Professional Documents

Culture Documents

2.manual ETR300S V1.0 Eng

Uploaded by

Agustinus Phatub KurniawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.manual ETR300S V1.0 Eng

Uploaded by

Agustinus Phatub KurniawanCopyright:

Available Formats

Release Date: Nov. 2009 / Manual Revision: 1.

00

Load Break Switch Control ETR300S

Users Manual

ENTEC

ENTEC

ELECTRIC & ELECTRONIC CO., LTD

Copyright 2009 by ENTEC ELECTRIC & ELECTRONIC CO., LTD all right reserved.

Forerunner Distribution & Automation

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

CONTENT

1. Product Introduction ..................................................................................................... 6

1.1. Introduction ......................................................................................................................... 6

1.2. Characteristic summary ....................................................................................................... 7

2. Technical Specification ................................................................................................. 10

2.1. Input and Output ................................................................................................................ 10

2.2. Environment Test ............................................................................................................... 12

2.3. Metering Accuracy ............................................................................................................ 13

2.4. Monitoring ......................................................................................................................... 14

2.5. Event Recorder .................................................................................................................. 18

2.6. Maintenance ...................................................................................................................... 21

2.7. Communication ................................................................................................................. 21

3. Dimension and structure ................................................................................................. 22

4. External Input/Output Connector ................................................................................... 23

4.1. Current Input(Connector type:STLZ960-10) .................................................................... 24

4.2. Voltage Input(Connector type:STLZ960-6P,8P) ............................................................... 24

4.3. Digital Output(DO) ........................................................................................................... 25

4.4. Digital Input(DI) ................................................................................................................ 25

4.5. Power supply input& Modem power supply output .......................................................... 26

4.6. Remote Communication Port(modem connection) ........................................................... 26

4.7. 485 Communication Port ................................................................................................... 27

4.8. Ethernet Port(RJ45) ........................................................................................................... 27

5. User Interface Panel .................................................................................................... 28

5.1. Construction ...................................................................................................................... 29

5.2. Operation Manual (LCD instruction) ................................................................................ 36

5.3. LCD Menu Use.................................................................................................................. 43

6. Global Setting ............................................................................................................... 47

6.1. System ............................................................................................................................... 47

6.2. Communication ................................................................................................................. 54

6.3. Event Recorder .................................................................................................................. 69

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

6.4. Monitoring ......................................................................................................................... 70

6.5. PLC.................................................................................................................................... 81

6.6. Other setting items............................................................................................................. 86

7. Group Setting ................................................................................................................ 89

7.1. Fault pickup element ......................................................................................................... 90

7.2. Inrush Current Restraint Function ..................................................................................... 95

7.3. Directional Detection Function ......................................................................................... 98

7.4. SECTION ........................................................................................................................ 102

7.5. Phase angle synch detect ................................................................................................. 106

7.6. Line cut / Phase lost detect .............................................................................................. 106

7.7. Overcurrent detect element.............................................................................................. 107

8. EVENT ........................................................................................................................ 109

8.1. Operation Event............................................................................................................... 109

8.2. Fault Event ...................................................................................................................... 110

8.3. Fault Cycle - Summary.................................................................................................... 112

8.4. System Events ................................................................................................................. 113

8.5. Set Change Event ............................................................................................................ 114

8.6. Aver. Load/Min ................................................................................................................ 115

8.7. Peak. Load/Hour.............................................................................................................. 115

8.8. Peak. Load/Day ............................................................................................................... 116

8.9. Diagnostic Event ............................................................................................................. 117

8.10. PQM .............................................................................................................................. 120

8.11. Clear Saved Data ........................................................................................................... 121

9. Maintenance ................................................................................................................ 122

9.1. Count ............................................................................................................................... 122

9.2. Interrupt Time .................................................................................................................. 129

9.3. Contact Wear ................................................................................................................... 130

9.4. Data Reset........................................................................................................................ 130

9.5. CCU Information ............................................................................................................. 131

10. Time ........................................................................................................................... 132

11. Status .......................................................................................................................... 133

11.1. Switch ............................................................................................................................ 133

11.2. Input Ports ..................................................................................................................... 135

11.3. Output Ports ................................................................................................................... 135

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

12. Metering .................................................................................................................... 136

12.1. Current ........................................................................................................................... 136

12.2. Voltage ........................................................................................................................... 137

12.3. Frequency ...................................................................................................................... 138

12.4. Power ............................................................................................................................. 138

12.5. Energy............................................................................................................................ 139

12.6. Demand Current ............................................................................................................ 139

12.7. Unbalance ...................................................................................................................... 140

12.8. Harmonics ..................................................................................................................... 140

12.9. True R.M.S .................................................................................................................... 141

12.10. TD Monitoring............................................................................................................. 141

12.11. CCU Reference ............................................................................................................ 141

13. PLC function ............................................................................................................ 142

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

1. Product Introduction

1.1. Introduction

ETR300-S01 is embedded in Distribution Automation 25.8kV SF6 gas insulated load break

switch(Pole mount) control box.

It receives measurement information(3 phases current &

voltages) and status information from Switch, and meters current and voltage, detecs FI, Line cut,

Live line/Dead line, Unbalance, and send those information to SCADA(Master station).

As well as, controlling a swich by receiving Control Signal from SCADA, provides Distribution

Automation and minimize a fault area.

ETR300-S01 monitors not only electric quality of dirstirbution line but also, provides Section

operation in case of fault occurring and minimize its fault area.

All events occurring in the distribution line, are saved and provides fault analysis. With using

DNP3.0 Protocol, provides monitored status to SCADA for switch operation. Not only DNP3.0

Protocol, other communication protocols can beprovided by users request.

Switch operation is available by operation buttion on front panel. Fault detect Enable/Diable,

Fault

detect

Enable/Disable,

SECTION

function

Enable/Disable,

operation

selection

Local/Remote, Operation lock Lock/Unlock, ALTERNATE SETTING Enable/Disable, SEF

function Enable/Disable, SEC/TIE LOCKOUT Enable/Disable can be set.

INTERFACE SOFTWARE is very much convenient to have the maintenance of Set change and

Operation records in PC. It also has Zoom In/Out feature to analize Fault wave and Digital

operation signal with real time so that it provides much more uniq functions for the users.

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

1.2. Characteristic summary

MONITORING

Phase fault detect(Permenant , Instantaneous)

Earth fault detect(Permenant, Instantaneous)

SEF fault detect(Permenant, Instantaneous)

Inrush current restraint (Phase/Earth/SEF)

Directional (Phase/Earth/ SEF)

SECTION operation function

Unbalance detect

Line cut/phase loss detect element

Live line detect

Operation counter limit

Switch contact wear monitoring

Battery auto load test

Power Quality Monitoring

-

Interrupt

Sag

Swell

Harmonics

Current Unbalance

Voltage Unbalance

Under Voltage

Over Voltage

Under Frequency

Over Current

DC Analog Input Monitoring

Zero Sequence voltage(V0) detect

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

EVENT RECORDER

Switch Operation Record Last 256 events

Fault Event Record Last 256 events

Fault Waves(20 cycles 8EA) record Last 8 events

System Event Record Last 2048 events

Set Change Event Last 100 events

Average Load Event Record Last 1024 events

Max. Load per hour Event Record Last 1024 events

Max Load per day Event Record Last 1024 events

Diagnostic Event Record Last 512 events

PQM Monitoring Event Record Last 100 events

METERING

Phase Current and Phase Angle, Fault Current and Angle, SEF Current and Angle

Voltage and Angle between phases, Forward/Revserse/Zero Sequence and Angle

Frequency magnitude and changing rate per second

Real Power/Apparent Power/Reactive Power per phase

Power Factor per phase

Forward/Reverse Phase Energy

Demand

Source/Load side Voltage and Current Unbalance

Voltage and Current Harmonic rate

Phase True R.M.S voltage and current

DC Analog Input value

ETR300 Inside Temperature

MAINTENANCE

Number of Restart

Number of Diagnostic detec

Number of Switch fault occurred

Number of Instantaneous current fluctuation and its number per phase

Number of PQM occurred and accumulated time

Switch contact wear

COMMUNICATIONS

Side Panel PORT1 RS232 Serial port : DNP 3.0, Modbus and IEC60870-5-101 Protocol

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

Side Panel PORT2 RS485 Serial port : DNP 3.0, Modbus and IEC60870-5-101 Protocol

Side Panel PORT3 RJ45 port : DNP 3.0 IEC60870-5-104 Protocol

Side Panel PORTF RS232 Serial port : ETR300-R Interface Software

USER INTERFACE

Fault Indicator

Manual battery load test: Battery voltage and chaged voltage

Dual function keypad

204 character display (LCD or VFD: Vacuum Fluorescent Display)

43 LED indicator Fault Indicator, Sequence Status, Battery status and so on

Fron Panel RS232 Port

Help Message

Security(Password)

AUXILIARY OUTPUTS

16 number of PLC Progoram available

AUXILIARY INPUTS

16 number of PLC Program available

Other

Fault Injection test available

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

2. Technical Specification

2.1. Input and Output

System

3 phases- 3 wires or 3 phases 4 wires, Max.38kW, Max 800A

Frequency

50/60 Hz System and ABC/ACB phase rotation

Control voltage input

AC Power supply input 110V/220Vac or other voltage(+10%,-15%)

Rated battery voltage : 24Vdc

User DC Poer Output Option

DC Power supply voltage : 12, 15, 24Vdc

Continuous DC Power supply : 30W

DC Power for 10 second: 70W

Voltage Transformer Input (VT) Standard

V11, V12, V13, V21, V22, V23 and V10

Input voltage range : Phase-Neutral continuous < 6V

Load burden : 0.002VA(4V)

Voltage Transformer Input (VT) Option

V11, V12, V13, V21, V22, V23 and V10

Input voltage range : Phase-Neutral continuous < 300V

Load burden : 0.6VA(300V), 0.2VA(220V), 0.05VA(120V), 0.02VA(67V)

Current Transformer (CT)

IA,IB,IC and IG, SEF, ZCT

IA,IB,IC,IG input current range

Nominal: AC 0.6Arms

Continuous: 2A

25A for 1 sec

10

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

Load burden : 0.38VA(1A)

SEF input current range

Rated current : 0.05A

Continuous current : 0.16A

0.6A for 1sec

Load burden : 0.0375VA(0.05A)

ZCT input current range Option

Rated current : 1.5mA

Continuous ????????????????? mA

200mA for 1sec

Load burden : 0.0005VA(1.5mA)

Control Input Option

Control Input 8 channel

Rated voltage and operation range

250Vdc(-15%,+20%)

125Vdc(-15%,+20%)

48Vdc(-15%,+20%)

24Vdc(-15%,+20%)

12Vdc(-10%,+30%)

Operation current: at rated voltage, < 5mA

Control Output Contact Option

Control Input 8 channel

Open 5 channel

Close 5 channel

Alarm 1 channel

Auto surge protection Varistor 300Vac / 350Vdc

Operation and release time: at +20(+68) , < 5ms

Max operation power supply

Table 2-1. Max. Operation power supply

(L/R=7ms)

(cos=0.4)

125Vdc

48Vdc

24Vdc

250Vac

125Vac

0.1A

0.8A

3A

3A

5A

ENHANCED TECHNOLOGY

11

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

2.2. Environment Test

Dielectric Strength

CT Input, VT Input, Control Power Input, Fiber-optic insulation Input and Relay output

AC 60, 2/1 minute

Impulse Voltage

IEEE C62.45 (1992) , 6(1.250), 3(820) of Relay System for Radio

Electromagnetic Interference Transceiver.

Surge Withstand Capability

Protection relay and Relay system protection purpsoe IEEE C37.90.1 - 1989 IEEE SWC test

(3 Vibration1 to 1.5, 5 fast saturation 1.250)

IEEE C37.90.2 - 1987 IEEE Test, Test use standard, relay system for Radio Electromagnetic

Interface that comes from Transceiver, 10 V/m(150 and 450, 5 W transmitter 10)

Vibration Test

IEC 255-21-1-1988 Electric Relay, Part 21: Metering relay and protection device vibration,

impact, crash and earthquake test, Section One - Vibration tests (sinusoidal), Class 2

IEC 255-21-1-1988 Electrical relays, Part 21 : Vibration, shock, bump, and seismic tests on

measuring relays and protection equipment, Section One - Vibration tests (sinusoidal), Class 2

Control Operating Temperature

Operation range : -25+70(-13+158)

LCD : -20+70(-4+158) Standard

VFD(Vacuum Fluorescent Display-Vacuum florecense zero sequence output device) : 40+85(-40+185) optoin

12

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

2.3. Metering Accuracy

Measurement values for metering and protection are based on Input voltage and current which are

eliminated Harmonic.

Voltage metering

Rated voltage : AC voltage 4 V

Each phase voltage : 0.2 %(Rated voltage 80 120 %), 0.5

Zero sequence voltage(Vo) : 0.2 %(Rated voltage 80 120%), 0.5

3V1, 3V0, 3V2 : 0.6 %(Rated voltage 80 120%), 1

Current metering

Rated current : AC 0.6 Arms

IA, IB, IC, IG : 0.5 mA 0.1 % of reading(0.03~1.5 A), 0.5

IN : 0.005 mA + 0.5 % of reading(0.5~16.0 mA), 1

3I1, 3I0, 3I2 : 0.01 A 3 % of reading(0.003~1.5A ), 1

Power metering

Power : 1.2 %(at rated voltage>80 %, at rated current>0.03)

Rea Power : 0.7 % PF=1, 1% PF>0.87(at rated voltage>80%, at rated current>0.03)

Reactive Power : 0.7 % PF=0, 1% PF<0.5(at rated voltage>80%, at rated current>0.03)

Harmonic metering : 5%

ENHANCED TECHNOLOGY

13

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

2.4. Monitoring

Fault detect function

Phase fault pickup level ................................................. OFF, 50 ~ 630A (step: 5A)

Earth fault pickup level ................................................. OFF, 25 ~ 315A (step: 5A)

SEF pickup level ........................................................... OFF, 0.1 ~ 10.0A (step: 0.1A)

Dropout.......................................................................... Pickup level 96 ~ 98%

Instantaneous FI detect time .......................................... 1 ~ 180sec (step: 1sec)

Instantaneous FI detect time .......................................... 1 ~ 180sec (step: 1sec)

Phase Directional detect function

Pole voltage ................................................................... normal voltage V1

Directional detect .......................................................... Disable, Enable

Max. Torque angle ......................................................... 0 ~ 345 (step: 15 )

Min. Operation voltage.................................................. 0, 10 ~ 80% (step: 1% )

Phase angle accuracy ..................................................... 2

Internal operation delay ................................................. 1.5cycle

Ground/SEF Directional detect function

Pole voltage ................................................................... Zero sequence voltage Vo

Source side VTs must be Wye connection.

Directional detec ........................................................... Disable, Enable

Max. Torque Angle ........................................................ 0 ~ 345 (step: 15 )

Min. Operation voltage.................................................. 0, 10 ~ 80% (step: 1% )

Phase angle accuracy ..................................................... 2

Internal operation delay ................................................. 1.5cycle

Phase/Ground/SEF Cold Load Pickup Blocking function

Pickup level ................................................................... 1 ~ 20 MTC (step: 1 MTC)

Pickup current restore time ........................................... 0.0 ~ 180.0sec (step: 0.1sec)

CLPU reset time ........................................................... 0.01 ~ 60.00sec (step: 0.01sec)

Pickup level accuracy .................................................... 5%

Timing accuracy ............................................................ 5% or 20msec

14

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

SECTION function

Function ......................................................................... Disable, Enable

Auto closing .................................................................. Disable, Enable

Section type ................................................................... V-T, O-T

Close direction............................................................... Always, Source, Load

Open delay time............................................................. 0.1 ~ 25.5sec (step: 0.1sec)

Close waiting time ......................................................... 1 ~ 255sec (step: 1sec)

Close delay time ............................................................ 1 ~ 255sec (step: 1sec)

Lockout time.................................................................. 1 ~ 255sec (step: 1sec)

Source side lockout time ............................................... 1 ~ 255sec (step: 1sec)

Source side reset time .................................................... 1 ~ 255sec (step: 1sec)

Block Time .................................................................... 1 ~ 255sec (step: 1sec)

Operation Time .............................................................. 1 ~ 4 time (step: 1 time)

Phase Unbalance

Angle difference ............................................................ OFF, 5 ~ 80 (step: 5)

Detect delay time ........................................................... 0.0 ~ 180.0sec (step: 0.1sec)

Phase Open/Lost

On Level ........................................................................ phase voltaeg 70 ~ 85% (step: 5%)

Off Level ....................................................................... phase voltage 30 ~ 75% (step: 5%)

Detect delay time ........................................................... 0.0 ~ 180.0sec (step: 0.1sec)

Live line/Dead line detect(Communication)

Live line detect value .................................................... 0.10 ~ 0.90pu (step: 0.01pu)

Deect delay time ............................................................ 0.5sec fixed

Operation counter

Alarm function .............................................................. Off, On

Reset counter ................................................................ 0 ~ 65535 (step: 1)

Alarm counter ................................................................ 0 ~ 20000 (step: 1)

Battery auto load test

Test cycle ....................................................................... 1 ~ 72 hour (step: 1hour)

ENHANCED TECHNOLOGY

15

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

Power Quality Monitoring - PQM

PQM function ............................................................... Disable, Enable

Sag pickup level ............................................................ 0(OFF), 0.50 ~ 0.99pu (step: 0.01pu)

Sag delay time ............................................................... 0.5 ~ 10.0cycle (step: 0.5cycle)

Swell pickup level ......................................................... 0(OFF), 1.01 ~ 1.50pu (step: 0.01pu)

Swell delay time ............................................................ 0.5 ~ 10.0cycle (step: 0.5cycle)

Interruption .................................................................... 0(OFF), 0.10 ~ 0.49pu (step: 0.01pu)

Interruption .................................................................... 0.5 ~ 10.0cycle (step: 0.5cycle)

Voltage harmonic pickup level ...................................... 0(OFF), 0.5 ~ 100.0% (step: 0.1%)

Current harmonic pickup level ...................................... 0(OFF), 0.5 ~ 100.0% (step: 0.1%)

Harmonic delay time ..................................................... 0.2 ~ 60.0sec (step: 0.1sec)

Voltage unbalance pickup level ..................................... 0(OFF), 1 ~ 100% (step: 1%)

Voltaeg unbalance delay time ........................................ 0.1 ~ 60.0sec (step: 0.1sec)

Current unbalance pickup level ..................................... 0(OFF), 1 ~ 100% (step: 1%)

Current unbalance delay time ........................................ 0.1 ~ 60.0sec (step: 0.1sec)

Low voltage pickuip level ............................................. 0(OFF), 0.30 ~ 0.95pu (step: 0.01pu)

Low voltage delay time ................................................. 0.0 ~ 180.0sec (step: 0.1sec)

Over voltage picup level................................................ 0(OFF), 1.05 ~ 1.50pu (step: 0.01pu)

Over voltage delay time ................................................ 0.0 ~ 180.0sec (step: 0.1sec)

Low frequency pickup level .......................................... 0(OFF), 46.00 ~ 59.98Hz (step: 0.01Hz)

Low frequency delay time ............................................. 0.03 ~ 10.00sec (step: 0.01sec)

Phase overcurrent pickup level...................................... 0(OFF), 50 ~ 630A (step: 5A)

Phase overcurrent delay time ........................................ 0.0 ~ 180.0sec (step: 0.1sec)

Ground overcurrent pickup level ................................... 0(OFF), 25 ~ 315A (step: 5A)

Ground overcurrent delay time...................................... 0.0 ~ 180.0sec (step: 0.1sec)

Current unbalance/THD detect Min. value ................... 0 ~ 630A (step: 1A)

Switch Contact wear

Contact wear detect ....................................................... Off, On

Pickup wear ................................................................... 0.0 ~ 50.0% (step: 0.1%)

Rated system ................................................................. 15, 27, 38

Rated interruption capacity() ..................................... 5.0 ~ 50.0 (step: 0.1)

Number of Max. interruption ........................................ 1 ~ 999 (step: 1)

Phase A contact wear ..................................................... 0.0 ~ 100.0 % (step: 0.1%)

Phase B contact wear..................................................... 0.0 ~ 100.0 % (step: 0.1%)

Phase C contact wear..................................................... 0.0 ~ 100.0 % (step: 0.1%)

16

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

TD Monitoring

TD1 rating ..................................................................... 20, 200

TD1 ratio ............................................................... ....... 1 ~ 3000 (step: 1)

TD1 offset.............................................................. ....... -10000 ~ +10000 (step: 1)

TD1-1 type ............................................................ ....... Under or Over

TD1-1 pickup value .............................................. ....... 0(OFF), 0.1 ~ 35.0V (step: 0.1V)

TD1-1 delay time................................................... ....... 0.01 ~ 600.00sec (step: 0.01sec)

TD1-2 type ............................................................ ....... Under or Over

TD1-2 pickup value .............................................. ....... 0(OFF), 0.1 ~ 35.0V (step: 0.1V)

TD1-2 delay time................................................... ....... 0.01 ~ 600.00sec (step: 0.01sec)

. NOTE : There are 4 more channels (TD2 ~ TD5) the same as above.

Zero Sequence Voltage(V0) detect

Pickup level detect..................................................... ... 0(OFF), 0.05 ~ 1.20pu (step: 0.01pu)

Detect dela time ......................................................... ... 0.1 ~ 6000.0sec (step: 0.1sec)

ENHANCED TECHNOLOGY

17

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

2.5. Event Recorder

Operation event recording device

Trigger source

Switch CLOSE

Switch OPEN

Earth Close(ECLOSE)

Earth Open(EOPEN)

Storage capacity : Total 256 events

Fault event recording device

Trigger source

Taget A, B, C, N phases, SEF

Fault detect : Instantaneous fault, Permenant fault

Detect direction : Forward, Reverse direction

Fault Sequence

Data channel

Current 4, Voltage 3, Frequency, Logic input status 32, Output relay 16channel, Input

16channel

Storage capacity : Total 256 events

Fault wave capture

Trigger source

Fault wave capture point

Fault current

Sampling ratio : 128x20, 64x40, 32x80, 16x160

Storage capacity: 8 fault waves of 20 cycle (20cycles 8EA).

System Event Recording device

Trigger source

52A contact

Input/Output status change

Front panel control

AC power supply

External control

18

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

External input status

System alarm

Sleep mode

Trigger time : each 1/4 cycle

Trigger type : Pickup and Dropout

Storage capacity : Last 2048 events

Set Change Event Recording device

Trigger source

Global setting change

Primary group setting change

Alternate group setting change

Storage capacity : Total 100events

Load Profile

1) Average Load/ Minute

Trigger source

Demand current(A, B, C, G)

Demand real power(A, B, C, 3)

Demand reactive power (A, B, C, 3)

Trigger time : 1, 2, 3, 4, 5, 6, 10, 12, 15, 20 or 30 min.

Storage capacity : Total 1024events (Storage Capacity : Total 1024 Events)

2) Peak Load/ Hour

Trigger source

Demand current(A, B, C, G)

Demand real power(A, B, C, 3)

Demand reactive power(A, B, C, 3)

Trigger time : Every 1 hour

Storage capacity : Total 1024 events, 42 days

3) Peak Load/ Day

Trigger source

Demand current(A, B, C, G)

Demand real power(A, B, C, 3)

Demand reactive power(A, B, C, 3)

Trigger time : Daily

ENHANCED TECHNOLOGY

19

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

Storage capacity : Total 1024 events, 1024days

DIAGNOSTIC EVENT RECORDER

Trigger source

DSP failure

ADC failure

RTC failure

Memory failure

Flash-Rom failure

Circuit voltage failure

Globlal setting failure

Primary setting failure

Alternate setting failure

Event failure

Count failure

DO failure

Close failure

Open failure

Trigger time : evey 1/4 cycle

Trigger type : Pickup and Dropout

Storage capacity : Last 512 events

PQM event recording device (PQM EVENT RECORDER)

Trigger source

PQM pickup element

20

Storage capacity : Total 100events

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

2.6. Maintenance

COUNTER

Number of System restart : 0 ~ 65534

Number of maintenance : 0 ~ 65534

Number of Operation : 0 ~ 65534

Numer of fault: 0 ~ 65534

Number of Instantaneous current change detect : 0 ~ 65534

Number of PQM detect: 0 ~ 65534

Switch contact wear

Phase A wear: 0.0 ~ 100.0%

Phase B wear: 0.0 ~ 100.0%

Phase C wear: 0.0 ~ 100.0%

2.7. Communication

Table 2-2. Communication

RS232, 1200-19200bps, None, Odd or Even Parity, 7 or 8 Data bits, 1or 2

Side panel Port1

Stop bit

DNP 3.0, Modbus and IEC60870-5-101 protocol

RS485/422, 1200-19200bps, None, Odd or Even Parity, 7 or 8 Data bits,

Side panel Port2

1 or 2 Stop bit

DNP 3.0, Modbus and IEC60870-5-101 Protocol

Side panel Port3

Front panel PortF

RJ-45, 10BASE-T/100BASE-T

DNP 3.0, Modbus and IEC60870-5-104 Protocol

RS232, 1200-57600bps, No Parity, 8 Data Bits, 1 Stop bit

ETR300 interface software

ENHANCED TECHNOLOGY

21

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

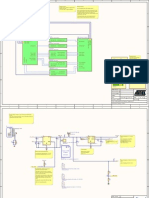

22

K04

K03

K02

POWER IN

K01

V0

V23

CN1

950

J01 J02 J03 J04

V22

V21

3

CN2

4

V12

INPUTS

CN3

V11

OUT206

OUT205

950

H01 H02 H03 H04 H05 H06

Ise

IN

OUTPUTS

E10

E07

IN104

CN4

4

1

8

3

CN5

2

1

4

3

CN6

4

3

CN7

1:+12V

2:DC01

3,4:GND

1:DC02

3:DC03

2,4:COM

I03

I02

TRIP & CLOSE

I01

E02

IN102

IN101

IN103

+

+

ENHANCED TECHNOLOGY

5559

1

Figure 3-1. Dimension and Structure

1,3:DC(+)

2,4:DC(-)

5559

PORT F

4,8:COM

5559

MONITORS

OPEN

3,7:OUT204

CLOSE

E01

L4

N.C

L3

OUT104

TAG

OUT103

HOT LINE

LOCKED

1,5:N/C

2,6:OUT202

CONTROL

OUT102

L2

OUT101

L1 MANUAL LOCK

ENABLED

2,5:+12V

5559

950-08

AUX1

950-10

VC / VT

REMOTE

4:IN205

VB / VS

LOCKOUT

A01 A02 A03 A04 A05 A06 A07 A08 A09 A10 B01 B02 B03 B04 B05 B06 B07 B08

RESET

E08

ABC / RST LIVE

VA / VR

ENABLED

E09

C Phase Unbalance

SECTION

1:IN204

GPS

B Phase Unbalance

E06

ENABLED

E05

SEF

A Phase Unbalance

E04

GROUND

ENABLED

5559

3,6:GND

E03

ALTERNATE

SETTINGS

1:IN203

2:IN202

3:IN201

4:+12V

RCV

SEF

PROTECTION

ENABLED

F02

Antenna

C FAULT

GROUND

5559

F03

Antenna

PORT RF

F01

RESET

RX

B FAULT

FI

TEST

TX

LAMP TEST

BATT'

CHECK

1,3:P

2,4:N

TIE CYCLE

F04

F05

SEC CYCLE

ENT

A FAULT

+BAT

V13

F06

G01

ESC

SEC/TIE LOCKOUT

-BAT

5559

POWER SUPPLY

G02

UP

DOWN

AC 24V

G07

G05

PORT2

3

2

950

FUN

AC 24V

485+ 485- SG

1TX

1RX

2TX

2RX

BATTERY

REVERSE POWER

G08

PORT3

CHARGER

G06

AC SUPPLY

G04

RX / TX

G03

DIAG/ERROR

PORT1

RUN

1:DCD 2:RXD 3:TXD 4:DTR

5:GND 6:DSR 7:RTS 8:CTS

9:N/C

10M/100M

ETR300 -S02

Control & Communication Unit

RJ45

XPORT

LINK

3. Dimension and structure

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

4. External Input/Output Connector

ETR300 provides terminals(connector) to connect control and modem, the termainal arrangement

is as belows;

A01 A02 A03 A04 A05 A06 A07 A08 A09 A10 B01 B02 B03 B04 B05 B06 B07 B08

10M/100M

2TX

2RX

LINK

TX

950-10

RJ45

XPORT

950

950-08

RX

RCV

OUT104

OUT103

N.C

E02

E01

IN101

IN102

IN103

IN104

E03

I01

F01

E10

F02

F03

1TX

1RX

V11

Ise

V12

G01

V21

G03

G04

G06

G07

V23

G08

V0

POWER SUPPLY

K02

K03

K04

AC 24V

5559

K01

AC 24V

-BAT

J01 J02 J03 J04

950

1,3:P

2,4:N

1:IN203

2:IN202

3:IN201

4:+12V

POWER IN

CN1

3

5559

3,6:GND

2,5:+12V

1:IN204

G05

V22

CN2

4

4:IN205

OUT206

G02

V13

5559

1,5:N/C

2,6:OUT202

3,7:OUT204

F06

INPUTS

950

OUT205

F05

PORT3

PORT1

+BAT

H01 H02 H03 H04 H05 H06

1:DCD 2:RXD 3:TXD 4:DTR

5:GND 6:DSR 7:RTS 8:CTS

9:N/C

PORT2

F04

CN3

5559

4,8:COM

1,3:DC(+)

2,4:DC(-)

E09

PORT RF

OUTPUTS

5559

1:+12V

2:DC01

3,4:GND

E08

IN

Antenna

GPS

CN4

3

5559

1:DC02

3:DC03

2,4:COM

E07

I03

CN5

3

5559

E06

TRIP & CLOSE

CN6

E05

I02

MONITORS

CN7

4

E04

Antenna

485+ 485- SG

OUT102

OUT101

Figure 4-1. External Input/Output connector

Table 4-1.Cable size for connecter

Item

Size( )

Length( )

Connecter name

Current

1.25(50/0.18)

300

AkZ 960-10P

Power supply

"

"

AkZ 960-4P

Digital Input

0.75(12/0.18)

"

Molex 5557-6P,4P

Digital Output

"

"

AkZ 950-6P

Voltage

"

"

AkZ 960-6P,8P

ENHANCED TECHNOLOGY

Remark

23

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

4.1. Current Input(Connector type:STLZ960-10)

Current connecters terminal no. 1 starts with phase A and follows by B, C, N, SEF phase turn.

ETR300 current terminal provides all phase name.

E02

E01

E03

I01

E04

E05

I02

E06

E07

I03

E08

E09

IN

E10

Ise

Table 4-2. Current connecter pin

IO1

IO2

IO3

IN

Ise

SEF

phase phase phase phase

Figure 4-2. Current connector

4.2. Voltage Input(Connector type:STLZ960-6P,8P)

Voltage connector has source side 3 phases(A,B,C) and load side 3 phases(R,S,T) as belows;

Table 4-3. Voltage connecter Pin

E01

E02

I01

E03

E04

I02

E05

E06

I03

E07

E08

IN

E09

E10

V12

V13

Phase

Phase

Phase

V21

V22

V23

V0

Zero

Phase

Phase

Ise

Figure 4-3. Voltage connector

24

V11

ENHANCED TECHNOLOGY

Phase Sequence

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

4.3. Digital Output(DO)

Digital Output has total 8 output relays. Digital Output connecter delivers the control single from

the controller and its construction is as belows.

H01 H02 H03 H04 H05 H06

Table 4-4. Digital Output Connecter Pin

Pin

950

Number

OUT205

Pin

Signal

Number

Close

Open

OUT206

Figure 4-4. Digital Output Connector

4.4. Digital Input(DI)

Digital Input receives 16 status signals through insulated electric contacts. This is how increasing

DI part surge withstand capability and provide more insulation to Main module where signali is

connected but weak to surge voltage. Digital Input connector is the part where receiving status

signal from control part and its structure is as belows.

CN3

CN2

4

Table 4-5. Digital Input Connecter Pin

Connecter

1:IN203

2:IN202

3:IN201

4:+12V

1:IN204

4:IN205

2,5:+12V

3,6:GND

CN2

CN3

Pin

Number

Signal Connecter

01

Open

02

03

Close

Lock

01

04

Spare

Number

04

CN2

Door

Open

Pin

CN3

04

04

02,05

02,05

Figure 4-5. Digital Input Connector

ENHANCED TECHNOLOGY

25

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

4.5. Power supply input& Modem power supply output

Power supply connecter has ETR300 operation power supply terminal and modem power supply

terminal. Each connecter provides its name and pin number 1 is for +24V input and pin number 2

is Grond input.

P : DC 24V +Terminal

N : DC 24V GND

N

Figure 4-6. Power Supply Connecter

4.6. Remote Communication Port(modem connection)

Modem communication port is D-SUB 9 pin male type and all pins are connected except the

number 9 pin (Ring Indicator)

Table 4-6. Remote Communication Port Pin

Pin No.

9

5 4

7 6

DTR : Data Terminal ready

RxD : Received Data

TxD : Transmitted Data

DTR : Data Terminal Ready

GND : Ground

DSR : Data Set Ready

RTS : Request To Send

CTS : Clear To Send

2 1

Figure 4-7. Remote Communication Port

26

Signal Info

RI

: Ring Indicator

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

4.7. 485 Communication Port

485 Communication Port has 3 pins and its construction is as follows.

3

2T

Table 4-7. 485Communication Port Pin

2R

Pin No.

485+

485-

485+ 485- SG

SG

Figure 4-8. 485Commnication Port

4.8. Ethernet Port(RJ45)

Ethernet Port (RJ-45) has 8 pins and its constructions is as follows.

Table 4-8. EthernetPort Pin

BPS

LINK

Pin No.

1

RJ45

XPORT

Figure 4-9. Ethernet Port

10Base-T Signal

100Base-TX Signal

White/Green

Transmit+

Wire Color

Green

Transmit-

White/Orange

Receive+

Blue

Unused

White/Blue

Unused

Orange

Receive-

White/Brown

Unused

Brown

Unused

ENHANCED TECHNOLOGY

27

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5. User Interface Panel

User Interface Panel uses LCD(20 4) and keypad to select functions and monitors switch status,

and also with LEDs, selected functions status and switch operation status can be checked.

User Interface Panel provides following functions;

Switch control

Control status check

System status check

Metering value check

Saved records check in ETR300

Set check and change in ETR300

ETR300 -S02

Control & Communication Unit

RUN

DIAG/ERROR

RX / TX

AC SUPPLY

CHARGER

BATTERY

REVERSE POWER

FUN

UP

ESC

SEC CYCLE

DOWN

ENT

TIE CYCLE

SEC/TIE LOCKOUT

A FAULT

LAMP TEST

B FAULT

BATT'

CHECK

FI

RESET

C FAULT

TEST

GROUND

SEF

PROTECTION

ALTERNATE

ENABLED

SETTINGS

GROUND

SEF

ENABLED

ENABLED

A Phase Unbalance

B Phase Unbalance

C Phase Unbalance

ABC / RST LIVE

VA / VR

SECTION

ENABLED

RESET

VB / VS

LOCKOUT

VC / VT

REMOTE

AUX1

L1

ENABLED

L2

CONTROL

AUX2

L3

LOCKED

L4

CLOSE

OPEN

PORT F

Figure 5-1. User Interface Panel

28

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.1. Construction

Panel consists of following 12 parts ;

Operation section

Local control section

Menu control section

Other control section

Fault indication section

Line status indication section

Section status section

System diagnostic section

Battery status section

PCL status section

Other status section

Spare ports section

5.1.1. Operation Section

OPEN

Press [OPEN] button to send Trip signal to Switch.

CLOSE

Press [CLOSE] button to send Close signal to Switch.

ETR300 has close time delay and the close operation can be conducted after a set time. Set time

range is from 0.00 ~ 600.00 sec.

POSITION LED

Switch staus is indicated. Position LED is operated based on 52a contact.

Figure 5-2. Operation Selection

ENHANCED TECHNOLOGY

29

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.1.2. Local Control Section

Control panel shows all the status of function. If a function is enabled, LED is ON, and when

disabled, LED is OFF. Button changes Enable to Disable vice versa.

PROTECTION

ALTERNATE

ENABLED

SETTINGS

GROUND

SEF

ENABLED

ENABLED

SECTION

RESET

ENABLED

LOCKOUT

AUX1

REMOTE

ENABLED

AUX2

CONTROL

LOCKED

Figure 5-3. Local Control Section

Protection(Enable/Disable)

When Enable(LED ON), phase fault detecting is enabled and when Disable(LED OFF), phase

fault detecting is disabled.

NOTE : When Protection is enabled, all protection of ETR300 is on operation, however,

Ground fault and SEF(Sensitive Earth Fault) function shall be set individually on font panel.

Ground (Enable/Disable)

When LED is on, ground fault detecting is enabled and when LED is off, ground fault detecting is

disabled. It is only available when Protection is enabled. Although Ground LED is on, protection

is disabled, ground fault detection is not conducted.

SECTION(Enable/Disable)

When LED is ON, SECTION is enabled, and when LED is OFF, SECTION is disabled.

30

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

Operation select(Local/Remote)

When LED is ON, Remote and Local operation are all available. When LED is OFF, only Local

operation is available.

Operation Lock(Lock/Unlock)

When it is Unlock, local and remote operations are all available. When it is Lock, local and

remote operations are not available.

NOTE : Even if operation lock status, Open, Lamp test, Battery load test and Menu

controlare all available.

ALTERNATE SETTINGS(Select)

When ALTERNATE SETTINGS LED is ON, Group setting becomes Alternate setting and the

Alternate setting is activated. When the LED is OFF,Group setting becomes Primary setting and

the primary setting is activated.

SEF(Enable/Disable)

When LED is ON, SEF is enabled. When LED is OFF, SEF is disabled. Although SEF is

enabled,Protoection is not enabled, SEF is not activated.

SEC/TIE LOCKOUT(Unlock)

SEC/TIE LOCKOUT is dismissed.

AUX(1/2)

Aux. function button.

ENHANCED TECHNOLOGY

31

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.1.3. Menu Control Section

204 LCD is used to check setting, metering and

events, details informations are refer to 5. Operation

manual(How to use LCD).

204 character LCD

4 operation button(Increase, Decrease, Function

selection)

FUN

UP

ESC

DOWN

ENT

Figure 5-4. Menu Control Section

5.1.4. Other Control Section

LAMP TEST

BATT'

CHECK

FI

RESET

TEST

Figure 5-5. Other Control Section

Lamp Test Button

Normal : Press the button to check all Lamps.

FI occurred : It resets FI Target by pressing the button.

Battery

It takes 5 seconds to check battery and charging circuit. When pressing the button and if AC

power supply is provided, charging circuit is disconnected and connects a load resister to battery

and check the charging circuit.

FI Test

When pressing FI Test button, trip test begins beased on set value.

32

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.1.5. Fault Indication Section

In case of Permenant or Instantaneous fault, corresponding LED

A FAULT

is ON. LED lamp can be off by manually from local by pressing

FI Reset button or from remote by sending a signal. Otherwise,

B FAULT

C FAULT

LED lamp will be on although H.V. line becomes normal.

GROUND

SEF

Figure 5-6. Fault Indication

Section

5.1.6. H.V. line status indication section

Phase Unbalance lamp

A Phase Unbalance

Phase A,B,C Unbalance are indicated.

B Phase Unbalance

Under condition that source side and load side are all live line

and switch is open status, check angles, if it meets then, it is OK,

C Phase Unbalance

ABC / RST LIVE

otherwise, it is unbalanced.

Although it is unbalanced, control is still available. Operater

shall decide an operation.

VA / VR

VB / VS

VC / VT

Live line lamp

Figure 5-7. Disconnect/Open

Source side and load side live line status are indicated.

phase Lamp

More than one phase voltage is higher than an Off Level of

Disconnect line/Open phase, it is Live line. And all 3 phases are

less than that, it is Dead line. Operater shall decide an operation.

Phase Open/Loss lamp

Source and load side Phase A, B, C Open/Loss phase are

indicated. In case that 1 or 2 phases voltage is less than Off

Level

of

Disconnect/Open

phase, it is determined

as

Disconnet/Open phase. LED will be Off when the voltages are

higher than On Level.

ENHANCED TECHNOLOGY

33

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.1.7. System Diagnostic Section

ETR300-R Diagnostic is displayed. RUN Lamp(green) indicates that ETR300 has passed the

internal diagnostic test and does not have any problem.

RX/TX Lamp(Red) indicates the

communication state of ETR300

RUN : It indicates the operation status. In normal

operation, it flicker periodically. In system problem

RUN

case , it is lighting or turned off.

DIAG/ERROR

DIAG/ERROR : Turn on with abnormality of Self

Diagnostic.

RX / TX

RX : Turn on when transmit data

TX : Turn on when transmit data

Figure 5-8.System Diagnostic Lamp

5.1.8. Section Status Section

Indicates present staus of set section function process.

SEC Sequence: Indicates Section operation status.

TIE Sequence: Indicates Tie sequence operation status.

SEC/TIE Sequence End : Indicates sequence Lockout

TIE CYCLE

status.

SEC/TIE LOCKOUT

SEC CYCLE

Figure 5-9. Section Status Lamp

5.1.9. Battery Status Section

The system power status of ETR300 is displayed. When ETR300 is supplying external power, AC

SUPPLY Lamp is on. CHARGER lamp shows the charging status of ETR300 and the BATTERY

lamp shows the battery status of ETR300.

AC SUPPLY : Indicates the external AC power supply

status.

CHARGER : Turn on, when the charger status is

AC SUPPLY

CHARGER

normal.

BATTERY : Turn on, when the battery status is

BATTERY

normal.

Figure 5-10. Battery Status

Lamp

34

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.1.10. User LED Section

LED can be indicated according to the user setting.

L1

LED logic can be set in ETR300 interface software

L2

L3

L4

Figure 5-11. User Lamp

5.1.11. Other Status Section

REVER POWER

REVERSE POWER

In reverse current case, the REVER POWER lamp becomes

On.

Figure 5-12. Rever Power lamp

5.1.12. Port F Section

This connection port is for the communication with administration program. It obtains setting

change, control and others events.

TYPE : RS232C(male)

Pin 2 : RXD

Pin 3 : TXD

Pin 5 : GND

Pin 1,4,6,7,8,9 : N/G

Location : Front panel

PORT F

Figure 5-13. Port F

ENHANCED TECHNOLOGY

35

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.2. Operation Manual (LCD instruction)

5.2.1. LCD Screen

20 4 character LCD which has back-light support, is used for a user to operate conveniently and

to check operation status clearly.

5.2.2. Control button

LCD Control button is composed of four basic keys(increase, decrease, function/cancel, ENT).

Following table is explanation of the keys.

Table 5-1.Control Button

Button

Explanation

Move to menu selection mode from display mode and move to prior menu from

sub-menu. When press the button in Main Menu it is changed into display

ESC

mode. When this key is operated after changed the value, all changed value are

FUNC/CANCEL reverted to original setting value.

FUN

ENT

ENT

UP

INCREASE

DOWN

DECREASE

36

It is used for menu selection or setting change. In menu selection screen this

button is used for menu selection function. In setting change status moves to

menu mode by pressing this button (it operates in toggle method in menu

selection.setting change)

It is used to move the menu into above side or to increase the setting point. As

all menu has circulated function, from the top menu moves into the lowest

menu. In setting change case, after highest setting value comes the lowest

setting value. A level is increased by pressing the button and it is increased

quickly by pressing the button over 2 seconds.

It is used to move the menu or to decrease the changed value.

This button has circulated function for menu change/setting change as

[increase] button. A level is decreased by pressing the button and it is decreased

quickly by pressing the button over 2 seconds.

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.2.3. Menu structure tree

Screen structure consists Initial Logo and Main menu.

Initial screen and all menu are round robin algorithm.

Menu screen is composed of setting and event management menu.

[ ]

[ ]

[MAIN MENU]

[BI-CCU(S) FOR DAS]

SECTION

: DISABLE

S/W STATUS :

OPEN

[ RESET ]

>1.GLOBAL SETTING

>2.GROUP SETTING

>3.EVENT

>4.MAINTENANCE

>5.TIME

A:00000

00.0/00.0

B:00000

00.0/00.0

C:00000

00.0/00.0

N:00000[00.000-0000]

>6.STATUS

>7.METERING

Figure 5-14. Initial Logo and Main Menu

ENHANCED TECHNOLOGY

37

SWITCH CONTROL ETR300-S01

[MAIN MENU]

http://www.entecene.co.kr

>1.GLOBAL SETTING

>1.SYSTEM

>1.POWER LINE

2.CURRNET SENSING

3.VOLTAGE SENSING

>2.COMMUNICATION

>1.PROTOCOL SETUP

>3.EVENT RECORDER

>2.PORT SETUP

>4.MONITORING

>1.PHASE DIFF

>1.DNP1

2.DNP2

3.IEC870-5-101

4.IEC870-5-104

5.MODBUS

>1.PORT1(232)

2.PORT2(485)

3.PORT3(ETHERNET)

4.PORTF(232)

>2.OPERATION COUNT

>3.CONTACT WEAR

>4.BATTERY TEST

>5.PQM

>6.TD MONITOR

>1.PQM FUNCTION

2.INTERRUPT

3.SAG

4.SWELL

5.HARMONICS

6.CURR UNBALANCE

7.VOLT UNBALANCE

8.UNDER VOLTAGE

9.OVER VOLTAGE

10.UNDER FREQUENCY

>7.V0 DETECT

>5.PLC

>1.COMMON

>2.DI/DO

>6.OTHERS

>*.SAVE SETTING

>2.GROUP SETTING

>1.PICKUP CURRENT

>2.INRUSH RESTRAINT

>2.ALTERNATE

>3.DIRECTION

>4.F.I SETTING TIME

>3.EVENT

>5.F.I RESET

>6.SECTION

>7.DELTA I

>8.OVER CURRENT

>*.SAVE SETTING

>4.MAINTENANCE

>1.COUNT

>2.INTERRUT TIME

>3.CONTACT WEAR

>4.DATA RESET

>5.CCU INFO

>5.TIME

>6.F.I TEST

>6.STATUS

>7.METERING

>1.SWITCH

2.INPUT PORTS

3.OUTPUT PORTS

>1.CCU

2.OPERATION

3.FAULT

4.DELTA I

5.PQM

>1.CCU COUNT

2.OPERATION COUNT

3.FAULT COUNT

4.DELTA I COUNT

5.PQM COUNT

6.COUNT ALL

7.INTERRUT TIME

8.CONTACT WEAR

9.ENERGY

10.ABOVE ALL

>1.CURRENT

2.VOLTAGE

3.FREQUENCY

4.POWER

5.ENERGY

6.DEMAND

7.UNBALANCE

8.HARMONICS

9.TRUE R.M.S

10.TD

11.CCU SEF

Figure 5-15. Menu Tree Structure

38

>1.INPUT DEBOUNCE

2.OUTPUT PULSE TIME

>1.FACTORY DEBUG

>1.PRIMARY

>1.OPERATION

2.FAULT

3.FAULT CYCLE

4.SYSTEM

5.SET CHANGE

6.AVER.LOAD/MIN

7.PEAK.LOAD/HOUR

8.PEAK.LOAD/DAY

9.DIGNOSTIC

10.PQM

11.CLEAR SAVED DATA

>1.LOGIC TIMER

2.PULSE TIMER

3.PULSE COUNTER

ENHANCED TECHNOLOGY

>1.PHASE

2.GROUND

3.SEF

SWITCH CONTROL ETR300-S01

[MAIN MENU]

>1.GLOBAL SETTING

http://www.entecene.co.kr

>1.SYSTEM

>2.COMMUNICATION

>1.POWER LINE

2.CURRENT SENSING

3.VOLTAGE SENSING

4.CB OPENING TIME

>1.PROTOCOL SETUP

>2.PORT SETUP

>1.PORT1(232)

2.PORT2(485)

3.PORT3(ETHERNET)

4.PORTF(232)

>3.EVENT RECORDER

>3.DIALUP MODEM

>1.DIAL1

2.DIAL2

>4.MONITORING

>1.SYNCHROCHECK

2.OPERATION COUNT

3.CONTACT WEAR

4.BATTERY TEST

>5.PQM

>5.LOOP CONTROL

>6.PLC

>7.OTHERS

>*.SAVE SETTING

>2.GROUP SETTING

>1.SELECT SETBANK

>2.PRIMARY

>3.ALTERNATE

>4.EDITBANK

>6.TD MONITOR

7.V0 DETECT

>1.LOGIC TIMER

2.PULSE TIMER

3.PULSE COUNTER

>2.DI/DO

>1.INPUT DEBOUNCE

2.OUTPUT PULSE TIME

>1.TIME DISPTYPE

2.PANEL SLEEP TIME

3.FACTORY DEBUG

>1.OPERATION

2.INTERVALS

3.PICKUP CURRENT

4.PHASE FAST

5.PHASE DELAY

6.GROUND FAST

7.GROUND DELAY

8.SEF ELEMENT

9.NEG SEQ FAST

10.NEG SEQ DELAY

11.H/C TRIP-PHA

12.H/C TRIP-GND

13.H/C TRIP-NEG

14.H/C LOCKUOT-PHA

15.H/C LOCKUOT-GND

16.H/C LOCKUOT-NEG

17.COLD LOAD PICKUP

>18.DIRECTION

>19.VOLTAGE

>20.FREQUENCY

>1.OPERATION

2.FAULT

3.FAULT CYCLE

4.SYSTEM

5.SET CHANGE

6.AVER.LOAD/MIN

7.PEAK.LOAD/HOUR

8.PEAK.LOAD/DAY

9.DIGNOSTIC

10.PQM

11.PD

>12.CLEAR SAVED DATA

>4.MAINTENANCE

>1.COUNT

>2.INTERRUT TIME

>3.CONTACT WEAR

>4.DATA RESET

>5.TIME

>5.CCU INFO

>6.STATUS

>7.METERING

>1.RECLOSER

2.INPUT PORTS

3.OUTPUT PORTS

>1.CURRENT

2.VOLTAGE

3.FREQUENCY

4.POWER

5.ENERGY

6.DEMAND

7.UNBALANCE

8.HARMONICS

9.TRUE R.M.S

10.PD

11.TD

12.CCU SEF

>1.PQM FUNCTION

2.INTERRUPT

3.SAG

4.SWELL

5.HARMONICS

6.CURR UNBALANCE

7.VOLT UNBALANCE

8.UNDER VOLTAGE

9.OVER VOLTAGE

10.UNDER FREQUENCY

>1.COMMON

>5.AUTO SGRP CHANGE

>3.EVENT

>1.DNP3

2.IEC870-5-101

3.IEC870-5-104

4.MODBUS

>21.OTHER ELEMENT

>22.USER CURVE

>1.PHASE

2.GROUND

3.SEF

4.NEG SEQ

>1.UNDER VOLTAGE 1

2.UNDER VOLTAGE 2

3.OVER VOLTAGE 1

4.OVER VOLTAGE 2

>1.UNDER FREQUENCY

2.OVER FREQUENCY

>1.USER

2.USER

3.USER

4.USER

CURVE

CURVE

CURVE

CURVE

1

2

3

4

>23.LIVE LOAD BLOCK

*.SAVE SETTING

>1.OPERATION

2.FAULT

3.SYSTEM

4.SET CHANGE

5.LOAD PROFILE

6.DIGNOSTIC

7.PQM

8.PD

9.ABOVE ALL

>1.CCU

2.OPERATION

3.FAULT

4.DELTA I

5.PQM

6.PD

>1.CCU COUNT

2.OPERATION COUNT

3.FAULT COUNT

4.DELTA I COUNT

5.PQM COUNT

6.PD COUNT

7.COUNT ALL

8.INTERRUT TIME

9.CONTACT WEAR

10.ENERGY

11.ABOVE ALL

ENHANCED TECHNOLOGY

39

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.2.4. GLOBAL Setting

SYSTEM

Set items related to system elements. Consists of POWER LINE, CURRENT SENSING,

VOLTAGE SENSING and CB OPENING TIME.

COMMUNICATION

Set the items related to the communication elements. Consists of PROTOCOL SETUP and PROT

SETUP.

EVENT RECORDER

Set the items related to the event recorder elements.

MONITORING

Set the items related to metering and maintenance. Consist of OPERATION COUNT, CONTACT

WEAR, BATTERY TEST, PQM, TD MONITOR and V0 DETECTION.

PLC

Set the items related to PLC (Progamable Logic Control) elementsConsist of COMMON and

DI/DO.

OTHERS

Set the items related to the others elements.

SAVE SETTING

Save all changed setting value.

40

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.2.5. GROUP Setting

This menu is divided into Primary Group and Alternate Group for the convenience of the user and

according to the ON/OFF of ALTERNATE SETTINGS lamp of ETR300 panel the applied

group is selected.

(1) Select Set-group

It is composed of Primary group and Alternate group.

PRIMARY group : When ALTERNATE SETTINGS lamp is OFF, the set point of

Primary group is applied in the line operating element.

ALTERNATE group : When ALTERNATE SETTINGS lamp is ON, the set point of

Alternate group is applied in the line operation element.

ALTERNATE

SETTINGS

[GROUP SETTING]

>1.PRIMARY

2.ALTERNATE

Ficture 5-16. PRIMARY group and ALTERNATE group

By using [ALTERNATE SETTINGS] button, can change the applied group of current protective

unit.

(2) Primary Setting

This menu set the items related to the line operating elements.

(3) Alternate Setting

This menu set items related to the line operating elements. Setting items are same with

PRIMARY SETTING.

ENHANCED TECHNOLOGY

41

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.2.6. Event

This menu displays the event information of ETR300. For more details refer the 8. Event

5.2.7. Maintenance

This menu displays the maintenance information of ETR300.

COUNTER : Indicates counter information related to the system.

INTERRUT TIME : Displays the occurring accumulated time if interruption.

CONTACT WEAR : Display the connect life of the switch.

DATA RESET : Reset the datas related to Maintenance.

CCU INFO : Display the current information of ETR300

For more details refer the 10. Maintenance .

5.2.8. Time

Check and set the current time.

5.2.9. Status

Display the current status and input output port status of the switch.

5.2.10. Metering

This menu displays the metering value. For more details, refer to 12. METERING .

42

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.3. LCD Menu Use

5.3.1. INITING screen

The main information of ETR300 is displayed in the initial screen, for the easy access and

understanding of the user.

To move to other initial screen, press [] [] button.

Press [FUN] button in initial screen to move to Main menu.

INITNG LOGO

[BI-CCU(S) FOR DAS]

SECTION

: DISABLE

S/W STATUS :

OPEN

[ RESET ]

[BI-CCU(S) FOR DAS]

SECTION

:

S/W STATUS :

Start-up screen1

SENTION: Indicate the section function status (DISABLE/ENABLE).

S/W STATUS: Indicate the switch status (OPEN/CLOSE).

SENTION Indicate the operation status

- RESET

- RUNNING

- LOCKOUT

NOTE :

When WARING SYSTEM ERROR is displayed,means that the control

section is in bad status. Finisht the operation immediately and contact to the

manufacturer.

A:00000

00.0/00.0

B:00000

00.0/00.0

C:00000

00.0/00.0

N:00000[00.000-0000]

A:

B:

C:

N: [

/

/

/

-

Starut-up screen2

Indicate the current of each phase(A,B,C,N).[A].

Indicate the voltage of each phase(A,B,C,R,S,T). [kV].

Indicate SEF current[A].

Indicate the zero phase voltage[V].

ENHANCED TECHNOLOGY

43

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.3.2. Main Menu

In the initial menu, press [FUN] button, it is moved into Main menu. If press [FUN] button in

main menu, it is moved to the initial menu. Main menu has sub-menu as below.

MAIN MENU

[MAIN MENU]

>1.GLOBAL SETTING

2.GROUP SETTING

3.EVENT

4.MAINTENANCE

5.TIME

6.STATUS

7.METERING

Main Menu is composed of 7 submenus.

Select the submenu by using [] [] key.

Move to the submenu by pressing [ENT] key.

As the above explanation, you can move or select the submenu..

5.3.3. View Example

Move to MAIN MENU / STATUS / INPUT PORTS to see the external input port status.

The following screen is displayed.

MAIN MENU/ STATUS/ INPUT PORTS

[INPUT PORT]

IN 101 :LO/DEASSERT

IN 102 :LO/DEASSERT

IN 103 :LO/DEASSERT

IN 104 :LO/DEASSERT

IN 105 :LO/DEASSERT

IN 106 :LO/DEASSERT

IN 107 :LO/DEASSERT

IN 108 :LO/DEASSERT

IN 201 : HI/ASSERT

IN 202 : HI/ASSERT

IN 203 : HI/ASSERT

IN 204 : HI/ASSERT

IN 205 : HI/ASSERT

IN 206 : HI/ASSERT

IN 207 : HI/ASSERT

IN 208 : HI/ASSERT

44

LO/DEASSERT : Shows External Input is de-asserted,

HI/ASSERT

: Shows External Input is asserted.

4 lines are displayed in the LCD screen.

See next line by using [] [] key .

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.3.4. Setting Example

Change of Phase Pickup Current of line operating element of Primary setting.

1) Move toMAIN MENU/ GROUP SETTING/ PRIMARY/ PICKUP CURRENT / PHASE.

The following screen is displayed.

MAIN MENU/ GROUP SETTING/ PRIMARY/ PICKUP CURRENT / PHASE

[PICKUP CURRENT]

>Phase:

400

Ground:

70

S.E.F:

OFF

Range

OFF, 50 ~ 630A

Default 300

Step

5A

Set the Phase Pickup Current.

2) In the above screen, locate the cursor on Phase by using choose [] [] key and then press

the [ENT] key to change the set point.

3) Change in new setting point by using [] [] key.

By pressing [ENT] key, you can see the changed phase setting point.

NOTE : Be sure to save all changed set point in the menu *. Setting Save.

ENHANCED TECHNOLOGY

45

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

5.3.5. Setting Save

Follow the following step to save all changed set point.

Move to MAIN MENU/ GROUP SETTING/ PRIMARY / SAVE SETTING and follow the

following step. (Global Setting menu and Group Setting or Alternate menu have the

*.Setting Save menu).

MAIN MENU / PRIMARY SETTING / SAVE SETTING

To save the changed setting value, press [ENT] button in screen . If

SETTING CHANGED

PRESS <ENT> TO SAVE

the change has succeed screen is appeared.

If, there is nothing changed and select *. SAVE SETTING, the

* NOTHING CHANGED *

[SAVE SETTING]

screen is displayed.

NOTE :

Changed set value is applied if the changed set value is saved.

If changed set value saving is cancelled, previous value is

remained.

* SUCCESS *

46

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

6. Global Setting

Locate the cursor on 1.GLOBAL SETTING in the main menu, and move to this menu by

pressing [ENT]. GLOBAL SETTING menu has the following submenu.

[GLOBAL SETTING]

>1.SYSTEM

2.COMMUNICATION

3.EVENT RECODER

4.MONITERING

5.PLC

6.OTHERS

*.SAVE SETTING

NOTE : The changed setting point works after being saved.

When cancel the save, setting point maintain the previous value.

6.1. System

Locate the cursor on 1.SYSETM in GLOBAL SETTING menu and move to this menu by

pressing [ENT] button. In this menu, various elements related to the system can be set. It has the

following submenu.

[SYSTEM]

>1.POWER LINE

2.CURRENT SENSING

3.VOLTAGE SENSING

NOTE : Do not change the setting elements of SYSTEM , as they are set according to the

characteristics of recloser.

ENHANCED TECHNOLOGY

47

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

6.1.1. Power Line

Locate the cursor on 1.POWER LINE in SYSTEM menu, move to this menu by pressing [ENT]

button. In this menu, enter the Line information of the device installation location.

GLOBAL SETTING / SYSTEM / POWER LINE / Frequency

[POWER LINE]

>Frequency:

50

Phase Rotation: ABC

[50/60Hz]

Range

50, 60

Default 50

Step

Select the nominal power system frequency. This value is used as a

default to set the optimal digital sampling rate.

GLOBAL SETTING / SYSTEM / POWER LINE / Phase Rotation

[POWER LINE]

Frequency:

60

>Phase Rotation: ABC

[ABC/ACB]

Range

ABC, ACB

Default ABC

Step

Select the phase rotation of the power system.

GLOBAL SETTING / SYSTEM / POWER LINE / Nominal Volt

[POWER LINE]

>Nominal Volt: 11500

[1000~30000:10V]

Range

1000 ~ 30000V

Default 11500

Step

10V

Set the rated voltage of the power system

6.1.2. Current Sensing

Locate the cursor on 2.CURRENT SENSING in SYSTEM menu, move to this menu by pressing

[ENT] button.

Enter the exact CT rate for the accurate metering and monitoring.

Enter the CT rate after changing the second side in 1 Amp.

GLOBAL SETTING / SYSTEM / CURRENT SENSING / CT-Ratio

[CURRENT SENSING]

>CT-Ratio:

1000

CT-Polarity:

FOR

[1~2000:1]

Range

1 ~ 2000

Default 1000

Step

Enter the CT rate.

GLOBAL SETTING / SYSTEM / CURRENT SENSING / CT-Polarity

48

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

[CURRENT SENSING]

CCT-Ratio:

1000

>CT-Polarity:

FOR

[FOR/REV]

Range

http://www.entecene.co.kr

Forward, Reverse

Default Forward

Step

Enter the CT polarity.

GLOBAL SETTING / SYSTEM / CURRENT SENSING / ZCT-Ratio

[CURRENT SENSING]

>ZCT-Ratio:

133.3

ZCT-Polarity:

FOR

0(OFF),0~1000.0:0.1

Range

0(OFF), 0.1 ~ 1000.0

Default 133.3

Step

0.1

Enter the ZCT rate..

GLOBAL SETTING / SYSTEM / CURRENT SENSING / CT-Polarity

[CURRENT SENSING]

CZCT-Ratio:

1.0

>ZCT-Polarity:

FOR

[FOR/REV]

Range

Forward, Reverse

Default Forward

Step

Enter the ZCT pole direction

ENHANCED TECHNOLOGY

49

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

6.1.3. Voltage Sensing

Locate the cursor on 3.VOLTAGE SENSING in the SYSTEM menu, move to this menu by

pressing the [ENT] button.

ETR300 has 2 Voltage Connectors. Voltage connectors are receiving Source side and Load side

line voltages. To measure received voltages, set Voltage connectors Connect Type, 2nd Nominal

Voltage and VT Ratio.

According to the installed line VT, ETR300 performs the voltage metering, power calculation and

direction control of over current, and the line VT can be used to perform the Phase Sync Fail.

GLOBAL SETTING / SYSTEM / VOLTAGE SENSING / 1V Connect Type

[VOLTAGE SENSING]

>1V CON-Type:

WYE

Reference Phase: A

[NONE/WYE/DELTY]

Range

NONE, WYE, DELTA

Default WYE

Step

st

Select 1V(1 voltage connector).

NONE : VT uninstalled. Select NONE if Voltage Sensing item is

not used.

WYE : If Voltage Connect type of 1V is Y type, select WYE.

DELTA : If Voltage Connect type of 1V is -type, select DELTA.

GLOBAL SETTING / SYSTEM / VOLTAGE SENSING / Reference Phase

[POWER LINE]

>1V CON-Type:

WYE

>Reference Phase: A

[A/B/C]

Range

A, B, C

Default A

Step

Enter base voltage of Voltage connector.

. NOTE ) The connect phase of main bushing changes according to

the Base Voltage of Voltage connector and phase

rotation of power system(MAIN MENU(COM)/

GLOBAL SETTING/ SYSTEM/ POWER LINE/

Phase Rotation). Table 6-1. Refer to the phase

selection according to the base voltage and phase

rotation.

50

ENHANCED TECHNOLOGY

SWITCH CONTROL ETR300-S01

http://www.entecene.co.kr

Table 6-1. Phase selection according to the base voltage and phase rotation.

Setting

Terminal

Base

Voltage

Phase

Rotation

REF A

REF B

REF C

ABC

ACB

ABC

ACB

ABC

ACB

Device A Bushing

Device B Bushing

Device C Bushing

GLOBAL SETTING / SYSTEM / VOLTAGE SENSING / 1V 2nd(V)

[VOLTAGE SENSING]

>1V 2nd(V):

4.0

>1V Ratio:

3300.0

[2.0~350.0:0.1V]

Range

2.0 ~ 350.0V

Default 4.0

Step

0.1V

Enter the second rated voltage(V) of 1V(1st Voltage connector).

This setting is the second rated voltage that entered in the relay about

line rated voltage.

GLOBAL SETTING / SYSTEM / VOLTAGE SENSING / 1V Ratio

[VOLTAGE SENSING]

>1V 2nd(V):

4.0

>1V Ratio:

3300.0

[10.0~6500.0:0.1]

Range

10.0 ~ 6500.0

Default 3300.0

Step

0.1