrical Discharge MachiningDocument42 pagesTechnology of Machine Tools: Electrical Discharge Machiningrajamannar322No ratings yet

- General Turning Insert Nomenclature For CNC DummiesDocument4 pagesGeneral Turning Insert Nomenclature For CNC DummiesSumitNo ratings yet

- Fanuc BasicDocument0 pagesFanuc BasicMarco A. Miranda RamírezNo ratings yet

- H4CL T Operation ManualDocument149 pagesH4CL T Operation Manuals_barrios100% (1)

- FANUC GFTE-589-EN - 04 - 101112. Manual Guide I, CNC Turning Made Easy.Document172 pagesFANUC GFTE-589-EN - 04 - 101112. Manual Guide I, CNC Turning Made Easy.JohnPaulSmith100% (6)

- Cnctrain Fanuc0M: CNC Simulation Systems 1995 2010Document51 pagesCnctrain Fanuc0M: CNC Simulation Systems 1995 2010Siti Idah TawhidNo ratings yet

- Mastercam X7 NCI Parameter RefDocument465 pagesMastercam X7 NCI Parameter Refmarkoskitp75% (8)

- Mastercam X7 NCI Parameter RefDocument465 pagesMastercam X7 NCI Parameter Refmarkoskitp75% (8)

- Belotti 5 Axis Post Processor For AlphaCAMDocument31 pagesBelotti 5 Axis Post Processor For AlphaCAMmarkoskitp100% (2)

- Belotti 5 Axis Post Processor For AlphaCAMDocument31 pagesBelotti 5 Axis Post Processor For AlphaCAMmarkoskitp100% (2)

- MoriSeikiSLSeriesProgrammingManual2008PMNLTMSC518I1ENL12002H02 PDFDocument570 pagesMoriSeikiSLSeriesProgrammingManual2008PMNLTMSC518I1ENL12002H02 PDFmarkoskitp100% (3)

- Haas Lathe Programming ManualDocument143 pagesHaas Lathe Programming Manualdoshi78No ratings yet

- Operating A CNC Powered Machine ShopDocument6 pagesOperating A CNC Powered Machine ShopAnonymous PJP78mSxNo ratings yet

- Doosan Puma MX Series BrochureDocument28 pagesDoosan Puma MX Series BrochuremarkoskitpNo ratings yet

- Doosan-Fanuc High Speed ModeDocument2 pagesDoosan-Fanuc High Speed Modemarkoskitp100% (1)

- Doosan Servo Driven Tail Stock MANUAL - ENGDocument5 pagesDoosan Servo Driven Tail Stock MANUAL - ENGmarkoskitp100% (1)

- Retrace Tool Paths with Reverse and Forward ExecutionDocument14 pagesRetrace Tool Paths with Reverse and Forward ExecutionmarkoskitpNo ratings yet

- Fanuc Seria 30,300,31,310,32,320i - ENGDocument568 pagesFanuc Seria 30,300,31,310,32,320i - ENGSilvia_282008roNo ratings yet

- Communications Instructions for DOOSAN, FANUC ControlsDocument27 pagesCommunications Instructions for DOOSAN, FANUC ControlsmarkoskitpNo ratings yet

- Doosan Puma MX SeriesDocument68 pagesDoosan Puma MX Seriesmarkoskitp100% (1)

- 3.1 From Algae To Terrestrial Plants-Student SheetDocument2 pages3.1 From Algae To Terrestrial Plants-Student Sheeteshaaljamal27No ratings yet

- อัตราภาษีของไทยที่ลดให้เปรูDocument124 pagesอัตราภาษีของไทยที่ลดให้เปรูDante FilhoNo ratings yet

- 3 Valvula Modular Serie 01Document42 pages3 Valvula Modular Serie 01Leandro AguiarNo ratings yet

- Data Biostataplus Sbi2014-EDocument4 pagesData Biostataplus Sbi2014-ELucila Milagros PinillosNo ratings yet

- Instrument To Be CalibratedDocument3 pagesInstrument To Be Calibratedsumit chauhanNo ratings yet

- Chemistry How To Make Stuff PDFDocument184 pagesChemistry How To Make Stuff PDF2967449CEENo ratings yet

- KTS - Sarao.bakus Temple of Eternal FiireDocument176 pagesKTS - Sarao.bakus Temple of Eternal FiireK.T.S. SaraoNo ratings yet

- Dimensions and Relations of The Dentogingival Junction in Humans. Gargiulo 1961Document7 pagesDimensions and Relations of The Dentogingival Junction in Humans. Gargiulo 1961Linda Garcia PNo ratings yet

- Numerical Modelling of Laterally Loaded Piles Captures Field Test ResponseDocument244 pagesNumerical Modelling of Laterally Loaded Piles Captures Field Test ResponseXiang ming GeNo ratings yet

- Tramadol Drug StudyDocument1 pageTramadol Drug Studymilkv82% (11)

- Refraction Through Lenses & Optical Instruments5Document144 pagesRefraction Through Lenses & Optical Instruments5geniusamahNo ratings yet

- Integrating Kuleana Rights and Land Trust PrioritesDocument50 pagesIntegrating Kuleana Rights and Land Trust PrioritesKeala Rodenhurst-JamesNo ratings yet

- Carte Automatic TransmissionsDocument20 pagesCarte Automatic TransmissionsGigelNo ratings yet

- Medication - Safety - v4 Last Update 2015Document81 pagesMedication - Safety - v4 Last Update 2015Retno PalupiNo ratings yet

- Abbey Pain Scale assessment toolDocument2 pagesAbbey Pain Scale assessment toolMuhammad RezgiaNo ratings yet

- Manoeuvrability Final EditedDocument12 pagesManoeuvrability Final EditedSaptarshi BasuNo ratings yet

- Dcom QuestionDocument3 pagesDcom Questionsushant sahooNo ratings yet

- Analytical Mechanics SolutionsDocument193 pagesAnalytical Mechanics SolutionsQuinton Boltin67% (9)

- Reference Design Hardware Guide for EVM CE-2Document7 pagesReference Design Hardware Guide for EVM CE-2Angie FoleyNo ratings yet

- Great Gatsby Study NotesDocument69 pagesGreat Gatsby Study NotesLara Westwood100% (2)

- Horizontal Projectile WSDocument3 pagesHorizontal Projectile WSForsbergPhysicsNo ratings yet

- Overview of Pathophysiology of Hypoxemia and HypoxiaDocument15 pagesOverview of Pathophysiology of Hypoxemia and HypoxiaMARY ANN CAGATANNo ratings yet

- FHM Espana 2010 12 PDFDocument2 pagesFHM Espana 2010 12 PDFBrandenNo ratings yet

- History of Cancer ChemotherapyDocument9 pagesHistory of Cancer ChemotherapyJoydeep MajumdarNo ratings yet

- Regular Manual Cleaning: Mimaki Printer Maintenance and Long-Term Storage OptionsDocument3 pagesRegular Manual Cleaning: Mimaki Printer Maintenance and Long-Term Storage OptionshumbyxNo ratings yet

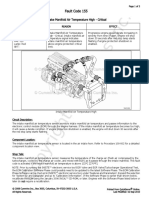

- Fault Code 155: Intake Manifold Air Temperature High - CriticalDocument3 pagesFault Code 155: Intake Manifold Air Temperature High - Criticalhamilton miranda100% (1)

- Niryana Shoola DasaDocument7 pagesNiryana Shoola DasaSuryasukraNo ratings yet

- VCDS Scan Reveals Faults in HVAC, ABS and Transmission SystemsDocument4 pagesVCDS Scan Reveals Faults in HVAC, ABS and Transmission SystemsDan MirceaNo ratings yet

- Vertical Jaw Relation Recording MethodsDocument17 pagesVertical Jaw Relation Recording MethodsHarish VsNo ratings yet

- Mycotoxin Test ProcedureDocument3 pagesMycotoxin Test ProcedureKishenthi KerisnanNo ratings yet