Professional Documents

Culture Documents

T 013573 e

Uploaded by

qfacuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T 013573 e

Uploaded by

qfacuCopyright:

Available Formats

INTERNATIONAL

STANDARD

IS0

7005-I

First edition

1992-04-I 5

Metallic

flanges

Part 1:

Steel flanges

Brides rnb ta lliques

This is a free 7 page sample. Access the full version online.

Partie I: Brides en acier

Reference number

IS0 7005-l : 1992 (E)

IS0 7005-I : 1992 (E)

Contents

This is a free 7 page sample. Access the full version online.

Section

Page

1: General .....................................................

1.1

Scope

1.2

Normative

1.3

Definitions

.......................................................

1.4

Designation

of types, components

...........................................................

references

..............................................

and facings.

........................

Section 2: General requirements.

.......................................

2.1

Pressure/temperature

ratings

.......................................

2.2

Materials

..............................................

2.3

Repairs

2.4

Dimensions

2.5

Facings

2.6

Spot-facing

or back-facing.

2.7

Tolerances

.......................................................

2.8

Marking

2.9

lnspectionandtest

2.10

Information

and bolting.

..........................................................

.......................................................

..........................................................

.........................................

................................................

by the purchaser

5

5

..........................................................

to be supplied

...........................

Section 3: Dimensions

.................................................

Section 4: Tolerances

..................................................

6

6

11

47

0

IS0

1992

All rights reserved. No part of this publication may be reproduced

or utilized in any form or by any

means, electronic

or mechanical,

including photocopying

and microfilm,

without

permission

in

writing from the publisher.

International

Case postale

Printed

ii

Organization

for Standardization

56 l CH-1211 Geneve 20 l Switzerland

in Switzerland

IS070051

:1992 (El

Annexes

A Bevel for specified wall thicknesses from 5 mm to 22 mm inclusive

greaterthan22mm......................................................

and

49

B Acceptable bevel designs for unequal wall thicknesses

(pipeline applications).

...................................................

50

C

Recommended

bevel for equal wall thicknesses f at the end of the flange

hub from 5 mm to 22 mm inclusive and greater than 22 mm (pipeline applications).

51

Guidance

on flange materials

52

Guidance

on pressure/temperature

Design criteria (pipeline applications).

Bibliography........................................................

.........................................

ratings.

.............................

62

..................................

78

79

Tables

1

Surface finish for facings types A, B and E/F (large) . . . . . . . . . . . . . . . . . . . . . .

Surface finish values for facings types C/D, E/F (small), G/H and J . . . . . . . . .

Synoptic

table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This is a free 7 page sample. Access the full version online.

4 Dimensions of flange facings for PN 2,5, PN 6, PN 10, PN 16, PN 25

andPN40..............................................................

11

15

5 Dimensions of flange facings up to nominal size DN 900 for PN 20,

PN50, PN 110, PN 150, PN260and

PN420 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

6 Dimensions of flange facings for nominal sizes DN 950 to DN 1 500

forPN20,

PN50, PN IlOand PN 150.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

Dimensions

of ring-joint

.......................................

19

Dimensions

of PN 2,5 flanges

.........................................

23

Dimensions

of PN 6 flanges.

..........................................

25

10

Dimensions

of PN 10 flanges.

.........................................

27

11

Dimensions

of PN 16 flanges.

.........................................

29

12

Dimensions

of PN 20 flanges.

.........................................

31

13

Dimensions

of PN 25 flanges.

.........................................

33

14

Dimensions

of PN 40 flanges.

.........................................

35

15

Dimensions

of PN 50 flanges.

.........................................

37

16

Dimensions

of PN 1 IO flanges.

........................................

39

17

Dimensions

of PN 150 flanges.

........................................

41

18

Dimensions

of PN 260 flanges.

........................................

43

19

Dimensions

of PN 420 flanges.

........................................

45

20

Tolerances.........................................................

21

Minimum

facings

hub radius after back-facing.

47

.................................

48

This is a free 7 page sample. Access the full version online.

Is0 7005-l : 1992 E)

D.1 Basic properties and reference standards for materials used for PN 2,5,

PN6, PN 10, PN 16, PN25and

PN40flanges..

..............................

53

0.2

Reference standards for materials used for PN 20, PN 50, PN 110,

PN 150, PN260and

PN420flanges

........................................

57

D.3

Materials applicable to tables 12, 15, 16 and 17 covering PN 20,

PN 50, PN 110 and PN 150 flanges types 05 and 11 in the size

range DN 300 and larger for pipeline applications.

............................

60

E.l Pressure/temperature

(P/T) ratings for flanges made using material

groupslEOto6EO

.......................................................

63

E.2 Pressure/temperature

(P/T) ratings for flanges

groups7EOto9EO.......................................................

64

made using material

E.3 Pressure/temperature

(P/T) ratings for flanges made using austenitic

stainless steels (based on 0,2 % proof stress), material groups IOEO to 15E0 . . . . . .

65

E.4 Pressure/temperature

(P/T) ratings for flanges made using austenitic

stainless steels (based on 1 % proof stress), material groups IOEO to 15E0. . . . . . . .

66

E.5 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group

67

E.6 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group

E.7 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group

E.8 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group

E.9 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group

1A2

67

IA3

68

IA4

68

IA5

69

E.10 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group

E.11 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group

E.12 Pressure/temperature

(P/T) ratings

materials...............................................................

made using group

for flanges

IA1

IA7

69

IA9

70

IA10

70

E.13 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group

E.14 Pressure/temperature

( P/T) ratings for flanges

materials . . . . . . . . . . . . . . . . . . ,............................................

made using group

IA13

71

IA14

71

P/T) ratings for flanges made using group 2Al

E.15 Pressure/temperature

materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

72

E.16 Pressure/temperature

P/T) ratings for flanges

materials...............................................................

made using group 2A2

72

NW

E.17 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group 2A3

E.18 Pressure/temperature

(P/T) ratings for flanges

materjals...............................................................

made using group 2A4

E.19 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group 2A5

E.20 Pressure/temperature

(P/T) ratings for flanges

materials...............................................................

made using group 2A6

73

74

75

76

IS0 7005-l : 1992 (El

(P/T) ratings for flanges

E.21 Pressure/temperature

materials...............................................................

E.22

Pressure/temperature

made using group 2A7

(P/T) ratings for pipeline flanges

77

.................

77

This is a free 7 page sample. Access the full version online.

Figures

1

Flanges - TypesOlto05

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..I.......

Flanges - Typesllto15

.............................................

Flange-Type21....................................................

Ancillary

- Types 32 to 34. . . . . . . . . . . . . . . . . . . . . . . .

Illustration

of flange facings (types A to J) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IO

PN 2,5, PN 6, PN 10, PN 16, PN 25 and PN 40 flange facing dimensions

PN 20, PN 50, PN 110, PN 150, PN 260 and PN 420 flange facing dimensions

Minimum

components

for flanges

hub radius after back-facing.

A.1

Bevel for specified

B.l

Acceptable

wall thicknesses

......

14

..

16

..................................

48

t ..................................

49

..................

50

Recommended

bevel for equal wall thicknesses t at the end

C.l

of the flange hub.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51

bevel designs for unequal wall thicknesses.

IS0 7005-l : 1992 (El

Foreword

IS0 (the International

Organization

for Standardization)

is a worldwide

federation of

national standards bodies (IS0 member bodies). The work of preparing International

Standards is normally carried out through IS0 technical committees.

Each member

body interested in a subject for which a technical committee has been established has

the right to be represented

on that committee.

International

organizations,

governmental and non-governmental,

in liaison with ISO, also take part in the work. IS0

collaborates

closely with the International

Electrotechnical

Commission

(IEC) on all

matters of electrotechnical

standardization.

Draft International

Standards adopted by the technical committees

are circulated to

the member bodies for voting.

Publication

as an International

Standard

requires

approval by at least 75 % of the member bodies casting a vote.

International

Standard IS0 7005-l was prepared by Technical Committee ISO/TC 5,

Ferrous metalpipes

and metallic fittings, Sub-Committee

SC IO, Metallic flanges and

their joints.

This first edition of IS0 7005-1, together with IS0 7005-Z and IS0 7005-3, cancels and

replaces IS0 2084 : 1974, IS0 2229 : 1973 and IS0 2441 : 1975, of which they constitute a technical revision.

IS0 7005 consists

of the following

Part 7: Steel flanges

Part 2: Cast iron flanges

parts, under the general title Metallic

This is a free 7 page sample. Access the full version online.

Part 3: Copper alloy and composite

flanges:

flanges

Annexes A and B form an integra I part of this part of IS0 7005. An nexes C to G are for

information

only.

vi

IS0 70051 : 1992 (E)

Introduction

Various flange systems based on differing design criteria have been in use throughout

the world for many years. Recognizing the increasing difficulties arising from such *a

situation,

representatives

of ISO/TC 5, Ferrous metal pipes and metallic fittings,

ISOITC 67, Materials and equipment

for petroleum and natural gas industries,

and

ISO/TC 153, Valves, established principles for the preparation of an International Standard for a single series of flanges.

This part of IS0 7005 is based on the American and European steel flange systems

combined with some changes to the dimensions specified in the two systems. PN 20,

PN 50, PN 110, PN 150, PN 260 and PN 420 steel flanges are designed to be interchangeable with flanges to American standards ANSI/ASME

B16.5 and MSS SP44;

they are not identical but are deemed to comply with dimensions

specified in

ANSI/ASME

B16.5 and MSS SP44 as appropriate.

This part of IS0 7005 takes into account unpublished work of the European Committee

for Standardization

CEN/TC 74, Flanges, up to 1972 and the amendments that would

have been necessary to IS0 2229 arising from the revision of ANSI/ASME

816.5 up to

1988 and MSS SP44 : 1985, plus amendments

due to the changes in pressure designation. In the American system, flanges are designated by a Class rating, but these

ratings have now been converted

to nominal pressure (PN) designations.

The

equivalent PN designations

are as follows:

This is a free 7 page sample. Access the full version online.

Class 150: PN

Class 300: PN

Class 600: PN

Class 900: PN

Class 1500: PN

Class 2500: PN

20

50

110

150

260

420

This part of IS0 7005 does not specify materials or pressure/temperature

ratings of

flanges, but guidance is given in annexes D and E on selected materials and pressure/temperature

ratings of flanges (see note IO to tables 8, 9, 10, 11, 13 and 14,

page 46) using the materials listed. Annex D lists German (DIN) steels on which ,the

European flange system is based and American (ASTM) steels on which the American

flange system is based, together with international

(ISO) steels given in published and

draft International

Standards.

Users of this part of IS0 7005 may wish to use steels

specified in national standards in preference to those given in annex D. Annex E gives

the pressure/temperature

ratings for certain flanges made using the materials given in

annex D. (See E.1 and tables E.l to E.4 for restrictions

on the applicability

of

pressure/temperature

ratings to flanges.)

Ultimately it is the intention that only IS0 materials and pressure/temperature

ratings

of flanges made using IS0 materials will be specified in this part of IS0 7005; this will

be achieved in a revision and when work on standardizing

the IS0 materials and their

elevated temperature

properties has been completed.

Flange details in all three parts of IS0 7005 are such as that flanges having the same PN

designations

and nominal size (DN) designations

and compatible flange facings will

mate together.

vii

This is a free 7 page sample. Access the full version online.

ISO 7005-1:1992 Metallic flanges - Part 1: Steel flanges

The remainder of this document

is available for purchase online at

www.saiglobal.com/shop

SAI Global also carries a wide range of publications from a wide variety of Standards Publishers:

Click on the logos to search the database online.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Alchemical Psychology Uniform Edition o - HillmanDocument207 pagesAlchemical Psychology Uniform Edition o - HillmanElsy Arana95% (22)

- Masonry Stove PlansDocument34 pagesMasonry Stove PlansBlayne Sukut100% (5)

- GX Audit Internal Audit Risk and Opportunities For 2022Document26 pagesGX Audit Internal Audit Risk and Opportunities For 2022Muhammad SamiNo ratings yet

- 4 5994641624901094407Document20 pages4 5994641624901094407Success100% (1)

- Hunch or Reason?: Reading File 11Document2 pagesHunch or Reason?: Reading File 11georgiana dinuNo ratings yet

- Nag 330Document12 pagesNag 330qfacuNo ratings yet

- 43312Document8 pages43312qfacuNo ratings yet

- LM3915Document24 pagesLM3915budituxNo ratings yet

- Prev - ORIA - Diseño de Recipientes A PresionDocument30 pagesPrev - ORIA - Diseño de Recipientes A PresionRuben ChumaceroNo ratings yet

- Computo de Analisis de Precios UnitariosDocument63 pagesComputo de Analisis de Precios UnitariosAngel CMNo ratings yet

- Wideband analog switch for high-end color monitorsDocument14 pagesWideband analog switch for high-end color monitorsqfacuNo ratings yet

- E7318 Maximus V GeneDocument208 pagesE7318 Maximus V GeneqfacuNo ratings yet

- Scia Engineer Tutorial Parametric InputDocument28 pagesScia Engineer Tutorial Parametric InputqfacuNo ratings yet

- Viewsonic E655 - TDA4850 Vertical Horizontal ControllerDocument20 pagesViewsonic E655 - TDA4850 Vertical Horizontal ControllerqfacuNo ratings yet

- Viewsonic E655 - TDA8172 - Uso Con TDA9102Document12 pagesViewsonic E655 - TDA8172 - Uso Con TDA9102qfacuNo ratings yet

- Viewsonic E655-3Document5 pagesViewsonic E655-3qfacuNo ratings yet

- Viewsonic E655-1 PowerDocument6 pagesViewsonic E655-1 PowerqfacuNo ratings yet

- Viewsonic E655 - Tda8172 TV Vertical DeflectionDocument7 pagesViewsonic E655 - Tda8172 TV Vertical DeflectionqfacuNo ratings yet

- LG He It Ss w2486lDocument2 pagesLG He It Ss w2486lqfacuNo ratings yet

- Viewsonic E655 TIP122 DarlingtonDocument3 pagesViewsonic E655 TIP122 DarlingtonqfacuNo ratings yet

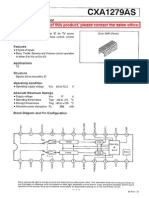

- Ic Cxa1279asDocument12 pagesIc Cxa1279ascintaka2000No ratings yet

- Viewsonic E655 - TDA4850Document16 pagesViewsonic E655 - TDA4850qfacuNo ratings yet

- Technics SH Ge50 PPDocument15 pagesTechnics SH Ge50 PPqfacuNo ratings yet

- Wideband analog switch for high-end color monitorsDocument14 pagesWideband analog switch for high-end color monitorsqfacuNo ratings yet

- Viewsonic E655 - TDA4850 Vertical Horizontal ControllerDocument20 pagesViewsonic E655 - TDA4850 Vertical Horizontal ControllerqfacuNo ratings yet

- Ic Cxa1279asDocument12 pagesIc Cxa1279ascintaka2000No ratings yet

- DVDSubEdit ManualDocument27 pagesDVDSubEdit ManualqfacuNo ratings yet

- LG Led - E2340v-Pnv UserDocument28 pagesLG Led - E2340v-Pnv UserqfacuNo ratings yet

- ViewSonic w2433Document2 pagesViewSonic w2433qfacuNo ratings yet

- Viewsonic E655 - TDA8172 - Uso Con TDA9102Document12 pagesViewsonic E655 - TDA8172 - Uso Con TDA9102qfacuNo ratings yet

- Viewsonic E655-1Document1 pageViewsonic E655-1qfacuNo ratings yet

- Chapter 16 Sheet Metal Design Solidworks 2003Document80 pagesChapter 16 Sheet Metal Design Solidworks 2003monado14No ratings yet

- Grade 9 SyllabusDocument23 pagesGrade 9 SyllabusClopzNo ratings yet

- 8th Edition of The AJCC - TNM Staging System of Thyroid Cancer - What To Expect (ITCO#2)Document5 pages8th Edition of The AJCC - TNM Staging System of Thyroid Cancer - What To Expect (ITCO#2)Valentina IndahNo ratings yet

- FDocument109 pagesFssissaaNo ratings yet

- Vaiana Et Al (2021)Document11 pagesVaiana Et Al (2021)Raffaele CapuanoNo ratings yet

- Nodal Officer Wise Student ListDocument48 pagesNodal Officer Wise Student ListguerellaNo ratings yet

- Material For Werable AntennaDocument4 pagesMaterial For Werable AntennaMujeeb AbdullahNo ratings yet

- Rebecca A. Endaya Beed-Iii Art Education: ExploreDocument5 pagesRebecca A. Endaya Beed-Iii Art Education: ExploreBhecca Endaya0% (1)

- Useful List of Responsive Navigation and Menu Patterns - UI Patterns - GibbonDocument16 pagesUseful List of Responsive Navigation and Menu Patterns - UI Patterns - Gibbonevandrix0% (1)

- Mahabharata Book 9 Shalya ParvaDocument413 pagesMahabharata Book 9 Shalya Parvaavacdis1969No ratings yet

- Total Cost of Ownership in PV Manufacturing - GuideDocument12 pagesTotal Cost of Ownership in PV Manufacturing - GuidebirlainNo ratings yet

- Impact of Aadhaar On Different Sectors of SocietyDocument5 pagesImpact of Aadhaar On Different Sectors of SocietyPunyak SatishNo ratings yet

- Essay #01 (First Draft)Document2 pagesEssay #01 (First Draft)thanhtam3819No ratings yet

- Ozone Layer EssayDocument7 pagesOzone Layer Essayb71bpjha100% (2)

- Dslam Commissioning Steps Punjab For 960 PortDocument8 pagesDslam Commissioning Steps Punjab For 960 Portanl_bhn100% (1)

- CHAPTER 8 SULLIVAN MyReviewerDocument7 pagesCHAPTER 8 SULLIVAN MyReviewerFrances LouiseNo ratings yet

- Embodied experience at the core of Performance StudiesDocument10 pagesEmbodied experience at the core of Performance StudiesVictor Bobadilla ParraNo ratings yet

- Sense Organs Lesson PlanDocument16 pagesSense Organs Lesson PlanBernard DayotNo ratings yet

- Should A Christian Believer Wear An ANKH?: Luxury Art By: Ketu'Rah GloreDocument4 pagesShould A Christian Believer Wear An ANKH?: Luxury Art By: Ketu'Rah GloreMyk Twentytwenty NBeyondNo ratings yet

- Complex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsDocument8 pagesComplex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsJorge Luis SotoNo ratings yet

- Introduction to Philippine LiteratureDocument61 pagesIntroduction to Philippine LiteraturealvindadacayNo ratings yet

- ST Biology Nervous System IEP TestDocument3 pagesST Biology Nervous System IEP TestDanielle WilsonNo ratings yet

- Investors' Perceptions of StocksDocument95 pagesInvestors' Perceptions of StocksPriya Ramanathan67% (3)

- Sexual ExtacyDocument18 pagesSexual ExtacyChal JhonnyNo ratings yet

- MR - Abhishek JiDocument4 pagesMR - Abhishek Jimalikgaurav01No ratings yet

- MARS Motor Cross Reference InformationDocument60 pagesMARS Motor Cross Reference InformationLee MausNo ratings yet

- The Neyveli Lignite Deposits (Cauvery Basin), India: Organic Composition, Age and Depositional PatternDocument53 pagesThe Neyveli Lignite Deposits (Cauvery Basin), India: Organic Composition, Age and Depositional PatternAlok SinghNo ratings yet