Professional Documents

Culture Documents

Methanol To Gasoline

Uploaded by

hhvgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methanol To Gasoline

Uploaded by

hhvgCopyright:

Available Formats

Methanol to Gasoline

May 2012 Report Contents

Methanol to Gasoline

Table of Contents

A Report by Nexants CHEMSYSTEMS

Process Evaluation/Research Planning (PERP) Program

PERP 2011S7 - Published May 2012

www.chemsystems.com

Section

1

Executive Summary .................................................................................................

1.1.1

Sources of Methanol ..........................................................................

1.1.2

Methanol as Automotive Fuel ............................................................

1.1.3

Methanol as a Blending Feedstock (M15 & M85) in

Automotive Fuel ................................................................................

1.1.4

Applications and Relevant Government Policies ..............................

1.1.5

Strategic, Technical, and Commercial Considerations of

Methanol Gasoline versus Gasoline from Methanol .........................

CHEMISTRY ................................................................................................

1.2.1

MTG Chemistry .................................................................................

1.3

MTG TECHNOLOGY ..................................................................................

1.5

RECENT TECHNOLOGY AND COMMERCIALIZATION

DEVELOPMENT ..........................................................................................

STATUS OF MTG COMMERCIALIZATION AND OPERATIONS.........

1.6.1

Outlook of MTG Technologies ..........................................................

ECONOMIC ANALYSIS .............................................................................

1.7.1

China (Shanxi Province) ....................................................................

1.7.2

United States Gulf Coast (USGC) .....................................................

11

COMMERCIAL ANALYSIS ........................................................................

13

1.8.1

Global Overview ................................................................................

13

Introduction ..............................................................................................................

16

2.1

COAL TO GASOLINE .................................................................................

16

2.2

HISTORY OF THE METHANOL TO GASOLINE (MTG)

PROCESS ......................................................................................................

17

2.2.1

Development of MTG Process in New Zealand ................................

17

SOURCES OF METHANOL ........................................................................

18

1.2

1.6

1.7

1.8

2

Page

2.3

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

PERP 2011S7, Methanol to Gasoline

A00101.0011.4115

Methanol to Gasoline

2.3.1

Methanol from Natural Gas ...............................................................

18

2.3.2

Methanol from Coal ...........................................................................

20

METHANOL AS AUTOMOTIVE FUEL ....................................................

23

2.4.1

Direct use of Methanol as Automotive Fuel ......................................

23

2.4.2

Methanol as Fuel Blending Feedstock (M15 & M85) .......................

25

2.4.3

Applications and Relevant Government Policies ..............................

26

STRATEGIC, TECHNICAL, AND COMMERCIAL

CONSIDERATIONS OF METHANOL GASOLINE VERSUS

GASOLINE FROM METHANOL ................................................................

26

ORGNIZATION OF THE REPORT .............................................................

29

Chemistry and Technology .....................................................................................

30

3.1

METHANOL TO GASOLINE (MTG) CHEMISTRY .................................

30

3.1.1

MTG Chemistry and Reaction Mechanism .......................................

30

3.1.2

Zeolite Socony Mobil # 5 (ZSM-5) Catalyst .....................................

31

3.2

ORIGINAL MOBIL MTG PROCESS FIXED BED PROCESS ...............

33

3.3

URBK-UHDE-MOBIL MTG PROCESS FLUID BED PROCESS ..........

38

3.4

LURGI-MOBIL MTG PROCESS MULTI TUBULAR FIXEDBED REACTOR ............................................................................................

40

COMPARISON OF TRADITIONAL MTG PROCESS ...............................

43

Recent Technology and Commercialization Development ..................................

45

2.4

2.5

2.6

3

3.5

4

4.1

RECENT METHANOL TO GASOLINE (MTG) TECHNOLOGY

DEVELOPMENTS ........................................................................................

45

4.1.1

Second Generation ExxonMobil MTG Process .................................

45

4.1.2

One-Step MTG Process .....................................................................

45

OTHER TECHNOLOGIES ...........................................................................

46

4.2.1

Topsoe Integrated Gasoline Synthesis (TIGAS) Process ..................

46

4.3

STATUS OF MTG COMMERCIALIZATION AND OPERATIONS.........

48

4.4

OUTLOOKS OF MTG TECHNOLOGIES...................................................

48

Process Economics ...................................................................................................

50

5.1

BASIS ............................................................................................................

50

5.1.1

Pricing Basis ......................................................................................

50

5.1.2

Investment Basis ................................................................................

51

5.1.3

Cost of Production Definitions ..........................................................

52

METHANOL TO GASOLINE COST OF PRODUCTION

ESTIMATES - CHINA LOCATION BASIS ................................................

53

4.2

May 2012 Report Contents

5.2

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

PERP 2011S7, Methanol to Gasoline

A00101.0011.4115

Methanol to Gasoline

May 2012 Report Contents

5.2.1

Gasoline Production using Coal-based Methanol ..............................

53

5.2.2

Gasoline Production using Natural Gas-Based Methanol .................

60

5.2.3

Gasoline Production using Purchased Methanol ...............................

67

METHANOL TO GASOLINE COST OF PRODUCTION

ESTIMATES U.S. LOCATION BASIS .....................................................

72

5.3.1

Gasoline Production using Coal-Based Methanol .............................

72

5.3.2

Gasoline Production using Natural Gas-Based Methanol .................

80

5.3.3

Gasoline Production using Purchased Methanol ...............................

86

COST COMPARISON ..................................................................................

90

5.4.1

China ..................................................................................................

90

5.4.2

United States Gulf Coast ....................................................................

93

Commercial Analysis ...............................................................................................

96

6.1

GLOBAL OVERVIEW .................................................................................

96

6.1.1

Demand ..............................................................................................

96

6.1.2

Current and Planned Refining Capacity ............................................

96

6.1.3

Supply ................................................................................................

98

6.1.4

Net Trade ...........................................................................................

100

REGIONAL MARKET ANALYSIS ............................................................

101

6.2.1

North America ...................................................................................

101

6.2.2

South America ...................................................................................

103

6.2.3

Western Europe ..................................................................................

105

6.2.4

Eastern Europe ...................................................................................

107

6.2.5

Africa .................................................................................................

109

6.2.6

Middle East ........................................................................................

111

6.2.7

Asia ....................................................................................................

113

Glossary ....................................................................................................................

116

References .................................................................................................................

119

CHEMSYSTEMS PERP PROGRAM

PERP 2011S7, Methanol to Gasoline

5.3

5.4

6.2

www.chemsystems.com

A00101.0011.4115

Methanol to Gasoline

May 2012 Report Contents

Appendix

Page

Definitions of Capital Cost Terms Used in Process Economics ...........................

A-1

Definitions of Operating Cost Terms Used in Process Economics ......................

B-1

PERP Program Title Index (2001/2002 - 2011) .....................................................

C-1

CHEMSYSTEMS PERP PROGRAM

PERP 2011S7, Methanol to Gasoline

www.chemsystems.com

A00101.0011.4115

Methanol to Gasoline

May 2012 Report Contents

Figure

Page

1.1

Gasoline Production Cost Comparison - China .........................................................

10

1.2

Gasoline Production Cost Comparison - USGC ........................................................

13

2.1

Producing Gasoline from Coal (CTG Route) ............................................................

17

2.2

Major Gasification Reactions ....................................................................................

21

2.3

Flow Scheme for the Production of Methanol from Coal..........................................

22

2.4

Vapor Pressure of Methanol-Gasoline Blends ...........................................................

25

2.5

Price Comparison Among Crude Oil, Gasoline and Methanol..................................

27

3.1

Structure of ZSM-5 Catalyst Pentasil Unit .............................................................

32

3.2

Structure of ZSM-5 Catalyst Pentasil Chain...........................................................

32

3.3

Structure of ZSM-5 Catalyst Corrugated Sheet ......................................................

32

3.4

Structure of ZSM-5 Catalyst Channel Structure .....................................................

33

3.5

Mobil Fixed-Bed MTG Process Methanol to Raw Gasoline ..................................

35

3.6

Mobil Fixed-bed MTG Process Raw Gasoline Upgrading .....................................

37

3.7

URBK-UHDE-MOBIL Fluid-bed MTG Process ......................................................

39

3.8

Lurgi-Mobil Multi Tubular MTG Process .................................................................

42

4.1

TIGAS Process Block Flow Diagram ........................................................................

46

5.1

Effects of Coal Price on Gasoline Cost of Production...............................................

58

5.2

Effects of Total Capital Employed on Gasoline Cost of Production .........................

59

5.3

Effects of Capacity on Gasoline Cost of Production .................................................

60

5.4

Effects of Natural Gas Price on Gasoline Cost of Production ...................................

64

5.5

Effects of Total Capital Employed on Gasoline Cost of Production .........................

65

5.6

Effects of Capacity on Gasoline Cost of Production .................................................

66

5.7

Effects of Natural Gas Price on Gasoline Cost of Production ...................................

69

5.8

Effects of Total Capital Employed on Gasoline Cost of Production .........................

70

5.9

Effects of Capacity on Gasoline Cost of Production .................................................

71

5.10 Effects of Coal Price on Gasoline Cost of Production...............................................

77

5.11 Effects of Total Capital Employed on Gasoline Cost of Production .........................

78

5.12 Effects of Capacity on Gasoline Cost of Production .................................................

79

5.13 Effects of Natural Gas Price on Gasoline Cost of Production ...................................

83

5.14 Effects of Total Capital Employed on Gasoline Cost of Production .........................

84

5.15 Effects of Capacity on Gasoline Cost of Production .................................................

85

5.16 Effects of Natural Gas Price on Gasoline Cost of Production ...................................

88

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

PERP 2011S7, Methanol to Gasoline

A00101.0011.4115

Methanol to Gasoline

May 2012 Report Contents

5.17 Effects of Total Capital Employed on Gasoline Cost of Production .........................

89

5.18 Effects of Capacity on Gasoline Cost of Production .................................................

90

5.19 Gasoline Production Cost Comparison - China .........................................................

92

5.20 Gasoline Production Cost Comparison - USGC ........................................................

95

6.1

World Refining Capacity ...........................................................................................

97

6.2

Global Refining..........................................................................................................

98

6.3

Regional Refinery Utilization ....................................................................................

98

6.4

Global Gasoline Trade ...............................................................................................

100

6.5

Gasoline Supply, Demand, and Trade in North America ..........................................

102

6.6

North American Refinery Utilization ........................................................................

103

6.7

Gasoline Supply, Demand, and Trade in South America ..........................................

104

6.8

South America Refinery Utilization ..........................................................................

105

6.9

Gasoline Supply, Demand, and Trade in Western Europe ........................................

106

6.10 Western Europe Refinery Utilization.........................................................................

107

6.11 Gasoline Supply, Demand, and Trade in Eastern Europe ..........................................

108

6.12 Eastern Europe Refinery Utilization ..........................................................................

109

6.13 Gasoline Supply, Demand, and Trade in Africa ........................................................

110

6.14 African Refinery Utilization ......................................................................................

111

6.15 Gasoline Supply, Demand, and Trade in the Middle East .........................................

112

6.16 Middle East Refinery Utilization ...............................................................................

113

6.17 Gasoline Supply, Demand, and Trade in Asia ...........................................................

114

6.18 Asian Refinery Utilization .........................................................................................

115

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

PERP 2011S7, Methanol to Gasoline

A00101.0011.4115

Methanol to Gasoline

May 2012 Report Contents

Table

Page

1.1

MTG Gasoline versus U.S. Conventional Refinery Gasoline ...................................

1.2

Comparison between Fixed-bed and Fluid-Bed MTG Process .................................

1.3

Summary of MTG Plants ...........................................................................................

1.4

Gasoline Production Cost Summary - China .............................................................

1.5

Gasoline Production Cost Summary - USGC ............................................................

12

1.6

Worldwide Refined Products Demand ......................................................................

14

1.7

Worldwide Gasoline Demand by Region ..................................................................

15

2.1

Comparison of Methanol and Gasoline Properties ....................................................

23

2.2

MTG Gasoline versus U.S. Conventional Refinery Gasoline ...................................

28

3.1

Operating Conditions for Fixed-bed MTG Process ...................................................

36

3.2

Operating Conditions for Fluid-bed MTG Process ....................................................

40

3.3

Comparison between Fixed-bed and Fluid-Bed MTG Process .................................

44

4.1

Summary of MTG Plants ...........................................................................................

48

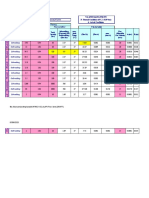

5.1

Price and Utilities Basis .............................................................................................

51

5.2

Methanol-to-gasoline Capital Cost Estimates............................................................

52

5.3

Cost of Production Estimate for: Syngas

Process: Coal Gasification and Water-Gas Shift .......................................................

55

Cost of Production Estimate for: Methanol

Process: via Syngas (SN = 2:1 H2:CO) ......................................................................

56

Cost of Production Estimate for: Gasoline

Process: ExxonMobils MTG Process (Coal-Based Methanol) ................................

57

Cost of Production Estimated for: Methanol

Process: via Syngas Derived from Natural Gas .........................................................

62

Cost of Production Estimate for: Gasoline

Process: ExxonMobils MTG Process (Natural Gas-Based Methanol) .....................

63

Cost of Production Estimate for: Gasoline

Process: ExxonMobils MTG Process (purchased methanol) ...................................

68

Cost of Production Estimate for: Syngas

Process: Coal Gasification and Water-gas Shift ........................................................

74

5.10 Cost of Production Estimate for: Methanol

Process: via Syngas (SN = 2:1 H2:CO) ......................................................................

75

5.11 Cost of Production Estimate for: Gasoline

Process: ExxonMobils MTG Process (Coal-Based Methanol) ................................

76

5.12 Cost of Production Estimate for: Methanol

Process: via Natural Gas ............................................................................................

81

5.4

5.5

5.6

5.7

5.8

5.9

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

PERP 2011S7, Methanol to Gasoline

A00101.0011.4115

Methanol to Gasoline

May 2012 Report Contents

5.13 Cost of Production Estimate for: Gasoline

Process: ExxonMobils MTG Process (Natural Gas-Based Methanol) .....................

82

5.14 Cost of Production Estimate for: Gasoline

Process: ExxonMobils MTG Process (Purchased Methanol)...................................

87

5.15 Gasoline Production Cost Summary - China .............................................................

91

5.16 Gasoline Production Cost Summary - USGC ............................................................

94

6.1

Worldwide Gasoline Demand by Region ..................................................................

96

6.2

Worldwide Refined Products Supply.........................................................................

99

6.3

Worldwide Gasoline Supply by Region ....................................................................

100

6.4

Worldwide Gasoline Net Trade .................................................................................

101

CHEMSYSTEMS PERP PROGRAM

PERP 2011S7, Methanol to Gasoline

www.chemsystems.com

A00101.0011.4115

Methanol to Gasoline

May 2012 Report Contents

CHEMSYSTEMS

PERP PROGRAM

www.chemsystems.com

The ChemSystems Process Evaluation/Research Planning (PERP) program is

recognized globally as the industry standard source for information relevant to

the chemical process and refining industries. PERP reports are available as a

subscription program or on a single report basis.

Contact Details:

London: Dr. Alexander Coker, Manager, PERP Program

Phone: + 44-(20)-7950-1570, e-mail: acoker@nexant.com

New York: Heidi Junker Coleman, Global Multi-Client Programs Support Manager

Phone: + 1-914-609-0381, e-mail: hcoleman@nexant.com

Shanghai: Dr. Y. Larry Song, General Manager, Nexant China

Phone: +86 21 6182 6791, e-mail: ylsong@nexant.com

Nexant, Inc. (www.nexant.com) is a leading management consultancy to the global energy, chemical, and related industries. For over 38 years,

ChemSystems has helped clients increase business value through assistance in all aspects of business strategy, including business intelligence, project

feasibility and implementation, operational improvement, portfolio planning, and growth through M&A activities. Nexant has its main offices in

San Francisco (California), White Plains (New York), and London (UK), and satellite offices worldwide.

Copyright by Nexant Inc. 2012. All Rights Reserved.

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

PERP 2011S7, Methanol to Gasoline

A00101.0011.4115

You might also like

- 2012 5 Toc r1Document11 pages2012 5 Toc r1adame_uds100% (1)

- Comparative Evaluation of Cryogenic Air SeparationDocument21 pagesComparative Evaluation of Cryogenic Air SeparationmuratNo ratings yet

- Df-25054-Rep-03-001 (Proceso H2)Document110 pagesDf-25054-Rep-03-001 (Proceso H2)María Macharé GutierrezNo ratings yet

- 0809S2 - Abs Nexant Report Phosphoric AcidDocument6 pages0809S2 - Abs Nexant Report Phosphoric Acidlhphong021191No ratings yet

- Preparing Indonesia For Its Petrochemical Future: Prof. Dr. Ir Maizar Rahman Chairman, Scientific BoardDocument25 pagesPreparing Indonesia For Its Petrochemical Future: Prof. Dr. Ir Maizar Rahman Chairman, Scientific BoardUnggul WahyuNo ratings yet

- Celanese PFD of MethanolDocument1 pageCelanese PFD of MethanolJessica CehNo ratings yet

- Electric Heaters For Safe Startup ofDocument9 pagesElectric Heaters For Safe Startup ofSteve WanNo ratings yet

- National Fertilizers Limited Nan Gal PunjabDocument3 pagesNational Fertilizers Limited Nan Gal PunjabNirmanyu JamwalNo ratings yet

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectFrom EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectNo ratings yet

- Photochemical Splitting of Water For Hydrogen ProductionDocument17 pagesPhotochemical Splitting of Water For Hydrogen ProductionClaudiaOllivveiraNo ratings yet

- Bio Fuels Blending & Technology PresentationDocument62 pagesBio Fuels Blending & Technology PresentationDaniel KunnigerNo ratings yet

- MTG ProcessDocument59 pagesMTG ProcessShehzad Afzal MaharNo ratings yet

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)From EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)No ratings yet

- FULLTEXT01Document210 pagesFULLTEXT01Mohamed TarekNo ratings yet

- OPEX Methanol Project in MozambiqDocument16 pagesOPEX Methanol Project in MozambiqUmesh DeshNo ratings yet

- 8q1pQq PDFDocument100 pages8q1pQq PDFJonathan Riveros RojasNo ratings yet

- PFDDocument1 pagePFDDenny FirmansyahNo ratings yet

- Techno Economic Evaluation of Bio Hydrogen ProductionDocument157 pagesTechno Economic Evaluation of Bio Hydrogen ProductionacikkalpgermanNo ratings yet

- Methyldiethanolamine As A Solvent For Gas DesulfurizationDocument66 pagesMethyldiethanolamine As A Solvent For Gas DesulfurizationAnime MtNo ratings yet

- Haldor Topsoe Hter First ExperiencesDocument8 pagesHaldor Topsoe Hter First ExperiencesGeorge Van BommelNo ratings yet

- KBR Advanced Ammonia Process PlusDocument1 pageKBR Advanced Ammonia Process PlusGajanan PadamwarNo ratings yet

- A Comprehensive Review On Wind Turbine Power Curve Modeling TechniquesDocument9 pagesA Comprehensive Review On Wind Turbine Power Curve Modeling Techniquesel_ruso__83No ratings yet

- 2019jan - IECM Amine-Based CO2 Capture PDFDocument63 pages2019jan - IECM Amine-Based CO2 Capture PDFFunky labsNo ratings yet

- Alcohol OctaneDocument18 pagesAlcohol OctanetoanvmpetrologxNo ratings yet

- Final ReportDocument29 pagesFinal ReportpratikNo ratings yet

- Hydroprocessing for Clean Energy: Design, Operation, and OptimizationFrom EverandHydroprocessing for Clean Energy: Design, Operation, and OptimizationNo ratings yet

- Finn JoensenDocument30 pagesFinn JoensenYogga AdhityaNo ratings yet

- Cansolv CO Capture: The Value of Integration: Energy ProcediaDocument10 pagesCansolv CO Capture: The Value of Integration: Energy ProcediasaverrNo ratings yet

- New SynCOR Ammonia™ ProcessDocument12 pagesNew SynCOR Ammonia™ Processrukam18No ratings yet

- Uop Merox Process: G. A. DziabisDocument13 pagesUop Merox Process: G. A. Dziabisespectrox07No ratings yet

- Topsoe EFUELS Technology For Converting CO2 To Renewable Synthetic FuelDocument19 pagesTopsoe EFUELS Technology For Converting CO2 To Renewable Synthetic FuelBen PowersNo ratings yet

- Amine AbsorberDocument4 pagesAmine AbsorberAnonymous v5uipHNo ratings yet

- Case Story DK - Green Methanol - Web 1Document4 pagesCase Story DK - Green Methanol - Web 1Pao M. MorenoNo ratings yet

- Air Separation Plants History and Technological Progress 2019 Tcm19 457349Document28 pagesAir Separation Plants History and Technological Progress 2019 Tcm19 457349Jambanlaya JasdNo ratings yet

- Maleic Anhydride Expansion ProjectDocument2 pagesMaleic Anhydride Expansion Projectthaneiro100% (1)

- Techno-Economic Assessment About PropyleneDocument6 pagesTechno-Economic Assessment About PropyleneIntratec SolutionsNo ratings yet

- Rectisol Aspen ModelDocument236 pagesRectisol Aspen ModelXristoforos Tsak100% (1)

- 201105151926340.nexant Industry Report 2011Document40 pages201105151926340.nexant Industry Report 2011yudhie_7No ratings yet

- Methanol Safe Handling Manual Final EnglishDocument207 pagesMethanol Safe Handling Manual Final Englishkenoly123No ratings yet

- Simulation and Evaluation of Flare Gas Recovery Unit For RefineriesDocument7 pagesSimulation and Evaluation of Flare Gas Recovery Unit For RefineriesJohnNo ratings yet

- Dewatering Column AA Grade MethanolDocument15 pagesDewatering Column AA Grade MethanolIrma BrennanNo ratings yet

- Small-Scale LNG Production System Using Ammonia AbsorptionDocument13 pagesSmall-Scale LNG Production System Using Ammonia Absorptionkaspersky2009No ratings yet

- Uhde Brochure Ammonia SCR PDFDocument28 pagesUhde Brochure Ammonia SCR PDFBaher ElsheikhNo ratings yet

- ButadieneDocument18 pagesButadieneminkucenNo ratings yet

- AmmoniaDocument24 pagesAmmoniaCamilo GarzonNo ratings yet

- Navigant's Kitimat Refinery Final ReportDocument33 pagesNavigant's Kitimat Refinery Final ReportThe Vancouver SunNo ratings yet

- Applying flare monitoring to identify major flaring contributorsDocument3 pagesApplying flare monitoring to identify major flaring contributorsrvkumar61No ratings yet

- Bringing It Together: Sophie Babusiaux Leandro Labanca Marie-Amélie Lambert Remi MoniotDocument41 pagesBringing It Together: Sophie Babusiaux Leandro Labanca Marie-Amélie Lambert Remi MoniotvietnampetrochemicalNo ratings yet

- Design Concentratiion-Class B FuelsDocument14 pagesDesign Concentratiion-Class B Fuelsmiguel angel garciaNo ratings yet

- Review of Small Stationary Reformers For Hydrogen ProductionDocument52 pagesReview of Small Stationary Reformers For Hydrogen ProductionSoineth GuzmánNo ratings yet

- 4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev ClaesDocument8 pages4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev Claesvaratharajan g rNo ratings yet

- GTL TechnologyDocument24 pagesGTL Technologychaitanya_scribd100% (1)

- Chapter V Regional Market Analysis PDFDocument222 pagesChapter V Regional Market Analysis PDFester dNo ratings yet

- 50 Olefin ReductionDocument2 pages50 Olefin ReductiondimkuhNo ratings yet

- VBE - Aug2008 Pressure Loss CalculatorDocument9 pagesVBE - Aug2008 Pressure Loss Calculatorakhilendraa4074No ratings yet

- Engineeringpracticejan2016 PDFDocument17 pagesEngineeringpracticejan2016 PDFChemkhiNo ratings yet

- How to calculate circulation ratio in a heat recovery boilerDocument17 pagesHow to calculate circulation ratio in a heat recovery boilerSatrio HaryoNo ratings yet

- Process Data Sheet of Incinerator Package Unit 113X-X1: Biturox ProjectDocument15 pagesProcess Data Sheet of Incinerator Package Unit 113X-X1: Biturox ProjecthhvgNo ratings yet

- Ambient Heat Loss From A VesselDocument2 pagesAmbient Heat Loss From A VesselandersonNo ratings yet

- Bitumen Bitorex-HMBDocument1 pageBitumen Bitorex-HMBhhvgNo ratings yet

- Saudi Arabia Petrochemical Industry LeadersDocument1 pageSaudi Arabia Petrochemical Industry LeadershhvgNo ratings yet

- Design Consideration of Hot Oil SystemDocument24 pagesDesign Consideration of Hot Oil SystemOmar EzzatNo ratings yet

- Atmospheric and Low Pressure Tank Venting RequirementsDocument4 pagesAtmospheric and Low Pressure Tank Venting Requirementshhvg100% (1)

- See Sheet API-2000: Normal Venting Liquid Movement Thermal EffectDocument33 pagesSee Sheet API-2000: Normal Venting Liquid Movement Thermal EffecthhvgNo ratings yet

- Flow Assurance Study For A Waxy Crude Oil PDFDocument73 pagesFlow Assurance Study For A Waxy Crude Oil PDFhhvgNo ratings yet

- Methanol To Gasoline: PERP 2011S7Document7 pagesMethanol To Gasoline: PERP 2011S7hhvgNo ratings yet

- Fall1391 Schedule MenDocument1 pageFall1391 Schedule MenhhvgNo ratings yet

- Bornemann - Twin Screw Pumps - Series W, V, U and TDocument16 pagesBornemann - Twin Screw Pumps - Series W, V, U and Tfwkl100% (1)

- Ajax DPC-2803 PDFDocument304 pagesAjax DPC-2803 PDFPaul Villa100% (3)

- Petrophysics in Shale GasDocument26 pagesPetrophysics in Shale GasAtul Bhoil100% (1)

- SSP 823603 3.2 - 3.6-FsiDocument72 pagesSSP 823603 3.2 - 3.6-Fsiaulin64_845645735No ratings yet

- Bosch p7100 Injection Pump Service Manual PDFDocument2 pagesBosch p7100 Injection Pump Service Manual PDFAdam Johnson7% (14)

- Technical SeminarDocument10 pagesTechnical Seminarprapto_tmNo ratings yet

- CPC PDFDocument2 pagesCPC PDFQichiix Kici100% (1)

- Alloytech VACCDocument8 pagesAlloytech VACCDaniel Hernandez100% (2)

- Waste Heat Recovery NDocument28 pagesWaste Heat Recovery NranveerNo ratings yet

- Braking R2900 PDFDocument56 pagesBraking R2900 PDFJunior Enrique Yataco Ariza100% (2)

- Pps 951103 Audi Variable Transmission 01j EngDocument99 pagesPps 951103 Audi Variable Transmission 01j EngManos StavrouNo ratings yet

- 2011 Devcon Permatex CatalogDocument52 pages2011 Devcon Permatex CatalogEBPENICHE6400No ratings yet

- (12.2.624) Aviation Refueling Business: A Goldmine of OpportunitiesDocument6 pages(12.2.624) Aviation Refueling Business: A Goldmine of OpportunitiesMuhammed SulfeekNo ratings yet

- D1 - T3 - Michael Goff - Black & VeatchDocument30 pagesD1 - T3 - Michael Goff - Black & VeatchSumant AggNo ratings yet

- AVL Emission Testing Handbook V1.0 PA3088E PDFDocument80 pagesAVL Emission Testing Handbook V1.0 PA3088E PDFmrginj67% (3)

- Chemical Quenching PDFDocument80 pagesChemical Quenching PDFAnonymous MAJuDkNo ratings yet

- Eliminate foam carryover to increase diesel and AGO yieldsDocument8 pagesEliminate foam carryover to increase diesel and AGO yieldsNXVNNo ratings yet

- Ivy Bridge House: Greenergy International LTD AddressDocument92 pagesIvy Bridge House: Greenergy International LTD AddressJohn Adam St Gang: Crown ControlNo ratings yet

- Main Engine Fuel Injection Valve Damage: ReturnDocument5 pagesMain Engine Fuel Injection Valve Damage: ReturnKupujem HNNo ratings yet

- Turbine Prestartup ChecklistDocument4 pagesTurbine Prestartup ChecklistSCE SOLAPURNo ratings yet

- John Paul de Villa: Work Experience SkillsDocument1 pageJohn Paul de Villa: Work Experience SkillsJohn De VillaNo ratings yet

- Self-Study Guide # 6 For 10 GradeDocument8 pagesSelf-Study Guide # 6 For 10 GradeJuandi CordobaNo ratings yet

- K Series 750-1010 (K38)Document4 pagesK Series 750-1010 (K38)sameer_ponnadaNo ratings yet

- Submitted To-Ajmer Singh Presented by Sandeep Kumar: Topic - Tesla Electric Vehicle Design TechnologiesDocument8 pagesSubmitted To-Ajmer Singh Presented by Sandeep Kumar: Topic - Tesla Electric Vehicle Design Technologiessandeep kumarNo ratings yet

- 26 10215spDocument2 pages26 10215spAndres Meneses100% (1)

- Sliding Contact Bearing NotesDocument4 pagesSliding Contact Bearing NotesSp PatelNo ratings yet

- NPSH MarginDocument5 pagesNPSH MarginKCFUNGNo ratings yet

- TLC PaprikaDocument6 pagesTLC Paprikamaysilee-katnissNo ratings yet

- MC DE - EEC Form 4A AEUR Commercial DEsDocument4 pagesMC DE - EEC Form 4A AEUR Commercial DEsJohn Evan Raymund BesidNo ratings yet

- (V) Residue Upgrading Using Ebullated Bed Hydrocracking - CriterionDocument2 pages(V) Residue Upgrading Using Ebullated Bed Hydrocracking - CriterionKwangsjungNo ratings yet