Professional Documents

Culture Documents

Sikadur Combiflex: Sealing System For Cracks and Problem Joints With Large Movements

Uploaded by

ArdiPratomoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sikadur Combiflex: Sealing System For Cracks and Problem Joints With Large Movements

Uploaded by

ArdiPratomoCopyright:

Available Formats

Technical Data Sheet

Edition 4, 2008

Identification no.

02 07 03 02 002 0 000002

Version no. 0010

Sikadur Combiflex

Sikadur Combiflex

Sealing System for Cracks and Problem Joints with Large

Movements

Construction

Description

The Sikadur-Combiflex joint sealing system consists of two products :

Sikadur 31 CF Normal

Combiflex strip (SikaNorm - Hypalon)

Sikadur 31 CF Normal is epoxy resin based and establishes a strong bond to the

substrate and the Combiflex is a highly elastic, chemically and UV resistant sheet

membrane

Uses

Universal joint sealing compound for building construction, e.g.

For movement joint in

Sealing internal joints in new or refurbished concrete water tanks, reservoirs,

pipelines, sewers, and swimming pools

Joints in bunds and tanks for heating oil and fuel oil, etc

Sealing joints in basements, roof joints, joints between rigid and flexible

surfaces.

Sealing joints in tunnels, silos and roofs.

Sealing and repairing joints that have more movement than can be

accommodated by conventional elastomeric wet applied sealants

Advantages

Coverage

Per linear metre Combiflex strip 0.4 to 0.7 kg Sikadur 31 CF Normal

Easy to install

Applicable on dry and damp surfaces

Quick hardening.

Extremely flexible.

For large expansion joints oil cracks.

Weather-resistant.

Water-resistant.

Approved for potable water contact.

Good chemical resistance.

Excellent adhesion to many materials..

No need to remove failed sealant from old joints before use

Technical Data

Colour

Light Grey (both Sikadur 31 CF Normal and Combiflex strip)

Density

Sikadur 31 CF Normal 1.90 kg/ltr

Weight per unit area

Combiflex strip

2 mm thick

3.0 kg/m2

20 cm width

25 cm width

Pot Life 30OC

35 minutes (Sikadur 31 CF Normal)

Adhesive Strength

On concrete

>15 kg/cm2 (rupture of concrete)

(DIN 53232)

On sandblasting steel

60 kg/cm2 (rupture of Combiflex)

Combiflex Strip

Tensile Strength

>6 N/mm2

DIN 53455 Part 4

mechanical properties

Tear Strength

>30 N/mm

DIN 53515

Back

Table of Contents

Sikadur Combiflex

1/3

Elongation at break

> 400%

Pulsation Resistance

(approx. 5% expansion

(Sika test)

approx. 4 cycles per sec)

Seam Strength

Crack next to seam not in seam

Max Permissible

Permanent Elongation

2-mm tape

Shelf Life

Packaging

DIN 53455, Part 4

> 100.000 cycles**

DIN 16726

25% of the non-adhered tape width

Sikadur 31 CF Normal

2 years if stored properly in unopened original container

Combiflex strip

3 years if stored properly in unopened original container

Sikadur 31 CF Normal

6 kg set

Combiflex strip

20 m roll

Instruction for Use

Surface Preparation

The concrete surface must be mechanically cleaned. The laitance must be

removed to establish good adhesion followed by vacuum/dust removal.

Age of concrete shall be minimum 3 weeks

All surfaces must be clean, sound and free from any oil, grease or other

contaminants

Application

Apply the well mixed Sikadur 31 CF Normal both sides along the joint or crack on

the prepared substrate with a spatula or notched trowel. Layer thickness 1-2 mm.

Place the cleaned activated Combiflex strip immediately into the adhesive layer with

the masking tape facing upwards and press well in with a roller.

Finally cover the inserted Combiflex strip laterally with Sikadur 31 CF Normal to

provide 1-2 mm cover.

When the adhesive has begun to set remove masking tape.

Should the Combiflex strip has to be welded into longer pieces (T-pieces etc), clean

the surface with Colma cleaner and simultaneously use hot air weld thermal

welding.

This joint sealing method can be carried out horizontally, vertically or overhead,

however it should be noted that Sikadur 31 CF Normal is not a contact adhesive

and some support of the uncured strip may be required on vertical and overhead

surfaces

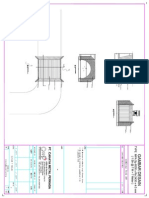

Drawing Applications

Sikadur Combiflex 2/3

Welding

The minimum lap is 40 mm.

The lap areas should be clean and dry free from grease or dust. Before welding the

lap should be cleaned with Sika Colma Cleaner. The lap should be fully sealed and

not be able to be parted with a screw driver blade. Use suitable hot air welding.

Hot air welding: as the hot air is being applied into the lap through a slot nozzle, the

lap must be rolled flat using a solid rubber pressure roller.

Limitations

Clean Combiflex strip at least hour/ maximum 8 hours with Colma Cleaner before

all applications. In heavy traffic areas (eg. parking decks) steel cover plates should

be used over Combiflex joints.

If a bituminous wearing layer is installed on top of a previously installed Combiflex

strip, the temperature of the hot mix must not exceed 180oC for 50 mm thickness.

At up to 10 mm thickness the temperature may be max. 220C.

If necessary apply in layers and allow to cool down in between.

Construction

Legal Notes

The information, and, in particular, the recommendations relating to the application and end-use of Sika

products, are given in good faith based on Sikas current knowledge and experience of the product when

properly stored, handled and applied under normal conditions in accordances with Sikas

recommendations. In practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising

out of any legal relationship whatsoever, can be inferred either from this information, or from any written

recommendations, or from any other advice offered. The user of the product must test the products

suitability for the intended application and purpose. Sika reserves the right to change the properties of its

products. The proprietary rights of third parties must be observed. All orders are accepted subject to our

current terms of sale and delivery. Users must always refer to the most recent issue of the local Product

Data Sheet for the product concerned, copies of which will be supplied on request.

PT. Sika Indonesia

Jl. Raya Cibinong- Bekasi km. 20

Limusnunggal- Cileungsi

BOGOR 16820 - Indonesia

Tel. +62 21 8230025

Fax +62 21 8230025

Website : www.sika.co. id

e-mail: sikacare@id.sika.com

Branches

Surabaya :

Puri Niaga Blok G No. 29, Jl. Raya Rungkut Menanggal 11, Surabaya

Tel : 031-8690202 ; Fax : 031-8682123

Medan :

Kawasan Industrial " Medan Star ", Tanjung Morawa Km.19,2

Jl. Pelita Raya Blok R No.32, Deli Serdang 20362

Tel : 061-7941200 ; Fax : 061-7940822

Batam :

Jl. Laksamana Bintan,Komp. Bumi Riau Makmur Blok E No.3,

Sungai Panas, Batam

Tel : 0778-424928 ; Fax : 0778-450189

Sikadur Combiflex 3/3

You might also like

- Ideal Paver Guide PDFDocument24 pagesIdeal Paver Guide PDFArdiPratomoNo ratings yet

- Dynamic Cone PenetrometerDocument3 pagesDynamic Cone Penetrometerme-elormNo ratings yet

- Pola KertamuktiDocument1 pagePola KertamuktiArdiPratomoNo ratings yet

- Handout - 6900 - CI6900-L Handout Civil ViewDocument18 pagesHandout - 6900 - CI6900-L Handout Civil ViewMartin GuerreroNo ratings yet

- Data Elevation Surface To Use in Civil3dDocument1 pageData Elevation Surface To Use in Civil3dArdiPratomoNo ratings yet

- Utm ZoneDocument11 pagesUtm ZoneArdiPratomoNo ratings yet

- PreconSewerageSystem PDFDocument10 pagesPreconSewerageSystem PDFArdiPratomoNo ratings yet

- MDOT-Vertical Curve Calcs 120887 7Document2 pagesMDOT-Vertical Curve Calcs 120887 7ArdiPratomoNo ratings yet

- Typical Section Interstate - 0705Document1 pageTypical Section Interstate - 0705ArdiPratomoNo ratings yet

- Typical Cross Sections - 0704Document1 pageTypical Cross Sections - 0704ArdiPratomoNo ratings yet

- Stanley Market / Stanley Main Street 14 Pennington Street Causeway BayDocument1 pageStanley Market / Stanley Main Street 14 Pennington Street Causeway BayArdiPratomoNo ratings yet

- OFFICE LayoutDocument1 pageOFFICE LayoutArdiPratomoNo ratings yet

- Presentation Subheading Goes HereDocument2 pagesPresentation Subheading Goes HereArdiPratomoNo ratings yet

- New Features For 2004Document9 pagesNew Features For 2004dmotwaniNo ratings yet

- Oceanpark To Stanley 6aDocument1 pageOceanpark To Stanley 6aArdiPratomoNo ratings yet

- METODE Volume CalculationDocument2 pagesMETODE Volume CalculationArdiPratomoNo ratings yet

- Halal Food HKDocument7 pagesHalal Food HKArdi Yoga PratomoNo ratings yet

- Ts Trimble Operation Hand OutDocument8 pagesTs Trimble Operation Hand OutArdiPratomoNo ratings yet

- Earthwork Volume Calculation Methods ExplainedDocument1 pageEarthwork Volume Calculation Methods ExplainedArdiPratomoNo ratings yet

- Precast Sewerage System GuideDocument10 pagesPrecast Sewerage System GuideArdiPratomoNo ratings yet

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- LBR 2 Legenda ModelDocument1 pageLBR 2 Legenda ModelArdiPratomoNo ratings yet

- S. MasjidDocument1 pageS. MasjidArdiPratomoNo ratings yet

- Volume CalculationDocument2 pagesVolume CalculationArdiPratomoNo ratings yet

- Volume CalculationDocument2 pagesVolume CalculationArdiPratomoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Gunnebo Lifting Standard Shackle No 854: Bow ShacklesDocument1 pageGunnebo Lifting Standard Shackle No 854: Bow ShacklesTito FebriantoNo ratings yet

- Biosimilars Advantages and DisadvantagesDocument2 pagesBiosimilars Advantages and DisadvantagesVeeda CR100% (1)

- New Companies 15th Jan 1st Feb OnlineDocument872 pagesNew Companies 15th Jan 1st Feb OnlineMultibrands IndiaNo ratings yet

- 14.0 Chapter 14 Global Logistic StrategiesDocument12 pages14.0 Chapter 14 Global Logistic StrategiesNor NaimahNo ratings yet

- Extrusion Moulding Process PDFDocument2 pagesExtrusion Moulding Process PDFKim100% (1)

- Truck or Lorry Rest AreasDocument5 pagesTruck or Lorry Rest AreasprasadNo ratings yet

- Performance IndicatorDocument34 pagesPerformance IndicatorSienna Marie CabreraNo ratings yet

- Bridge Crossing Design GuidelinesDocument11 pagesBridge Crossing Design Guidelinessofianina05No ratings yet

- Scheduled Maintenance Program Seminar - 4. Maintenance Program Establishment-Part1Document50 pagesScheduled Maintenance Program Seminar - 4. Maintenance Program Establishment-Part1Omar Mallad100% (1)

- Time Schedule Amandemen 2: Submitted By: Contractor PT. Dutaraya DinametroDocument1 pageTime Schedule Amandemen 2: Submitted By: Contractor PT. Dutaraya DinametroAdew WahyudinNo ratings yet

- Charter PartyDocument150 pagesCharter PartyAnemonia100% (8)

- METHOD of STATEMENT For Grounding SystemDocument12 pagesMETHOD of STATEMENT For Grounding SystemHamada Khamis100% (1)

- Cars Reading ComprehensionDocument1 pageCars Reading ComprehensionChan PhakkdeyNo ratings yet

- Wagons Modern Bulk Material HandlingDocument4 pagesWagons Modern Bulk Material Handlingparuchurivenkat5272No ratings yet

- ASTM A312-2004 (Especificaciones Tuberia Acero Inoxidable) PDFDocument11 pagesASTM A312-2004 (Especificaciones Tuberia Acero Inoxidable) PDFcesar_p80-1No ratings yet

- Sterling LiteratureDocument18 pagesSterling Literaturekar1270No ratings yet

- Mill Scale 2Document7 pagesMill Scale 2viswaprasad005No ratings yet

- Gleeble SimulationDocument4 pagesGleeble SimulationmanasikarthikNo ratings yet

- Enterprise Map of TanzaniaDocument210 pagesEnterprise Map of TanzaniaRavinder Casley GeraNo ratings yet

- Appendix A1: Deficiency Codes: USCG Marine Safety Manual, Vol. II: Materiel InspectionDocument50 pagesAppendix A1: Deficiency Codes: USCG Marine Safety Manual, Vol. II: Materiel InspectionMarcus M. BlakeNo ratings yet

- Brand ManagementDocument40 pagesBrand Managementحسيب مرتضي100% (773)

- Introduction to Shipping Group One SyllabusDocument2 pagesIntroduction to Shipping Group One SyllabusvjmarinerNo ratings yet

- Lokfix PDFDocument4 pagesLokfix PDFnafis2uNo ratings yet

- Mindanao Terminal and Brokerage Service, Inc. vs. PhoenixDocument2 pagesMindanao Terminal and Brokerage Service, Inc. vs. PhoenixKrizzia GojarNo ratings yet

- ExampleDocument2 pagesExampleM A INo ratings yet

- WWF Paper PDFDocument7 pagesWWF Paper PDFniharNo ratings yet

- BMCP Question PapersDocument4 pagesBMCP Question PapersSyed Mujeeb0% (1)

- ACO RainDrain BrochureDocument2 pagesACO RainDrain BrochureDoug WeirNo ratings yet