Professional Documents

Culture Documents

Inline Vacuum and Pressure Relief Valve

Uploaded by

AshaHingoraniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inline Vacuum and Pressure Relief Valve

Uploaded by

AshaHingoraniCopyright:

Available Formats

Pressure and Vacuum Relief Valve, In-Line

PROTEGO DV/ZT

c

technology the tank pressure is maintained up to set pressure

with a tightness that is far superior to the conventional standard.

This feature is facilitated by valve seats made of high quality

stainless steel and with individually lapped valve pallets (1) or

with an air cushion seal (2) in conjunction with high quality FEP

diaphragm. The valve pallets are also available with a PTFE

seal to prevent the valve pallets from sticking when sticky products are used and to enable the use of corrosive fluids. After the

excess pressure is discharged or vacuum is balanced, the valve

reseats and provides a tight seal.

The optimized fluid dynamic design of the valve body and valve

pallet is a result of many years of research work, which allow a

stable operation of the valve pallet and optimized performance

resulting in reduction of product losses.

DN

Special Features and Advantages

full lift type technology valve utilizes only 10% overpressure

to reach full lift

a

high performance seal reducing product loss below EPAs

500ppm rule preventing environmental pollution

Detail X

1

Tank connection depends upon flow capacity, set pressure and

set vacuum for in- and outbreathing

Pressure or vacuum settings:

Upper valve pallet:

2.0 mbar

up to 60 mbar

0.8 inch W.C. up to 24 inch W.C.

Lower valve pallet:

3.5 mbar

up to 50 mbar

1.4 inch W.C. up to 20 inch W.C.

For higher set pressure refer to type DV/ZT-F. Lower set vacuum

upon request.

based on 10% technology the set pressure is close to the

opening pressure which results in best possible pressure

management of the system compared to conventional

40%- or 100%- technology valves

optimized flow performance, which reduces capital cost to

a minimum as smaller sized valves may be used

can be installed in explosion hazardous areas

housing designed to 150 psi (PN 10)

maintenance friendly design

Function and Description

Designs and Specifications

The PROTEGO in-line valve DV/ZT is a state-of-the-art pressure and vacuum relief valve. Typically the valve is installed in

the in- and out-breathing lines of tanks, vessels and process

apparatus to protect against unallowable high and low pressure.

The valve prevents emission losses almost up to the set pressure and provides protection from product entry into the system.

Due to its design the lower valve pallet is one size smaller than

the upper valve pallet.

The valve pallets are weight loaded. Higher set pressures are

achieved by using spring loaded type DV/ZT-F

The device will start to open as soon as the set pressure is

reached and only requires 10% overpressure to full lift. Continuous investments into research and development have allowed PROTEGO to develop a low pressure valve which has

the same opening characteristic as a high pressure safety relief

valve. This full lift type technology allows the valve to be set

just 10% below the maximum allowable working pressure or

vacuum (MAWP or MAWV) of the tank and still safely vent the

required mass flow. Due to our highly developed manufacturing

Additional special devices available upon request.

Two different designs are available:

In-line pressure and vacuum relief valve,

standard design

DV/ZT -

In-line pressure and vacuum relief valve with

heating jacket

DV/ZT - H

Within piping systems the influence of backpressure has to

be considered in deciding the set pressure and opening characteristics. For special design solutions (e.g. partial load operation) the valve can be supplied with standard valve pallets (with

proportional opening function).

All rights and alterations reserved acc. ISO 16016 - Active data sheet at www.protego.de

262

KA / 6 / 0414 / GB

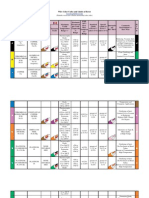

Table 1: Dimensions

Dimensions in mm / inches

To select the nominal size (DN), please use the flow capacity charts on the following page

DN

40 / 1 "

50 / 2"

80 / 3"

100 / 4"

150 / 6"

280 / 11.02

280 / 11.02

340 / 13.39

390 / 15.35

520 / 20.47

270 / 10.63

270 / 10.63

290 / 11.42

355 / 13.98

425 / 16.73

210 / 8.27

210 / 8.27

280 / 11.02

310 / 12.20

390 / 15.35

Larger sizes upon request

Dimensions for pressure and vacuum relief valve with heating jacket upon request

Table 2: Material selection for housing

Design

Housing

Heating jacket (DV/ZT-H-...)

Steel

Steel

Stainless Steel

Stainless Steel

Valve seat

Stainless Steel Stainless Steel

Gasket

PTFE

Option: Housing with ECTFE-lining

Special materials upon request

PTFE

Table 3: Material selection for upper valve pallet

Design

Pressure range (mbar) 2.0 up to 3.5

(inch W.C.) 0.8 up to 1.4

3.5 up to 14

1.4 up to 5.6

14 up to 60

5.6 up to 24

14 up to 60

5.6 up to 24

Valve pallet

Aluminium

Stainless Steel

Stainless Steel

Stainless Steel

Sealing

FEP

FEP

Metal to Metal

PTFE

Pressure range (mbar) 3.5 up to 5.0

(inch W.C.) 1.4 up to 2.0

5.0 up to 14

2.0 up to 5.6

14 up to 35

5.6 up to 14

35 up to 50

14 up to 20

14 up to 35

5.6 up to 14

35 up to 50

14 up to 20

Valve pallet

Aluminium

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Sealing

FEP

FEP

Metal to Metal

Metal to Metal

PTFE

PTFE

Special materials upon request

For higher set pressures refer

to type DV/ZT-F

Table 4: Material selection for lower valve pallet

Design

Special materials and lower set vacuum upon request

Table 5: Flange connection type

EN 1092-1, Form B1 or DIN 2501, Form C, PN 16

EN or DIN

ANSI 150 lbs RFSF

ANSI

other types upon request

for safety and environment

KA / 6 / 0414 / GB

263

Pressure and Vacuum Relief Valve, In-Line

Flow Capacity Charts

PROTEGO DV/ZT

pressure or vacuum - inch W.C.

pressure or vacuum (mbar)

airflow in thousands of CFH

DV/ZT

upper valve pallet

.

flow rate V (m/h)

2739-L

pressure or vacuum - inch W.C.

pressure or vacuum (mbar)

airflow in thousands of CFH

DV/ZT

lower valve pallet

.

flow rate V (m/h)

2738-L

The flow capacity charts have been determined with a calibrated and TV certified flow capacity test rig.

.

Volume flow V in (m/h) and CFH refer to the standard reference conditions of air ISO 6358 (20C, 1bar).

Conversion to other densities and temperatures refer to Vol. 1: Technical Fundamentals.

All rights and alterations reserved acc. ISO 16016 - Active data sheet at www.protego.de

264

KA / 6 / 0414 / GB

You might also like

- Direct-Acting and Reverse-Acting Positioners: There Must Always Be A Balance Maintained in The SystemDocument3 pagesDirect-Acting and Reverse-Acting Positioners: There Must Always Be A Balance Maintained in The SystemAshaHingoraniNo ratings yet

- A Control Valve Is A PowerDocument3 pagesA Control Valve Is A PowerAshaHingoraniNo ratings yet

- A Control Valve Is A PowerDocument3 pagesA Control Valve Is A PowerAshaHingoraniNo ratings yet

- Instrumentation TextbookDocument166 pagesInstrumentation TextbookGerman ToledoNo ratings yet

- Non Newtonian FluidsDocument2 pagesNon Newtonian FluidsAshaHingorani100% (1)

- Colour Coding - ThermocouplesDocument4 pagesColour Coding - ThermocouplesAshaHingoraniNo ratings yet

- Thomas Egenes Introduction To Sanskrit Part 1Document400 pagesThomas Egenes Introduction To Sanskrit Part 1Deepak Gore100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Integrated Management of Childhood IllnessDocument8 pagesIntegrated Management of Childhood IllnessSehar162No ratings yet

- 2.7 Dna Replication Transcription and Translation 4Document168 pages2.7 Dna Replication Transcription and Translation 4Senam DzakpasuNo ratings yet

- AZIZ Ur RehmanDocument3 pagesAZIZ Ur Rehmantop writerNo ratings yet

- New Accreditation ToolsDocument52 pagesNew Accreditation ToolsLyle Guion Paguio100% (1)

- Specialty PIPE SCHEDULES PDFDocument1 pageSpecialty PIPE SCHEDULES PDFAlfred LamNo ratings yet

- Geoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016Document14 pagesGeoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016songkkNo ratings yet

- SF 9 - ES Learners Progress Report CardDocument3 pagesSF 9 - ES Learners Progress Report Cardroxanne50% (2)

- 20K-S100 - CK20S10 - 21MK50-Chasis SN-80 SharpDocument26 pages20K-S100 - CK20S10 - 21MK50-Chasis SN-80 SharpAmadou FallNo ratings yet

- Oxygen Therapy ProtocolDocument4 pagesOxygen Therapy ProtocolTeri Martin-Allen100% (1)

- ACCT 4410 Taxation Salaries tax (Part II) Key areasDocument40 pagesACCT 4410 Taxation Salaries tax (Part II) Key areasElaine LingxNo ratings yet

- Cap Dev Dimalinao 2023-2027Document4 pagesCap Dev Dimalinao 2023-2027CA T HeNo ratings yet

- ABO BLOOD GROUP Part 1Document104 pagesABO BLOOD GROUP Part 1Taladua Cayla Grace O.No ratings yet

- 02-Plant Morphology (Exercise)Document5 pages02-Plant Morphology (Exercise)varshavishuNo ratings yet

- CKD EsrdDocument83 pagesCKD EsrdRita Lakhani100% (1)

- Crosbys Molasses and MoreDocument37 pagesCrosbys Molasses and MoreShaikh MeenatullahNo ratings yet

- Environmental Clearance CertificateDocument4 pagesEnvironmental Clearance CertificateAra Jane T. PiniliNo ratings yet

- Body Mechanics, Alignment, and MobilityDocument42 pagesBody Mechanics, Alignment, and MobilityAbigail Filio Monge86% (7)

- Traceability Summary - Supplies July 2015 - June 2016: PT Multimas Nabati Asahan, Kuala TanjungDocument4 pagesTraceability Summary - Supplies July 2015 - June 2016: PT Multimas Nabati Asahan, Kuala TanjungAbu KhalidNo ratings yet

- 1 s2.0 S0149763418301957 MainDocument24 pages1 s2.0 S0149763418301957 MainjackNo ratings yet

- Proposed Rule: Airworthiness Directives: Bell Helicopter Textron CanadaDocument3 pagesProposed Rule: Airworthiness Directives: Bell Helicopter Textron CanadaJustia.comNo ratings yet

- Wildseed Dinner MenuDocument1 pageWildseed Dinner MenuCaleb PershanNo ratings yet

- Do We Still Need Formocresol in Pediatric DentistryDocument3 pagesDo We Still Need Formocresol in Pediatric DentistryAlexanderDetorakisNo ratings yet

- Performance Task MidTerm Second Sem. AY 2022 2023Document2 pagesPerformance Task MidTerm Second Sem. AY 2022 2023KZpathryn Jemimench AleurevNo ratings yet

- Lesson Plan The Food: TH THDocument8 pagesLesson Plan The Food: TH THFeraru FlorinNo ratings yet

- Aquatic Ecology and LimnologyDocument96 pagesAquatic Ecology and LimnologySale AlebachewNo ratings yet

- Understand TSGLI BenefitsDocument2 pagesUnderstand TSGLI BenefitsJoseph LawerenceNo ratings yet

- DC72D MK2 Genset Controller User Manual V1.5Document61 pagesDC72D MK2 Genset Controller User Manual V1.5Cristobal AvecillaNo ratings yet

- Battery: Ultrasonic Welding TechnologyDocument12 pagesBattery: Ultrasonic Welding TechnologyNam Cao HuỳnhNo ratings yet

- How Children Learn LanguageDocument28 pagesHow Children Learn LanguageHuỳnh Lê Quang ĐệNo ratings yet

- Electrical: Mep Project Progress ReportDocument11 pagesElectrical: Mep Project Progress ReportAvinash GuptaNo ratings yet