Professional Documents

Culture Documents

Design of Steel Structures II

Uploaded by

Ivan Jansen SaragihCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Steel Structures II

Uploaded by

Ivan Jansen SaragihCopyright:

Available Formats

Design of Steel Structures

Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

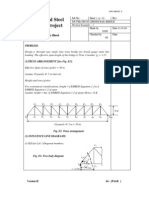

(3) Loads:

(i) Dead load - Dead loads acting on truss girder are as follows:

Weight of rails = 2 x 0.6 = 1.2 kN/m.

* Weight of sleepers = 0.25 x 0.25 x 7.5 / 0.4 = 2.34 kN/m.

Weight of fastenings (assumed) = 0.25 kN/m.

Weight of stringers (assumed) = 3.0 kN/m

Weight of cross girders (assumed) = 5.0 kN/m.

** Self-weight of truss by Fullers Formula = 13.0 kN/m

Total dead load per track = 24.8 kN/m

Therefore, Total dead load per girder = 24.8 / 2 = 12.4 kN/m

*[Assume 250 mm 250 mm 2m wooden sleepers @ 400 mm apart and weight

of 7.5 kN/m3]

** Fuller 's Formula

15l 550 15 x 50 550

13.0 kN / m

100

100

(ii) Live load

(a) Areas of Influence line diagrams for truss members discussed:

Area of influence line for L0 U1

1

x 50 x1.17

2

Area of influence line for L1U1

1

x10 x1.0

2

Area of influence line for U 4 U5

1

x 50 x 2.08

2

Area of influence line for L4 L5

1

x 50 x 2

2

Indian Institute of Technology Madras

29.3 (Compression)

(Tensile)

5.0

52

50

(Compression)

(Tensile)

Design of Steel Structures

Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

(b) Live loads and impact loads from IRS Bridge Rules - 1982:

Live loads and impact factors for each loaded length are found from IRS

Bridge Rules - 1982. For maximum forces in chord members, the whole of the

span should be loaded and Live load is determined corresponding to maximum

B.M. For other diagonal and vertical members, part of the span as indicated by

influence line diagrams, should be loaded and the live load is determined

corresponding to S.F. The impact factor is found corresponding to loaded length.

For maximum force in members L4L5 and U4U5:

Load length = 50 m

Live load for B.M. = 3895.2 kN

Impact factor = 0.15

8

6 l

(LL+ IL) per m per girder =

0.15

8

6 50

0.293

3895.2 x 1 0.293

2 x 50

50.36 kN / m

For maximum force in members L0 U1 and L1 U1:

L0 U1

Load length = 50 m

Live load for B.M. = 4184.6 kN

Impact factor = 0.15

8

6 l

(LL+ IL) per m per girder =

0.15

0.293

4184.6 x 1 0.293

L1 U1:

Load length = 10 m

Live load for S.F. = 1227.8 kN

Indian Institute of Technology Madras

8

6 50

2 x 50

54.1kN / m

Design of Steel Structures

Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Impact factor = 0.15

8

6 l

(LL+ IL) per m per girder =

8

6 50

0.15

0.293

1227.8 x 1 0.65

2 x10

101.3kN / m

(c) Longitudinal Loads from IRS Bridge Rules - 1982

Assume, there exist rail expansion joints in the bridge and prevent the

transfer of longitudinal loads to approaches. It may be noted that for broad gauge

bridges upto a loaded length of 44 m, the tractive effort is more than the braking

force and for loaded lengths more than 44 m the braking force is more than the

tractive effort.

Assume truss under consideration is simply supported by a hinge at L0

and a roller at L10. The longitudinal force in a member can be tensile or

compressive depending on the direction of movement of train.

Panel L4L5:

Loaded length = 30 m

Tractive effort = 637.4 kN

Force per chord = 637.4/2 =

318.7 kN

Unfactored loads:

Area Load in kN/m

of ILD

DL

LL+IL

DL

LL+IL

Long.L

L0 U1

- 29.3 12.4

54.1

-363.3

-1585.1

L1 U1

+5.0

12.4

101.3

+ 62

+ 506.5

U4U5

- 52.0 12.4

50.36

-644.8

-2618.7

L4L5

+ 50.0 12.4

50.36

+620

+2518

Member

Indian Institute of Technology Madras

Forces in members (kN)

Design of Steel Structures

Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Use following Partial safety factors for the loads:

DL

= 1.35;

LL

= 1.50;

LongL

= 1.50

Factored loads:

Factored Forces in members

Member (kN)

Total load (kN)

DL

LL+IL

Long.L

L0 U1

-490.4

- 2377.6

- 2868.0

L1 U1

+83.7

+ 759.8

+ 843.4

U4U5

-870.5

-3928

- 4798.5

L4L5

+ 837

+3777

+ 5092

- 478

Note: Negative sign represents compression and positive sign represents

tension.

(4) Design for truss members:

(i) Design of diagonal member (L0U1): Note that in this illustration of this

Member, the portal effect and fatigue are not considered.

Length of the chord, L0U1 = l = 7810 mm

Assume, effective length, le = 0.7*l = 5467mm

Try a built up member with two ISHB350 spaced @ 300 mm

Indian Institute of Technology Madras

Design of Steel Structures

Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

A = 18442 mm2

rx = 146.5 mm

ry = 158.8 mm

x

= 5467/146.5 = 37.3

Then,

= 221.8 N/mm2

[See chapter on axially compressed columns using curve c]

Axial capacity = (221.8/1.15)*18442/1000 = 3556.5 kN > 2868 kN

Hence, section is safe against axial compression

(ii) Design of vertical member (L1U1):

Maximum tensile force = 843.4 kN

Try ISMB 350 @ 0.524 kN/m shown.

A = 6671 mm2

Axial tension capacity of the selected section = 6671* 250/1.15

= 1450 kN > 843.4 kN

Hence, section is safe in tension.

[Note: Welded connection assumed]

(iii) Design of top chord member (U4U5):

Member length, l = 5000 mm

Assume, effective length = 0.85l = 4250 mm

Try the section shown.

A = 25786 mm2

Indian Institute of Technology Madras

Design of Steel Structures

Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

rx= 165.4 mm

ry = 210 mm

x

= 4250/165.4 = 25.7

Then,

= 239 N/mm2

[See chapter on axially compressed columns using column curve c]

Axial capacity = (239/1.15)*25786/1000 = 5359 kN > 4798.5 kN

Hence, section is safe against axial compression

(iv) Bottom chord design (L4L5):

Maximum compressive force = 478 kN

Maximum tensile force = 5092 kN

Try the box section shown.

A = 25386 mm2

rx = 144 mm

ry = 210 mm

Indian Institute of Technology Madras

Design of Steel Structures

Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Axial tension capacity of the selected section = 25386* 250/1.15

= 5518 kN > 5092 kN

Hence, section is safe in tension.

Maximum unrestrained length = l = 5000 mm

x

= 5000/144 = 34.7

Then,

= 225 N/mm2

Axial capacity = (225/1.15)* 25386/1000

= 4967 kN > 478 kN

Hence, section is safe against axial compression also.

The example is only an illustration. The following have to be taken into

consideration:

Design of lacings/batten

Design of connections and effect of bolt holes on member strength

Secondary bending effects

Design for fatigue

Indian Institute of Technology Madras

Design of Steel Structures

Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

7.9 Summary

After brief introduction, the steel used in bridges and its properties were

discussed. The broad classification of bridges was mentioned and various loads

to be considered in designing railway and highway bridges in India were

discussed. Finally analysis of girder bridges was discussed using influence line

diagrams.

This chapter deals with the design of steel bridges using Limit States

approach. Various types of plate girder and truss girder bridges were covered.

Basic considerations that are to be taken into account while designing the plate

girder bridges are emphasised. Practical considerations in the design of truss

members and lateral bracing systems are discussed briefly. A worked example

on through type truss girder Railway Bridge is given in the appendix.

Indian Institute of Technology Madras

Design of Steel Structures

Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

7.10 References

1. Owens. G.W., Knowles. P.R., Dowling. P.J. (1994): Steel Designers'

Manual, Fifth edition, Blackwell Scientific Publications.

2. Chatterjee. S. (1991): The Design of Modern Steel Bridges, First

edition, BSP Professional books.

3. Demetrios. E.T. (1994): Design, Rehabilitation and Maintenance of

Modern Highway Bridges, McGraw-Hill Publishers.

4. Victor. D.J. (1973): Essentials of Bridge Engineering, Oxford and IBH

Publishers.

5. IRC: 6 - 2000 Section II, Indian Standard for loads and stresses on

Highway Bridges.

6. Bridge rules - 1982, Specifications for Indian Railway loading.

7. ESDEP, Group 15B, Volume 25: Structural systems - Steel Bridges,

SCI, UK.

8. IS: 1915 - 1961: The Indian Standard Code of Practice for Design of

Steel Bridges

9. BS: 5400 - Part 3: 1982: British Standard Code of Practice for Design

of Steel Bridges

Indian Institute of Technology Madras

You might also like

- Unit 10 Gantry Girders: StructureDocument54 pagesUnit 10 Gantry Girders: StructureMahendra DewasiNo ratings yet

- Loading Considerations for Structural DesignDocument4 pagesLoading Considerations for Structural DesignVishal TiwariNo ratings yet

- DeflectionDocument4 pagesDeflectionronyNo ratings yet

- Gantry Beam Design PDFDocument5 pagesGantry Beam Design PDFanwarNo ratings yet

- Crane Girder Capacity CalculationDocument4 pagesCrane Girder Capacity Calculationsatoni12No ratings yet

- Design Calculation of Gantry GirderDocument7 pagesDesign Calculation of Gantry GirderKushal ChhetriNo ratings yet

- Garg, Aamod. 'Gantry Girders in India' - IJCMES PDFDocument5 pagesGarg, Aamod. 'Gantry Girders in India' - IJCMES PDFAamod GargNo ratings yet

- Gantry Girder DesignDocument6 pagesGantry Girder DesignpandianNo ratings yet

- Portal FrameDocument42 pagesPortal Framesurendra_pangaNo ratings yet

- Knee ConnectionsDocument13 pagesKnee ConnectionsNag RajNo ratings yet

- Design of Connectionv.3Document15 pagesDesign of Connectionv.3Apple Grace S. Valencia100% (1)

- Fan Foundation DesignDocument71 pagesFan Foundation DesignPalani RNo ratings yet

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- Beam Design Calculations and SelectionDocument24 pagesBeam Design Calculations and SelectionA.K.M Shafiq MondolNo ratings yet

- Column+Footing - Xls Nuwan01: SearchDocument9 pagesColumn+Footing - Xls Nuwan01: Searchmb5bariyaNo ratings yet

- Latest IS800: 2007 Purlin DesignDocument31 pagesLatest IS800: 2007 Purlin DesignGopi GopinathanNo ratings yet

- Beam to column connection design analysisDocument2 pagesBeam to column connection design analysisHAZIRACFS SURATNo ratings yet

- Structural Analysis and Design of Fuel Gas Coalescer Platform FoundationDocument29 pagesStructural Analysis and Design of Fuel Gas Coalescer Platform FoundationsridharNo ratings yet

- Raft DesignDocument8 pagesRaft Designomolewa joshuaNo ratings yet

- Isolated Footing DesignDocument5 pagesIsolated Footing DesignMJ AbunagaNo ratings yet

- Beam Bending Strenght Aisc 9th EditionDocument17 pagesBeam Bending Strenght Aisc 9th EditionKory Estes100% (1)

- Steel Section Design as per IS 800:2007Document12 pagesSteel Section Design as per IS 800:2007vishalnalwar100% (1)

- Grillage Footage - STEEL STRUCTURESDocument8 pagesGrillage Footage - STEEL STRUCTURESDarya MemonNo ratings yet

- Purlins & GirtsDocument10 pagesPurlins & GirtsRaviKiranNo ratings yet

- Staad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1Document17 pagesStaad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1kardels100% (14)

- Steel BeamDocument12 pagesSteel BeamV.m. RajanNo ratings yet

- Plinth Beam Design CalculationDocument4 pagesPlinth Beam Design CalculationVinod NairNo ratings yet

- Truss PDFDocument18 pagesTruss PDFNitesh SinghNo ratings yet

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- Indian Codes - Steel Design Per IS 800:2007Document4 pagesIndian Codes - Steel Design Per IS 800:2007Akshay Duggal100% (1)

- Design of Curved Monorail StructureDocument2 pagesDesign of Curved Monorail StructuredsanandaNo ratings yet

- Gantry GirderDocument12 pagesGantry GirderRakeshkumar T RNo ratings yet

- Design Optimization of EOT Crane GirderDocument5 pagesDesign Optimization of EOT Crane Girdermech_abhiNo ratings yet

- Mechanical Columns Buckling FailureDocument19 pagesMechanical Columns Buckling FailurePraful Patil100% (1)

- PILE FOUNDATION DESIGN Manual Cal - CommentsDocument6 pagesPILE FOUNDATION DESIGN Manual Cal - CommentsDilip PatelNo ratings yet

- Insert Plate DesignDocument8 pagesInsert Plate DesignPiyushNo ratings yet

- Shear Wall Design Presentation1Document11 pagesShear Wall Design Presentation1Parag KulkarniNo ratings yet

- Load Calculation for Pipe Conveyor Junction Tower Side RunnersDocument2 pagesLoad Calculation for Pipe Conveyor Junction Tower Side RunnersMuhammad HasanNo ratings yet

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiNo ratings yet

- Design of Combined FootingDocument23 pagesDesign of Combined Footingsameed malik100% (1)

- NOTES SeviceabilityDocument81 pagesNOTES Seviceabilitydileep 443No ratings yet

- MSFS LOAD CALCULATIONDocument9 pagesMSFS LOAD CALCULATIONNaveen RevannaNo ratings yet

- Load calculations for EOT crane framesDocument4 pagesLoad calculations for EOT crane framesknight1729No ratings yet

- Larsen & Toubros 330MW Power Plant Footing DesignDocument6 pagesLarsen & Toubros 330MW Power Plant Footing DesignAnand.5100% (1)

- 01 Design of Angle Purlin As Per Is 800 (2007) DR Ganesh KameDocument40 pages01 Design of Angle Purlin As Per Is 800 (2007) DR Ganesh KameDrGanesh Kame100% (1)

- Structural Steelwork ConnectionsDocument4 pagesStructural Steelwork Connectionstheunknown076No ratings yet

- Upgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectDocument14 pagesUpgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectkuttakhaoNo ratings yet

- Truss DesignDocument10 pagesTruss DesignselvakumarNo ratings yet

- Steel Truss DesignDocument10 pagesSteel Truss DesignRichard Teves100% (3)

- Static Instability Analysis of Long-Span Cable-Stayed Bridges With Carbon Fiber Composite Cable Under Wind LoadDocument8 pagesStatic Instability Analysis of Long-Span Cable-Stayed Bridges With Carbon Fiber Composite Cable Under Wind Loadshimic32000No ratings yet

- Example of Structural CalculationDocument18 pagesExample of Structural Calculationdeua2004No ratings yet

- MODULE VIII ColumnDocument19 pagesMODULE VIII ColumnNiel John BaquilarNo ratings yet

- SM 1Document1 pageSM 1Technical4uNo ratings yet

- Materials: Shear Behavior Models of Steel Fiber Reinforced Concrete Beams Modifying Softened Truss Model ApproachesDocument21 pagesMaterials: Shear Behavior Models of Steel Fiber Reinforced Concrete Beams Modifying Softened Truss Model Approachesmoraru_gabriel_2No ratings yet

- Scomposite-24.24Document87 pagesScomposite-24.24manish sharmaNo ratings yet

- Text 3Document2 pagesText 3Amiid Ahmed AbdiNo ratings yet

- Buckling Analysis of 4140 Alloy Steel Columns with Different Cross SectionsDocument9 pagesBuckling Analysis of 4140 Alloy Steel Columns with Different Cross Sectionssmg26thmayNo ratings yet

- 2.13 Nonlinear Finite Element Analysis of Unbonded Post-Tensioned Concrete BeamsDocument6 pages2.13 Nonlinear Finite Element Analysis of Unbonded Post-Tensioned Concrete Beamsfoufou2003No ratings yet

- Soil InvestigationDocument5 pagesSoil InvestigationIvan Jansen SaragihNo ratings yet

- Foundation BookDocument4 pagesFoundation BookIvan Jansen SaragihNo ratings yet

- Basics of Foundation DesignDocument8 pagesBasics of Foundation DesignIvan Jansen SaragihNo ratings yet

- STS03601 (Epoxy Grout Specification)Document9 pagesSTS03601 (Epoxy Grout Specification)keshavnvaityNo ratings yet

- Basics of Foundation DesignDocument9 pagesBasics of Foundation DesignIvan Jansen SaragihNo ratings yet

- Shell Design and Tank ConstructionDocument9 pagesShell Design and Tank ConstructionIvan Jansen Saragih0% (1)

- Pile Foundation EngineeringDocument11 pagesPile Foundation EngineeringIvan Jansen SaragihNo ratings yet

- One For StructureDocument1 pageOne For StructureIvan Jansen SaragihNo ratings yet

- Rate Analysis For ConcDocument6 pagesRate Analysis For Concamandeepsuperan100% (1)

- Factorio Train Automation (Parts 1-3)Document99 pagesFactorio Train Automation (Parts 1-3)Anonymous v86yaQKFNo ratings yet

- Year 8 SCDocument4 pagesYear 8 SCAmarpreet Kaur0% (1)

- Sedan Automobile)Document5 pagesSedan Automobile)salunkhe_pramodNo ratings yet

- Airport Engineering-1 PDFDocument106 pagesAirport Engineering-1 PDFSanthosh KumarNo ratings yet

- Debarment Notice Structure Failure Reg - SMSDocument2 pagesDebarment Notice Structure Failure Reg - SMSDevesh Kumar PandeyNo ratings yet

- Tiger in The Tunnel by Ruskin BondDocument9 pagesTiger in The Tunnel by Ruskin BondRajrupa Saha100% (1)

- Kajang Local Plan Sustainable DevelopmentDocument51 pagesKajang Local Plan Sustainable DevelopmentYong Siew FengNo ratings yet

- KC Aa201afig1Document292 pagesKC Aa201afig1locario1No ratings yet

- OOSP B1Plus AnEventfulJourney Yourname PDFDocument1 pageOOSP B1Plus AnEventfulJourney Yourname PDFWilser Aldair Condori HolgadoNo ratings yet

- Persuade Against Distracted DrivingDocument5 pagesPersuade Against Distracted DrivingAirul Anuar50% (2)

- Spouses Teodoro and Nanette Perena v. Spouses Nicolas and Teresita L. Zarate, G.R. No. 157917, August 29, 2012Document38 pagesSpouses Teodoro and Nanette Perena v. Spouses Nicolas and Teresita L. Zarate, G.R. No. 157917, August 29, 2012JasenNo ratings yet

- Active School Travel Worksheet 1 - Crossing The Road The Roadstar WayDocument3 pagesActive School Travel Worksheet 1 - Crossing The Road The Roadstar WayPatricia GeorgeNo ratings yet

- Versova Bandra Sea Link Structural Design StatusDocument18 pagesVersova Bandra Sea Link Structural Design StatusPravin AwalkondeNo ratings yet

- Details of Road Projects in Andhra Pradesh Projects Inaugurated: Sanctioned Cost (Rs in CR) StatusDocument22 pagesDetails of Road Projects in Andhra Pradesh Projects Inaugurated: Sanctioned Cost (Rs in CR) StatusRamana ReddyNo ratings yet

- Boating Safety Signage and Buoyage GuidelinesDocument31 pagesBoating Safety Signage and Buoyage Guidelinesshanrama100% (1)

- Hyundai Sonata Engine Failure Recall Lawsuit AttorneysstlwDocument4 pagesHyundai Sonata Engine Failure Recall Lawsuit Attorneysstlweraoboe4No ratings yet

- Safe Scaffolding CodeDocument134 pagesSafe Scaffolding CodeFadel Muhammad AkbarNo ratings yet

- NHAI Safety Manual PDFDocument239 pagesNHAI Safety Manual PDFSonia MazumderNo ratings yet

- A Critical Review of Bituminous Mixes Used in IndiaDocument42 pagesA Critical Review of Bituminous Mixes Used in IndiaProf. Prithvi Singh Kandhal100% (2)

- Toyota Premio NZT260Document7 pagesToyota Premio NZT260jaliyaw100% (2)

- Road Geometry Section 2 Junctions: Design Manual For Roads and BridgesDocument51 pagesRoad Geometry Section 2 Junctions: Design Manual For Roads and BridgesukhmcducjwNo ratings yet

- 2001 enDocument1 page2001 enRicardo Marcia DonadonNo ratings yet

- E Comm Rai UniversityDocument97 pagesE Comm Rai UniversityhitkNo ratings yet

- Jazz 2014 BrochureDocument21 pagesJazz 2014 BrochureRichard SuakingNo ratings yet

- AXOR Specifications GuideDocument18 pagesAXOR Specifications Guideenzo7259No ratings yet

- Charity Man Hit With Fine For Parking in Deserted Bus Lane: Kitchen WorktopsDocument1 pageCharity Man Hit With Fine For Parking in Deserted Bus Lane: Kitchen WorktopsJacob JarvisNo ratings yet

- Improving Silay-Lantawan RoadDocument10 pagesImproving Silay-Lantawan RoadRandy Cerna100% (1)

- Harbours and Landing Places On The Balka PDFDocument59 pagesHarbours and Landing Places On The Balka PDFFityDianiNo ratings yet

- MS - 4 Manhole Installation Rev.0 BausherDocument18 pagesMS - 4 Manhole Installation Rev.0 BausherSyed Umair HashmiNo ratings yet