Professional Documents

Culture Documents

List of MiniProject Titles

Uploaded by

Ben AzriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

List of MiniProject Titles

Uploaded by

Ben AzriCopyright:

Available Formats

List of Mini Project Titles

EET203 [Microcontroller Systems Design]

Semester 2 2013/2014 Academic Session

Start time: 1st March 2014

Finish time: 31st May 1st June 2014

Team members per group = 5 students

Mini Project Title Selection:

Select one title per group from the attached list of mini project titles

First registration first selection

Registration becomes active at the instant of signature

of all the group members.

Page 1 of 8

Any required extra components should be provided by

the students themselves

At the completion of your mini project, you should

provide the followings:

1-Printed copy of your report, including the

followings:

Cover Page

Table of Contents

Introduction

Requirements

Methodology

Application & Results

Conclusion.

References.

2-Attach CD

followings:

to

you

report,

containing

the

Copy of your report in DOC, PDF formats & the PPT

slides you used in your presentation.

Includes a copy of your mini project code scripts.

Write on top of the CD, your mini project number,

your mini project title, list of names of group

members.

Includes a copy of a demonstration video records

shows your mini project progress, application &

results demonstration of your of your hardware

(This can be used for demonstration in case of your

hardware stops working).

Page 2 of 8

3-Presentation of your mini project in front of

the panels.

4-Demonstrating your Mini project.

Introduction:

Based on PIC 16F877A hardware and PTK40A PIC training kit, you

are requested to design and implement your mini project, using the

followings:

PTK40A PIC Training Kit

MPLAB IDE

HI TECH C Compiler

Computer Unit

PTK40A Training Board is developed based on Microchip 8-bit 40

pins PIC MCU (Micro Controller Unit). It is compatible between

PIC16F and PIC18F. It covers programming, interfacing, and

applications of microcontroller and mechanical hardware to allow

users to easily learn and develop their project with PIC MCU.

The systems hardware is well configured so that it can be programmed

by any compatible programming language such as assembly, BASIC

and C (for PIC MCU). MPLAB IDE from Microchip Technology .Inc

is included in this kit which has assembler that allows user to develop

the program with assembly language. However, the explanation and

Page 3 of 8

sample programs provided in the users manual are based on C

language due to its relatively flexibility and easiness in understand and

developing program.

The final viva requirements:

1. Copy of your report

2. Submit your report one week before your presentation date.

3. Presentation includes Demonstration.

Remarks:

Try to use the available kit tools and you may use external tools as

inputs or outputs like function generator, measurements meter

instrument etc that are available in labs to achieve your mini projects.

You need to provide specific tools and components in order to achieve

your mini project successfully.

Page 4 of 8

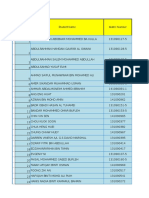

LIST OF SUGGESTED MINI PROJECTS TITLES

(SELECT ONE ONLY)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

1.

Multi-Level intensity effect running light for lamp.

2. Automatic advanced railway gate control system (Selection at least 2 directional rail

ways).

3.

4.

Automatic Bidirectional Visitor Counter

Automatic intrusion Alarm/Alert System.

5. Automatic Irrigation water supply monitoring and control system (Selection at least 4

optional sequence).

6.

Automatic room light intensity based window blinds control system.

7. Automatic washing machine motor control system (Selection at least 4 optional

sequence).

8.

9.

AVR Meter

DC Motor Controller (Selection at least 4 optional sequence).

10.

Digital alarm clock with option set and reset (Selection 4 optional sequence).

11.

AC Frequency detector meter.

12.

AC voltage stabilizer system.

Page 5 of 8

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

13.

DC voltage stabilizer system.

14.

DC to AC converter with adjustable frequency converter

15.

DC to DC Up/Down with adjustable voltage converter

16.

AC to AC Up/Down with adjustable voltage converter

17.

AC frequency stabilizer to an optional level (Selection at least 4 optional sequence).

18.

Battery charger controller system.

19.

Digital solar Energy Meter LCD display.

20.

Digital Frequency Meter with LCD Display.

21.

Digital real-time clock implementation with microcontroller and LCD.

22.

Digital RPM indicator for electrical motor with over speed alarm indicator.

23.

Digital thermostat with LCD temperature display.

24.

Electronic code lock system

25.

High voltage fuse blown indicator with LCD display (use low voltage level)

26.

Humidity detection meter.

27.

Industrial application; advanced temperature monitoring system.

Page 6 of 8

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

28.

Industrial conveyer belt object counting system.

29.

Intelligent high power LED street light control system.

30.

LCD based voting machine.

31.

Automatic lamp illumination controller intensity LED lighting (PWM control).

32.

Serial to PIC Interface to power the LEDs from PC serial output.

33.

Three phase induction motor using PWM technique.

34.

Digital Alpha-numeric message scrolling display (Selection at least 4 optional sequence).

35.

Digital Over voltage Protection system for industrial loads.

36.

Pulse Width Modulation (PWM) Speed Control of a DC Motor.

37.

Real-time car battery monitoring and low voltage alert system.

38.

Temperature based fan speed control system (AC or DC Motor).

39.

Temperature Controlled Fan (DC Motor based with PWM).

40.

Transformer real time temperature monitoring and thermal overload protection

41.

Vehicle inside and outside temperature monitoring system.

42.

Water Level Controller with LCD display (use at least 4 levels).

Page 7 of 8

43.

Water level monitoring and control system (Selection at least 4 optional outputs).

44.

45.

46.

Page 8 of 8

You might also like

- C# With Dot Net 5 Years of Experience ResumeDocument3 pagesC# With Dot Net 5 Years of Experience ResumekonnojuNo ratings yet

- PIC Microcontrollers: An Introduction to MicroelectronicsFrom EverandPIC Microcontrollers: An Introduction to MicroelectronicsRating: 5 out of 5 stars5/5 (1)

- Assignment: Systems Programming and Computer Control (50%) Date Assigned: Week 3 Date Due: Week 15 Lecturer: Submission: Softcopy & HardDocument6 pagesAssignment: Systems Programming and Computer Control (50%) Date Assigned: Week 3 Date Due: Week 15 Lecturer: Submission: Softcopy & HardMikeyy NzuziNo ratings yet

- SPCC DocumentationDocument33 pagesSPCC DocumentationKumar Dzhunushaliev100% (1)

- Example ReportDocument26 pagesExample ReportSofi FaizalNo ratings yet

- Fire Alarm System MonitoringDocument56 pagesFire Alarm System MonitoringRagini GudelliNo ratings yet

- LED DisplayDocument25 pagesLED DisplayCreative StudioNo ratings yet

- Activity No 1 - Setting Up and Programming Controllers-1Document6 pagesActivity No 1 - Setting Up and Programming Controllers-1RUEL ALEJANDRONo ratings yet

- SPCC AssignmentDocument6 pagesSPCC AssignmentKennethNo ratings yet

- Designing Embedded Systems with 32-Bit PIC Microcontrollers and MikroCFrom EverandDesigning Embedded Systems with 32-Bit PIC Microcontrollers and MikroCRating: 5 out of 5 stars5/5 (2)

- Stock Maintenanace SystemDocument15 pagesStock Maintenanace SystemAshok KumarNo ratings yet

- 4 5780930464638307470 PDFDocument41 pages4 5780930464638307470 PDFYihun DesalegnNo ratings yet

- Hicalc ManualDocument46 pagesHicalc ManualYasir ShigileeniNo ratings yet

- 19ELC212 - MCA - Lab ManualDocument52 pages19ELC212 - MCA - Lab ManualVatsalya NagNo ratings yet

- Unit 16 AssignmentDocument15 pagesUnit 16 AssignmentRavi Gajenthran100% (1)

- PIC32 Microcontrollers and the Digilent Chipkit: Introductory to Advanced ProjectsFrom EverandPIC32 Microcontrollers and the Digilent Chipkit: Introductory to Advanced ProjectsRating: 5 out of 5 stars5/5 (1)

- Embedded System Training Report on AVR MicrocontrollerDocument48 pagesEmbedded System Training Report on AVR MicrocontrollerAtishay Kumar100% (3)

- Manual Cpe006Document57 pagesManual Cpe006ALlan ABiangNo ratings yet

- Pic Timer0 Tutorial Part1Document18 pagesPic Timer0 Tutorial Part1ivan10mNo ratings yet

- Flowcode: Design Electronic Systems with this Powerful Visual Programming SoftwareDocument20 pagesFlowcode: Design Electronic Systems with this Powerful Visual Programming SoftwareSetyo Budi MulyonoNo ratings yet

- Click and Start M340 EN - V1 - ModifiedDocument71 pagesClick and Start M340 EN - V1 - Modifiedshaikhsajid242No ratings yet

- Design and Fabrication of Control Sytems On Production LineDocument4 pagesDesign and Fabrication of Control Sytems On Production LinegithinjipeterNo ratings yet

- Flowcode 5 BookletDocument14 pagesFlowcode 5 BookletRed Squerrel100% (1)

- Handbook McuDocument31 pagesHandbook McuMohd Hanif bin Che HasanNo ratings yet

- (IJET-V2I3 - 1P9) Authors: Apurva Ganar, Rachana Borghate, Kumudini Borkute, Nilesh ChideDocument4 pages(IJET-V2I3 - 1P9) Authors: Apurva Ganar, Rachana Borghate, Kumudini Borkute, Nilesh ChideInternational Journal of Engineering and TechniquesNo ratings yet

- Academic Program MICROCHIPDocument8 pagesAcademic Program MICROCHIPanitat2012No ratings yet

- Microcontroller Based Automatic Traffic Light ControllerDocument17 pagesMicrocontroller Based Automatic Traffic Light ControllerAmina AnsariNo ratings yet

- Real Time Embedded Systems Lab ManualDocument51 pagesReal Time Embedded Systems Lab ManualHamid SaeedNo ratings yet

- Universiti Malaysia Perlis: School of Electrical Systems EngineeringDocument17 pagesUniversiti Malaysia Perlis: School of Electrical Systems EngineeringMayu ZukaNo ratings yet

- Intermediate C Programming for the PIC Microcontroller: Simplifying Embedded ProgrammingFrom EverandIntermediate C Programming for the PIC Microcontroller: Simplifying Embedded ProgrammingNo ratings yet

- Pic ManualDocument30 pagesPic Manualgg.ganapathy100% (2)

- Iot Based Air Quality Monitoring System Progress Report March 19Document5 pagesIot Based Air Quality Monitoring System Progress Report March 19Rishabh Khanna100% (1)

- Tutorial 03 PLCDocument12 pagesTutorial 03 PLCAllanNo ratings yet

- Pic-Programming-With-Ccs-C - (Cuuduongthancong - Com) PDFDocument135 pagesPic-Programming-With-Ccs-C - (Cuuduongthancong - Com) PDFbenjarrayNo ratings yet

- Pic Lab BD ManualDocument24 pagesPic Lab BD ManualprabhumadhavNo ratings yet

- Sem 6 Full Report Projek PoliteknikDocument71 pagesSem 6 Full Report Projek PoliteknikAMar Ridhwan43% (23)

- ES Lab Manual 1Document95 pagesES Lab Manual 1Rufus DavidNo ratings yet

- Flowcode5 BookletDocument14 pagesFlowcode5 BookletBeer GardenNo ratings yet

- Flowcode5Booklet 2 PDFDocument14 pagesFlowcode5Booklet 2 PDFgrovlhus0% (1)

- Pro II Input ManualDocument69 pagesPro II Input ManualNareshNo ratings yet

- Prasoon Raj - 1709131099 - ReportDocument41 pagesPrasoon Raj - 1709131099 - ReportPAWAN TIWARI100% (1)

- Fom MicroprojectDocument9 pagesFom MicroprojectPRABHAVATI TANAJI DESHMUKH100% (1)

- Advantages of PIPENET Spray Sprinkler ModuleDocument20 pagesAdvantages of PIPENET Spray Sprinkler ModuleLeonardSergiuNo ratings yet

- Visitor CounterDocument55 pagesVisitor CounterNikhith ReddyNo ratings yet

- Chapter 3Document11 pagesChapter 3nikhilNo ratings yet

- Aircom System®: Airline Ticketing and Reservation SystemDocument21 pagesAircom System®: Airline Ticketing and Reservation Systemmaclean_kumiNo ratings yet

- Development of Embedded Software and Verification For Peripherals of Arm7Tdmi-SDocument5 pagesDevelopment of Embedded Software and Verification For Peripherals of Arm7Tdmi-SInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Internship 1Document19 pagesInternship 1UnknownNo ratings yet

- Mini Project DesignDocument4 pagesMini Project DesignÎQbãl HãikãmNo ratings yet

- Temperature MeasurementDocument68 pagesTemperature Measurementarsyed05100% (1)

- Interfacing PIC Microcontrollers: Embedded Design by Interactive SimulationFrom EverandInterfacing PIC Microcontrollers: Embedded Design by Interactive SimulationNo ratings yet

- Programming 8-bit PIC Microcontrollers in C: with Interactive Hardware SimulationFrom EverandProgramming 8-bit PIC Microcontrollers in C: with Interactive Hardware SimulationRating: 2.5 out of 5 stars2.5/5 (5)

- PIC Projects and Applications using C: A Project-based ApproachFrom EverandPIC Projects and Applications using C: A Project-based ApproachRating: 4 out of 5 stars4/5 (2)

- C Programming for the PIC Microcontroller: Demystify Coding with Embedded ProgrammingFrom EverandC Programming for the PIC Microcontroller: Demystify Coding with Embedded ProgrammingNo ratings yet

- ARM-based Microcontroller Projects Using mbedFrom EverandARM-based Microcontroller Projects Using mbedRating: 5 out of 5 stars5/5 (2)

- Fast and Effective Embedded Systems Design: Applying the ARM mbedFrom EverandFast and Effective Embedded Systems Design: Applying the ARM mbedRating: 5 out of 5 stars5/5 (2)

- ESP32 Programming for the Internet of Things: JavaScript, AJAX, MQTT and WebSockets SolutionsFrom EverandESP32 Programming for the Internet of Things: JavaScript, AJAX, MQTT and WebSockets SolutionsRating: 5 out of 5 stars5/5 (2)

- Designing SCADA Application Software: A Practical ApproachFrom EverandDesigning SCADA Application Software: A Practical ApproachNo ratings yet

- Designing Embedded Systems with PIC Microcontrollers: Principles and ApplicationsFrom EverandDesigning Embedded Systems with PIC Microcontrollers: Principles and ApplicationsRating: 2 out of 5 stars2/5 (1)

- Malezya - en Büyük 1000 Şirket - İrtibat BilgileriDocument114 pagesMalezya - en Büyük 1000 Şirket - İrtibat BilgileribluepuppygirlNo ratings yet

- Dateline MarathonDocument1 pageDateline MarathonBen AzriNo ratings yet

- Full ReportDocument2 pagesFull ReportBen AzriNo ratings yet

- EET424 Exp2 (New Ver3)Document4 pagesEET424 Exp2 (New Ver3)Ben AzriNo ratings yet

- Timetable For Bachelor Degree Programmes Semester 220142015 (Draft)Document2 pagesTimetable For Bachelor Degree Programmes Semester 220142015 (Draft)Ben AzriNo ratings yet

- Assignment MarksDocument164 pagesAssignment MarksBen AzriNo ratings yet

- Hydraulic PressDocument24 pagesHydraulic Pressjyoti1234321100% (3)

- Bh.StudyRoom Engineering Study MaterialsDocument56 pagesBh.StudyRoom Engineering Study MaterialsPrasad PatilNo ratings yet

- Ryobi 750wDocument19 pagesRyobi 750wSerhii ZhytnykNo ratings yet

- Oil & Gas Separation Book 2 PDFDocument47 pagesOil & Gas Separation Book 2 PDFMahathir Che Ap100% (4)

- Computer Numerical ControlDocument28 pagesComputer Numerical ControlsaisenthNo ratings yet

- Instrumentation Data Acquisition SystemsDocument21 pagesInstrumentation Data Acquisition SystemsRolls RoyalNo ratings yet

- Introduction To Control SystemsDocument3 pagesIntroduction To Control SystemsRahul SandilyaNo ratings yet

- Mechanical Engineering, Course Descriptions Autumn 2013-2014Document11 pagesMechanical Engineering, Course Descriptions Autumn 2013-2014Shah Jehan HanifNo ratings yet

- FN 300-500 dry heat sterilizer user manualDocument15 pagesFN 300-500 dry heat sterilizer user manualbiologist26No ratings yet

- 3DCS Advanced Analyzer OptimizerDocument15 pages3DCS Advanced Analyzer OptimizerMarcelo Hayashi NeyNo ratings yet

- Ejercicios ClaseDocument5 pagesEjercicios ClaseDuvan BayonaNo ratings yet

- Iqan-Xp Uk Ed0607 InstructionbookDocument30 pagesIqan-Xp Uk Ed0607 InstructionbookAndres Emilio Veloso Ramirez100% (1)

- Automatic Control For Mechanical Engineers by M. Galal Rabie - OptDocument176 pagesAutomatic Control For Mechanical Engineers by M. Galal Rabie - OptSusan LamNo ratings yet

- Jntu World: R05 Set No. 2Document8 pagesJntu World: R05 Set No. 2Samiullah MohammedNo ratings yet

- Tome 1: Magelis Range XBT-H/P/E/HMDocument155 pagesTome 1: Magelis Range XBT-H/P/E/HMFarovixNo ratings yet

- Control System - Closed Loop Open Loop Control SystemDocument9 pagesControl System - Closed Loop Open Loop Control SystemSiva B PositiveNo ratings yet

- Agard Flight Test Technique Series Volume 3 Part 1 Dynamic Systems Output Error ApproachDocument186 pagesAgard Flight Test Technique Series Volume 3 Part 1 Dynamic Systems Output Error ApproachDavid RussoNo ratings yet

- Automation Production System and Computer Integrated Manuacturing - Lecture Notes, Study Material and Important Questions, AnswersDocument18 pagesAutomation Production System and Computer Integrated Manuacturing - Lecture Notes, Study Material and Important Questions, AnswersM.V. TV0% (1)

- Isa TrainDocument32 pagesIsa TrainahmedNo ratings yet

- ME7732 Lecture 1 - Basics of Control Engineering - BADocument79 pagesME7732 Lecture 1 - Basics of Control Engineering - BATaiwo TaiwoNo ratings yet

- Fuzzy Logic Controller For Superheated SDocument4 pagesFuzzy Logic Controller For Superheated Smahendra ANo ratings yet

- Robotics Unit-3 Question BankDocument3 pagesRobotics Unit-3 Question BankNitish rajNo ratings yet

- Engineering Design ManualDocument23 pagesEngineering Design ManualDuraisamy Panchatcharam100% (1)

- Plazmax SpecDocument9 pagesPlazmax SpecmannspaarthNo ratings yet

- Study of Neural Network PID Control in Variable Frequency Air-Conditioning SystemDocument6 pagesStudy of Neural Network PID Control in Variable Frequency Air-Conditioning Systemsolarflare_No ratings yet

- Chapter1-Introduction To Automation PDFDocument29 pagesChapter1-Introduction To Automation PDFAbdul Razzi86% (7)

- Tracking Time Adjustment in Back Calculation Anti-Windup SchemeDocument6 pagesTracking Time Adjustment in Back Calculation Anti-Windup SchemeFrancesco FaninNo ratings yet

- Instrumentation and Control: 10.1 ObjectivesDocument8 pagesInstrumentation and Control: 10.1 ObjectivesMuhammadNo ratings yet

- Firmware Version Notes MPH-05, MPB-05, MPD-05 R911320184 - 01 - MV PDFDocument120 pagesFirmware Version Notes MPH-05, MPB-05, MPD-05 R911320184 - 01 - MV PDFCristopher EntenaNo ratings yet

- Transmissão Voith Retarder 120-3 131 Pag.Document131 pagesTransmissão Voith Retarder 120-3 131 Pag.Carlos Lao88% (8)