Professional Documents

Culture Documents

KKS Designation System

Uploaded by

Tamer Ahmed SalemCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KKS Designation System

Uploaded by

Tamer Ahmed SalemCopyright:

Available Formats

Doc. No.

Documentation Overview

1CS36949

Rev. ind.

E

Techn. Area / DCC

KKS Designation System

M /& DB103

Page

1 (19)

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

KKS Designation System

SE-612 83 FINSPONG, Sweden

Based on

Product

1CCG50048en-1

Plant

This document is issued in Pulse.

Siemens Industrial Turbomachinery AB

Author

SIT/GPTT/L.Lindman

Gunilla Strand

Appr. 2003-10-10

Doc. Kind

Description of Designation

Language

en

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

KKS Designation System

Techn. Area / DCC

M /& DB103

Page

2 (19)

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

Contents

SE-612 83 FINSPONG, Sweden

Introduction............................................................................................... 3

Process related identification................................................................... 4

Function Code Key ................................................................................... 6

3.1 A Grid and distribution systems

3.2 B Power transmission and auxiliary power supply

3.3 C Instrumentation and control equipment

3.4 E Conventional fuel supply and residues disposal

3.5 G Water supply and disposal

3.6 H Conventional heat generation

3.7 L Steam, water, gas cycles

3.8 M Main machine sets

3.9 N Process energy supply for external users

3.10 P Cooling water systems

3.11 Q Auxiliary systems

3.12 S Ancillary systems

Equipment unit code key........................................................................ 14

4.1 A Mechanical equipment

4.2 B Mechanical equipment

4.3 C Direct measuring circuits

4.4 D Closed loop control circuits

4.5 E Analog and binary signal conditioning

4.6 F Indirect measuring circuits

4.7 G Electrical equipment

Item code key .......................................................................................... 17

5.1 K Mechanical items

5.2 M Mechanical items

5.3 Q Instrumentation and control items

5.4 X Signal origins

5.5 Y Signal applications

5.6 Z Gated signals

5.7 - Electrical items

Siemens Industrial Turbomachinery AB

Standard / Plant

Doc. No.

Documentation Overview

1CS36949

Rev. ind.

E

Techn. Area / DCC

KKS Designation System

M /& DB103

Page

3 (19)

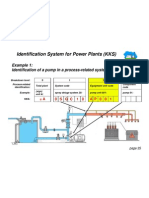

Introduction

This document describes the designation system used by Siemens Industrial

Turbomachinery AB (SIT) for plant and turbine deliveries. The system is based on the

Kraftwerk-Kennzeichen-System (KKS) and is used for identifying plants, sections of plant

and equipment in a clear manner according to their function.

The KKS includes three identification types:

Process related identification (function)

Point of installation identification (normally not used by SIT)

Location identification (normally not used by SIT)

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

KKS Designation System

M /& DB103

Page

4 (19)

Process related identification

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

Techn. Area / DCC

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Doc. No.

Documentation Overview

1CS36949

Rev. ind.

E

Techn. Area / DCC

KKS Designation System

Serial number of

breakdown level

Name of breakdown level

Type of data character

Page

M /& DB103

5 (19)

Overall Plant

Function

Equipment

Unit

Item

(A) or (N)

(N) A A A N N

A A N N N (A)

AANN

( ) = These data characters may be omitted.

A = Alphanumeric symbols (letters, special symbols)

N = Numerical symbols (digits)

Example:

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

MBV10

AP005

M01

Equipment Unit

Item

AANNN(A)

AANN

Serial number and

name of breakdown

level:

Overall Plant

A or N

Function

N

AAANN

Overall Plant. It may be necessary to identify units, unit-free plants or expansion stages within

a power station, such that a clear and unambiguous distinction exists between them. The

level Overall Plant can be omitted when the designation used in the power plant is otherwise

unambiguous.

A or N

AAANN

AANNN(A)

AANN

Prefix number. If in the Overall Plant two or more identical subsystems are to be identified the

prefix number is used to distinguish between them. E.g. two turbo sets, two boiler plants.

A or N

AAANN

AANNN(A)

AANN

Function. The alphabetical symbol of this breakdown level are used to classify and divide the

Overall Plant into subsystems or systems. The digits are of no significance as far as

classification is concerned; these simply count and subdivide the unit (e.g. line) coded in the

last alphanumeric symbol. E.g. MBV51, MBV52, MBV53 represents three lines in the lube oil

system. See Appendix A.

A or N

AAANN

AANNN(A)

AANN

Equipment Unit. The first two alphabetical symbols are used to distinguish between the

mechanical apparatus and equipment units, electrical and I&C equipment, and between the

measuring and closed-loop control circuits. The digits are of no significance as far as

classification is concerned, they are consecutive numbers in respectively system. If required,

the last alphanumeric symbol can be used to designate pilot valves, dual-thermometers etc.

See Appendix B.

A or N

AAANN

AANNN(A)

AANN

Item. In case of electrical and I&C equipment this section serves for designation of equipment

item - e.g. switches, push buttons, measuring instruments. For mechanical and process

engineering this level can be used to designate mechanical equipment and items, such as

pump couplings and gear units. At this breakdown level the digits are used for counting only.

E.g. KA01 equals globe valve with consecutive number 1, -P05 equals electrical measuring

instrument consecutive number 5. See Appendix C.

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

KKS Designation System

Function Code Key

3.1

3.2

M /& DB103

Page

6 (19)

Grid and distribution systems

AE

110 kv systems

AEA

Unit circuit breaker 60 kV

AK

10 kv systems

AKA

Unit circuit breaker 15 kV

Techn. Area / DCC

Power transmission and auxiliary power supply

BA

Power transmission

BAA

Generator leads

BAC

Generator circuit breaker

BAT

Generator transformers

BAW

Earthing and lighting protection systems

BAX

Fluid supply system for control and protection equipment

BB

Medium-voltage distribution boards and transformers, normal system

BBA

Medium voltage distribution boards, normal system

BF

Low voltage main distribution boards and transformers, normal

system

BFA

Low voltage main distribution boards, normal system

BP

Power installations for variable-speed drives

BPA

Power installations for variable-speed drives

BR

Low voltage distribution boards, uninterruptible (converter) power

supply, UPS

BRA

Low voltage distribution boards, uninterruptible (converter) power supply

BRU

Converter (static), inverter

BRV

Emergency power generating equipment

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

KKS Designation System

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

3.3

BT

Battery systems

BTA-BTK

Batteries (free for use according to voltage level)

BTL-BTV

Battery chargers (free for use according to voltage level)

BTW

Common equipment

BU

Direct voltage distribution boards, normal system

BUA-BUJ

Direct voltage distribution boards

Techn. Area / DCC

M /& DB103

Page

7 (19)

Instrumentation and control equipment

CA

Protective interlocks

CAA-CAB

Cabinets for protective interlocks

CB

Functional group control, sub loop control

CBP

Cabinets for synchronization

CE

Annunciation

CEA

Cabinets for annunciation systems

CF

Measurement, recording

CFA-CFE

Cabinets for measurement

CH

Protection

CHA-CHB

Cabinets for generator and transformer protection

CHE

Turbine Protection

CJ

Unit coordination level

CJA

Unit control system (including cabinets)

CJF

Boiler control system (including cabinets)

CJJ

Instrumentation and control cabinets for steam turbine set

CJP-CJQ

Instrumentation and control cabinets for gas turbine set

CK

Process computer system

CKA

Online supervisory and diagnostic computer

CN

Cubicles

CNA

Control cubicle

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Doc. No.

Documentation Overview

1CS36949

Rev. ind.

E

Techn. Area / DCC

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

KKS Designation System

3.4

CR

Control equipment

CRB

Control equipment

CW

Control rooms

CWA-CWB

Main control videos and consoles

CWF

Main control panels

CY

Communication equipment

CYA

Telephone system

CYB

Control console telephone system

CYC

Alarm system (acoustic)

CYD

Alarm system (optical)

CYE

Fire alarm system

CYF

Clock system

CYG

Remote control system

CYH

Telemetry system

M /& DB103

Page

8 (19)

Conventional fuel supply and residues disposal

EG

Supply of liquid fuels (External liquid fuel system)

EGA

Receiving equipment incl. pipeline

EGB

Tank farm

EGC

Pump system

EGD

Piping system

EGR

Residues removal system

EGT

Heating medium system

EK

Supply of gaseous fuel

EKA

Receiving equipment incl. pipeline (External gas fuel system)

EKB

Moisture separation system

EGC

Heating system

EKD

Main reducing station, expansion turbine

EKF

Storage system

EKG

Piping system

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

KKS Designation System

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

3.5

3.6

Techn. Area / DCC

M /& DB103

Water supply and disposal

GA

Raw water supply

GAA

Extraction, mechanical cleaning

GAC

Piping and channel system

GAD

Storage system

GC

Treatment system

GCB

Filtering, mechanical cleaning system

GCE

Acid proportioning system

GCF

Ion exchange, reverse osmosis system

GCJ

Preheating, cooling system

GCK

Piping system, temporary storage system, pump system for main fluid

GH

Distribution system

GHC

Distribution system after treatment (demineralization)

GK

Drinking water supply

GKB

Storage, forwarding, distribution system

GKC-GKE

Drinking water supply

GN

Process drains treatment system

GNB

Filtering, mechanical cleaning system

Page

9 (19)

Conventional heat generation

HA

Pressure system

HAC

Economizer system

HAD

Evaporator system

HAH

HP super heater system

HAN

Pressure system drainage and venting systems

HN

Flue gas exhaust

HNA

Ducting system

HNE

Smoke stack system (chimney)

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

KKS Designation System

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

3.7

3.8

Techn. Area / DCC

M /& DB103

Steam, water, gas cycles

LA

Feed water system

LAA

Storage, deaeration

LAB

Feed water piping system

LAC

Feed water pump system

LAE

HP desuperheating spray system

LAF

IP desuperheating spray system

LB

Steam system

LBA

Main steam piping system

LBB

Hot reheat piping system

LBC

Cold reheat piping system

LBD

Extraction piping system

LBE

Back-pressure piping system

LBH

Start-up steam system, shutdown steam system

LBQ

Extraction steam piping system for HP feed water heating

LBS

Extraction steam piping system for LP feed water heating

LC

Condensate system

LCA

Main condensate piping system

LCB

Main condensate pump system

LCE

Condensate superheating spray system

LF

Common installations for steam, water, gas cycles

LFN

Proportioning system for feed water, condensate system, incl. proportioning

in boiler and turbine area

Page

10 (19)

Main machine sets

MA

Steam turbine plant

MAA

HP-turbine system

MAB

MP-turbine system

MAC

LP-turbine system

MAG

Condensing system (Condenser system)

MAJ

Air removal system (Evacuation system)

MAK

Transmission gear between prime mover and driven machine (Gear system)

MAL

Drain and vent systems (Drain system)

MAM

Leak-off steam system

MAV

Lubricant supply system (Lube oil system)

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Doc. No.

Documentation Overview

1CS36949

Rev. ind.

E

Techn. Area / DCC

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

KKS Designation System

M /& DB103

MAW

Sealing, heating and cooling steam system (Sealing steam system)

MAX

Non-electric control and protection equipment including fluid supply system

(Hydraulic system)

MAY

Electrical control and protection equipment (Turbine controller)

MB

Gas turbine plant

MBA

Turbine, compressor rotor with common casing (Gas turbine system)

MBB

Turbine casing and rotor (Power turbine system)

MBH

Cooling and sealing gas system

MBJ

Start-up unit (Starting system)

MBK

Transmission gear between prime mover and driven machine

MBL

Intake air, cold gas system

MBM

Combustion chamber

MBN

Fuel supply system (Liquid fuel system)

MBP

Fuel supply system (Gas fuel system)

MBQ

Ignition fuel supply system

MBR

Exhaust gas system

MBT

Motive gas generator unit, incl. combustion chamber (Gas generator system)

MBU

Additive system

MBV

Lubricant supply system

MBX

Non-electric control and protection equipment, incl. fluid supply

MK

Generator plant

MKA

Generator, complete

MKB

Generator exciter set, including set with electrical braking system

Page

11 (19)

(uses only if *MKC* is not sufficient for identification)

MKC

Generator exciter set, including set with electrical braking system

MKD

Bearings

MKY

Control and protection equipment

MM

Compressor plant

MMA

Compressor incl. internal systems

MMC

Suction piping system

MMG

Gas cooling system

MMH

Discharge piping system

MMV

Lubricant supply system

MMW

Sealing fluid supply system

MMY

Control and protection equipment

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

KKS Designation System

3.9

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

3.10

3.11

MP

Common installations for main machine sets

MPS

Drying and lay-up system

M /& DB103

Process steam system

NAA

Piping system (steam)

NAB

Piping system (condensate)

Cooling water systems

PA

Circulating (main cooling) water system

PAC

Circulating (main cooling) water pump system

PAH

Condenser cleaning system

PG

Closed cooling water treatment system for conventional area

PGA-PGU

Closed cooling water system for conventional area

Page

12 (19)

Process energy supply for external users

NA

Techn. Area / DCC

Auxiliary systems

QE

General compressed air and carrier air supply

QEA

Central compressed air and carrier air generation system

QEB

Central compressed air and carrier air distribution system

QEC

General compressed air and carrier air supply

QF

General control air supply

QFA

Central control air generation system (Instrument air system)

QFB

Central control air distribution system

QFD

General control air supply

QFE

General control air supply

QL

Feed water, steam, condensate cycle of auxiliary steam generating and

distribution system

QLA

Feed water system

QLB

Steam system

QU

Sampling systems for conventional areas

QUA-QUB

Sampling system for conventional area

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Doc. No.

Documentation Overview

1CS36949

Rev. ind.

E

Techn. Area / DCC

KKS Designation System

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

3.12

M /& DB103

Page

13 (19)

Ancillary systems

SA

Heating, ventilation, air-conditioning (HVAC) systems for conventional

area

SAA-SAU

Heating, ventilation, air-conditioning (HVAC) systems for conventional

area (building specific)

SAG

Ventilation system gas turbine

SD

Stationary cleaning systems

SDA-SDU

Stationary cleaning systems

SDB

Compressor washing system

SF

Heating and fuel gas system

SFY

Control and protection equipment (Gas detection system)

SG

Stationary fire protection systems

SGA

Fire water system, conventional area

SGC

Spray deluge system

SGE

Sprinkler system

SGF

Foam fire-fighting systems

SGJ

CO2 fire fighting system

SM

Cranes, stationary hoists and conveying appliances

SMA-SMU

Cranes, stationary hoists and conveying appliances

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

KKS Designation System

Equipment unit code key

4.1

4.2

4.3

Techn. Area / DCC

M /& DB103

Mechanical equipment

AA

Valves, dampers etc.

AB

Isolating elements, air locks

AC

Heat exchangers, heat transfer surfaces

AE

Turning, driving, lifting and slewing gear

AF

Continuous conveyors, feeders

AG

Generator units

AH

Heating, cooling and air conditioning units

AM

Mixers, agitators

AN

Compressor units, fans

AP

Pump units

AT

Cleaning, drying, filtering and separating equipment

AU

Braking, gearbox, coupling equipment, non-electrical converters

AV

Combustion equipment

Mechanical equipment

BB

Storage equipment (tanks)

BN

Jet pumps, ejectors, injectors

BP

Flow restrictors, limiters, orifices

BR

Piping, ductwork, chutes

BS

Silencers

BU

Insulation, sheathing

Page

14 (19)

Direct measuring circuits

CD

Density

CE

Electrical variables

CF

Flow, rate

CG

Distance, length, position, direction of rotation

CH

Manual input as manually operated sensor

CK

Time

CL

Level

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

KKS Designation System

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

4.4

4.5

4.6

CM

Moisture, humidity

CP

Pressure

CS

Velocity, speed

CT

Temperature

CY

Vibration, expansion

Closed loop control circuits

DD

Density

DE

Electrical variables

DF

Flow, rate

DG

Distance, length

DL

Level

DM

Moisture, humidity

DP

Pressure

DS

Velocity, speed

DT

Temperature

DV

Viscosity

DW

Weight, mass

DY

Vibration, expansion

M /& DB103

Page

15 (19)

Analog and binary signal conditioning

EA-EE

Open loop control

EG-EK

Alarm, annunciation

EM-EQ

Process computer

EU

Combined analogue and binary signal conditioning

EW-EZ

Protection

Techn. Area / DCC

Indirect measuring circuits

FD

Density

FE

Electrical variables

FF

Flow, rate

FG

Distance, length, position, direction of rotation

FL

Level

FM

Moisture, humidity

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

KKS Designation System

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

4.7

FS

Velocity, speed

FT

Temperature

FV

Viscosity

FW

Weight, mass

FY

Vibration, expansion

Techn. Area / DCC

M /& DB103

Page

16 (19)

Electrical equipment

GA-GE

Junction boxes and cable (bus bar penetrations)

GH

Electrical and instrumentation and control installation units as preprocess

system

GK

Information display and operator control equipment for process computers

and automation system

GM

Junction boxes for light-current systems of national telecommunication

services

GP

Sub distribution/junction boxes for lighting

GQ

Sub distribution/junction boxes for power sockets

GR

DC generating equipment, batteries

GS

Switch gear equipment

GT

Transformer equipment

GU

Converter equipment

GV

Structure related earthing and lightning protection equipment, sure arrestors

GW

Cabinet power supply equipment

GX

Actuating equipment for electrical variables

GY

Junction boxes for light current systems

GZ

Hangers, supports and racks for electrical and instrumentation and control

equipment

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

KKS Designation System

Item code key

5.1

5.2

5.3

Techn. Area / DCC

M /& DB103

Mechanical items

KA

Gate valves, globe valves, dampers, cooks, rupture disks, orifices

KB

Gates, doors, dam boards

KC

Heat exchangers, coolers

KD

Vessels/tanks, pools, surge tanks

KE

Turning, driving, lifting and slewing gear

KN

Compressors, blowers, fans

KP

Pumps

KT

Cleaning machines, dryers, separators, filters

KV

Burners, grates

Mechanical items

MB

Brakes

MF

Foundations

MG

Gear boxes

MK

Clutches, couplings

MM

Engines

MR

Piping components, ductwork components

MS

Positioner

MT

Turbines

MU

Transmission gear

Page

17 (19)

Instrumentation and control items

QB

Sensors

QH

Signaling devices

QN

Controllers, fly bolt governor

QP

Measuring instruments, testing equipment

QR

Instrument piping

QT

Thermo wells and pockets for protection of sensors

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Documentation Overview

Doc. No.

1CS36949

Rev. ind.

KKS Designation System

5.4

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

5.7

Signal applications

Signal applications (free for use)

Gated signals

ZA

Gated signal for alarm

ZT

Gated signal for shut down

Page

18 (19)

Signal origins (free for use)

YA-YZ

5.6

M /& DB103

Signal origins

XA-XZ

5.5

Techn. Area / DCC

Electrical items

-A

Assemblies and subassemblies

-B

Transducers for non-electrical to electrical variables and vice-versa

-C

Capacitors

-D

Binary elements

-E

Special components

-F

Protective devices

-G

Generators, power supplies

-H

Signaling devices

-K

Relays, contractors

-L

Inductors

-M

Motors

-N

Amplifiers, controllers

-P

Measuring instruments, testing equipment

-Q

Power switchgear

-R

Resistors

-S

Switches, selectors

-T

Transformers

-U

Modulators

-V

Tubes, semiconductors

-W

Transmission paths, waveguides, aerials

-X

Terminals, plugs, sockets

-Y

Electrical positioners

-Z

Terminations, balancing equipment, filters, limiters, cable terminations

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

Doc. No.

Documentation Overview

1CS36949

Rev. ind.

E

Techn. Area / DCC

KKS Designation System

M /& DB103

Page

19 (19)

REVISION

Rev. Page (P) Description

ind. Chapt. (C)

P 19

-

P3

D

E

Adjustment, Revision page added

Company name has changed to Siemens Industrial

Turbomachinery AB (SIT)

Turbine deliveries changed to plant and turbine

deliveries.

Spelling errors corrected.

Doc. Designation changed to 1A0401 all pages.

Ref. des. and Doc. des. removed (all pages).

060707

GPMT/LFN

070510 GPMT/LL

071214

GPTT/LFN

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

Siemens Industrial Turbomachinery AB

A

B

Date

Dept. / Init.

040202 AQI/LL

050415 AQI/AR

SE-612 83 FINSPONG, Sweden

Siemens Industrial Turbomachinery AB

Standard / Plant

You might also like

- Kks Ama00m Pmfna252 A Kks GuidelinesDocument102 pagesKks Ama00m Pmfna252 A Kks GuidelinesRafil Alani100% (1)

- TM - Intro & KKS GeschDocument33 pagesTM - Intro & KKS GeschTemitope Vic100% (1)

- 02 KksDocument8 pages02 KksManuel Jesus Perez MelgarNo ratings yet

- Article Transition KKS To RDS-PP Rev2011-EnGDocument10 pagesArticle Transition KKS To RDS-PP Rev2011-EnGsdiamanNo ratings yet

- Kks Key Book AlstomDocument136 pagesKks Key Book AlstomGentelmanOnly100% (3)

- KksDocument78 pagesKksgopi_dey8649No ratings yet

- KKS Guidelines - 1AHA062168 - Rev. B PDFDocument26 pagesKKS Guidelines - 1AHA062168 - Rev. B PDFsbiliristhodNo ratings yet

- Kks 2Document157 pagesKks 2Aldiarso UtomoNo ratings yet

- VGB-S-002-05-2015-10-EN (Public License)Document52 pagesVGB-S-002-05-2015-10-EN (Public License)Mohamed Zaghloul100% (1)

- Kraftwerk Kennezeichen SystemDocument78 pagesKraftwerk Kennezeichen SystemGopinathan Bipin50% (2)

- KKS Identification SystemDocument381 pagesKKS Identification SystemJonathan Alexi Molina Roa100% (1)

- Kks AlstomDocument135 pagesKks Alstomcabral1205100% (5)

- Full Documentation of Resume Builder ProjectDocument130 pagesFull Documentation of Resume Builder Projectshaheryar xhahNo ratings yet

- KKS General View SDocument56 pagesKKS General View SArslan Abbas Malik100% (4)

- VGB KKS CodeDocument48 pagesVGB KKS CodeEymenNo ratings yet

- Identification System Kks Chapter I KksDocument280 pagesIdentification System Kks Chapter I KksSupratim PalNo ratings yet

- Guideline: Letter Code For Power Plant SystemsDocument244 pagesGuideline: Letter Code For Power Plant SystemsLuis Felipe Cortes Pacheco100% (3)

- 05 KKS Engl TSDocument23 pages05 KKS Engl TSImam Syarifudin100% (1)

- KKS ConceptDocument6 pagesKKS ConceptAmit Nigam100% (2)

- KKS Identification - Mong Duong 1 PowerPlant PDFDocument82 pagesKKS Identification - Mong Duong 1 PowerPlant PDFTran HoangNo ratings yet

- Panduan KKS SiemensDocument54 pagesPanduan KKS SiemensAnonymous GVfWfdNo ratings yet

- KKS ProcedureDocument33 pagesKKS Procedurepmvelilla100% (1)

- KKS Handbook English - November 2016Document85 pagesKKS Handbook English - November 2016apurnomoNo ratings yet

- S 821 91 2020 10 ENeBookupdate21Document76 pagesS 821 91 2020 10 ENeBookupdate21mohdfirdausNo ratings yet

- KKS Handbook Edition 07Document126 pagesKKS Handbook Edition 07Leonardo Ernesto Cornejo Pino100% (1)

- 71 OFFSHORE2011presentationDocument19 pages71 OFFSHORE2011presentationJACKNo ratings yet

- Industrial Training Presentation on NTPC Gas Power PlantDocument19 pagesIndustrial Training Presentation on NTPC Gas Power PlantYogesh Gurjar100% (1)

- Aku Aeb0001enDocument101 pagesAku Aeb0001enManuel Enrique Coto ReyesNo ratings yet

- KKS Coding Concepts & Decoding Techniques: Control and Instrumentation Department Simhadri Super Thermal Power StationDocument523 pagesKKS Coding Concepts & Decoding Techniques: Control and Instrumentation Department Simhadri Super Thermal Power StationPriyankaNo ratings yet

- KKS HandbookDocument93 pagesKKS HandbookJose Aguilos BotanaNo ratings yet

- Kks Handbook Edition 08Document113 pagesKks Handbook Edition 08David BenderNo ratings yet

- Kks Codes r3Document18 pagesKks Codes r3Ram SinghNo ratings yet

- KKS NumberingDocument100 pagesKKS Numberingali_naghibNo ratings yet

- KKS Codes in BriefDocument47 pagesKKS Codes in BriefGopinathan Bipin100% (2)

- Att.1 QT1-L-G-020-05-00003, KKS Numbering SystemDocument85 pagesAtt.1 QT1-L-G-020-05-00003, KKS Numbering SystemDoan Ngoc DucNo ratings yet

- Equipment and Components Identification SystemDocument50 pagesEquipment and Components Identification SystemShaik Nizam Uddin0% (1)

- GT24/GT26 Operation (Propane Only / Staged Fuel Gas Injection)Document36 pagesGT24/GT26 Operation (Propane Only / Staged Fuel Gas Injection)SUNILNo ratings yet

- Kks CodeDocument1 pageKks Coderokorio0% (1)

- Procedure For Plant Identification (KKS Numbering System)Document82 pagesProcedure For Plant Identification (KKS Numbering System)zerocool86100% (8)

- Att.2 KKS System 2010-01Document462 pagesAtt.2 KKS System 2010-01ryanguntoroNo ratings yet

- KKS Guideline For Equipments-Rev1Document74 pagesKKS Guideline For Equipments-Rev1Dragos Ungureanu100% (1)

- KKS coding in Foster Wheeler projectDocument8 pagesKKS coding in Foster Wheeler projectPatrick MonteroNo ratings yet

- Gas Turbine Generator Mars 100 - SolarDocument2 pagesGas Turbine Generator Mars 100 - SolarIslem KhalfaouiNo ratings yet

- 9700 06eDocument19 pages9700 06eaanouar77No ratings yet

- PST Teknik KatalogDocument40 pagesPST Teknik Katalogiyilmaz1No ratings yet

- 29TC679FDocument29 pages29TC679FGustavo ChavezNo ratings yet

- TCM3.1L LA Colour TV Manual SectionsDocument67 pagesTCM3.1L LA Colour TV Manual SectionsAnonymous Gj5yPUC2JNo ratings yet

- Sinumerik Basic FunctionsFB10306enDocument2,025 pagesSinumerik Basic FunctionsFB10306enkeizerpeterNo ratings yet

- Volvo FL 2008 WiringDocument190 pagesVolvo FL 2008 WiringDan Birkenhead100% (7)

- TV Philco Pfs2980Document30 pagesTV Philco Pfs2980Mario Cesar RuizNo ratings yet

- C29FS51 Service ManualDocument30 pagesC29FS51 Service Manualdmst622No ratings yet

- Gen 12MW PDFDocument11 pagesGen 12MW PDFTesta Bonaventura Vincenzo100% (1)

- en 1Document1,266 pagesen 1Dave JohnsonNo ratings yet

- Special Functions 840D 840di 810DDocument722 pagesSpecial Functions 840D 840di 810Dstanalina00100% (1)

- 2SD863Document5 pages2SD863FeryBaleaNo ratings yet

- 2ch AF Power Amplifier (Split Power Supply) (40W + 40W Min, THD 10%)Document6 pages2ch AF Power Amplifier (Split Power Supply) (40W + 40W Min, THD 10%)Jhonny BNo ratings yet

- 00 Siemens Protective Relay OverviewDocument38 pages00 Siemens Protective Relay Overviewapi-241473079No ratings yet

- ET B1 T 2005 EnglishDocument649 pagesET B1 T 2005 EnglishLaurentiu CatalinNo ratings yet

- Noblex 21TC667U STR-W6754 LA76933 LA78141-E R2S15908SPP LA72703 LA42205-E Chassis LA8-ADocument29 pagesNoblex 21TC667U STR-W6754 LA76933 LA78141-E R2S15908SPP LA72703 LA42205-E Chassis LA8-Amarquitos550b100% (1)

- InfoGraphic - IndustrialprotocolsDocument1 pageInfoGraphic - IndustrialprotocolsTamer Ahmed SalemNo ratings yet

- DeepLearning TextDocument21 pagesDeepLearning TextTamer Ahmed SalemNo ratings yet

- Manual Soft Starter 3RW44 enDocument262 pagesManual Soft Starter 3RW44 ennvijaymohan0% (1)

- CAP Short PresentationDocument12 pagesCAP Short PresentationTamer Ahmed SalemNo ratings yet

- InBatch ReportsDocument3 pagesInBatch ReportsTamer Ahmed SalemNo ratings yet

- STL Cheat Sheet by Category PDFDocument2 pagesSTL Cheat Sheet by Category PDFMehtab AhmedNo ratings yet

- Step7 STL Cheat Sheet by AlphabetDocument0 pagesStep7 STL Cheat Sheet by AlphabetAdrian McDermottNo ratings yet

- Personal Log For Professional Development For Renewal of CertifcationDocument4 pagesPersonal Log For Professional Development For Renewal of CertifcationTamer Ahmed SalemNo ratings yet

- STL Cheat Sheet by Category PDFDocument2 pagesSTL Cheat Sheet by Category PDFMehtab AhmedNo ratings yet

- Step7 STL Cheat Sheet by AlphabetDocument0 pagesStep7 STL Cheat Sheet by AlphabetAdrian McDermottNo ratings yet

- ICC Modbus Master Tool User's ManualDocument22 pagesICC Modbus Master Tool User's ManualTamer Ahmed SalemNo ratings yet

- 2013indusoft 131024105419 Phpapp02 - 2Document58 pages2013indusoft 131024105419 Phpapp02 - 2Tamer Ahmed SalemNo ratings yet

- Control Valves Tuning PDFDocument13 pagesControl Valves Tuning PDFsteam100deg1658No ratings yet

- Analyzers StartDocument1 pageAnalyzers StartTamer Ahmed SalemNo ratings yet

- Auma DataDocument2 pagesAuma Datasulejmanavdi100% (1)

- Simatic Working With STEP 7Document112 pagesSimatic Working With STEP 7Slavisa LejicNo ratings yet

- SQ L TutorialDocument10 pagesSQ L TutorialTamer Ahmed SalemNo ratings yet

- InBatch ReportsDocument3 pagesInBatch ReportsTamer Ahmed SalemNo ratings yet

- Flow Metering: "Installation and Set-Up Require A Particular Care"Document18 pagesFlow Metering: "Installation and Set-Up Require A Particular Care"chellahari2922No ratings yet

- Voltage Drop and Circuit Sizing CalculatorsDocument5 pagesVoltage Drop and Circuit Sizing Calculatorsdarsh2001patelNo ratings yet

- 5.4 Instrument Loop DiagramsDocument22 pages5.4 Instrument Loop Diagramsfxnt76100% (1)

- Nema Vs IPDocument1 pageNema Vs IPTamer Ahmed SalemNo ratings yet

- Flange Ratings in PSIG PDFDocument3 pagesFlange Ratings in PSIG PDFTamer Ahmed SalemNo ratings yet

- Altivar 61 ATV61HC16N4D PDFDocument12 pagesAltivar 61 ATV61HC16N4D PDFTamer Ahmed SalemNo ratings yet

- Control Valves Tuning PDFDocument13 pagesControl Valves Tuning PDFsteam100deg1658No ratings yet

- S7 - Standard FunctionsDocument756 pagesS7 - Standard FunctionsAkram SayeedNo ratings yet

- Sepam Series 80 - Tamer PDFDocument1 pageSepam Series 80 - Tamer PDFTamer Ahmed SalemNo ratings yet

- SIMATIC HMI ProTool V6.0 Service Pack 2 How To Configure Windows-Based SystemsDocument398 pagesSIMATIC HMI ProTool V6.0 Service Pack 2 How To Configure Windows-Based SystemsTamer Ahmed SalemNo ratings yet

- SIMATIC HMI ProTool Configuring Windows-Based SystemsDocument40 pagesSIMATIC HMI ProTool Configuring Windows-Based SystemsTamer Ahmed SalemNo ratings yet

- Westinghouse Technology Systems Manual Section 3.2 Reactor Coolant SystemDocument62 pagesWestinghouse Technology Systems Manual Section 3.2 Reactor Coolant SystemSheikh ShoaibNo ratings yet

- PDS LZ 5703Document3 pagesPDS LZ 5703Alfredo BallonNo ratings yet

- Cci OverviewDocument8 pagesCci OverviewDinesh KumarNo ratings yet

- Rankine Cycle ProblemDocument2 pagesRankine Cycle ProblemJohn Paul RodriguezNo ratings yet

- Boiler InterlocksDocument6 pagesBoiler Interlocksgovindkani100% (3)

- Pemilihan Steam TrapDocument1 pagePemilihan Steam TrapmaliklduNo ratings yet

- Changes of State and The Particle Model: Learning OutcomesDocument2 pagesChanges of State and The Particle Model: Learning OutcomesSIRRVET BUKHARINo ratings yet

- Groen SSB 3G GF SteamerDocument2 pagesGroen SSB 3G GF Steamerwsfc-ebayNo ratings yet

- Applied Thermal Engineering: Ralf Starkloff, Falah Alobaid, Karl Karner, Bernd Epple, Martin Schmitz, Felix BoehmDocument11 pagesApplied Thermal Engineering: Ralf Starkloff, Falah Alobaid, Karl Karner, Bernd Epple, Martin Schmitz, Felix Boehmjhugo_mirandaNo ratings yet

- Biogas Plant - Food WastesDocument33 pagesBiogas Plant - Food Wastesayman1111167% (3)

- Example 1: Bar 035 - 0 at 2 Bar 42 at 1Document3 pagesExample 1: Bar 035 - 0 at 2 Bar 42 at 1CantalicioNo ratings yet

- Steam Turbine SolutionsDocument12 pagesSteam Turbine Solutionsdanioachim1945No ratings yet

- DNVGL RU SHIP Pt4Ch7Document129 pagesDNVGL RU SHIP Pt4Ch7Julio Andrés Casal RamosNo ratings yet

- H.W - 3 MCQ : Multiple Choice QuestionDocument2 pagesH.W - 3 MCQ : Multiple Choice QuestionJohnNo ratings yet

- Block 10 Module 2Document18 pagesBlock 10 Module 2Sandra FerrellNo ratings yet

- Cairn IndiaDocument128 pagesCairn IndiasrinivasNo ratings yet

- Ansaldo - Steam - TurbinesDocument8 pagesAnsaldo - Steam - TurbinesPratama Trendy LeoNo ratings yet

- Barometric CondenserDocument4 pagesBarometric Condenserasfarjee100% (3)

- All Ever Need OcrDocument4 pagesAll Ever Need OcrHassan HaiderNo ratings yet

- Mit El 79 034 09531582Document289 pagesMit El 79 034 09531582Fatima MarahNo ratings yet

- Calculate compressible gas flow and pressure dropDocument7 pagesCalculate compressible gas flow and pressure dropAl KappNo ratings yet

- 1231 - Water For Pharmaceutical PurposesDocument58 pages1231 - Water For Pharmaceutical PurposesMaleja Suarez100% (1)

- Oman Oil Refinery Systemization ProcedureDocument28 pagesOman Oil Refinery Systemization ProcedureMahadevan Mahalingam100% (4)

- STHE As Closed Feed Water HeaterDocument56 pagesSTHE As Closed Feed Water HeatersrinivasNo ratings yet

- Boiler Preservation Procedure For Thermal PlantsDocument5 pagesBoiler Preservation Procedure For Thermal Plantseng_fayNo ratings yet

- Problem SetDocument4 pagesProblem SetGeloii Panda0% (1)

- Enhanced WaterSteam Cycle For Advanced Combined Cycle TechnologyDocument30 pagesEnhanced WaterSteam Cycle For Advanced Combined Cycle TechnologyshimabekhradNo ratings yet

- BR 1701 PDFDocument7 pagesBR 1701 PDFdestiny2bnNo ratings yet

- Combined CyclesDocument17 pagesCombined CyclesMuhammad HarisNo ratings yet

- PFX Plate and Frame Heat Exchanger: Installation and Operating InstructionsDocument26 pagesPFX Plate and Frame Heat Exchanger: Installation and Operating InstructionsLe Quang SonNo ratings yet