Professional Documents

Culture Documents

Intsallation of Hot Tap FittingsSAEP0311

Uploaded by

Ehab SaadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intsallation of Hot Tap FittingsSAEP0311

Uploaded by

Ehab SaadCopyright:

Available Formats

Engineering Procedure

SAEP-311

29 January, 2003

Installation of Hot Tapped Connections

Piping Standards Committee Members

Al-Sannaa, M.S., Chairman

Al-Dossary, M.B.

Al-Nasri, N.I.

Al-Sabti, R.A.

Al-Sharif, T.M.

Al-Teraiki, A.M.

Balhareth, N.M.

Chen, J.T.

Fadley, G.L.

Ismail, A.A.

Khashab, J.M.

Kim, S.U.

Lewis, T.

Mahmoud, K.A.

Mullen, M.A.

Phan, H.C.

Solaiman, M.Z.

Stark, G.D.

Previous Issue: 29 February, 2000

Next Planned Update: 1 March, 2003

Revised paragraphs are indicated in the right margin

Primary contact: Muhsen S. Al-Sannaa on phone 874-6679

Page 1 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

Saudi Aramco DeskTop Standards

Table of Contents

Scope.............................................................

Applicable Documents...................................

Instructions.....................................................

Responsibilities.............................................

14

Appendix I - Ultrasonic Thickness

Measurements

17

Appendix II - Hot Tap Checklist..........................

18

Scope

This SAEP provides the installation procedures for hot tapping pipe, pressure vessels and tanks.

It assigns responsibilities for the work required and the safety precautions to be taken. Any

deviation to this procedure requires the approval of the Manager, Consulting Services

Department, Dhahran.

Applicable Documents

2.1

Saudi Aramco References

Page 2 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

Saudi Aramco Engineering Procedure

SAEP-310

Pipeline Repair and Maintenance

Saudi Aramco Engineering Standards

SAES-A-004

Pressure Testing

SAES-L-052

Hot Tap Connections

SAES-L-056

Pressure Testing of Plant Piping and Pipelines

SAES-W-010

Welding Requirements for Pressure Vessels

SAES-W-011

Welding Requirements for On-Plot Piping

SAES-W-012

Welding Requirements for Pipelines

Saudi Aramco Standard Drawings

AB-036719

Reinforcement of Welded Branch Connections

AB-036715

Detail of Heavy Welding Boss for Threaded

Connections

AB-036643

Detail of Heavy Welding Boss for Socket Weld

Connections

Saudi Aramco Forms and Data Sheets

Form SA 7235-ENG

Hot Tap Data and Checklist

Form SA 7627-ENG

Hot Tap/Stopple & Reinforcement Calculation Sheet

Saudi Aramco General Instructions

2.2

GI-0002.100

Work Permits

GI-0002.102

Safety Precautions for Pressure Testing

GI-0002.711

Fire and Safety Watch

GI-1780.001

Atmosphere-Supplying Respirators

Industry Codes and Standards

American Petroleum Institute

API STD 598

Valve Inspection and Test

Page 3 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

API RP 2201

Installation of Hot Tapped Connections

Procedures for Welding or Hot Tapping on Equipment

Containing Flammables

American Society of Mechanical Engineers/Boiler and Pressure Vessel Code

ASME SEC VIII D1

Pressure Vessels

ASME B31.3

Process Piping

ASME B31.4

Liquid Transportation Systems for Hydrocarbons

ASME B31.8

Gas Transmission and Distribution Piping Systems

Instructions

3.1

Definitions

Hot Tap: The technique of attaching a welded branch fitting to piping or equipment in

service, and creating an opening in that piping or equipment by drilling or cutting a

portion of the piping or equipment within the attached fitting.

3.2

General Requirements

3.2.1

Hot tap connections shall be designed and installed to meet all requirements

of this SAEP, and SAES-L-052, "Hot Tap Connections".

3.2.2

The hot tapping operations are initiated, designed, and controlled by:

3.2.3

3.2.2.1

Operations Engineering Organization in the case of existing

facilities.

3.2.2.2

Project Manager with the approval of the Area Operations

Superintendent and Operations Engineering General Supervisor/

Superintendent in the case of tying in new installations to

existing facilities.

The appropriate management shall appoint an Initiating Engineer. The

Initiating Engineer shall be made responsible for the overall coordination of

the hot tapping activities. This is to ensure that designers,

construction/maintenance installation unit, hot tap, stopple and valve crew,

operations and/or project management, engineering staff, and inspection staff

cooperate closely during all phases of the hot tapping operations.

Page 4 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

3.2.4

The Initiating Engineer shall identify the equipment in terms of service,

location, pipe diameter, header and branch pressure rating, and material type

and notify the Hot Tap, Stopple and Valve Unit of this information.

3.2.5

The construction or maintenance units are responsible for ensuring that

approved welding procedures and qualified welders are employed. The

Piping & Valves Unit/M&CED/CSD shall verify this.

3.2.6

For carbon steels with minimum specified yield stresses less than or equal to

60 ksi, pre-approved welding procedures may be used.

3.2.7

For carbon steels with minimum specified yield stresses greater than 60 ksi,

the Consulting Services Department shall be contacted for welding procedure

approval.

3.2.8

For hardenable or high strength steels and for piping where pipe or fitting

wall thickness requires preheat, the Consulting Services Department shall be

contacted for welding procedure approval.

3.2.9

Compressed air piping and equipment shall not be hot tapped nor welded

while in service. Refer to SAES-L-052, paragraph 4.3.

3.2.10

Hot tapping lines upstream of rotating equipment shall be avoided unless

such equipment is protected from the cuttings by means of filters or traps.

The normal in-line suction screens are not considered adequate for this

purpose.

3.2.11

Hot tap connections are not allowed for certain cases (refer to SAES-L-052

paragraph 4.1), unless a detailed design and installation procedure has

received prior approval from the Manager of CSD and concurrence from the

Loss Prevention Department.

3.2.12

All hot tap connections, valves, and hot tap machines shall be pressure tested

in accordance with this SAEP. (Refer to Para. 3.8)

3.2.13

Precautions against electric shock, due to induced voltage, shall be taken

when installing hot tap connections on above ground pipelines near high

voltage power lines. Refer to SAEP-310," Pipelines Repair and

Maintenance".

Page 5 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

3.2.14

Adequate support of the hot tap machine shall be provided to prevent

overstressing of the pipe and/or fitting, particularly in cases where the hot tap

sticker is not installed in a vertical position.

3.2.15

Hot tapping shall not be permitted:

a)

within 457 mm (18 inches) of a flange (or threaded connection) as

measured from the toe of the reinforcement sleeve, or split tee

circumferential fillet weld to the toe of the flange circumferential butt

weld (or the closest edge of the threaded connection);

Commentary Note:

If this requirement can not be met the placement of the hot tap

may be positioned closer than 457 mm (18 inches) provided

there is enough room to allow for the installation, operation and

removal of the hot tap machine, and the removal of the piping or

pipeline flange bolts.

b)

within 19 mm (0.75 inch) of a circumferential girth weld seam as

measured from the toe of the sticker weld or split tee circumferential

fillet weld, to the toe of the nearest girth weld.

Existing welds under the hot tap shall be ground smooth prior to fit up of the

sticker and reinforcing sleeve. Care should be taken when cutting across

existing welds since the cutter can be damaged.

3.2.16

Storage Tanks

3.2.16.1

For atmospheric or low pressure hydrocarbon storage tanks, hot

tap connections shall be located at least 1 m (39 inches) below

the liquid level while welding or hot tapping is in progress.

3.2.16.2

The liquid level in a tank shall remain constant at the stated level

and no flow into or out of the tank shall occur while welding or

hot tapping is in progress.

3.2.16.3

Hot tapping is not permitted on cone or floating roofs of inservice tanks.

Page 6 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

3.2.16.4

3.3

Installation of Hot Tapped Connections

On tanks, connections larger than 2 inch NPS require written

approval of the Manager, CSD.

3.2.17

When hot taps are being made to obtain coupons for HIC determination, the

Saudi Aramco Form SA 7627-ENG and the ultrasonic scan data shall be

evaluated by M&CED of the Consulting Services Department. The

Consulting Services Department shall designate the location of the hot tap,

type of reinforcement, and other special requirements.

3.2.18

Hot tap connections made to obtain coupons for HIC determination,

according to paragraph 3.2.17 shall not be used for future connections with

process piping unless approved by CSD. Such hot taps shall be marked "Do

Not Use" with a non-corroding metal tag permanently affixed to the hot tap

connection. (Reference para. 3.5.7)

3.2.18.1

Wall thickness above the lamination must be greater than

5 mm (0.2 inch).

3.2.18.2

Reinforcement of the nozzle shall be based on the wall thickness

above the lamination. (Does not apply to split-tee installation)

3.2.19

Appropriate barricades and warning signs shall be posted around the worksite

to minimize the number of personnel in the work area while performing the

hot tapping operation.

3.2.20

Compact steel gate valves with extended body ends shall not be used for hot

tap connections.

Precautions against H2S and other Toxic/Hazardous Materials

3.3.1

If a potential exists for a Hydrogen Sulfide (or other Toxic material) release at

a work site, all personnel involved shall be provided with an appropriate

breathing apparatus. (Refer to GI-1780.001, "Atmosphere-Supplying

Respirators"). The standby person or fire watch, or other person certified as a

gas tester, shall continuously monitor the work site for the presence of

hazardous materials during the work activity using established gas testing

procedures.

3.3.2

When welding sour gas or sour crude lines, the fire watch personnel shall be

clearly instructed that should a burn-thru occur, the fire of the gas jetting from

Page 7 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

the pipe should not be extinquished. If a burn-thru should occur, the

Operations Superintendent should immediately be notified to advise further

action or be included in the emergency instructions as required by para. 3.3.5.

Firewater and extinquishers should be applied as required to workers,

clothing, equipment, etc., exposed to the burn-thru flame.

3.3.3

3.4

The chamber of the hot tap machine and valve shall be purged with nitrogen

after cutting the coupon, retracting the cutter and closing the tapping valve

when any of the following exist:

1.

H2S concentration is greater than 10 ppm.

2.

Gas release may affect others in the area.

3.

Hot tap equipment is larger than 36 inches.

4.

The work is in a confined area.

3.3.4

In enclosed or confined areas, air horns/industrial fans shall be provided to

improve air circulation. However, the air velocity shall not interfere with the

welding arc shielding gases. Fans shall meet the electrical area classification

requirements.

3.3.5

The Operations Engineering Organization should provide written and verbal

emergency instructions (including evacuation procedure) to the hot tapping

crew, fire watch personnel, and other workers who may be in the work area.

Preparation of Hot Tap Specification and Test Calculations

3.4.1

The Initiating Engineer shall provide Form SA 7627-ENG for each hot tap

operation.

3.4.2

Each Form SA 7627-ENG shall be completed in sequence and by the

organization identified:

Form Section #

Person/Organization

Summary

(includes; Hot Tap Location,

Header Info, and Branch Info)

Initiating Engineer

Initiating Engineer

Operations Engineer

Page 8 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

3.5

Installation of Hot Tapped Connections

Responsible I.e.,. Unit

Operations Eng. Div.

Summary

(includes: Test & Process Info)

Initiating Engineer

(To be completed with actual

conditions just prior to welding or

cutting)

Locate and Inspect Hot Tap Position

3.5.1

The Initiating Engineer shall make all necessary arrangements for the

preparation of hot tapping (i.e., location, excavation, pipe inspection, surface

preparation, etc.)

3.5.2

The Initiating Engineer shall arrange for a team, consisting of himself,

operations, the responsible inspector, and a representative of the Hot Tap and

Stoppling crew, to survey the general hot tap location in order to specify and

mark the hot tap locations in detail.

3.5.3

The Initiating Engineer shall mark of the exact hot tap locations, and mark

the hot tap number alongside each hot tap location, ensuring the hot tap

locations are at a position where the pipe out-of-roundness does not exceed 3

mm. (Out of roundness criteria only applies to split tee or full encirclement

sleeves).

3.5.4

The hot tap number is obtained from Form SA 7627-ENG developed for each

location.

3.5.5

The Piping & Valves Unit/M&CED/CSD shall inform the Initiating Engineer

if the seam weld or any other projection needs to be ground flush with the

pipe surface for proper UT scanning and fit-up and if the out of roundness

criteria is met for split tees/full encirclement sleeves.

3.5.6

The Piping & Valves Unit/M&CED/CSD shall inspect and determine the

minimum pipe wall thickness at the tie-in weld areas by a continuous UT

scan along the lines to be welded and record this on the Appendix I form.

The area to be scanned shall include the weld zone and 50 mm (2 inches)

each side of it. The minimum remaining wall thickness at the weld

connection area shall not be below minimum thickness, Tm, and in all cases,

no less than 5 mm (0.2 inch). The inspected area shall be permanently

marked for future reference and identification.

Page 9 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

Commentary Note:

When hot tapping components containing non-hazardous material such

as water at less than 1034 kPa (150 psi) and below 65C, then the

components with wall thicknesses less than 5 mm (0.2 inch) may be

hot tapped provided precautions against burn-through are taken.

(THIS CONDITION STILL REQUIRES A WAIVER TO BE

PROCESSED THRU CSD).

3.6

3.5.7

If ultrasonic readings indicate a lamination or evidence of hydrogen induced

cracking (HIC) damage, the hot tap position shall be relocated after

consultation with the Initiating Engineer and the responsible Operations

Engineering Organization. CSD and the proponent group shall be notified of

this condition.

3.5.8

The Piping & Valves Unit/M&CED/CSD shall complete Section 3 of form

SA 7627-ENG and return it to the Initiating Engineer.

3.5.9

The Piping & Valves Unit/M&CED/CSD shall review the welding procedure

specification (WPS) for the installation of the hot tap fittings and assure a

CSD approved WPS is employed.

Approval and Distribution of Form SA 7627-ENG

3.6.1

The Initiating Engineer shall forward the form, when Sections 1, 2, 3 and the

Summary section (excluding the test and process information, are complete

and signed), together with ultrasonic thickness measurements (Appendix I of

this SAEP), to the Project Engineer or responsible Operations Engineering

Supervisor.

3.6.2

The Project Engineer or the responsible Operations Engineering Supervisor,

shall complete Section 4 of Form SA 7627-ENG when the design and

calculations are complete. Full responsibility for the hot tap design is to be

assumed by the engineering group that prepares the calculations, design

drawings and installation procedures. The responsible engineering group

shall determine and obtain the appropriate approvals on Form SA 7627-ENG.

Drawings and specifications prepared by the responsible engineering group

shall include the length, diameter, wall thickness, flange rating and material

of the new connection plus the type and dimensions of the connection

Page 10 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

reinforcement, if required (Refer to Std. Dwg. AB-036719) and the Weld

Procedure Specifications approved by the Consulting Services Department.

3.6.3

After the responsible engineering group has obtained the appropriate

approvals, a record copy shall be retained in a permanent central file, and the

design package forwarded to the Initiating Engineer for construction.

3.6.4

Once approval is obtained, the Initiating engineer shall distribute copies of

each Form SA 7627-ENG to the following personnel:

3.6.5

1)

Operations Superintendent

2)

Hot Tap and Stopple Crew or Operations Engineering Supervisor

3)

Construction/Maintenance Installation Crew

4)

Responsible CSD/M&CED/Piping & Valves Unit Supervisor

5)

Area Loss Prevention Engineer

6)

Project Manager (if appropriate)

The Initiating Engineer shall prepare and forward Form SA 7235-ENG "Hot

Tap Data & Check List" to the appropriate maintenance group performing the

actual hot tap. For hot taps to be made by Pipelines Maintenance Hot Tap,

Stopple, and Valve Unit, the SA 7235-ENG Form shall be sent to:

Superintendent

Pipelines Maint. Services Div.

Hot Tap, Stopple, and Valve Unit

Bldg. 3071, Old Abqaiq Rd., Dhahran

3.6.6

3.7

The Initiating Engineer is responsible for revising existing Saudi Aramco

drawings, P&IDs, or preparing new drawings, as may be required, as a result

of the hot tap installation.

Safety Requirements

3.7.1

The Initiating Engineer shall ensure that the requirements of SAES-L-052,

"Hot Tap Connections" are followed. The responsibility for the safety of

work crews involved in the hot tapping operation is shared jointly by the

Operator and the Hot Tap Supervisor/Maintenance Foreman.

Page 11 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

3.8

Installation of Hot Tapped Connections

3.7.2

Written approval of the detailed hot tap installation shall be obtained from the

Operations Superintendent, or higher, and a copy sent to the Area Loss

Prevention Office and responsible Piping & Valves Unit/M&CED/CSD for

their review and concurrence prior to starting the installation. The

installation package shall be on-site during the entire installation process and

verified, by the Piping & Valves Unit/M&CED/CSD, that it is understood by

the person(s) carrying out the work.

3.7.3

All work shall be in strict compliance with GI-0002.100, Work Permit

System. The Work Permit shall be approved by the Operations

Superintendent, prior to each of the following:

1)

Vehicle entry

2)

Welding

3)

Grinding

4)

Hot Tapping

3.7.4

The Hot Work Permit (Red Saudi Aramco Form SA 924-2) shall have

recorded under the "Other precaution" section the maximum allowable line

pressure, minimum and maximum flow rates, and level limitations during

welding/cutting plus the number of this SAEP.

3.7.5

The Initiating Engineer shall make available to the site a copy of this SAEP

and ensure the area has been sufficiently roped off to prevent unauthorized

personnel from entering the work area.

3.7.6

The Operations Superintendent will assure that both Operations and the

Installation Organization have the proper safety and fire protection equipment

on site and in workable condition prior to the start of the job and that all

relevant personnel are notified of the scheduled hot work. Refer to GI0002.711, "Fire and Safety Watch".

Pressure Test Requirements

3.8.1

The Initiating Engineer shall be responsible for ensuring that the pressure

tests are performed in accordance with this SAEP on the hot tapping

equipment, including the hot tap valve and branch connection prior to and

after installation. The initial pressure testing of the hot tap machine, will take

Page 12 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

place in the shop after the machine has been checked and worn parts

replaced, per paragraph 3.8.2.

3.8.2

The hot tap machine shall have an overhaul of its renewable pressure sealing

components and be subjected to a shop rated pressure test, in accordance with

the following criteria:

3.8.2.1

Pressure test once every four months and overhaul once every 12

months.

3.8.2.2

After it has been used on lines with operating temperatures in

excess of 150C, even if the elapsed time is less than four

months. For a series of consecutive hot taps on a single type of

service (i.e., steam, process stream, etc.) the hot tap machine

shall be shop tested at the end of the series of hot taps.

3.8.2.3

A stamped brass tag shall be affixed to the hot tap machine

indicating the test pressure, overhaul date, and the name of the

testing organization.

3.8.3

Maximum hydrostatic test pressure applied to the branch (or hot tap)

connection shall be in accordance with SAES-L-052, paragraph 7.3.b).

3.8.4

Pneumatic testing of hot tap connections on hot lines over 93C is not

permitted unless approved by the Manager, Consulting Services Department.

3.8.5

Hot tap connections installed on hot lines where hydrostatic testing with

water is not practical shall be hydrostatically tested using high temperature

turbine oil or silicone fluid, as follows:

Line Temperature

Hydrotest Fluid

Stock No.

93C to 290C

Turbine Oil

Over 290C

Silicone Fluid 200

26-001-330

26-001-340

26-010-037

Commentary Note:

Check to ensure compatibility of fluids used in hot tapping with that of

the line being hot tapped.

Page 13 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

3.8.6

Installation of Hot Tapped Connections

A body and high pressure seat test (on both sides of the seat) shall be

performed in the shop on all hot tap valves prior to installation. Resilient

(soft) seat valves shall have zero leakage. Valves with metal to metal seats

shall meet the leakage criteria of API STD 598. A back seat test and low

pressure seat test is not required. A tag shall be attached to the valve

indicating test date, test pressure and Inspector's name.

Commentary Note:

This seat test does not apply to sandwich valves.

3.8.7

After installation of the branch connection, but prior to installing the

reinforcing pad or full encirclement ring, a full hydrostatic pressure test shall

be applied to the branch connection. This test pressure shall be the lower

value shown in 4.4c or 4.4e on Saudi Aramco Form SA 7627-ENG. During

the test, the branch connection shall have a blind flange installed and pressure

applied through the branch connection boss as shown on Std. Dwg. AB036719.

CAUTION: Header walls can collapse during testing by applying

insufficient internal operating pressure or excessive external hydrostatic test

pressure. This is especially true when large diameter connections are being

tested.

3.8.8

A pneumatic test of 173 kPa (ga) (25 psi) shall be applied to the reinforcing

pad or ring after installation. This pressure will then be reduced to 21 - 35

kPa (ga) (3 - 5 psi) for a tightness test using a soap solution.

3.8.9

Install the hot tap valve and apply another high pressure closure test (seat

test) per para. 3.8.6 above, with the valve in the closed position. The test

pressure shall be the lower value shown in 4.4c or 4.4d on Saudi Aramco

Form SA 7627-ENG, and applied through the branch connection boss.

3.8.10

Return the valve to the open position, mount the hot tap machine and apply

another full pressure test per paragraph 3.8.7 above, however, the MAOP of

the line need not be exceeded.

3.8.11

Ensure that the connection is opened, drained and vented upon completion of

hydrostatic testing to prevent possible build up of pressure from any source of

heat. (Refer to paragraph 3.8.5)

Page 14 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

3.9

Installation of Hot Tapped Connections

3.8.12

After completion of the above tests, install a bar stock plug in the branch

connection boss and seal weld. At the option of the Inspector, an MT or PT

may be applied to the branch connection seal weld.

3.8.13

The appropriate CSD Representative shall witness and approve all hydrostatic

testing required for completion of the hot tap connection.

Operating Conditions Requirements

3.9.1

The Operations Superintendent shall ensure that pipeline pressure and flow

are correct as specified on Form SA 7627-ENG and shall arrange for these

conditions to be maintained prior to and during welding, hot tapping, and

testing operations.

Commentary Note:

Operations, Maintenance, and Construction are to ensure that the hot

tap machine operating pressure is higher than the actual header

pressure while cutting the coupon. Hot tap machine operating

pressure is to be provided by the Hot Tap machine operating

Supervisor before starting the job. (The allowable operating pressure

defined by the hot tap crew is different than the test pressure).

3.9.2

Maximum internal pressure of the piping/equipment during welding shall be

in accordance with SAES-L-052 paragraph 5.3 on welding of pipelines under

pressure. A positive pressure and flow shall be maintained at all times while

welding and hot tapping is in progress.

3.9.3

The minimum flow rates per para. 3.9.4 or the maximum attainable flow

under normal working pressure, whichever is less, shall be maintained during

all welding operations.

3.9.3.1

Flow in a line shall be maintained while welding is being

performed, unless approved otherwise by the Operations

Superintendent. In certain cases, such as flare lines with

insufficient or intermittent flow, the line shall be purged with

steam, inert gas, or hydrocarbon gas. This steam or gas shall be

kept flowing through the line during the entire welding operation.

Page 15 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

3.9.3.2

3.9.4

Installation of Hot Tapped Connections

In systems where hydrocarbon and oxygen mixtures are

definitely not a possibility, flow is not required (e.g., sea water

injection lines). However, to weld with "NO-FLOW" conditions,

the following must be satisfied:

3.9.3.2.1

For new construction tie-ins to existing lines,

approval shall be obtained from the responsible

Project Manager, General

Supervisor/Superintendent Operations

Engineering, and the Operations Superintendent.

3.9.3.2.2

For normal maintenance tie-ins to existing systems

not involving new construction, approval shall be

obtained from the General

Supervisor/Superintendent Operations

Engineering, and the Operations Superintendent.

3.9.3.2.3

Prior to and during any welding, Operations shall

verify a non-combustible mixture in the line. This

shall be stated in the remarks section of the Work

Permit.

Maximum and minimum flow rates during hot tapping shall be as follows:

a)

b)

Liquid &

0.40 m/sec minimum

Two-Phase

4.50 m/sec maximum

Gas

0.40 m/sec minimum

9.10 m/sec maximum

however, if the branch connection size is less than 50% of the size of the line

being hot tapped, then the minimum values do not apply but a positive flow

shall be maintained.

Commentary Notes:

1)

T.D. Williamson has established the above maximum flow velocity in

lines during the hot tapping operation.

Page 16 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

2)

3.10

Installation of Hot Tapped Connections

Small diameter hot taps (i.e., 2 inch and less) have no maximum or

minimum flow limitations. Pressure requirements still apply.

3.9.5

While hot tap work and pressure testing is in-progress, an operator shall

remain in a location where he can control operating conditions such as flow,

pressure, and liquid level within the limits specified in the hot tap design

information. An additional operator shall standby at the job site while the

work is in progress, if deemed necessary by the Operations Superintendent.

Continuous radio communications between the job site operator and the

Control Room is required.

3.9.6

Work shall be immediately stopped when constant flow and pressure as noted

in paragraphs 3.9.2 and 3.9.3 cannot be maintained during the welding and

hot tapping operations. Pressure testing shall also stop if pressure in the

header / equipment is lost.

Hot Tap Fittings/Sandwich Valve Installation Requirements

3.10.1

The Initiating Engineer shall coordinate all activities.

3.10.2

The Operations Superintendent shall ensure compliance with the safety

precautions arranged under paragraph 3.9 of this SAEP, including acceptance

of the work permit.

3.10.3

The Inspector shall perform the following:

3.10.3.1

Verify a CSD approved welding procedure specification is

utilized for installation of the connection (Refer para. 3.5.9).

3.10.3.2

Verify that 3.2 mm diameter cellulose weld electrodes are utilized

only for the root pass and low hydrogen electrodes are used for

all other passes for carbon steel branch connection welds.

3.10.3.3

Inspect the branch connection/split tee, before and during the

installation, for compliance with the approved drawings and

welding procedures.

3.10.3.4

Verify that a calibrated pressure gauge and relief valve are

properly installed for testing.

Page 17 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

3.10.3.5

Installation of Hot Tapped Connections

Confirm that the hydrostatic test pressure for the branch

connection is correct at the time of the test, as prescribed in

Section 4 of Form SA 7627-ENG.

CAUTION: Pipe or pressure vessel walls can collapse during

testing by applying insufficient internal operating pressure or

excessive external hydrostatic test pressure. This is especially

true when large diameter connections are being tested.

Responsibilities

4.11

Hot Tapping Operation Procedure

Procedure

Responsibilities

4.11.1

Review the design drawings and requirements for the

branch connection, including an approved welding

procedure in accordance with the applicable

SAES-W-XXX.

Init. Eng/CSD

4.11.2

Ensure all the requirements of paragraph 3.2

"General Requirements" are met.

Init. Eng/Maint/

Constr

4.11.3

Check that the location of the installation is that

location specified by the initiating Engineer with the

concurrence of the Operations Supt.

Opers/Maint/

Constr

4.11.4

Obtain an approved Hot Work Permit, Saudi Aramco

Form SA 924-2 (Para. 3.7.3) from the Operations

Superintendent, or his designee, prior to starting with

work.

Init. Eng/Maint/

Constr

4.11.5

If long seam is under hot tap fitting, grind seam weld

flush with the surface of the pipe taking care not to

reduce the pipe wall thickness. Check pipe wall

thickness ensuring it does not violate para. 3.5.6.

Maint/CSD/

Constr

4.11.6

Ensure the pressure and flow requirements as identified

in section 4 of Form SA 7627-ENG have been established

prior to any welding.

Init Eng/CSD/

Maint/Constr

Opers

4.11.7

Power wire brush the area for attachment welds to

remove all traces of paint, rust and scale. The fit-up

of the connection to the header shall provide for a

standard pipe bevel and 1/16 inch minimum root gap.

Install the nozzle or boss connection using full

penetration welds in the exact location shown on the

approved drawing, using a qualified welder and a CSD

approved welding procedure. The Piping & Valves Unit/

Maint/Constr/

CSD

Page 18 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

M&CED/CSD will verify proper weld joint fit-up.

4.11.8

Ensure that the nozzle connections are not welded on

the inside unless the hot tap cutter is at least one pipe

size smaller than the nozzle. The cutters sometimes

break if the cut is made through a weld.

CSD/Init Eng/

Maint/Constr

4.11.9

Precheck the tapping valve and the hot tap machine

to assure good operable condition, including the cutter

and coupon retaining device.

Hot Tap Unit

4.11.10 Confirm that the shop rating test of the hot tap machine

is current per para. 3.8.2.

CSD/Hot Tap Unit

4.11.11 Mount the valve on the fitting ensuring that its alignment

is within the manufacturer's tolerance

CSD/Hot Tap Unit

4.11.12 Close the valve and perform the hydrostatic test

according to this instruction.

Maint/Constr/Hot

Tap/CSD

4.11.13 Check the valve by opening and the hot tap machine

for operability and examine the condition of the cutter

and coupon retaining device.

Hot Tap Unit/Maint/

Constr

4.11.14 Mount the hot tap machine on the valve.

Hot Tap Unit/Maint/

Constr

4.11.15 Ensure that the tapping valve is tested in accordance

with paragraph 3.8.9 and will easily pass the hot tap

cutter. This may require grinding of the lugs on the

valve seat rings to provide adequate clearance.

Ensure that the dimension from the face of the valve

flange to the surface to be hot tapped will permit

enough cutter travel to completely cut out the coupon

and not travel to the opposite side of the header.

Hot Tap Unit/CSD

4.11.16 Apply hydrostatic and pneumatic pressure tests to the

hot tap machine, valve, and welded connection in

with the testing procedure specified in this SAEP and

SAES-L-052, paragraph 5.

Hot Tap Unit/ICSD/

Maint/Constr

4.11.17 Install and seal weld a threaded plug in the weld boss

on the connection after all testing has been completed.

Refer to paragraph 3.8.12

Maint/Constr

4.11.18 After assembly of the hot tap machine on the tapping

valve and before the tapping operation is started:

4.11.18.1 Completely close and then completely open

valve to ensure that it Is operable, and that

the cutter can be withdrawn a sufficient

distance to permit closure of the valve.

Hot Tap Unit

Page 19 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

4.11.18.2 Set the cutter travel indicator to prevent over

travel and consequent damage to the opposite

side of the header being hot tapped.

4.11.19 Drill and cut coupon.

Hot Tap Unit

4.11.20 Retract the hot tap machine boring bar.

Hot Tap Unit

4.11.21 Close the valve, purge with nitrogen, if required, and

depressurize the hot tap machine adaptor.

Hot Tap Unit

4.11.22 Remove the hot tap machine from the line.

Hot Tap Unit/

Maint/Constr

4.11.23 Remove the coupon from the pilot drill and tag and

wire the coupon to the tapping valve on the connection

after hot tap is completed.

Hot Tap Unit/

Maint/Constr

4.11.24 The coupon shall be removed only by the Operations

Supervisor and forwarded to the responsible Operations

Piping & Valves Unit/M&CED/CSD.

Opers

4.11.25 Ensure that the completed connection is blinded or

plugged before leaving the job site.

Hot Tap Unit/CSD/

Maint/Constr

1 Decenver, 1996

30 September, 1997

29 April, 1998

29 February, 2000

29 January, 2003

Hot Tap Unit

Revision Summary

Editorial revision to convert document to new format.

Minor revision to paragraphs 2, 3.1, 3.2.9, 3.2.11, 3.2.15, 3.6.1, 3.6.2, 3.8.3, 3.8.6 & 3.9.2

Added GI-1780.001 in the reference.

Added SAES-A-056 in the reference.

Editorial revision to paragraphs 3.2.15(a) (b), 3.2.16.1, 3.2.18.1, 3.5.6 and 3.8.8.

Added four new lines of statements to Appendix II.

Editorial revision to change the Document Responsibility from Inspection Department to

Piping Standards Committee, CSD.

Page 20 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

Appendix I Ultrasonic Thickness Measurements

Hot Tap #_________________

J.O./W.O. ______________PLANT #_______________ DWG. # ________________

Description (Job, Location, etc.) ___________________________________________

Diameter

Grade

Schedule

Flange Rating

HEADER: _____________

______________

_____________

____________

STICKER _____________

______________

_____________

____________

HEADER MEASUREMENTS

(CONTINUOUS SCANNING)

Point A

Min:__________

Max.:_________

Circle B

Min:__________

Max:__________

Circle C

Min:__________

Max:__________

Line D-D

Min:__________

Max:__________

Line E-E

Min:__________

Max:__________

180 deg. from Pt. A

Min:__________

Max:__________

STICKER MEASUREMENT

Min:__________

Max.:__________

Page 21 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

C

FLOW

LOCATION-------DESCRIPTION

Point A------------Branch Center

Circle B-----------Branch Diameter

Circle C-----------Reinfr. Pad Dia.

RESPONSIBLE PIPING & VALVES UNIT/M&CED/CSD:

Line D-D----------Reinf. Sleeve Ends

ENGINEER:

REFERENCE: SAES-L-052, STD. DWG. AB-036719

NOTE:

For connection reinforcement requirements refer to ASME B31.3, ASME B31.4, ASME B31.8, ASME SEC VIII, and

STD. DWG. AB-036719.

Page 22 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

Appendix II Hot Tap Checklist

This checklist should be used as a reminder to accomplish the steps in order, but should not be

considered as including all preparation steps which may be dictated by the particular

circumstances of the job. It should be kept as a part of the final documentation package.

LOCATION:________________________________

DATE:____________________

Before Starting Hot Tap

1.

Has the properly approved work permit been obtained?

2.

Does the tapping machine have a suitable pressure and temperature rating for the job?

3.

Has the exact location of the hot tap on the line or vessel been identified or marked?

4.

Has the area to be welded been inspected for thickness and freedom from lamination or

HIC?

5.

Has the need for stress relieving the weld area been considered?

6.

Do the flanges, bolts, gaskets, pipe, and valve to be installed meet the piping code for the

line or vessel to be hot tapped?

7.

Is there sufficient clearance to accommodate the operation of the hot tap machine and

sufficient clearance to retract the cutter through the valve?

8.

Is the hot tap fitting of the proper length to accommodate operation of the hot tap

machine?

9.

Have combustible and/or toxic gas tests been conducted in the area of hot tapping?

10.

Has the chemical composition of the contents in the line or vessel been considered to

avoid welding or equipment containing flammable mixtures, hydrogen or chemicals

which could affect metal strength?

11.

Is the contents in the line stable under heated conditions and free of oxygen?

12.

Has fire fighting equipment been provided?

Page 23 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

13.

Has suitable protective equipment been provided to all exposed personnel in the hot tap

area?

14.

Is the area to be hot tapped located below the liquid level of a tank or on a line or piece of

equipment in which fluid flow has been established?

Before Starting Welding

1.

Is preheat of the weld area required?

2.

Is the fitting properly positioned so misalignment of the hot tap machine will not occur?

Before Starting Cutting

1.

Has the weld been tested?

2.

Have the hot tap valve, gaskets, and bolts been checked for possible leakage?

3.

Has the packing on the hot tap machine been checked?

4.

Has the bleed off valve been checked to be sure it will hold and is not stopped up?

5.

Are all bolts on the cutter and pilot bit tight and is the coupon catcher on the pilot bit?

6.

Is the valve centered on the flange?

7.

Has the cutting depth been calculated to avoid cutting the opposite side of the pipe?

8.

Has the boring bar been run through the valve several times to ensure free passage?

9.

Has the pressure and temperature of the contained material been reduced as much as the

process operations will allow?

10.

Is there liquid or flowing gas in contact with the area to be hot tapped?

Before Removing the Hot Tap Machine

1.

Follow the manufacturer's instructions to be sure the boring bar is fully retracted before

closing the valve.

2.

Close the valve.

Page 24 of 25

Document Responsibility: Piping

SAEP-311

Issue Date: 29 January, 2003

Next Planned Update: 1 March, 2003

Installation of Hot Tapped Connections

3.

Make sure any necessary nitrogen purging is completed.

4.

Open the bleeder valve and be sure all pressure is off the hot tap machine before

removing bolts from the flange. If flow or pressure persists, the main valve is probably

leaking.

5.

Remove the hot tap machine from the tapping valve.

6.

Remove the coupon and from the pilot drill and wire to the tapping valve.

7.

Ensure the completed hot tap is blinded or plugged before leaving the jobsite.

8.

Operations Supervisor is to ensure that the coupon is forwarded to the responsible

Operations Piping & Valves Unit/M&CED/CSD to verify wall thickness or corrosion

patterns.

Page 25 of 25

You might also like

- TurbochargersDocument193 pagesTurbochargersGato Richy95% (22)

- Final Concrete Cutting and Drilling Doc CroppedDocument20 pagesFinal Concrete Cutting and Drilling Doc CroppedEhab SaadNo ratings yet

- PIPE LINE Presentation PART 1Document33 pagesPIPE LINE Presentation PART 1kannan100% (1)

- XSteam Excel v2.6Document9 pagesXSteam Excel v2.6Yos Cornel TariganNo ratings yet

- Lined Pipes & Fittings GuideDocument68 pagesLined Pipes & Fittings Guidegilbert4285No ratings yet

- Pipeline Hydro-Test and Pre-CommissioningDocument24 pagesPipeline Hydro-Test and Pre-Commissioningdreamer198293% (14)

- Centrifugal ChillersDocument16 pagesCentrifugal ChillersDevan Sadhu100% (3)

- Petroleum Development Oman L.L.C.: Unrestricted Document ID: SP-1190 November 2004 Filing KeyDocument15 pagesPetroleum Development Oman L.L.C.: Unrestricted Document ID: SP-1190 November 2004 Filing KeySherifMouradNo ratings yet

- Piping Inspection Procedure GuideDocument8 pagesPiping Inspection Procedure Guidemohd as shahiddin jafriNo ratings yet

- Hot Taps Connect Pipelines Without Shutting Down Gas FlowDocument17 pagesHot Taps Connect Pipelines Without Shutting Down Gas FlowMSNo ratings yet

- Safety in Gas Welding & Cutting Process PDFDocument11 pagesSafety in Gas Welding & Cutting Process PDFviswamanojNo ratings yet

- SP1210 Pipeline Operation and MaintDocument25 pagesSP1210 Pipeline Operation and MaintRoshin99100% (2)

- Codes & Standards For Natural GasDocument13 pagesCodes & Standards For Natural Gasharikrishnanpd3327No ratings yet

- PipingDocument16 pagesPipingraja11185100% (1)

- Method Statement For Hot Tapping Rev 0Document9 pagesMethod Statement For Hot Tapping Rev 0Thomas100% (4)

- SP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Document94 pagesSP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Rjeb mohamed100% (1)

- Construction of PipelineDocument44 pagesConstruction of PipelinePraveen Kumar100% (1)

- COOLING WATER HOT TAP CALCULATIONSDocument20 pagesCOOLING WATER HOT TAP CALCULATIONSsurekha_ahireNo ratings yet

- Site Inspection Workplace Trasport ChecklistDocument6 pagesSite Inspection Workplace Trasport ChecklisttipuNo ratings yet

- GU-501 - Guidelines For Excavating and Working Around Live PipelinesDocument22 pagesGU-501 - Guidelines For Excavating and Working Around Live PipelinesDhameemAnsari0% (1)

- Costing of PipelineDocument16 pagesCosting of Pipelinevuong100% (2)

- AAL01-000-25-55-SP-0004 Rev A1 Piping Standard Details PDFDocument65 pagesAAL01-000-25-55-SP-0004 Rev A1 Piping Standard Details PDFJosuaNo ratings yet

- Introduction To Civil Aspects of Piping SystemsDocument75 pagesIntroduction To Civil Aspects of Piping SystemsPierre DibNo ratings yet

- 31-SAMSS-010 - Nov. 12, 2013Document9 pages31-SAMSS-010 - Nov. 12, 2013Lainhatanh100% (1)

- Hot Tapping Scope of WorkDocument3 pagesHot Tapping Scope of WorkSukhen Das50% (2)

- Flowlines and Well Gas Lift LinesDocument4 pagesFlowlines and Well Gas Lift LinesDaniel Dambo100% (1)

- Lifting Categorisation Flow Chart OnshoreDocument3 pagesLifting Categorisation Flow Chart OnshoreEhab SaadNo ratings yet

- Saep 11Document29 pagesSaep 11Anonymous 4IpmN7On100% (1)

- Engineering Encyclopedia: Saudi Aramco Piping SystemsDocument23 pagesEngineering Encyclopedia: Saudi Aramco Piping SystemsPrakhar KulshreshthaNo ratings yet

- M.S For Hydro TestDocument16 pagesM.S For Hydro TestjahaanNo ratings yet

- Example Method Statement For The Installation of Concrete Floor SlabsDocument8 pagesExample Method Statement For The Installation of Concrete Floor SlabsLombe Paul OkparaNo ratings yet

- Hottap - SPC (Specification For Hot Tapping)Document14 pagesHottap - SPC (Specification For Hot Tapping)Hector MejiaNo ratings yet

- Pipeline Integrity ManagementDocument47 pagesPipeline Integrity Managementixotee100% (2)

- Pipeline RepairsDocument44 pagesPipeline RepairsMohamad PizulNo ratings yet

- Tank Builders ScaffoldDocument40 pagesTank Builders ScaffoldEhab SaadNo ratings yet

- Corrosion of Steels in Sour Gas EnvironmentDocument179 pagesCorrosion of Steels in Sour Gas Environmentaathittaya100% (1)

- Desarmado de La Transmision de Motoniveladora SERIE HDocument221 pagesDesarmado de La Transmision de Motoniveladora SERIE Hluisitolokitod100% (1)

- 10606.1.401 Guidelines For Hot - Tapping. 99Document13 pages10606.1.401 Guidelines For Hot - Tapping. 99Anonymous ojtevpUs0% (1)

- Design Basis Module Impact Process EngineeringDocument26 pagesDesign Basis Module Impact Process EngineeringjackNo ratings yet

- Hot Tap Procedures ExonDocument17 pagesHot Tap Procedures ExonDian Ardiansyah67% (3)

- PipingDocument15 pagesPipingDerick Mendoza100% (1)

- Saep 311Document30 pagesSaep 311GulfamNo ratings yet

- Dep 30.48.40.31-Gen-Feb-2019 Thermally Sprayed Aluminium CoatingsDocument21 pagesDep 30.48.40.31-Gen-Feb-2019 Thermally Sprayed Aluminium CoatingsDevam RajNo ratings yet

- 2016natural Gas Pipeline Annual Safety ReportDocument15 pages2016natural Gas Pipeline Annual Safety ReportnankingNo ratings yet

- Reservoir Fluid PropertiesDocument52 pagesReservoir Fluid PropertiesAhmed Bubaker100% (6)

- Mersen Process Technologies ProviderDocument6 pagesMersen Process Technologies ProviderIbhar Santos MumentheyNo ratings yet

- Hot Tap Form Proposed SignatoriesDocument43 pagesHot Tap Form Proposed SignatoriesSongAn BuiNo ratings yet

- Petroleum Refinery Relocation Projects: 5-Phases of Project ManagementFrom EverandPetroleum Refinery Relocation Projects: 5-Phases of Project ManagementNo ratings yet

- Pipeline DryingDocument2 pagesPipeline DryingAriel Anasco100% (2)

- Msog-M1402-P-Rp-006 Rev 1Document44 pagesMsog-M1402-P-Rp-006 Rev 1Mohd Nazir NorlanNo ratings yet

- 42 Inch Flare Hot TappingDocument4 pages42 Inch Flare Hot Tappingavi07me4uNo ratings yet

- Typical Questions For Piping EngineerDocument15 pagesTypical Questions For Piping EngineeranappanNo ratings yet

- How to Safely Modify Pipelines and Piping While in OperationDocument28 pagesHow to Safely Modify Pipelines and Piping While in Operationk dharmaNo ratings yet

- How To Proceed For A Hot TapDocument16 pagesHow To Proceed For A Hot TapThamaraikani ManiNo ratings yet

- GP 43-46-DRAFT - Pipeline Pre-CommissioningDocument33 pagesGP 43-46-DRAFT - Pipeline Pre-Commissioningmengelito almonte100% (2)

- MS-HKSS-Pigging Testing Drying Rev A - YNB 16''Document64 pagesMS-HKSS-Pigging Testing Drying Rev A - YNB 16''AAISATNo ratings yet

- GP 20 01 01Document19 pagesGP 20 01 01Osmar Amadeo Bejarano Jimenez100% (1)

- CH 02 Piping and Pipeline MaintenanceDocument30 pagesCH 02 Piping and Pipeline MaintenanceAmbar Nurul AnsariNo ratings yet

- Pipeline Road Crossing SpecificationDocument15 pagesPipeline Road Crossing SpecificationSend Mail100% (1)

- ETS 601, Piping ClassesDocument17 pagesETS 601, Piping ClassesElmokadem EinsteinNo ratings yet

- Valve Car SealDocument3 pagesValve Car SealRicNo ratings yet

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- ASME Training-FRP Piping Fabrication and Installation ProcessesDocument1 pageASME Training-FRP Piping Fabrication and Installation Processesninju1No ratings yet

- OISD Standard on Process Design and Operating Philosophy for Fired Process FurnacesDocument25 pagesOISD Standard on Process Design and Operating Philosophy for Fired Process FurnacesSanjay Patel0% (1)

- Hydrostatic TestingDocument18 pagesHydrostatic TestingRicardoNo ratings yet

- PIPING Work ProcessesDocument36 pagesPIPING Work Processesandi100% (1)

- The ability to safely add connections to pressurized pipelines (40/40 charactersDocument6 pagesThe ability to safely add connections to pressurized pipelines (40/40 characterskrishna_piping67% (3)

- ONGC Effluent Plant Pipe Installation GuideDocument14 pagesONGC Effluent Plant Pipe Installation GuideNithin Mathai100% (1)

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988From EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNo ratings yet

- Intsallation of Hot Tap Fittings SAEP0311 2003Document33 pagesIntsallation of Hot Tap Fittings SAEP0311 2003fishzlz_847012012No ratings yet

- Equipment SpecificationDocument8 pagesEquipment SpecificationPraveen ChandrakarNo ratings yet

- Safety Information Sheet Lifting Plans (LOLER 1998)Document5 pagesSafety Information Sheet Lifting Plans (LOLER 1998)Muhammad Azhar AliNo ratings yet

- Signs Signals Barricades Subpart GDocument11 pagesSigns Signals Barricades Subpart GEhab SaadNo ratings yet

- Safety Information Sheet Lifting Plans (LOLER 1998)Document5 pagesSafety Information Sheet Lifting Plans (LOLER 1998)Muhammad Azhar AliNo ratings yet

- 10 Elec Standards2Document113 pages10 Elec Standards2limresNo ratings yet

- Cranes Signal Person FactsheetDocument1 pageCranes Signal Person FactsheetEhab SaadNo ratings yet

- Electrical Safety - SampleDocument29 pagesElectrical Safety - SamplesyakirohNo ratings yet

- Writing Work Method Statement Plain English Guidelines 0231Document24 pagesWriting Work Method Statement Plain English Guidelines 0231Vincent TengNo ratings yet

- AnchorageDocument1 pageAnchoragesujiyakhanNo ratings yet

- Back InjuryDocument2 pagesBack InjuryEhab SaadNo ratings yet

- Lessons Learnt - Trench CollapseDocument2 pagesLessons Learnt - Trench CollapseEhab SaadNo ratings yet

- 154 Bsu Best Practice Alert - Preventing Falling Objects & MaterialsDocument1 page154 Bsu Best Practice Alert - Preventing Falling Objects & MaterialsEhab SaadNo ratings yet

- Ultrasonic Inspection of Pipeline Split-TeesDocument8 pagesUltrasonic Inspection of Pipeline Split-TeesEhab SaadNo ratings yet

- BRM Hsse AlertDocument1 pageBRM Hsse AlertEhab SaadNo ratings yet

- Hand GlovesDocument1 pageHand GlovesEhab SaadNo ratings yet

- GPA Hearing Protection Requirements Updated for Berths and OperationsDocument1 pageGPA Hearing Protection Requirements Updated for Berths and OperationsEhab SaadNo ratings yet

- 155 Bsu Best Practice Alert - Confined Space Rescue DrillDocument2 pages155 Bsu Best Practice Alert - Confined Space Rescue DrillEhab SaadNo ratings yet

- 02 01 FatalitiesDocument12 pages02 01 FatalitiesEhab SaadNo ratings yet

- Bus SeatbeltDocument1 pageBus SeatbeltEhab SaadNo ratings yet

- 382 - Bsu Safety Alert - Fatal Grinder IncidentDocument1 page382 - Bsu Safety Alert - Fatal Grinder IncidentEhab SaadNo ratings yet

- 235-2009 Pipe Fitter Injured by High Pressure Water JetDocument1 page235-2009 Pipe Fitter Injured by High Pressure Water JetEhab SaadNo ratings yet

- 236-2009 Employee Struck in The Arm by Fragment From Cold ChiselDocument3 pages236-2009 Employee Struck in The Arm by Fragment From Cold ChiselEhab SaadNo ratings yet

- Aerial Lift Safety: Hazard AlertDocument2 pagesAerial Lift Safety: Hazard AlertScribdbahrainNo ratings yet

- HKDocument17 pagesHKEhab SaadNo ratings yet

- Laminar Flow Table: Name: Animesh Phatowali Roll No: 17AE30005 Group: 6 Experiment:7Document7 pagesLaminar Flow Table: Name: Animesh Phatowali Roll No: 17AE30005 Group: 6 Experiment:7Animesh PhatowaliNo ratings yet

- IPUE 208 Introduction To Process and Utilities Engineering: Gmol CM VDocument8 pagesIPUE 208 Introduction To Process and Utilities Engineering: Gmol CM VRandy SooknananNo ratings yet

- Travel Counterbalance Valve: Systems OperationDocument10 pagesTravel Counterbalance Valve: Systems OperationRainer Lopez E100% (3)

- GA 808 Sr. No.: APR 865094 SN Drawing Ref. Part No. Description QntyDocument7 pagesGA 808 Sr. No.: APR 865094 SN Drawing Ref. Part No. Description QntyraizoNo ratings yet

- ComapDocument44 pagesComapfabianoal50% (2)

- NPTEL IIT Roorkee Steam Power Systems Assignment #1Document3 pagesNPTEL IIT Roorkee Steam Power Systems Assignment #1Suraj ChaudharyNo ratings yet

- Rotodynamic PumpsDocument21 pagesRotodynamic PumpsDANIEL ALFONSO SAMPER BRITONo ratings yet

- The Ideal Gas Law: Lecture 2: Atmospheric ThermodynamicsDocument16 pagesThe Ideal Gas Law: Lecture 2: Atmospheric ThermodynamicsAAKIL AHAMEDNo ratings yet

- Change of State of Gases ExperimentDocument6 pagesChange of State of Gases ExperimentRetriana Maharani Retri100% (1)

- 18MW Co-Generation system with low emissionsDocument2 pages18MW Co-Generation system with low emissionsfrdnNo ratings yet

- 18ME54 Turbo Machines Module 02 Question No 3a & 3bDocument14 pages18ME54 Turbo Machines Module 02 Question No 3a & 3bThanmay JSNo ratings yet

- Sulfur Recovery From Acid Gas Using The Claus ProcDocument11 pagesSulfur Recovery From Acid Gas Using The Claus ProcAceh NyakponNo ratings yet

- Arzator TD PDFDocument4 pagesArzator TD PDFadrianradulescuNo ratings yet

- CDS 31Document2 pagesCDS 31MarleyNo ratings yet

- The Gaseous StateDocument12 pagesThe Gaseous Statelim keng xun faganNo ratings yet

- 189 010 - en 15.710057 V3.0Document12 pages189 010 - en 15.710057 V3.0balzac191No ratings yet

- API Standard 674 positive displacement pump errataDocument2 pagesAPI Standard 674 positive displacement pump erratajairo davidNo ratings yet

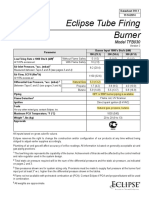

- Eclipse Tube Firing Burner: Model TFB030Document4 pagesEclipse Tube Firing Burner: Model TFB030Ing. Rodolfo Rincon GarciaNo ratings yet

- Understanding Gas BehaviorDocument17 pagesUnderstanding Gas BehaviorJhon Mhark GarinNo ratings yet

- Pitot TubeDocument30 pagesPitot Tubepushpzala86No ratings yet

- Trainig Report For IoclDocument30 pagesTrainig Report For IoclAshish Jha67% (3)

- HEAT EXCHANGER SPECIFICATION SHEETDocument2 pagesHEAT EXCHANGER SPECIFICATION SHEETMurad ALiNo ratings yet

- Completion Types: 1. Interface Between Wellbore and ReservoirDocument14 pagesCompletion Types: 1. Interface Between Wellbore and ReservoirsmogydNo ratings yet

- Breathing Apparatus-List-SCBA-06072020-GR PDFDocument1 pageBreathing Apparatus-List-SCBA-06072020-GR PDFwarikhNo ratings yet

- (O) ' Abj1f5 WT+T T,: L (Document1 page(O) ' Abj1f5 WT+T T,: L (RoviclopezNo ratings yet