Professional Documents

Culture Documents

Upgrade Fire Detection System

Uploaded by

Paul SodipoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Upgrade Fire Detection System

Uploaded by

Paul SodipoCopyright:

Available Formats

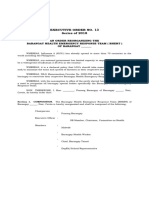

JOB SAFETY ANALYSIS WORKSHEET

COMPANY NAME:

DATE:

SITE NAME:

PERMIT TO WORK REQUIREMENT: YES

STAKEHOLDER REPRESENTATIVE NAME/TEL. NO:

CONTRACT NO.:

NO

ACTIVITY: To re-engineer the entire Fire Detection & Alarm System within Customers Complex (changing the installation

cable into Fire resistant cable, re-positioning of devices, extension to other areas that were not covered and integration of

the 4 Zone Conventional Fire Alarm Control Panel with interconnection to Fire Authority within the state

ATLASNET Contact Person - PM

Atlasnet Contact

HSE Officer

SITE

EMERGENCY NO.

EMERGENCY RESPONSE

NO. :

START DATE:

List plant, equipment

& tools to be used,

and Places to Work

Ladder

Electrical Tool Box

(Screw Drivers Set,

Plier, Cutter, Knife etc.)

Avometer

FINISH DATE:

List Hazardous

Substances

to be used or

handled

Fall from Heights,

Slippery

Electric Shock, Cut &

Injury

List PPE to be worn

Electric Shock

Hard Hat, Safety Boot,

Eye Glasses

Hand Gloves & Safety

Boot

Hand Gloves & Eye

Goggle

Safety Glasses, Highvisy clothing

(Reflective Vest),

Complete PPE, Torch

Light & Work with 2 or

more men

Dust Masks, Hearing

Protection, Hand

Gloves

Measuring Tape,

Cutter, Hand gloves,

Eye Glasses

Hammer

Hand /Leg Injury

PVC Pipes & Pegs

Hand/Eye Injury

Work at Ceiling

Insect Bite, Electric

Shock, fall from

height

Drilling Machine

Noise Pollution, Dust

& Vibration

Cables, Fishing Tape &

Devices

Fragile handle with

Care, Hand cuts,

pulling to damage

Hard Hat, Safety Boot

Safety Boots, Hand

Gloves, Eye Glass

(Tick)

List Hazards to

consider

(Tick)

Slips, trips and

falls from heights

Falling objects,

Electric Shock,

Cuts

Electric Shock,

Spark

Manual handling,

Injuries

Struck by moving

section

Inhalation of dust

or fumes, hidden

insect bite, dark

environment

Noise, Inhalation

of dust or fumes,

Vibration trips

Injuries, Pull, fall,

slips, cuts

paulsodipo@gmail.com

Page 1

JOB SAFETY ANALYSIS WORKSHEET

JOB HAZARD ANALYSIS PROPER:

ACTIVITY

HAZARDS

IDENTIFICATION

This are the tasks required to

perform the activity in the Sequence

they are carried out.

Against each task the

hazards lists that could

cause injury when the task

is performed.

CONTROLS &

RECOMMENDED &

ACTIONS

Control measures required to eliminate

or minimise the risk of injury arising

from the identified hazard

RESPONSIBILTY

PERSON

Name of the person responsible

(supervisor or above) to implement

the control measure identified

Decommissioning of the Existing Cable, PVC Pipe & Cable Laying, Connection, Integration, Configuration & Commissioning.

Entry to Site/Venue

Entry to unsafe area

Movement of site

personnel, vehicles, plant

& equipment

Report to site office for site

induction, Work Area, Mustard

Point

Risk assessment of site condition

PVC Piping, Cable Laying &

Fixing of devices

Fall from heights, Slips, Cuts

& dust

Training employees in manual

handling and team lifting

Manual handling injuries, cuts,

splinters & abrasions

Wear gloves (PPE)

Being struck by hammer,

Noise, Load lifting

Training employees in manual handling

The use of P.P.E equipment such

as gloves. Team lifting

Slips, trips & falls

Unload equipment on a level

clear area

Device & Equipment

Connection, System

Integration, Configuration,

Programming &

Commissioning

Trips & falls

Handle & Proper handling, Ensure

site is clear of any debris,

obstructions

Wearing Safety boot

Handling Over & Work Area

Clearing and Documentation

Pearce with debris, pins &

spares

Stakeholders Reps, HSE &

PM

PM

/IMPLEMENTATION

LEADER/ CIVIL

ENGINEER HEAD &

HSE MGR.

Define & barricade work area &

fall areas

Clearing area

Stakeholder & PM

paulsodipo@gmail.com

Page 2

JOB SAFETY ANALYSIS WORKSHEET

LADDERS

When using a ladder, abide by the following guidelines:

Your ladder will indicate which rungs you may stand on. Do not stand on any rungs not recommended by the

ladders manufacturer.

To minimise slippage, clean boots of mud and debris before use.

Ensure the ladder is on a stable even surface.

Keep both hands free to use when climbing or ascending, maintain three point of contact with the ladder.

Carry tools in pockets or hoist them up with a rope in a canvas bag.

Have an assistant hold the bottom of the ladder to prevent movement.

Barricade the work area when the public or vehicles are in the vicinity.

Keep the body within the ladder side rails.

Do not straddle the ladder or support planks with the ladder.

Do not perform hot work while working on a ladder.

Do not work backwards on the ladder.

Do not use any equipment requiring two-handed operation.

Do not use any PPE, which impairs vision.

Do not use the ladder for anything but its intended purpose.

Do not work over other people and do not allow anybody else to be on the ladder at the same time.

Do not use the ladder in wet or windy conditions.

Ladders should not be used in access areas or within the arc of swinging doors.

INCIDENTS

Report all incidents or near misses to the Stakeholders representative

PERSONAL PROTECTIVE EQUIPMENT (PPE)

All persons working on the CAP site must identify and use appropriate PPE for the works they are undertaking,

including eye, hearing and sun protection.

SAFETY VESTS

Safety Vests are compulsory whilst in the CAP venues during the move in and move out of events.

paulsodipo@gmail.com

Page 3

You might also like

- Effective Safety Committee MeetingsDocument25 pagesEffective Safety Committee Meetingsyawikhan100% (1)

- Risk Assessment - Construction of DWFI, Sewerage System and Deepening of Kai Tak River BedDocument8 pagesRisk Assessment - Construction of DWFI, Sewerage System and Deepening of Kai Tak River Bed逍逾No ratings yet

- Yoga Your Home Practice CompanionDocument257 pagesYoga Your Home Practice Companionjohncoltrane97% (33)

- Jsa Grinding Welding Gas CuttingDocument4 pagesJsa Grinding Welding Gas CuttingMark Roger Huberit IINo ratings yet

- Lockout Tagout TRNG GuideDocument7 pagesLockout Tagout TRNG GuideSyed Mujtaba Ali Bukhari100% (1)

- Fall Protection Self Inspection ChecklistDocument4 pagesFall Protection Self Inspection ChecklistSantosh Kolhatkar100% (2)

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisDedi Apriadi71% (7)

- Lock-Out Tag-Out Safe Work Procedures SWP-10Document6 pagesLock-Out Tag-Out Safe Work Procedures SWP-10ShafiqNo ratings yet

- HISTORY AND PHYSICAL EXAMINATION (Putul)Document2 pagesHISTORY AND PHYSICAL EXAMINATION (Putul)Reshma Francis100% (1)

- Job Safety Analysis JSADocument23 pagesJob Safety Analysis JSAmohame30dNo ratings yet

- Jobs Safety Plan - TemplateDocument16 pagesJobs Safety Plan - TemplateFairus Md Yusof100% (1)

- PPE Matrix for Baichele Plumbing ConstructionDocument1 pagePPE Matrix for Baichele Plumbing ConstructionVictorNo ratings yet

- Jsa For Weld and GrindingDocument6 pagesJsa For Weld and GrindingTanzeel LiaqatNo ratings yet

- JSA WorkingWithHazardousSubstancesDocument2 pagesJSA WorkingWithHazardousSubstancesCristina RicanNo ratings yet

- Activity Hazard AnalysisDocument43 pagesActivity Hazard AnalysisShawn James100% (4)

- Jsa Working at HeightDocument4 pagesJsa Working at HeightDedy Kurniawan100% (1)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- QP Cutting JSADocument6 pagesQP Cutting JSAMohammed MujahidNo ratings yet

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNo ratings yet

- JSA LoadingDocument10 pagesJSA LoadingOcktri Bobet100% (3)

- Risk Assesment For Demolition of Factory Buildings at 14 Tuas Ave 1Document4 pagesRisk Assesment For Demolition of Factory Buildings at 14 Tuas Ave 1Yam Balaoing100% (1)

- JSA ScaffoldingDocument2 pagesJSA Scaffoldingmyco samNo ratings yet

- Daily EHS Inspection Checklist: Date: General Yes No CommentsDocument2 pagesDaily EHS Inspection Checklist: Date: General Yes No CommentsWaqasNo ratings yet

- Job Safety Analysis: JSA Reference #: DateDocument3 pagesJob Safety Analysis: JSA Reference #: DateLi QiNo ratings yet

- JSA Formet New Structural Steel ErectionDocument11 pagesJSA Formet New Structural Steel Erectionsakthi venkatNo ratings yet

- Permit To Work EOH-SP-FORM 531.01Document2 pagesPermit To Work EOH-SP-FORM 531.01Brad EubankNo ratings yet

- Job Safety Analysis TemplateDocument9 pagesJob Safety Analysis Templatecathodic protection100% (1)

- Install Rockwall, Fabrication and Install Cladding, Handling and Moving Material Risk AssessmentDocument11 pagesInstall Rockwall, Fabrication and Install Cladding, Handling and Moving Material Risk AssessmentFerdyCodetzNo ratings yet

- College of Medicine & Health SciencesDocument56 pagesCollege of Medicine & Health SciencesMebratu DemessNo ratings yet

- JSA UnloadingDocument4 pagesJSA Unloadinganon_50254931100% (2)

- Saf 113 A Daily She Inspection Report 1Document4 pagesSaf 113 A Daily She Inspection Report 1saravana3kumar3ravic100% (1)

- FRM-00413 Corporate Safety - Excavation and Trenching Permit FormDocument3 pagesFRM-00413 Corporate Safety - Excavation and Trenching Permit FormAhmad Hafidz Mahendra100% (1)

- Site Induction PresentationDocument16 pagesSite Induction PresentationMewan Naveenda Perera100% (1)

- Job Safety AnalysisDocument5 pagesJob Safety AnalysisMuhammad Zarif Amir100% (2)

- JSA Shut Down and Tie in Work PDFDocument6 pagesJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- 22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentDocument30 pages22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentMohammed Hasnain Saleem/KSA/EMD100% (1)

- Check List For ScaffoldingDocument3 pagesCheck List For ScaffoldingyakuzaQ100% (1)

- JSA For Fab Erec of STRL Steel StackDocument5 pagesJSA For Fab Erec of STRL Steel StackkrishnakumarNo ratings yet

- Aerial Lift Safety: Weekly ES&H Toolbox TalkDocument1 pageAerial Lift Safety: Weekly ES&H Toolbox TalkrjlafortezaNo ratings yet

- Employee Safety Inspection ChecklistDocument2 pagesEmployee Safety Inspection ChecklistEvert W. VanderBerg100% (1)

- Job Hazard AssessmentDocument2 pagesJob Hazard AssessmentSreekumarNo ratings yet

- System Cause Analyzed Technique Accident Investigation Root Analysis Cause ChecklistDocument5 pagesSystem Cause Analyzed Technique Accident Investigation Root Analysis Cause ChecklistponggoooNo ratings yet

- Job Safety Analysis: Calalang Residence J. Fajardo St. Sampaloc ManillaDocument4 pagesJob Safety Analysis: Calalang Residence J. Fajardo St. Sampaloc ManillaJoey Stanley GuzmanNo ratings yet

- JSA FormDocument4 pagesJSA Formandrew rachmanNo ratings yet

- Job Safety Analysis For Rebar FixingDocument4 pagesJob Safety Analysis For Rebar FixingJayvee Baradas Valdez67% (3)

- Behavioral Based Safety - 10thoctDocument2 pagesBehavioral Based Safety - 10thoctGrady HopkinsNo ratings yet

- STP 1560-2013Document346 pagesSTP 1560-2013HieuHTNo ratings yet

- JSA STEEL ERECTIONDocument4 pagesJSA STEEL ERECTIONCherry BetonioNo ratings yet

- Postpartum Health TeachingDocument8 pagesPostpartum Health TeachingMsOrange96% (24)

- Weekly HSE Inspection Form-MTHLDocument138 pagesWeekly HSE Inspection Form-MTHLdeepak925No ratings yet

- The NBCP Referral Code SubDocument4 pagesThe NBCP Referral Code SubArcon Solite BarbanidaNo ratings yet

- 03.JSA - Confined Space EntryDocument1 page03.JSA - Confined Space Entryr0shNo ratings yet

- Job Site Safety ChecklistDocument4 pagesJob Site Safety Checklistတိုး ေဝ ေအာင္No ratings yet

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarNo ratings yet

- Toolbox Talks Pneumatic Tools EnglishDocument1 pageToolbox Talks Pneumatic Tools EnglishebbasinghNo ratings yet

- Appendix A-Job Safety Analysis FormDocument3 pagesAppendix A-Job Safety Analysis Formjiks_i4uNo ratings yet

- Job Safety Analysis: Potential Risk FactorsDocument1 pageJob Safety Analysis: Potential Risk FactorsFrancis VinojNo ratings yet

- Construction Job Safety/Hazard Analysis Job #: Location/Description: OwnerDocument33 pagesConstruction Job Safety/Hazard Analysis Job #: Location/Description: OwnerHortencio SamuelNo ratings yet

- Electrical Work Permit ACC JamulDocument1 pageElectrical Work Permit ACC JamulathulpcucekNo ratings yet

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradNo ratings yet

- Daily JSADocument4 pagesDaily JSAumn_mlkNo ratings yet

- Q1. Read The Passage Given Below and Answer The Questions That FollowDocument2 pagesQ1. Read The Passage Given Below and Answer The Questions That FollowUdikshaNo ratings yet

- عقد خدمDocument2 pagesعقد خدمtasheelonlineNo ratings yet

- GastroparesisDocument10 pagesGastroparesisapi-437831510No ratings yet

- Maharashtra State Bams Private Colleges Fess.Document2 pagesMaharashtra State Bams Private Colleges Fess.Bhavesh RajpurohitNo ratings yet

- The Differential Diagnosis of Fluoride and Non-Fluoride OpacitiesDocument4 pagesThe Differential Diagnosis of Fluoride and Non-Fluoride OpacitiesRajshekhar BanerjeeNo ratings yet

- 11 Foods That Lower Cholesterol: Foods That Make Up A Low Cholesterol Diet Can Help Reduce High LevelsDocument3 pages11 Foods That Lower Cholesterol: Foods That Make Up A Low Cholesterol Diet Can Help Reduce High Levelsaj dancel marcosNo ratings yet

- Dowtherm TDocument3 pagesDowtherm Tthehoang12310No ratings yet

- Pta ResumeDocument2 pagesPta Resumeapi-669470996No ratings yet

- Stetler Model EBP PosterDocument1 pageStetler Model EBP PosterEmily MNo ratings yet

- The Effect of Warm Ginger Compress on Hypertension Headache Scale in the ElderlyDocument7 pagesThe Effect of Warm Ginger Compress on Hypertension Headache Scale in the Elderlyjembatan gantungNo ratings yet

- Pneumonia Care PlanDocument1 pagePneumonia Care Plantcumurphish67% (3)

- How To Make An ELearning ModuleDocument22 pagesHow To Make An ELearning ModulePradeep RawatNo ratings yet

- Intro To Wastewater Collection and PumpingDocument84 pagesIntro To Wastewater Collection and PumpingMoh'd KhadNo ratings yet

- DK50 Developer Parts ABDocument15 pagesDK50 Developer Parts ABedu3ipbNo ratings yet

- Bio-Oil® Product ManualDocument60 pagesBio-Oil® Product ManualguitarristaclasicosdnNo ratings yet

- Methodological Literature Review 1 1Document8 pagesMethodological Literature Review 1 1api-584018105No ratings yet

- AIIMS Bibinagar Recruitment for Faculty PostsDocument22 pagesAIIMS Bibinagar Recruitment for Faculty PostsavinashNo ratings yet

- Eo No. 013 - 2018 Reorganization of BhertDocument2 pagesEo No. 013 - 2018 Reorganization of BhertAnne Kimberly Peñalba BabaanNo ratings yet

- Prepositions of Time ExplainedDocument18 pagesPrepositions of Time ExplainedyuèNo ratings yet

- Assessed Conference Presentations ScheduleDocument2 pagesAssessed Conference Presentations ScheduleAna Maria Uribe AguirreNo ratings yet

- Hahnemann Advance MethodDocument2 pagesHahnemann Advance MethodRehan AnisNo ratings yet

- Behavioral Economics Applications GuideDocument12 pagesBehavioral Economics Applications GuideJosé Luis BalbontínNo ratings yet

- Journal On The Impact of Nursing Informatics To Clinical PracticeDocument2 pagesJournal On The Impact of Nursing Informatics To Clinical PracticeLhara Vhaneza CuetoNo ratings yet

- Jacked at Home - Bodyweight Muscle-Building WorkoutsDocument6 pagesJacked at Home - Bodyweight Muscle-Building Workoutsmohamed aliNo ratings yet