Professional Documents

Culture Documents

04 Samss 048 PDF

Uploaded by

ShojikuriakoseTOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Samss 048 PDF

Uploaded by

ShojikuriakoseTCopyright:

Available Formats

Materials System Specification

04-SAMSS-048

Valve Inspection and Testing Requirements

28 August 2013

Document Responsibility: Valves Standards Committee

Saudi Aramco DeskTop Standards

Table of Contents

1

Scope............................................................. 2

Conflicts and Deviations................................. 2

References..................................................... 2

General Requirements................................... 4

Pressure and Functional Tests...................... 5

Hardness Testing........................................... 6

Impact Testing................................................ 6

Inspection and Testing of Castings................ 7

Plating Tests................................................... 8

10

Sampling Criteria............................................ 8

11

Documentation Requirements........................ 9

Previous Issue: 17 May 2011

Next Planned Update: 11 October 2015

Revised paragraphs are indicated in the right margin

Primary contact: Shiha, Saad Mohammed on +966-3-8809615

CopyrightSaudi Aramco 2013. All rights reserved.

Page 1 of 9

Document Responsibility: Valves Standards Committee

Issue Date: 28 August 2013

Next Planned Update: 11 October 2015

04-SAMSS-048

Valve Inspection and Testing Requirements

Scope

1.1

This Specification, together with the Purchase Order and appropriate data sheets,

cover the minimum requirements for inspection and testing of metallic and

nonmetallic valves normally classified under Saudi Aramco Materials System

(SAMS) Class 04. Such valves include gate, globe, angle, check, needle, ball,

plug, piston, butterfly, choke, diaphragm, etc., used for on-off, manual control

service or for prevention of reverse flow, as appropriate.

1.2

Specifically excluded from the scope are: control, safety-relief, relief, surge

relief, solenoid, pilot and other valves classified under SAMS Class 34; and

wellhead valves classified under SAMS Class 45.

1.3

Requirements for SAMS Class 04 API STD 6A 10,000 psi (1-13/16 inch size

and above) valves and chokes are covered in 04-SAMSS-049.

1.4

The typical quality characteristics to be witnessed and the documents to be

reviewed by and/or provided to Buyer's Representative by the Vendor, are

specified on Saudi Aramco Inspection Requirements Forms 175-043000,

175-043600 and 175-043601 which shall be included as part of the Purchase

Order, as applicable.

Conflicts and Deviations

2.1

Any conflicts between this specification and other applicable Saudi Aramco

Materials System Specifications (SAMSSs), Engineering Standards (SAESs),

Standard Drawings (SASDs), or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the Valves

Standards Committee Chairman (VSCC), Consulting Services Department, of

Saudi Aramco, Dhahran.

2.2

Direct all requests to deviate from this specification in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the VSCC, Consulting Services Department, of

Saudi Aramco, Dhahran.

References

Material or equipment supplied to this specification shall comply with the latest edition

of the references listed below unless otherwise noted:

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302

Instructions for Obtaining a Waiver of a Mandatory

Page 2 of 9

Document Responsibility: Valves Standards Committee

Issue Date: 28 August 2013

Next Planned Update: 11 October 2015

04-SAMSS-048

Valve Inspection and Testing Requirements

Saudi Aramco Engineering Requirement

Saudi Aramco Engineering Standard

SAES-A-206

Positive Material Identification

Saudi Aramco Materials System Specification

04-SAMSS-003

Additional Requirements for Low Temperature

Valves

Saudi Aramco Inspection and Testing Requirements

Form 175-043000

Valve Materials Certification Requirements

Form 175-043600

Metallic and Non-Metallic Valves

Form 175-043601

Low Severity, Valves

Note: Please check the above form numbers and make sure they are correct.

3.2

Industry Codes and Standards

American Petroleum Institute

API STD 598

Valve Inspection and Testing

American Society of Mechanical Engineers

ASME B16.34

Valves-Flanged, Threaded, and Welding End

ASME SEC VIII

Boiler and Pressure Vessel Code

American Society for Testing and Materials

ASTM A956

Standard Test Method for Leeb Hardness Testing

of Steel Products

ASTM B733

Standard Specification for Autocatalytic NickelPhosphorus Coatings on Metals

ASTM E10

Test Method for Brinnell Hardness of Metallic

Materials

ASTM E18

Test Methods for Rockwell Hardness and

Rockwell Superficial Hardness of Metallic

Materials

Manufacturers Standardization Society

MSS SP-53

Quality Standard for Steel Castings - Magnetic

Particle Examination Method

Page 3 of 9

Document Responsibility: Valves Standards Committee

Issue Date: 28 August 2013

Next Planned Update: 11 October 2015

04-SAMSS-048

Valve Inspection and Testing Requirements

MSS SP-55

Quality Standard for Steel Castings - Visual

Method

MSS SP-93

Quality Standard for Steel Castings - Liquid

Penetrant Examination Method

General Requirements

4.1

Each individual valve shall be at least tested, examined and qualified as

specified in the industrial standard (such as ASME, API, AWWA, MSS)

referenced in the Purchase Order or to the manufacturer's approved standard if

no industrial standard has been specified. Nothing in this Specification shall be

construed as waiving any mandatory requirement of the referenced Standard.

4.2

Steel valves shall not be externally painted or coated before the shell pressure

tests are completed. Internally coated or lined valves shall be shell tested before

and after application of the coating or lining unless reviewed and exempted by

the Valves Standards Committee Chairman. Iron valves specified for raw,

sweet, seawater and sanitary services are exempt from this requirement.

4.3

Repairs of valve components with unacceptable defects shall be in accordance

with the governing material specification for the component. Repair by grinding

or redressing of the casting surface is acceptable, provided that during the repair

not more than 10% of the original wall thickness will be removed and provided

that the minimum required wall thickness is not affected. Repair of major

defects shall not be performed without the knowledge of the Saudi Aramco

Representative Company. Welding, NDE and heat treatment procedures for

major weld repairs shall be approved by Saudi Aramco representative prior to

execution. Weld repairs shall be considered major if any of the following

conditions apply:

a)

Castings leak during hydrostatic testing.

b)

The depth of the repair cavity prepared for welding exceeds 20% of the

wall thickness or 25 mm (1 in), whichever is smaller.

c)

The surface area of the repair cavity exceeds 65 cm (10 in).

Welds shall be 100% radiographed and evaluated in accordance with the

applicable ANSI/ASME standard with a minimum casting quality factor of 0.95.

4.4

Welding repair requirements (procedures, welders performance, welding

operators, etc.) shall comply with ASTM A488 and other ASME codes as

applicable. All welding procedure specifications, performance qualification

records and weld map documents must be available for the purchaser inspector

upon his request.

Page 4 of 9

Document Responsibility: Valves Standards Committee

Issue Date: 28 August 2013

Next Planned Update: 11 October 2015

04-SAMSS-048

Valve Inspection and Testing Requirements

4.5

All valves with weld repair to the pressure retaining components shall receive

High-pressure Pneumatic Shell Test (as per API STD 598) after the subject weld

repair.

4.6

Positive Material Identification (PMI) Requirements

Positive Material Identification (PMI) shall be performed on alloy steel material

valves. PMI shall be performed in accordance with SAES-A-206. PMI alloy

verification is required on Pressure Retaining Components (body, bonnet etc.)

materials (100%). Alloy verification for trim parts is not required unless

specified in the purchase order.

4.7

All steel valves NPS 6 and larger shall be pressure tested in a horizontal

position i.e., with stem in vertical position. However, when valve installation

orientation (NPS 6 and larger) is specified in the Purchase Order, applicable

pressure tests shall be conducted with the valve in the specified orientation.

Pressure and Functional Tests

5.1

When there is an industrial standard referenced in the Purchase Order, valves

shall be tested to the requirements of that standard (e.g., ASME, API, MSS,

AWWA, etc.). In addition to tests per the applicable standard, the testing

requirements in the following paragraphs shall apply for steel valves:

5.1.1

For all cast steel valves NPS 2 and below, the shell hydrostatic test shall

be maintained for one minute. For larger sizes, valve shall be subjected

to cyclic hydrostatic shell test for two cycles as follow:

Primary pressure-holding period;

Reduction of the pressure to zero;

Secondary pressure-holding period.

For the first cycle Primary Period the shell test pressure shall be

maintained for a minimum of five minutes or as required by the

applicable industry standard, whichever is greater. For the second cycle

Secondary Period shell test pressure shall be maintained for a

minimum of 15 minutes.

5.1.2

High pressure flanged cast, steel valves in Class 900 and higher which

are specified for gas service shall be subjected to a pneumatic highpressure shell test per API STD 598 paragraph 3.5. The holding time

shall be a minimum of 5 minutes and no visible leakage is allowed.

Page 5 of 9

Document Responsibility: Valves Standards Committee

Issue Date: 28 August 2013

Next Planned Update: 11 October 2015

04-SAMSS-048

Valve Inspection and Testing Requirements

5.1.3

Valves specified for flare system isolation service, regardless of size,

shall receive low pressure pneumatic seat tests at 5 psig.

5.1.4

All valves specified for subsea service, regardless of size, shall receive

100% witnessing of the shell hydrotest.

5.1.5

Metallic valves NPS 2 and larger shall be subjected to a high pressure

closure test in accordance to API STD 598 irrespective of type and

pressure class.

5.2

When there is a governing industrial standard, but it does not specify test

durations or leakage acceptance criteria, paragraph 5.1.1 and API STD 598

requirements for durations and leakage shall apply, unless specified otherwise

by the Valves Standards Committee Chairman.

5.3

When there is no referenced governing industrial standard, valve testing shall be

in accordance with the following requirements:

5.3.1

Metallic valves smaller than NPS 2, and all non-metallic valves, shall be

tested per Vendor's procedure as approved by the Valves Standards

Committee Chairman or his delegate.

5.3.2

Metallic valves NPS 2 and larger shall be tested in accordance with

paragraph 5.1.1 and API STD 598 requirements for shell tests and

closure tests, unless specified otherwise by the Valves Standards

Committee Chairman.

5.4

When a valve is ordered together with an actuator, the valve/actuator assembly

shall be tested together as a unit. As part of functional testing, the valve shall be

opened under the maximum differential pressure that the actuator has been rated

for. The vendor shall take necessary steps to ensure that the valve is not

damaged during this functional test.

5.5

10% of all valves specified for cryogenic service, regardless of size, shall be

tested in accordance with the specified standard at the service temperature

specified by the Purchaser. One valve shall be tested from each PO item as a

minimum.

Hardness Testing

Hardness tests, when required by specified service and/or material specification, shall

be conducted by the Vendor on all wetted parts in accordance with ASTM E10,

ASTM E18 or ASTM A956 Leeb hardness test.

Page 6 of 9

Document Responsibility: Valves Standards Committee

Issue Date: 28 August 2013

Next Planned Update: 11 October 2015

04-SAMSS-048

Valve Inspection and Testing Requirements

Impact Testing

When 04-SAMSS-003 is specified in the Purchase Order, the Vendor shall conduct

impact tests as required by the Specification.

Inspection and Testing of Major Components Material

8.1

Visual Inspection

All castings shall be visually inspected in accordance with MSS SP-55. A casting

shall be rejected if any surface irregularity exceeds example a of any defect type

as per MSS SP-55.

8.2

Surface Examination

For cast steel valves NPS 6 and larger, the internal and external surface areas of

10% (minimum one) of all pressure retaining components (bodies, bonnets,

covers, ball) per heat shall be magnetic particle or liquid penetrant inspected in

accordance with MSS SP-53 or MSS SP-93. If any unacceptable defect is

detected, all castings from the quantity on order shall be inspected.

8.3

QA Program Casting Qualification and Volumetric Examination

8.3.1

As part of their QA program, the Vendor shall implement a qualification

procedure for all pressure containing steel castings. As a minimum, the

vendor shall have qualified each foundry's casting patterns by

radiographic examination of the initial casting. Records of these

qualifications shall be made available upon request.

8.3.2

Radiography shall be performed on all valves listed in 8.3.3.

The examination shall be in accordance with and have included all critical

areas as defined in ASME B16.34, paragraph 8.3.1.1. For valves other

than those included in ASME B16.34 figures, ASME SEC VIII, App. 7,

Section 7.3(a).1 Footnote 1 shall be used to determine the critical areas.

See Acceptance criteria shall be in accordance with ASME B16.34

Appendix I.

8.3.3

The vendor shall radiographically examine and qualify all cast steel

valves NPS 24 and larger. For cast steel valves NPS 2 and larger in

ASME Class 600 and higher, the vendor shall radiographically examine

and qualify one valve per size per heat from the lot on order. If this

radiographic sampling results in a rejection (defined as requiring weld

repair) then an additional 10% sample from the same size and foundry

shall be subjected to radiographic examination as defined in 8.3.2.

Further radiographic rejects resulting from this inspection mandates

Page 7 of 9

Document Responsibility: Valves Standards Committee

Issue Date: 28 August 2013

Next Planned Update: 11 October 2015

04-SAMSS-048

Valve Inspection and Testing Requirements

100% Radiography of castings as defined in 8.3.2.

8.4

Valves fabricated by welding shall be qualified in accordance with

ASME B16.34, paragraph 2.1.6.

8.5

Radiography can be replaced by ultrasonic examination for valves with

minimum wall thickness higher than 175 mm the acceptance criteria shall be in

accordance with ASME B16.34, Appendix I.

Plating Tests

The Vendor's Quality Assurance program shall include the following tests of carbon and

low alloy steel electroless nickel plated parts on a sample basis:

9.1

Bend Test per ASTM B733 paragraph 9.4.1.

There shall be no evidence of lifting upon insertion of a sharp probe at any

ENP-Base Metal interface.

9.2

Ferroxyl Test per ASTM B733 paragraph 9.6.1.

There shall be no indications in primary service exposure areas. When this test

is impractical due to the size of the parts, the Vendor shall submit an alternate

procedure for approval by the Valves Standards Committee Chairman.

10

Sampling Criteria

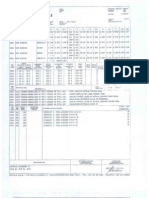

Visual inspection and witnessing shall be based on Table 1 sampling plan. At minimum,

the sample shall include at least one valve from each Purchase Order item.

The sampling plan does not relieve the Vendor of the responsibility to ensure

compliance of each valve with specified requirements and to test each valve.

When a discrepancy is found, the entire lot shall be rejected. The lot shall be

re-inspected and re-tested by the Vendor, prior to presenting them again for inspection.

Table 1

Valve Category

Minimum Sample Size

(% of Item Quantity)

All valves NPS 2 and smaller all ratings

10%

2< valves < 14 NPS and less than ASME Class 600

25%

All valves NPS 14 and above

All valves >2" and ANSI Class 600 and above

All valves >2" and API rating 2000 psi and above

100%

Page 8 of 9

Document Responsibility: Valves Standards Committee

Issue Date: 28 August 2013

Next Planned Update: 11 October 2015

04-SAMSS-048

Valve Inspection and Testing Requirements

However, if Buyer's Representative witnesses a failure of a hydrostatic shell test, all

valves in the lot shall be re-tested and witnessed by Buyer's Representative. The cause

of failure shall be investigated and reported.

11

Documentation and Traceability Requirements

11.1

Material Test Reports and Certificates shall be supplied in accordance with

Saudi Aramco Inspection Requirements Form 175-043000.

11.2

All certificates and test reports shall identify the valve(s) by stating Purchase

Order and Item number, Vendor's name, type, size and rating of valves, and

quantity of valves covered.

11.3

Certificates of castings shall include weld repair data including extent of repair,

WPS, welder qualifications, post weld heat treatment and NDE following the

repair(s).

11.4

Vendor shall obtain a release note from Saudi Aramco inspection representative

prior to commencing assembly activities.

11.5

All traceability documents shall be made available upon request by Saudi

Aramco representative.

11 October 2010

17 May 2011

28 August 2013

Revision Summary

Revised the "Next Planned Update." Reaffirmed the contents of the document, and reissued

with editorial revision to reflect the changes in committee members list.

Minor revision.

Minor revision to avoid any conflict or misinterpretation by the vendor with regard to valve

testing orientation and to have better quality casting by having a better casting testing and

inspection requirements. Also, to avoid getting low quality valves.

Page 9 of 9

You might also like

- 2cep ComplianceDocument7 pages2cep ComplianceShojikuriakoseTNo ratings yet

- 04 Samss 042Document6 pages04 Samss 042ShojikuriakoseTNo ratings yet

- 04 Samss 048 PDFDocument9 pages04 Samss 048 PDFShojikuriakoseTNo ratings yet

- Ayuda Asme B36.10M PDFDocument26 pagesAyuda Asme B36.10M PDFEdgargar100% (1)

- Astm A333 PDFDocument8 pagesAstm A333 PDFrams789No ratings yet

- 34 Samss 711Document26 pages34 Samss 711ShojikuriakoseTNo ratings yet

- 04 Samss 005Document10 pages04 Samss 005ShojikuriakoseT100% (1)

- Ayuda Asme B36.10M PDFDocument26 pagesAyuda Asme B36.10M PDFEdgargar100% (1)

- ASME V Art 7 MTDocument14 pagesASME V Art 7 MTShojikuriakoseTNo ratings yet

- Astm A333 PDFDocument8 pagesAstm A333 PDFrams789No ratings yet

- Astm A 519Document12 pagesAstm A 519ShojikuriakoseTNo ratings yet

- DNV Inspection RequirementDocument1 pageDNV Inspection RequirementShojikuriakoseTNo ratings yet

- Filter Element Specification Sheet - OHIO INDUSTRIALDocument1 pageFilter Element Specification Sheet - OHIO INDUSTRIALShojikuriakoseTNo ratings yet

- ASNT NDT Level III Certification GuideDocument8 pagesASNT NDT Level III Certification GuideIndigo Wave0% (2)

- A 105 N PDFDocument6 pagesA 105 N PDFShojikuriakoseTNo ratings yet

- Zinc CoatingsDocument16 pagesZinc CoatingsShojikuriakoseT100% (2)

- ASNT NDT Level III Certification GuideDocument8 pagesASNT NDT Level III Certification GuideIndigo Wave0% (2)

- ASNT NDT Level III Certification GuideDocument8 pagesASNT NDT Level III Certification GuideIndigo Wave0% (2)

- Hampel PaintDocument2 pagesHampel PaintdaimaheshNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Transport in PlantsDocument28 pagesTransport in PlantsGautam Dayal100% (1)

- GV Actuator Adv. Rev.4 (Webinar)Document37 pagesGV Actuator Adv. Rev.4 (Webinar)Boriche DivitisNo ratings yet

- Chapter 1.3 Women EnvironmentDocument27 pagesChapter 1.3 Women Environmentdonna mendozaNo ratings yet

- Installation Instructions For The TBLZ-1-27-a, Set of Electrical Connections For Air Heater/air Cooler, Water GOLD, Version E/FDocument2 pagesInstallation Instructions For The TBLZ-1-27-a, Set of Electrical Connections For Air Heater/air Cooler, Water GOLD, Version E/FKaptinNo ratings yet

- Final Diesel DesignDocument111 pagesFinal Diesel DesignJerome JeremiasNo ratings yet

- 2005 Dec - Approved Module For Stage Wise Training OfLoco Running StaffDocument91 pages2005 Dec - Approved Module For Stage Wise Training OfLoco Running StaffR Sathish KumarNo ratings yet

- ASME Thermal Shock Design Guidleines 2007Document8 pagesASME Thermal Shock Design Guidleines 2007Roddy CastroNo ratings yet

- Tesla meter,Gauss meter、Magnetic flux densimeter、Introduction Handy typeDocument2 pagesTesla meter,Gauss meter、Magnetic flux densimeter、Introduction Handy typesomkiat kongprasiatNo ratings yet

- DCA0012601P0001 Dca0012601p0001Document7 pagesDCA0012601P0001 Dca0012601p0001Sakahi SharmaNo ratings yet

- Busduct PDFDocument7 pagesBusduct PDFrohith87nairNo ratings yet

- Curriculum - ITDocument169 pagesCurriculum - ITMeenakshi TripathiNo ratings yet

- BV Webinar SlidesDocument64 pagesBV Webinar SlidessuinsasNo ratings yet

- LR HAZID Study For LNG Fuel SupplyDocument116 pagesLR HAZID Study For LNG Fuel SupplyMatteo ConciNo ratings yet

- PedgkDocument32 pagesPedgkGokulakrishnanNo ratings yet

- SNP Tanker ReportDocument3 pagesSNP Tanker ReportfikrifadzalNo ratings yet

- Heui PDFDocument56 pagesHeui PDFGerman Ramos German Ramos100% (5)

- Lect01 (MT 353)Document14 pagesLect01 (MT 353)Afzal Khan sulemaniNo ratings yet

- Refrigeration & Air Conditioning Systems ExplainedDocument23 pagesRefrigeration & Air Conditioning Systems ExplainedLovedeep LoviNo ratings yet

- Nuclear Industry in ChinaDocument37 pagesNuclear Industry in ChinaagbnetNo ratings yet

- HC100 PDFDocument2 pagesHC100 PDFTommy MarínNo ratings yet

- Manual - IR Nirvana Troubleshooting GuideDocument63 pagesManual - IR Nirvana Troubleshooting GuideKurserg92% (51)

- FullReport Status Quo Analysis of Various Segments of Electric Mobility-CompressedDocument342 pagesFullReport Status Quo Analysis of Various Segments of Electric Mobility-CompressedNishi MandaviaNo ratings yet

- Faculty of Engineering Technology Department of Civil Engineering TechnologyDocument3 pagesFaculty of Engineering Technology Department of Civil Engineering TechnologyNrlFlztiNo ratings yet

- GEI41047 Rev K - Liquid FuelDocument24 pagesGEI41047 Rev K - Liquid FuelHameed100% (3)

- Kac 728 628 528Document12 pagesKac 728 628 528solungeNo ratings yet

- Eurosun2014-Proceedings - ImportentDocument1,524 pagesEurosun2014-Proceedings - ImportentAkhileshkumar PandeyNo ratings yet

- Wiring and Replacement Float Switch For Low Water Cut-Offs Installation InstructionsDocument2 pagesWiring and Replacement Float Switch For Low Water Cut-Offs Installation InstructionsWattsNo ratings yet

- Yanmar 3TNV76-DWL Engine Parts CatalogDocument20 pagesYanmar 3TNV76-DWL Engine Parts CatalogDarryl CareyNo ratings yet

- Work, Energy and PowerDocument4 pagesWork, Energy and PowerSwaapnil Shinde100% (1)